Professional Documents

Culture Documents

Us 8461286

Uploaded by

rajesh kothari0 ratings0% found this document useful (0 votes)

8 views7 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views7 pagesUs 8461286

Uploaded by

rajesh kothariCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

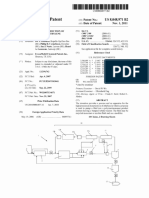

US008461286B2

(12) United States Patent (10) Patent No.: US 8.461.286 B2

Young et al. (45) Date of Patent: Jun. 11, 2013

(54) PROCESS FOR MANUFACTURING LIQUID (51) Int. Cl.

EPOXY RESINS C08G 59/06 (2006.01)

COSL 6/12 (2006.01)

(75) Inventors: Thomas C. Young, Lake Jackson, TX C07D 301/27 (2006.01)

(US); Clinton J. Boriack, Brenham, TX (52) U.S. Cl.

(US); Elwin G. Collier, Houston, TX USPC .............................. 528/87; 525/507; 549/517

(US); Robert M. Drake, Richwood, TX (58) Field of Classification Search

USPC .............................. 549/517; 528/87; 525/507

(US); Joachim Drewing, See application file for complete search history.

Hollern-Twielenfleth (DE); Edward J.

Kronenberger, Missouri City, TX (US); (56) References Cited

Shuji Maeda, Lake Jackson, TX (US); U.S. PATENT DOCUMENTS

Paulo Alfonso Dos Santos Pereira,

Lake Jackson, TX (US); Andreas 3,221,032. A 11, 1965 McWhorter

Tigges, Stade (DE); Roland Werner, 4,373,073. A 2/1983 Wojtech et al.

4,390,680 A 6, 1983 Nelson

Hamburg (DE); Mark S. Burkinshaw, 4,582,892 A 4, 1986 Chang et al.

Lake Jackson, TX (US) 4,624,975 A 11, 1986 Pham

4,900,801 A * 2/1990 Takata et al. .................... 528/87

(73) Assignee: Dow Global Technologies LLC, 5,245,057 A 9, 1993 Shirtum

Midland, MI (US) FOREIGN PATENT DOCUMENTS

CH 575,405 A5 5, 1976

(*) Notice: Subject to any disclaimer, the term of this FR 2217372 A1 9, 1974

patent is extended or adjusted under 35 (Continued)

U.S.C. 154(b) by 285 days. Primary Examiner — Taylor Victor Oh

(21) Appl. No.: 12/933,840 (57) ABSTRACT

A process for the production of liquid epoxy resins, includ

(22) PCT Filed: Mar. 24, 2009 ing: contacting a polyhydric phenol and an epihalohydrin in

the presence of an ionic catalyst to form a halohydrin inter

(86). PCT No.: PCT/US2009/038O89

mediate reaction product; concurrently: reacting a portion of

S371 (c)(1), the halohydrin intermediate reaction product with an alkali

(2), (4) Date: Sep. 21, 2010 hydroxide to form a solid salt Suspended in a liquid mixture

including a dehydrohalogenated product and unreacted halo

(87) PCT Pub. No.: WO2009/120685 hydrin intermediate, wherein the alkali hydroxide is used at

PCT Pub. Date: Oct. 1, 2009 less than a stoichiometric amount; and removing water and

epihalohydrin as a vapor from the reacting mixture; separat

(65) Prior Publication Data ing the solid salt from the liquid mixture; reacting at least a

portion of the unreacted halohydrin intermediate with an

US 2011 FOO28744 A1 Feb. 3, 2011 alkali hydroxide in the presence of water to form an organic

mixture including an epoxy resin and unreacted epihalohy

drin and an aqueous solution including a salt; separating the

Related U.S. Application Data aqueous mixture from the organic mixture; and separating the

(60) Provisional application No. 61/039,269, filed on Mar. unreacted epihalohydrin from the liquid epoxy resin.

25, 2008. 9 Claims, 1 Drawing Sheet

US 8.461.286 B2

Page 2

FOREIGN PATENT DOCUMENTS JP 58-24578 2, 1983

JP 11158248. A 6, 1999

GB T88887 A 1, 1958

GB 1278.737 A 6, 1972 * cited by examiner

U.S. Patent Jun. 11, 2013 US 8.461.286 B2

US 8,461,286 B2

1. 2

PROCESS FOR MANUFACTURING LIQUID JP58-24578 discloses a process in which a phenol and an

EPOXY RESNS epihalohydrin are reacted using a quaternary amine catalyst,

then dehydrohalogenated with an alkali hydroxide while

BACKGROUND OF DISCLOSURE removing water.

GB 778887 discloses a process in which a polyhydric

1. Field of the Disclosure phenol and an epihalohydrinare etherified and partially dehy

Embodiments disclosed herein relate generally to a process drohalogenated in an alkaline medium using 90-98 percent of

to manufacture liquid epoxy resins by reaction of a polyhy an equivalent of alkali metal hydroxide per phenolic hydroxyl

dric phenol with an epihalohydrin using an anionic catalyst. 10

equivalent. The excess epihalohydrin is then removed and a

The resulting reaction product may then be dehydrohaloge second dehydrohalogenation step is performed, optionally in

nated using an alkali metal hydroxide or alkali earth hydrox solvent.

ide in two reaction steps. The dehydrohalogenation reactions Accordingly, there exists a need for processes for the

are performed to achieve a high raw material yield while manufacture of liquid epoxy resins (LER) with a high raw

avoiding problems associated with insoluble polymer forma 15 material yield and without polymer formation. Such pro

tion. cesses should have a high reliability and a low cost. Addition

2. Background ally the processes should have a low variability, avoiding the

In the manufacture of epoxy resins, a high raw material need to rework product.

yield can be achieved by removing water during dehydroha

logenation with alkali hydroxides to maintain a low water SUMMARY OF THE DISCLOSURE

content. However, reactions done under these conditions are

susceptible to the formation of insoluble polymers, which can In one aspect, embodiments disclosed herein relate to a

cause problems in the Subsequent processing steps. process for the production of liquid epoxy resins, including:

In contrast, dehydrohalogenation reactions done without contacting a polyhydric phenol and an epihalohydrin in the

water removal can be less Susceptible to polymer formation, 25 presence of an ionic catalyst to form a halohydrin intermedi

but also results in a lower raw material yield. Another diffi ate reaction product; concurrently: reacting a portion of the

culty with dehydrohalogenation reactions done with water halohydrin intermediate reaction product with an alkali

removal is the difficulty in obtaining a product with low hydroxide to form a solid salt Suspended in a liquid mixture

variability, because of the sensitivity of product hydrolysable including a dehydrohalogenated product and unreacted halo

chlorides to the amount of caustic added. 30 hydrin intermediate, wherein the alkali hydroxide is used at

As a result of the above, post-treatment reactions are fre less than a stoichiometric amount; and removing water and

quently used to achieve the desired levels of hydrolysable epihalohydrin as a vapor from the reacting mixture; separat

chlorides, and reprocessing of material must often be done. ing the solid salt from the liquid mixture; reacting at least a

GB 1278737 discloses a process in which bisphenol-A and portion of the unreacted halohydrin intermediate with an

epichlorohydrin are reacted with a catalyst, and then dehy 35 alkali hydroxide in the presence of water to form an organic

drochlorinated using 80-99 percent of the stoichiometric mixture including an epoxy resin and unreacted epihalohy

caustic requirement in an azeotropically distilled reactor. drin and an aqueous solution including a salt; separating the

Then, the unreacted epichlorohydrin is removed by evapora aqueous mixture from the organic mixture; and separating the

tion and the Stripped epoxy resin is combined with a solvent, unreacted epihalohydrin from the liquid epoxy resin.

and then subjected to a second dehydrochlorination reaction. 40 In another aspect, embodiments disclosed herein relate to a

U.S. Pat. No. 3,221,032 discloses a process in which system for the production of a liquid epoxy resin, the system

bisphenol-A and epichlorohydrin are reacted with a catalyst including: at least one reactor for contacting a polyhydric

at 125° C. or above, then subjecting the mixture to a dehy phenol and an epihalohydrin in the presence of an ionic cata

drohalogenation reaction using an alkali hydroxide, alkaline lyst to form a halohydrin intermediate reaction product; at

earth hydroxide or other base. 45 least one reactor for concurrently: reacting a portion of the

U.S. Pat. No. 4,582,892 discloses a process in which halohydrin intermediate reaction product with an alkali

bisphenol-A and epichlorohydrin are reacted with a catalyst hydroxide to form a solid salt Suspended in a liquid mixture

to forma halohydrin intermediate, then removing the epichlo including a dehydrohalogenated product and unreacted halo

rohydrin and adding a solvent, then Subjecting the resulting hydrin intermediate, wherein the alkali hydroxide is used at

mixture to a dehydrohalogenation reaction. 50 less than a stoichiometric amount; and removing water and

CH 575405 discloses a process in which bisphenol-A and epihalohydrin as a vapor from the reacting mixture; a sepa

epichlorohydrin are reacted with a catalyst to form a halohy rator for separating the Solid salt from the liquid mixture; at

drin intermediate, then dehydrohalogenating with an alkali least one reactor for reacting at least a portion of the unreacted

with the excess epichlorohydrin either present or removed. halohydrin intermediate with an alkali hydroxide in the pres

The dehydrohalogenation step is to be done in Such away that 55 ence of water to form an organic mixture including an epoxy

no solid salt forms. resin and unreacted epihalohydrin and an aqueous Solution

U.S. Pat. No. 4,373,073 discloses a process in which including a salt; a separator for separating the aqueous mix

bisphenol-A and epichlorohydrin are reacted to form a chlo ture from the organic mixture; and a separator for separating

rohydrin ether intermediate, and then a quaternary ammo the unreacted epihalohydrin from the liquid epoxy resin.

nium catalyst or a similar catalyst is added to accelerate phase 60 Other aspects and advantages will be apparent from the

transfer reactions during the dehydrohalogenation step. following description and the appended claims.

JP 11158248 discloses a process in which a monofunc

tional or polyhydric phenol and epichlorohydrin are reacted BRIEF DESCRIPTION OF DRAWINGS

with 0.2 to 0.9 equivalents alkali metal hydroxide with azeo

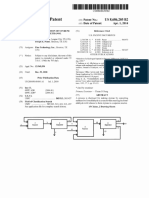

tropic distillation to remove water, and then with additional 65 FIG. 1 is a simplified process flow diagram illustrating a

alkali metal hydroxide after “the pressure is returned to nor process for manufacturing liquid epoxy resins according to

mal’ and an organic solvent is added. embodiments disclosed herein.

US 8,461,286 B2

3

DETAILED DESCRIPTION

O

In one aspect, embodiments disclosed herein relate to a

process to manufacture liquid epoxy resins by reaction of a R

polyhydric phenol with an epihalohydrin using an anionic

catalyst. The resulting reaction product may then be dehydro

halogenated using an alkali metal hydroxide or alkali earth where R is hydrogen or a hydrocarbyl group having from 1 to

hydroxide in two reaction steps. The dehydrohalogenation about 4 carbon atoms and X is a halogen, such as chlorine or

bromine.

reactions are performed to achieve a high raw material yield 10

while avoiding problems associated with insoluble polymer Suitable dehydrohalogenating agents that may be used in

formation. embodiments disclosed herein include alkali metal hydrox

ides such as, for example, Sodium hydroxide, potassium

Processes disclosed herein include the reaction of a poly hydroxide, lithium hydroxide or mixtures thereof. The alkali

hydric phenol. Such as bisphenol-A, with an epihalohydrin, metal hydroxide can be added either continuously or incre

Such as epichlorohydrin, using a quaternary ammonium cata 15

mentally. In other embodiments, the dehydrohalogenating

lyst. The resulting reaction product is then partially dehydro agent may include alkali earth hydroxides.

halogenated using 80-95 percent of the stoichiometric caustic Anionic catalysts useful in embodiments disclosed herein

requirement in an agitated reactor where the water content is include quaternary ammonium halide catalysts such as ben

controlled by evaporation. The solid salt formed in this reac Zyltrimethylammonium chloride, benzyl triethylammonium

tor is then removed by centrifuge and is treated to recover chloride, tetraethyl ammonium chloride, tetramethyl ammo

resin. The centrate from the centrifuge is then contacted with nium chloride, tetraethanol ammonium chloride, tetraethanol

a caustic/water mixture in a second reactor to complete the ammonium hydroxide and the like. Other useful catalysts

dehydrohalogenation, and the water level is maintained to include quaternary phosphonium compounds, Sulfonium

prevent polymer formation. The reactor effluent is then con 25 compounds and the like. Suitable quaternary phosphonium

tacted with water to remove ionic impurities. Volatile com compounds include ethyl triphenyl phosphonium iodide,

ponents, including the excess epichlorohydrin, are then ethyl triphenyl phosphonium bicarbonate, benzyl triphenyl

stripped to give a liquid epoxy resin product, which has low phosphonium chloride, tetrabutyl phosphonium chloride and

hydrolysable chloride content.

the like. Suitable sulfonium catalysts include thiourea cata

Suitable polyhydric phenols that may be used in embodi 30

lysts such as tetramethyl thiourea, N,N'-diphenyl thiourea

ments disclosed herein include, for example, those mono and the like. Basic ion exchange resins, such as DOWEX

nuclear and polynuclear polyhydric phenols represented by MSA-1, available from The Dow Chemical Company, Mid

the formulas (R)-Ph-(A)-Ph-(R), R-Ph-A-PhI-R, R-Ph land, Mich., are also useful catalysts. Other ionic catalysts

A'-(Ph-R), and that may be used in embodiments disclosed herein are dis

35

closed in U.S. Pat. Nos. 4,624,975 and 5,245,057, each of

Ph-R Ph-R which are incorporated herein by reference.

The amount of catalyst employed in the coupling reaction

CH-CH-(CH-CH)-H is any quantity that will Suitably catalyze the reaction between

40 the polyhydric phenol and the epihalohydrin. In some

wherein Ph represents a phenol group; each A is indepen embodiments, quantities from about 0.001 to about 0.15

dently a divalent hydrocarbon group having from 1 to about moles of catalyst per mole of polyhydric phenol is used; in

12 carbon atoms, —O— —S— —S—S , other embodiments, from about 0.01 to about 0.02 moles of

catalyst per mole of polyhydric phenol is used.

45 Embodiments of the processes disclose herein may be per

O O O formed without any added organic solvent. When used, suit

able solvents may include ketones, aromatic hydrocarbons,

-S-, -S-, -O-C-O-, or halogenated aliphatic compounds such as, for example,

O methyl isobutyl ketone, methyl ethyl ketone, toluene, xylene,

O 50 methylene chloride, ethylene dichloride, mixtures thereof

and the like.

-C-: Referring now to FIG. 1, a simplified process flow diagram

illustrating a process for manufacturing liquid epoxy resins

A is a trivalent hydrocarbon group having from 1 to about 12 according to embodiments disclosed herein is illustrated. A

carbonatoms; each Ris independently hydrogen, a hydrocar 55 polyhydric phenol 2. Such as Bisphenol A, and an epihalohy

byl group having from 1 to about 10 carbon atoms, a halogen drin 4. Such as epichlorohydrin, are contacted with an anionic

atom, such as chlorine or bromine, or a hydroxyl group; p has catalyst 6 in one or more reactors 8. An excess of epichloro

a value of from about 1 to about 100; m has a value from about hydrin is used to produce a coupled bisphenol-A/epichloro

1 to about 6; and n has a value of Zero or 1. hydrin reaction product.

60 The reactors 8 may be batch or continuous reactors. If

Other polyhydric phenols are described in U.S. Pat. Nos. continuous, a series of reactors may be used. The reactors 8

4.582,892 and 4,373,073, which are incorporated herein by may be operated at temperatures from 20° C. to 100° C. in

reference. Suitable polycyclopentadiene polyphenols and some embodiments; from 40° C. to 70° C. in other embodi

methods for their preparation can be found in U.S. Pat. No. ments. The reactors may be cooled to remove the heat of

4.390,680, which is incorporated herein by reference. 65 reaction.

Suitable epihalohydrins that may be used in embodiments Epichlorohydrin to bisphenol molar ratios in the initial

disclosed herein include those represented by the formula mixture may be from 2:1 to 20:1 in some embodiments; 5:1 to

US 8,461,286 B2

5 6

10:1 in other embodiments; and may be varied depending on difficult to separate from the organic phase. These reactors

the composition of the epoxy resin to be produced. may be operated in association with settling stages where the

The coupled polyhydric phenol and epihalohydrin mixture aqueous and organic phases will be separated. If a series of

10 is partially dehydrohalogenated by reaction with an alkali reactors are used, they may be connected in a countercurrent,

hydroxide 12 in one or more agitated reactors 14. Water may co-current or crossflow arrangement. Alternatively, a con

be removed by evaporation of an epihalohydrin-water mix tinuous reactor with multiple stages may be used.

ture 16, Such as by maintaining the reaction mixture under Alkalihydroxide/water mixture 26 includes aqueous alkali

vacuum to keep the reaction temperatures low. Water removal hydroxide solutions, and can include various concentrations

results in decreased byproduct formation, resulting in high of the alkali halide in water. In reactor 28, in contrast to the

yield. Partial dehalohydrogenation, using s95 percent of the 10 operation of reactor 14, water is not removed by evaporation.

Stoichiometric caustic, prevents polymerformation (stoichio As such, the concentration of the alkali hydroxide in water

metric caustic being defined as 1 mole of NaOH per mole should not be so high that the saturation point of the alkali

equivalent of phenolic hydroxide groups in the original mix hydroxide or the byproduct salt in the water is exceeded, so

ture of polyhydric phenol and epihalohydrin). Solid salt that no solids precipitate in the reactor. Other components

may be added to the alkali hydroxide solutions. Such as com

forms in reactors 14, and may be suspended in the organic 15

ponents that would increase the density difference between

medium in the reactors by agitation. the phases or otherwise improve the operation of the reactor.

The reactors 14 may be batch or continuous reactors. If Reactors 28 should be operated at temperatures sufficient

continuous, a series of reactors may be used. In some embodi to avoid or minimize raw material loss due to hydrolysis. In

ments, one continuous reactoris used. The reactors are heated Some embodiments, reactors 28 may be operated attempera

to evaporate water, either by external heat exchangers or by tures less than 50° C.; in other embodiments, reactor 28

incorporating passages for a heating fluid in the reactor. operating temperatures are less than 30° C.

Because of the physical properties of the water and epihalo Following the reaction of the alkali hydroxide in reactors

hydrin, evaporation of water results in a mixed epihalohydrin/ 28, the aqueous and organic phases may be separated, result

water vapor, which must be removed from the reactor. The ing in a waste brine solution 30, and an organic phase 32

reactors 14 may be operated at temperatures from 30° C. to 25 including the epoxy resin (the coupled and dehydrohaloge

90° C. in some embodiments; from 40° C. to 75° C. in other nated polyhydric phenol/epihalohydrin reaction product) and

embodiments. The reactors are operated below atmospheric any residual epihalohydrin. Separation of the organic phase

pressure to allow water removal at these low operating tem and the aqueous phase may be accomplished via any liquid

peratures. Operating pressures may range from 0.05-0.9 bar liquid separation, including decanters, coalescers, and

in Some embodiments. 30

decanting centrifuges.

The alkali hydroxide 12 used in reactors 14 may include, The epoxy resin may then be separated from the epihalo

hydrin by any Suitable means. For example, the excess epi

for example, sodium hydroxide, which may be in solid or halohydrin and other volatile components can be removed

liquid form. In some embodiments, a sodium hydroxide/wa from the liquid epoxy resin in separator 34, Such as by evapo

ter solution containing 25 percent or more NaOH is used. ration or distillation. This is typically performed at high tem

Less than the stoichiometric amount of alkali hydroxide 35 peratures and under vacuum. The epihalohydrin and other

needed to fully dehydrohalogenate the epoxy resin is added to volatile components may be recovered via stream 36, and the

this reactor. For example, in some embodiments, 0.5-0.95 of liquid epoxy resin via stream 38.

the Stoichiometric amount is used; in other embodiments, A variety of process equipment 34 may be used to recover

0.8-0.95 of the stoichiometric amount is used. The reactor 14 the epoxy resin from the epichlorohydrin/epoxy resin mix

may be agitated to ensure good mixing of the reactants, 40 ture. For example, one method is to evaporate epihalohydrin

achieve good heat transfer and to Suspend the salt. Mechani and other Volatile components from the liquid epoxy resin

cal agitation or jet mixing may be used, for example. using a flash evaporator, falling film evaporator, boiling tube

The effluent 18 from reactor 14 may then be processed to evaporators, wiped film evaporator, stripping columns, and

separate the solid salt formed from the organic liquid. Effluent other thin-film evaporators. This evaporation step may be

18 may pass through a salt removal system 20, resulting in Salt 45 performed at temperatures of 150° C. or higher and under

stream 22 and a coupled polyhydric phenol/epihalohydrin vacuum. Pressures of 100 millibar or less are typically used.

mixture 24. In some embodiments, the Solid salt may be Combinations of evaporation operations may also be used.

removed by filtration, centrifugation or other solid/liquid In some embodiments, the reaction product 32 may be

separation techniques. Alternatively, the salt may be sepa washed by contact with water to remove ionic species and

rated from the organic liquid by dissolving the salt in water, 50

other water soluble impurities prior to epichlorohydrin

removal.

then separating the aqueous and organic phases. In other embodiments, the solid salt 22 may be treated to

The Solid Saltcake separated by centrifuge or filtration may remove residual epichlorohydrin, epoxy resin and other com

contain residual liquid. In some embodiments, the residual ponents, and to prepare the Solid salt for disposal. For

liquid content of the cake is less than 60 percent, by weight; in example, a filter cake including the solid salt and residual

other embodiments, the liquid content is less than 40 percent, 55 liquid may be pressed or washed to separate the organic

by weight. liquids from the solid salt.

The coupled polyhydric phenol/epihalohydrin mixture 24 Various methods may also be used to recover and/or

(halohydrin intermediate) is then contacted with an alkali recycle raw material. Such as epichlorohydrin, from waste

hydroxide/water mixture 26 in one or more reactors 28 to streams from the process, such as streams 16, 22, 30, and 36.

complete the dehydrohalogenation of the epoxy resin. Water 60 For example, the epichlorohydrin/water vapor 16 from reac

is present in this reaction step to prevent the formation of tor 14 may be condensed, and then may be treated to recover

polymer. A stoichiometric excess of alkali hydroxide may be the water and epichlorohydrin for additional use.

used to obtain low levels of halohydrin content.

The reactors 28 may be batch or continuous. If continuous, EXAMPLES

a series of reactors may be used. Reactors 28 may be agitated 65

to improve contacting of the two liquid phases, but not so A mixture of 21.5 percent bisphenol-A and 0.214 percent

highly agitated that the aqueous phase is finely dispersed and benzyl trimethyl ammonium chloride by weight in epichlo

US 8,461,286 B2

7 8

rohydrin is prepared and reacted in agitated reactors at atmo While the disclosure includes a limited number of embodi

spheric pressure and temperatures ranging from 50° C. to 62 ments, those skilled in the art, having benefit of this disclo

C. The resulting reaction product is analyzed by HPLC and sure, will appreciate that other embodiments may be devised

greater than 95 percent of the phenolic hydroxyl groups are which do not depart from the scope of the present disclosure.

found to have reacted. The mixture is then reacted with a 50 5 Accordingly, the scope should be limited only by the attached

claims.

percent sodium hydroxide/water mixture at a temperature of What is claimed:

about 65° C. and a pressure of about 200 mm Hg. Steam is 1. A process for the production of liquid epoxy resins, the

Supplied to the jacket of the reactor, and a vapor containing process consisting essentially of

water and epichlorohydrin is removed from the reactor and 10

contacting a polyhydric phenol and an epihalohydrin in the

condensed. Sodium hydroxide is added in an amount of 0.89 presence of an ionic catalyst comprising at least one of a

gmol-equivalents per gmol-equivalent of phenolic hydroxyl quaternary ammonium halide, a quaternary phospho

groups contained in the bisphenol-A of the original mixture. nium compound, a Sulfonium compound, and a basic

Solid sodium chloride is formed as a result of the reaction. ionic exchange resin to form a halohydrin intermediate

The reaction mixture is analyzed and found to contain 0.13 reaction product;

percent by weight 1,3-dichloro-2-propanol and the epoxy

15 concurrently:

reacting a portion of the halohydrin intermediate reac

resin contained in the mixture is found to have 1.45 percent tion product with an alkali hydroxide to form a solid

hydrolysable chloride content by weight based on the resin salt Suspended in a liquid mixture comprising a dehy

content of the mixture. The mixture is also found to contain no drohalogenated product and unreacted halohydrin

insoluble polymer. intermediate, wherein the alkali hydroxide is used at

The mixture is treated in a centrifuge to remove the solid less than a stoichiometric amount; and

salt. The resulting centrate is treated with an aqueous mixture removing water and epihalohydrin as a vapor from the

of sodium hydroxide and Sodium carbonate. The aqueous reacting mixture;

mixture is added to the reactor in an amount of 0.58 gmol separating the Solid salt from the liquid mixture;

equivalent sodium hydroxide per gmol-equivalents of phe 25 reacting at least a portion of the unreacted halohydrin inter

nolic hydroxyl groups contained in the bisphenol-A of the mediate with an alkali hydroxide in the presence of

original mixture. The reactor is maintained at a temperature water to form an organic mixture comprising an epoxy

from 17° C. to 20°C. The organic and aqueous phases are resin and unreacted epihalohydrin and an aqueous solu

separated and the organic phase is analyzed and found to have tion comprising a salt;

50 to 100 ppm by weight hydrolysable chloride content based 30 separating the aqueous mixture from the organic mixture;

on the resin content of the mixture. The organic phase is then and

contacted with water to remove ionic and water soluble spe separating the unreacted epihalohydrin from the liquid

cies, using a ratio of 1 part water to 10 parts organic, by epoxy resin.

weight. The water and organic phases are separated, and the 2. The process of claim 1, further comprising contacting

epoxy resin is recovered from the organic phase by vacuum 35 the organic mixture with water to separate ionic species and

distillation. The resulting epoxy resin is analyzed and found water-soluble impurities from the organic mixture.

to have the properties shown in Table 1. 3. The process of claim 1, further comprising treating the

solid salt separated from the liquid mixture to recover at least

TABLE 1. one of epihalohydrin and liquid epoxy resin.

Viscosity at 25°C., cP 94OO-9900

40 4. The process of claim 1, wherein the contacting a poly

Hydrolysable chloride (ppm) SO-100 hydric phenol and an epihalohydrin is performed at a tem

Total Chloride (ppm) 1500-1900 perature in the range from 20°C. to 100° C.

5. The process of claim 1, wherein the epihalohydrin and

As described above, embodiments disclosed herein may the polyhydric phenol are contacted at a molar ratio, epiha

provide for systems and processes for producing liquid epoxy 45 lohydrin to polyhydric phenol, within the range from 2:1 to

20:1.

resins that do not require the use of solvents, which eliminates 6. The process of claim 1, wherein the reacting a portion of

Solvent separation and purification equipment. Processes

which use solvents require separate evaporation of the epiha the halohydrin intermediate reaction product with an alkali

lohydrin and solvent from the epoxy resin, which requires hydroxide is performed at a temperature in the range from 30°

additional equipment, and the associated capital costs, and

50 C. to 90° C. and at a pressure within the range from 0.05 to 0.9

consumes a Substantial amount of additional energy. bar, and wherein the alkali hydroxide is used at less than 98

Advantageously, embodiments disclosed herein may pro percent of the Stoichiometric amount.

vide for use of an azeotropically-distilled reaction for 80-95 7. The process of claim 1, wherein the alkali hydroxide is

percent of the dehydrohalogenation to achieve a high raw Sodium hydroxide.

material yield, preventing the formation of polymer that can 55 8. The process of claim 1, wherein, during the reacting a

occur when more than 95 percent of the stoichiometric alkali portion of the halohydrin intermediate reaction product, the

hydroxide is added under azeotropically-distilled conditions. alkali hydroxide is used at 80 percent to 95 percent of the

Additionally, removing the Solid salt and completing the Stoichiometric amount.

dehydrohalogenation with an aqueous brine phase present 9. The process of claim 1, wherein the reacting at least a

prevents polymer formation while allowing production with 60 portion of the unreacted halohydrin intermediate is per

very low levels of hydrolysable halides. The combination of formed at a temperature of less than 50° C., and wherein,

these two reaction steps allows production of an epoxy resin during the reacting at least a portion of the unreacted halohy

with low hydrolysable halide content with high raw material drin intermediate, the alkali hydroxide is used at a greater

than Stoichiometric amount.

yield and without polymer formation which cannot be

achieved with one reactor technology alone. k k k k k

You might also like

- Organic Pollutants in the Water Cycle: Properties, Occurrence, Analysis and Environmental Relevance of Polar CompoundsFrom EverandOrganic Pollutants in the Water Cycle: Properties, Occurrence, Analysis and Environmental Relevance of Polar CompoundsThorsten ReemtsmaNo ratings yet

- US7141214Document6 pagesUS7141214Vijayan Vgn NNo ratings yet

- United States Patent: (10) Patent No.: US 8,026.401 B2Document8 pagesUnited States Patent: (10) Patent No.: US 8,026.401 B2jonathanNo ratings yet

- United States Patent (10) Patent No.: US 8,076,507 B2Document12 pagesUnited States Patent (10) Patent No.: US 8,076,507 B2Manuel Gonzalez GalvezNo ratings yet

- Us8455685 UseDocument10 pagesUs8455685 UseRefi RahmanNo ratings yet

- United States Patent: Pez Et Al. (45) Date of Patent: Sep. 30, 2008Document57 pagesUnited States Patent: Pez Et Al. (45) Date of Patent: Sep. 30, 2008Mazin FathiNo ratings yet

- RESEARCHDocument23 pagesRESEARCHKulet GuazonNo ratings yet

- Patent - Methylation of Benzene or TolueneDocument10 pagesPatent - Methylation of Benzene or TolueneWilly DinataNo ratings yet

- Chiyoda Corp PatentDocument8 pagesChiyoda Corp Patentadityachoumal07No ratings yet

- US8034246 PatentDocument9 pagesUS8034246 PatentCatalina SarriaNo ratings yet

- United States Patent (10) Patent N0.: US 7,531,066 B2Document9 pagesUnited States Patent (10) Patent N0.: US 7,531,066 B2IsraelPala-RosasNo ratings yet

- Tepzz 6Zz67B - T: European Patent SpecificationDocument10 pagesTepzz 6Zz67B - T: European Patent SpecificationChetan PawadeNo ratings yet

- Lambda + Chlorantraniliprole - Cómo Estabilizar La SuspensiónDocument8 pagesLambda + Chlorantraniliprole - Cómo Estabilizar La SuspensiónAlfredo MéndezNo ratings yet

- (2014) US8841445 Process For Preparing Purified Caprolactam From The Beckmann RearrangementDocument6 pages(2014) US8841445 Process For Preparing Purified Caprolactam From The Beckmann RearrangementThitikorn WassanarpheernphongNo ratings yet

- Us 7402709Document5 pagesUs 7402709asim shahzadNo ratings yet

- US8663343 - Method For Manufacturing An Emulsified FuelDocument9 pagesUS8663343 - Method For Manufacturing An Emulsified FuelMichael MedinaNo ratings yet

- Biodiesel 3Document12 pagesBiodiesel 3Uswatun AnnaNo ratings yet

- United States Patent: Masson (10) Patent N0.: (45) Date of PatentDocument26 pagesUnited States Patent: Masson (10) Patent N0.: (45) Date of PatentaNo ratings yet

- Patent 1Document45 pagesPatent 1Maheesha GunathungaNo ratings yet

- US7985725Document9 pagesUS7985725Sharda RamberanNo ratings yet

- US7385092 Alkenediol Octene To Octene DiolDocument8 pagesUS7385092 Alkenediol Octene To Octene DiolArya KurniawanNo ratings yet

- United States Patent (10) Patent No.: US 8,791,302 B2Document5 pagesUnited States Patent (10) Patent No.: US 8,791,302 B2Sundari RaviNo ratings yet

- US8710171High-purity Diphenyl Sulphone (DPS), Its Preparation and The Purposes For Being Used To Prepare Poly - (Aryl Ether Ketones)Document21 pagesUS8710171High-purity Diphenyl Sulphone (DPS), Its Preparation and The Purposes For Being Used To Prepare Poly - (Aryl Ether Ketones)MorkizgaNo ratings yet

- US7390358Document8 pagesUS7390358lic.escobar2018No ratings yet

- Us 7172742Document5 pagesUs 7172742Nguyen Khanh DuyNo ratings yet

- Acido PropionicoDocument6 pagesAcido Propionicoromina orellanaNo ratings yet

- (2012) US8231765 Process For The Purification of LactamsDocument9 pages(2012) US8231765 Process For The Purification of LactamsThitikorn WassanarpheernphongNo ratings yet

- United States Patent (10) Patent No.: US 8,158,822 B2Document4 pagesUnited States Patent (10) Patent No.: US 8,158,822 B2JFPacNo ratings yet

- Proceso de HidrocarburosDocument14 pagesProceso de Hidrocarburosingeniomeca8800No ratings yet

- United States Patent (10) Patent No.: US 8,372,274 B2Document28 pagesUnited States Patent (10) Patent No.: US 8,372,274 B2Alexander Franco CastrillonNo ratings yet

- United States Patent (10) Patent No.: US 9,096,564 B2Document6 pagesUnited States Patent (10) Patent No.: US 9,096,564 B2Ahmad InterestaNo ratings yet

- United States Patent (10) Patent No.: US 8,283,504 B2Document8 pagesUnited States Patent (10) Patent No.: US 8,283,504 B2Arka Krisna PratamaNo ratings yet

- BusaDocument10 pagesBusadewiNo ratings yet

- US Patent US6657057Document6 pagesUS Patent US6657057Vandit KhareNo ratings yet

- US7186345Document16 pagesUS7186345Baba DookNo ratings yet

- US6767528Document6 pagesUS6767528Helwinda ApriliaNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7482.410 B2Document15 pagesUnited States Patent: (12) (10) Patent No.: US 7482.410 B2ariefNo ratings yet

- US8475539Document8 pagesUS8475539Nasir UddinNo ratings yet

- United States Patent (10) Patent No.: US 7,550,278 B2: Du Et Al. (45) Date of Patent: Jun. 23, 2009Document5 pagesUnited States Patent (10) Patent No.: US 7,550,278 B2: Du Et Al. (45) Date of Patent: Jun. 23, 2009marie mahmudiNo ratings yet

- United States Patent: MG, Christopher Lbecke, (58) Field of Classification SearchDocument11 pagesUnited States Patent: MG, Christopher Lbecke, (58) Field of Classification SearchAkbarNo ratings yet

- Tereftalic Acid 2002Document14 pagesTereftalic Acid 2002Anonymous EIUhdCNo ratings yet

- United States Patent (10) Patent No.: US 9,017,983 B2Document90 pagesUnited States Patent (10) Patent No.: US 9,017,983 B2Дмитрий КоваленкоNo ratings yet

- US8318990Document9 pagesUS8318990Khuram MaqsoodNo ratings yet

- US7525004 New EditedDocument11 pagesUS7525004 New EditedFahreza HidayatullahNo ratings yet

- Patent Pabrik Ethyl Tert Butyl Ether (ETBE) Proses PhillipsDocument16 pagesPatent Pabrik Ethyl Tert Butyl Ether (ETBE) Proses PhillipsFaizhal DimazNo ratings yet

- US8722593 Break FluidDocument5 pagesUS8722593 Break FluidMorkizgaNo ratings yet

- Us7084310 PG PDFDocument9 pagesUs7084310 PG PDFmeimeiNo ratings yet

- Sintesis de TopotecanDocument5 pagesSintesis de TopotecanSantiago AguirreNo ratings yet

- Us8048971 PDFDocument8 pagesUs8048971 PDFSyahdillaNo ratings yet

- US8183190B2Document3 pagesUS8183190B2Risma Dewi SNo ratings yet

- US8322575Document7 pagesUS8322575r3marcosNo ratings yet

- Wetting Agent 2Document5 pagesWetting Agent 2Sarah HawaisayahyaNo ratings yet

- United States Patent (10) Patent No.: US 8,147,768 B2Document12 pagesUnited States Patent (10) Patent No.: US 8,147,768 B2habbibrachmanNo ratings yet

- Perpindahan PanasDocument9 pagesPerpindahan Panasadit dwipawarmanNo ratings yet

- Paten Produksi Syn Gas BaruDocument6 pagesPaten Produksi Syn Gas BaruFarras HaidaryNo ratings yet

- 2008 March 4 Acetaldehyde From Ethylene OxidationDocument4 pages2008 March 4 Acetaldehyde From Ethylene OxidationameymurudkarNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument7 pagesUnited States Patent: (10) Patent No.: (45) Date of Patentnur mxNo ratings yet

- Us 8334035Document7 pagesUs 8334035vzimak2355No ratings yet

- US Patent Manufacturing of Propylene GlycolDocument5 pagesUS Patent Manufacturing of Propylene GlycolRegiyanti RNo ratings yet

- US8658823Document16 pagesUS8658823Santiago BorgesNo ratings yet

- Pva Emulsion PolymerisationDocument15 pagesPva Emulsion Polymerisationrajesh kothariNo ratings yet

- FRP Tank 10 KLDocument1 pageFRP Tank 10 KLrajesh kothariNo ratings yet

- Mixing TankDocument2 pagesMixing Tankrajesh kothariNo ratings yet

- Plant3000 Vikram MehataDocument24 pagesPlant3000 Vikram Mehatarajesh kothariNo ratings yet

- Acrylic Acid Maleic Anhydride CopolymerDocument29 pagesAcrylic Acid Maleic Anhydride CopolymerAndreia FrassiniNo ratings yet

- 2,2,4-Trimethyl-1,3-pentanediol DiisobutyrateDocument3 pages2,2,4-Trimethyl-1,3-pentanediol Diisobutyraterajesh kothariNo ratings yet

- 2,2,4-Trimethyl-1,3-pentanediol DiisobutyrateDocument3 pages2,2,4-Trimethyl-1,3-pentanediol Diisobutyraterajesh kothariNo ratings yet

- Etp ZLD 75 KLD 1Document25 pagesEtp ZLD 75 KLD 1rajesh kothariNo ratings yet

- Msum AerationDocument2 pagesMsum Aerationrajesh kothariNo ratings yet

- Atpd OperationDocument1 pageAtpd Operationrajesh kothariNo ratings yet

- ATFD Offer KBDocument10 pagesATFD Offer KBrajesh kothariNo ratings yet

- Pva Emulsion PolymerisationDocument15 pagesPva Emulsion Polymerisationrajesh kothariNo ratings yet

- Plant3000 Vikram MehataDocument24 pagesPlant3000 Vikram Mehatarajesh kothariNo ratings yet

- 200KLD ETP Abhisekh BalarDocument28 pages200KLD ETP Abhisekh Balarrajesh kothariNo ratings yet

- Drum Dryer ConfirmationDocument1 pageDrum Dryer Confirmationrajesh kothariNo ratings yet

- EvaporationDocument8 pagesEvaporationrajesh kothariNo ratings yet

- Aro Aodd PumpDocument1 pageAro Aodd Pumprajesh kothariNo ratings yet

- Tulsi 500KLDDocument18 pagesTulsi 500KLDrajesh kothariNo ratings yet

- ATFD PiparDocument10 pagesATFD Piparrajesh kothariNo ratings yet

- FRP Coating Cept 6Document1 pageFRP Coating Cept 6rajesh kothariNo ratings yet

- Bangur Hospital2Document2 pagesBangur Hospital2rajesh kothariNo ratings yet

- FRP Tank 10 KLDocument1 pageFRP Tank 10 KLrajesh kothariNo ratings yet

- Business ProfileDocument6 pagesBusiness Profilerajesh kothariNo ratings yet

- Plant5000lph2Document23 pagesPlant5000lph2rajesh kothariNo ratings yet

- FRP Junction BoxDocument1 pageFRP Junction Boxrajesh kothariNo ratings yet

- Litz Wire DatasheetDocument1 pageLitz Wire Datasheetrajesh kothariNo ratings yet

- AntiscalantDocument1 pageAntiscalantrajesh kothariNo ratings yet

- Plant5001Document23 pagesPlant5001rajesh kothariNo ratings yet

- ATFD Operation Data1Document2 pagesATFD Operation Data1rajesh kothariNo ratings yet

- Litz Wire Practical Design Considerations For Todays HF Applications Jensen, RubadueDocument30 pagesLitz Wire Practical Design Considerations For Todays HF Applications Jensen, Rubaduerajesh kothariNo ratings yet

- Decision Making Assignment..!!!Document18 pagesDecision Making Assignment..!!!Laji Abraham50% (2)

- Dangers in Reusing Water BottlesDocument10 pagesDangers in Reusing Water BottlesVicyn TNo ratings yet

- Keto Meal Prep Lose Weight, Save Time, and Feel Your Best On The Ketogenic Diet by Liz WilliamsDocument227 pagesKeto Meal Prep Lose Weight, Save Time, and Feel Your Best On The Ketogenic Diet by Liz WilliamsKim Possible100% (2)

- Body Care Ingredients To AvoidDocument4 pagesBody Care Ingredients To AvoidadriagNo ratings yet

- Phenols - Sources andDocument16 pagesPhenols - Sources andRamadan AhmedNo ratings yet

- 061813Document104 pages061813Norman IskandarNo ratings yet

- Polymer Degradation and StabilityDocument10 pagesPolymer Degradation and StabilityAlly HerreraNo ratings yet

- Bisphenol A (BPA) and Pall F&B Filter Cartridge ProductsDocument4 pagesBisphenol A (BPA) and Pall F&B Filter Cartridge ProductsTriều VõNo ratings yet

- Physical Education (Buhawi)Document5 pagesPhysical Education (Buhawi)JustineMalingNo ratings yet

- XSDB Kem 90 Harz en 2484Document8 pagesXSDB Kem 90 Harz en 2484Marius IanaNo ratings yet

- Class Action Lawsuit - Gaiam Aluminum Water BottleDocument12 pagesClass Action Lawsuit - Gaiam Aluminum Water BottleJeff OrensteinNo ratings yet

- PlasticDocument55 pagesPlasticdtaneja11100% (1)

- Buesing&Fasch Gel&TopDocument6 pagesBuesing&Fasch Gel&TopBen Abdallah BecemNo ratings yet

- 5250-4rtm Structural Prepreg English SdsDocument11 pages5250-4rtm Structural Prepreg English Sdsanacarol09No ratings yet

- PT 2 Annotated Bib Part 1Document4 pagesPT 2 Annotated Bib Part 1Krish PokhrelNo ratings yet

- Project On Environmental Toxicants in FoodDocument29 pagesProject On Environmental Toxicants in FoodNouf BabuNo ratings yet

- Study of The Occurrence and Ecosystem Danger of Selected Endocrine Disruptors in The Urban Water Cycle of The City of Bogotá, ColombiaDocument10 pagesStudy of The Occurrence and Ecosystem Danger of Selected Endocrine Disruptors in The Urban Water Cycle of The City of Bogotá, ColombiaSHIRLEY PAOLA BARRERA BARRIOSNo ratings yet

- Mark Richardson PHD Risk Assessment of Two Dental MaterialsDocument32 pagesMark Richardson PHD Risk Assessment of Two Dental MaterialsMercury ExposureNo ratings yet

- Nestle Product Differentiation - Assign 2Document2 pagesNestle Product Differentiation - Assign 2zakavisionNo ratings yet

- HCD2Document2 pagesHCD2fwijaya888No ratings yet

- BPA Toxicity During Development of Zebrafish EmbryoDocument11 pagesBPA Toxicity During Development of Zebrafish EmbryojavelezhNo ratings yet

- Thermal Properties of PolycarbonatesDocument20 pagesThermal Properties of PolycarbonatesThụy Thảo LinhNo ratings yet

- Plastics Are A Wide Range of Synthetic or SemiDocument18 pagesPlastics Are A Wide Range of Synthetic or SemiJuan CorvalánNo ratings yet

- PlasticbagbannedDocument80 pagesPlasticbagbannedSunita ChayalNo ratings yet

- MarkDocument24 pagesMarkJay Mark FontanillaNo ratings yet

- BPA Molecular SizeDocument12 pagesBPA Molecular Sizesilambarasan kNo ratings yet

- Chemistry of MoneyDocument7 pagesChemistry of MoneymaieruchanNo ratings yet

- Safety Data Sheet: Epcon C8 ResinDocument3 pagesSafety Data Sheet: Epcon C8 ResinAhmed Samir SalimNo ratings yet

- Asahi KaseiDocument24 pagesAsahi KaseiRitam GhoshNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Phase Equilibria in Chemical EngineeringFrom EverandPhase Equilibria in Chemical EngineeringRating: 4 out of 5 stars4/5 (11)

- Pharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryFrom EverandPharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryOtilia M. Y. KooNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksFrom EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNo ratings yet

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86From EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86No ratings yet