DESIGN CALCULATIONS

FOR STEEL STRUCTURE

Owner

Project name PROPOSED 3-STOREY WAREHOUSE

Location PHILIPPINES

Designed by NGUYEN DINH TIEP

Checked by NGO DOAN KHAM

10/2017

1

�Introduction

This Design Calculations has been prepared using the applicable American codes and

standards and the developments in engineering practices. A design engineer prepared the

calculations and another engineer checked his work. The initials of both engineers are shown

on page 01.

Computer programs have been used where applicable to determine structural requirements.

The output of these programs has been incorporated in this package together with

explanation text where possible. The whole package has been prepared using an advanced

computer text processor.

For your easy reference, all pages have been numbered. We have divided the package into

three sections as follows:

1. Design Information: This section contains the description of the building designed,

design codes and material specifications used, design assumptions, loads and design

sketches showing building components layouts and members sizes.

2. Computer Design Printouts: This section includes the output of computer

programs used in the design along with explanations for the output where possible.

3. Column Reactions: DDC prints the column reactions from the output structural

design. Concrete contractor can take the results to design the building footings.

For any questions regarding this package please do not hesitate to contact us. Dai Dung

keeps records of reference on design calculations for each building designed as a part of our

total quality system.

Engineering Department

Dai Dung Corporation

2

�Section 1: Design Information

Applicable Design Codes

Material Specifications

Design Assumptions & Load Combinations

New Warehouse

Mezzanine Floor

3

�Applicable Design Codes & References

The Pre-Engineered Building described in these calculations was designed according to the U.S.A.

Buildings and Design Codes that have been referred to in the design:

1. The loads as described in the Design Summary Sheet have been applied on the structure

in accordance with: ASCE 7-10 & MBMA “Metal Building Manufacturer’s

Association” For Low Rise Building Systems Manual.

2. Hot rolled sections and built up components have been designed in accordance with:

AISC “American Institute of Steel Construction” Manual of Steel Construction -

Allowable Stress Design, 2005 Edition.

3. Cold formed components have been designed in accordance with:

AISI “American Iron and Steel Institute” Cold Formed Steel Design Manual, 1999

Edition.

1000 16th Street, NW, Washington, DC 20036, USA.

4. Welding has been applied in accordance with:

AWS D1.1.2008 “American Welding Society” Structural Welding Code – Steel.

5. Composite slabs and beams using steel decking: best practice for design and

construction. The Steel Construction Institute and Steel Deck Institute.

4

� Material Specifications

The following is the list of the material standards and specifications for which the building

components have been designed:

Material Specifications

Sl

Material Specifications

No.

1 Built-up Q345B (JIS), Fy=34.5 kN/cm2

2 Hot Rolled SS400 (JIS) Fy=24.5 kN/cm2 (thk. <16 mm)

Cold

3 Pre-Galvanized G450 (JIS) Fy=45.0 kN/cm2

Formed

4 Decking Galvanized G300 (JIS) Fy=30.0 kN/cm2

Rods JIS G3101 - SS 400 (or equivalent) Fu = 40.0 kN/cm2

5 X-Bracing Cable Fu = ±55.0 kN/cm2

Round/Sag Rods JIS G3101 - SS 400 (or equivalent) Fu = 40.0 kN/cm2

Class 8.8 Type 1 (or equivalent)

6 High Strength Bolts, Stud

Hot Dip Galvanized Fu = 80.0 kN/cm2

7 Machine Bolts Class 4.6 (or equivalent) Fu = 40.0 kN/cm2

Fy = Yield Strength, Fu = Tensile Strength

5

�Design Assumptions

The building was designed as enclosed for wind load.

The main frame rafters and exterior columns are rigidly connected to each other (using

moment type connections).

The columns are pin connected to the foundations.

The lateral stability of the building is provided through the frame action of the main

frames.

The longitudinal stability of the building is provided through diagonal cables and the

frame action of main frames.

Load combinations using ASCE 7-10 Allowable Stress Design

1. Dead Load + Coll + Live Load Roof

2. Dead Load + Coll + 0.75Live Load Roof

3. Dead Load + Coll + 0.6Wind Load

4. Dead Load + Coll + 0.7Seismic Load

5. Dead Load + Coll + 0.525Seismic Load

6. Dead Load + Coll + 0.75 Live Load Roof + 0.45Wind Load

7. 0.6Dead Load + 0.6Coll + 0.6Wind Load

8. 0.6Dead Load + 0.6Coll + 0.7Seismic Load

9. Dead Load + Coll + Crane Load

10. Dead Load + Coll + 0.5 Wind Load + Crane Load

6

�A. NEW WAREHOUSE

7

�STEEL COLUMN PLAN

8

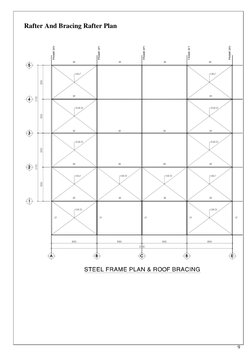

�Rafter And Bracing Rafter Plan

9

�Roof Purlins & Sagrod Plan

10

�Main Frames

11

�End Frame Purlin

12

�Wall Girt

13

�Wind Load Calculation

14

�15

�16

�Seismic Load

17

�Because, hn 14.50m T Ct hn 0.75 0.0853 14.500.75 0.6338

Base Shear = 0.2083W

From General Equation = 0.1667W

Upper Limit = 0.0440W

Lower Limits = 0.0640W

Design Base Shear = 0.1667W

W = 100% (Dead load + Coll load) + 25% Live load = (629.59+105.182) + 0 = 734.772 kN

Design Base Shear = 0.1667W = 0.1667*734.772 = 122.5 kN

This value will be divided into 15 points on top of columns as the concentrated load when we analyze the

structure. The value for one point is: 122.5/15 = 8.2 kN

We take the value of 10 kN to put in the structure load

18

�Deflection Criteria

19

�Horizontal Drift

20

�Model STAAD

Node number

21

�Dead load

Coll load

22

�Live load

Wind load 1

23

�Wind load 2

Wind load 3

24

�Wind load 4

Wind load 5

25

�Wind load 6

26

�Seismic X1

Seismic X2

27

�Seismic Z1

Seismic Z2

28

�Crane load 1

Crane load 2

29

�Crane load 3

Crane load 4

30

�Stress ratios

Concludsion:

All the element stress ratios are < 1.0 so the structure are OK.

Deflection and Drift

fy_max=113 mm < [fgh]=1/180*L=1/180*24200=134 mm OK

(Deal load + Coll load + Live load)

fx_max=43 mm < [fgh]=1/100*H=1/100*11185=112 mm OK

(Wind 10 year = 0.45*Wind 700 year)

fz_max=69 mm < [fgh]=1/100*H=1/100*11185=112 mm OK

(Wind 10 year = 0.45*Wind 700 year)

31

�Roof Purlin Design

Member Check - 1999 AISI Specification (ASD)

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Load Combination: 0.6D+0.6W

Design Parameters at 29.1402 m:

Lx 8.0000 m Ly 2.0000 m Lt 2.0000 m

Kx 1.0000 Ky 1.0000 Kt 1.0000

Section: [Link]

Material Type: [DDC GRADE 450], Fy=448.15 MPa

Cbx 1.0128 Cby 1.0000 ex 0.0000 mm

Cmx 1.0000 Cmy 1.0000 ey 0.0000 mm

Braced Flange: Top k 0 kN

Red. Factor, R: 0 Lm 6.0960 m

Loads: P Mx Vy My Vx

(kN) (kN-m) (kN) (kN-m) (kN)

Total 0.000 -8.9425 0.000 0.0000 0.000

Applied 0.000 -8.9425 0.000 0.0000 0.000

Strength 49.656 8.9401 42.679 2.3891 45.786

Effective section properties at applied loads:

Ae 839.55 mm^2 Ixe 4987251 mm^4 Iye 714264 mm^4

Sxe(t) 49873 mm^3 Sye(l) 9792 mm^3

Sxe(b) 49873 mm^3 Sye(r) 9792 mm^3

Interaction Equations

AISI Eq. C5.2.1-1 (P, Mx, My) 0.000 + 1.000 + 0.000 = 1.000 <= 1.0

AISI Eq. C5.2.1-2 (P, Mx, My) 0.000 + 1.000 + 0.000 = 1.000 <= 1.0

AISI Eq. C3.3.1-1 (Mx, Vy) 0.529 + 0.000 = 0.529 <= 1.0

AISI Eq. C3.3.1-1 (My, Vx) 0.000 + 0.000 = 0.000 <= 1.0

Web Crippling Check - 1999 AISI Specification (ASD)

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Load Combination: 0.6D+0.6W

Parameters at 8.000 m:

Total Load: 15.940 kN on top flange

Total Moment: 13.128 kN-m

Bearing: 50.800 mm

Flange fastened to bearing surface: Yes

Distance from edge of bearing to edge of opposite load: 32.000 m

Section: [Link]

Material Type: [DDC GRADE 450], Fy=448.15 MPa

Applied Load: 8.653 kN on top flange

Applied Moment: 7.126 kN-m

Distance from edge of bearing to end of member: 0.67460 m

Part Elem Calculation Type Pa (kN) Pay (kN) Notes

1 3 1999 AISI Eq.-4 18.305 18.305

Web Crippling Strength 18.305

Web Crippling Check: 8.653 kN <= 18.305 kN

Moment Check: 7.126 kN-m <= 12.291 kN-m

Interaction Equations

AISI Eq. C3.5.1-1 (P, M) 0.567 + 0.580 = 1.147 <= 1.500

Section: [Link]

Material Type: [DDC GRADE 450], Fy=448.15 MPa

Applied Load: 7.287 kN on top flange

Applied Moment: 6.0019 kN-m

Distance from edge of bearing to end of member: 0.67460 m

Part Elem Calculation Type Pa (kN) Pay (kN) Notes

32

� 1 3 1999 AISI Eq.-4 12.704 12.704

Web Crippling Strength 12.704

Web Crippling Check: 7.287 kN <= 12.704 kN

Moment Check: 6.0019 kN-m <= 9.4475 kN-m

Interaction Equations

AISI Eq. C3.5.1-1 (P, M) 0.688 + 0.635 = 1.324 <= 1.500

Maximum Shears, Moments, and Deflections

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Load Combination: 0.6D+0.6W, Y Direction

Location Shear(l) Shear(r) Reaction

(m) (kN) (kN) (kN)

0.000 0.000 -6.522 -6.522

8.000 8.568 -7.372 -15.940

16.000 5.999 -5.999 -11.997

24.000 7.372 -8.568 -15.940

32.000 6.522 0.000 -6.522

Location Moment Location Deflection Inflections

(m) (kN-m) (m) (mm) (m)

2.860 -8.942 3.420 45.793 6.131

8.000 13.128 8.968 -3.261 10.464

12.411 -3.179 12.557 9.207 14.358

16.000 7.619 16.000 0.000 17.642

19.589 -3.179 19.443 9.207 21.536

24.000 13.128 23.032 -3.261 25.869

29.140 -8.942 28.580 45.793

All the stress ratios are < 1.0, the defflection is 45.8 mm < 8000/150 = 53.3 mm => the roof purlins are

OK

33

�End Wall Purlin Design

Member Check - 1999 AISI Specification (ASD)

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Load Combination: 0.6D+0.6W

Design Parameters at 2.2340 m:

Lx 6.0500 m Ly 2.0167 m Lt 2.0167 m

Kx 1.0000 Ky 1.0000 Kt 1.0000

Section: [Link]

Material Type: [DDC GRADE 450], Fy=448.15 MPa

Cbx 1.1248 Cby 1.0000 ex 0.0000 mm

Cmx 1.0000 Cmy 1.0000 ey 0.0000 mm

Braced Flange: Top k 0 kN

Red. Factor, R: 0 Lm 6.0960 m

Loads: P Mx Vy My Vx

(kN) (kN-m) (kN) (kN-m) (kN)

Total 0.000 -5.7064 0.000 0.0000 0.000

Applied 0.000 -5.7064 0.000 0.0000 0.000

Strength 36.516 6.5397 17.781 1.4260 35.435

Effective section properties at applied loads:

Ae 634.25 mm^2 Ixe 3800318 mm^4 Iye 547543 mm^4

Sxe(t) 38003 mm^3 Sye(l) 7476 mm^3

Sxe(b) 38003 mm^3 Sye(r) 7476 mm^3

Interaction Equations

AISI Eq. C5.2.1-1 (P, Mx, My) 0.000 + 0.873 + 0.000 = 0.873 <= 1.0

AISI Eq. C5.2.1-2 (P, Mx, My) 0.000 + 0.873 + 0.000 = 0.873 <= 1.0

AISI Eq. C3.3.1-1 (Mx, Vy) 0.441 + 0.000 = 0.441 <= 1.0

AISI Eq. C3.3.1-1 (My, Vx) 0.000 + 0.000 = 0.000 <= 1.0

Web Crippling Check - 1999 AISI Specification (ASD)

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Load Combination: 0.6D+0.6W

Parameters at 18.150 m:

Total Load: 13.691 kN on top flange

Total Moment: 8.4500 kN-m

Bearing: 50.800 mm

Flange fastened to bearing surface: Yes

Distance from edge of bearing to edge of opposite load: 24.200 m

Section: [Link]

Material Type: [DDC GRADE 450], Fy=448.15 MPa

Applied Load: 6.845 kN on top flange

Applied Moment: 4.2250 kN-m

Distance from edge of bearing to end of member: 0.37460 m

Part Elem Calculation Type Pa (kN) Pay (kN) Notes

1 3 1999 AISI Eq.-4 10.279 10.279

Web Crippling Strength 10.279

Web Crippling Check: 6.845 kN <= 10.279 kN

Moment Check: 4.2250 kN-m <= 8.5938 kN-m

Interaction Equations

AISI Eq. C3.5.1-1 (P, M) 0.799 + 0.492 = 1.291 <= 1.500

34

�Maximum Shears, Moments, and Deflections

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Load Combination: 0.6D+0.6W, Y Direction

Location Shear(l) Shear(r) Reaction

(m) (kN) (kN) (kN)

0.000 0.000 -5.109 -5.109

6.050 7.342 -6.348 -13.691

12.100 5.176 -5.176 -10.352

18.150 6.348 -7.342 -13.691

24.200 5.109 0.000 -5.109

Location Moment Location Deflection Inflections

(m) (kN-m) (m) (mm) (m)

2.234 -5.7064 2.599 21.796 4.644

6.050 8.4500 6.736 -1.401 7.883

9.382 -2.1437 9.486 4.045 10.881

12.100 4.9039 12.100 0.000 13.319

14.818 -2.1437 14.714 4.045 16.317

18.150 8.4500 17.464 -1.401 19.556

21.966 -5.7064 21.601 21.796

All the stress ratios are < 1.0, the defflection is 21.8 mm < 6050/150 = 40.3mm => the end wall purlins

are OK

35

�Side Wall Purlin Design

Member Check - 1999 AISI Specification (ASD)

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Load Combination: 0.6D+0.6W

Design Parameters at 3.1041 m:

Lx 8.1000 m Ly 2.0250 m Lt 2.0250 m

Kx 1.0000 Ky 1.0000 Kt 1.0000

Section: [Link]

Material Type: [DDC GRADE 450], Fy=448.15 MPa

Cbx 1.0131 Cby 1.0000 ex 0.0000 mm

Cmx 1.0000 Cmy 1.0000 ey 0.0000 mm

Braced Flange: Top k 0 kN

Red. Factor, R: 0 Lm 6.0960 m

Loads: P Mx Vy My Vx

(kN) (kN-m) (kN) (kN-m) (kN)

Total 0.000 -8.3594 0.000 0.0000 0.000

Applied 0.000 -8.3594 0.000 0.0000 0.000

Strength 49.656 8.7964 42.679 2.3880 45.786

Effective section properties at applied loads:

Ae 839.55 mm^2 Ixe 4987251 mm^4 Iye 714264 mm^4

Sxe(t) 49873 mm^3 Sye(l) 9792 mm^3

Sxe(b) 49873 mm^3 Sye(r) 9792 mm^3

Interaction Equations

AISI Eq. C5.2.1-1 (P, Mx, My) 0.000 + 0.950 + 0.000 = 0.950 <= 1.0

AISI Eq. C5.2.1-2 (P, Mx, My) 0.000 + 0.950 + 0.000 = 0.950 <= 1.0

AISI Eq. C3.3.1-1 (Mx, Vy) 0.463 + 0.000 = 0.463 <= 1.0

AISI Eq. C3.3.1-1 (My, Vx) 0.000 + 0.000 = 0.000 <= 1.0

Web Crippling Check - 1999 AISI Specification (ASD)

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Load Combination: 0.6D+0.6W

Parameters at 24.100 m:

Total Load: 15.986 kN on top flange

Total Moment: 13.032 kN-m

Bearing: 50.800 mm

Flange fastened to bearing surface: Yes

Distance from edge of bearing to edge of opposite load: 32.200 m

Section: [Link]

Material Type: [DDC GRADE 450], Fy=448.15 MPa

Applied Load: 7.309 kN on top flange

Applied Moment: 5.9579 kN-m

Distance from edge of bearing to end of member: 0.67460 m

Part Elem Calculation Type Pa (kN) Pay (kN) Notes

1 3 1999 AISI Eq.-4 12.704 12.704

Web Crippling Strength 12.704

Web Crippling Check: 7.309 kN <= 12.704 kN

Moment Check: 5.9579 kN-m <= 9.4475 kN-m

Interaction Equations

AISI Eq. C3.5.1-1 (P, M) 0.690 + 0.631 = 1.321 <= 1.500

Section: [Link]

Material Type: [DDC GRADE 450], Fy=448.15 MPa

Applied Load: 8.678 kN on top flange

Applied Moment: 7.074 kN-m

Distance from edge of bearing to end of member: 0.67460 m

36

�Part Elem Calculation Type Pa (kN) Pay (kN) Notes

1 3 1999 AISI Eq.-4 18.305 18.305

Web Crippling Strength 18.305

Web Crippling Check: 8.678 kN <= 18.305 kN

Moment Check: 7.074 kN-m <= 12.291 kN-m

Interaction Equations

AISI Eq. C3.5.1-1 (P, M) 0.569 + 0.576 = 1.144 <= 1.500

Maximum Shears, Moments, and Deflections

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Load Combination: 0.6D+0.6W, Y Direction

Location Shear(l) Shear(r) Reaction

(m) (kN) (kN) (kN)

0.000 0.000 -5.405 -5.405

8.100 8.537 -7.450 -15.986

16.100 6.257 -6.227 -12.484

24.100 7.447 -8.539 -15.986

32.200 5.403 0.000 -5.403

Location Moment Location Deflection Inflections

(m) (kN-m) (m) (mm) (m)

3.104 -8.359 3.509 44.100 6.228

8.100 13.013 9.028 -2.905 10.509

12.448 -3.233 12.574 9.407 14.387

16.100 8.224 16.001 -0.023 17.823

19.753 -3.203 19.582 9.836 21.684

24.100 13.032 23.179 -2.859 25.975

29.097 -8.352 28.692 44.030

All the stress ratios are < 1.0, the defflection is 21.8 mm < 6050/150 = 40.3mm => the side wall purlins

are OK

37

�B. MEZZANINE FLOOR

38

�Seismic Load

39

�Because, hn 3.65m T Ct hn 0.75 0.0853 3.650.75 0.2253

Base Shear = 0.5860W

From General Equation = 0.1667W

Upper Limit = 0.0440W

Lower Limits = 0.0640W

Design Base Shear = 0.1667W

W = 100% Dead load + 25% Live load = 1908.9 + 0.25*1922.4 = 2389.5 kN

Design Base Shear = 0.1667W = 0.1667*2389.5 = 398.3 kN

This value will be divided into 18 points on top of columns as the concentrated load when we analyze the

structure. The value for one point is: 398.3/18 = 22.1 kN

We take the value of 22.5 kN to put in the structure load

40

�Deflection Criteria

41

�Model STAAD

Node number

42

�Dead load

Live load

43

�Seismic X1

Seismic X2

44

�Seismic Z1

Seismic Z2

45

�Stress ratios

Concludsion:

All the element stress ratios are < 1.0 so the structure are OK.

Deflection

fy_max=10.1 mm < [fgh]=1/240*L=1/240*5400=22.5 mm OK

(Deal load + Live load)

46