Professional Documents

Culture Documents

Low Level Oxygenates Analyser: Astm D7423, Astm D7754, Uop 960 Robust Highest Uptime 99% Optional Ms Detection

Low Level Oxygenates Analyser: Astm D7423, Astm D7754, Uop 960 Robust Highest Uptime 99% Optional Ms Detection

Uploaded by

Iman MoghadamCopyright:

Available Formats

You might also like

- Aldehyde, Ketones and Carboxylic AcidDocument18 pagesAldehyde, Ketones and Carboxylic AcidPRADEEP CNo ratings yet

- Astm - D6277Document10 pagesAstm - D6277Sofia Fasolo CunhaNo ratings yet

- Measuring Hydrocarbon Oil Index PDFDocument4 pagesMeasuring Hydrocarbon Oil Index PDFMukhtiar Ahmed LakhanNo ratings yet

- 9 Dna Replication Scramble KeyDocument2 pages9 Dna Replication Scramble KeyTy Neal25% (4)

- An Sulfur Compounds in Hydrogen GC SCD 5994 5864en AgilentDocument6 pagesAn Sulfur Compounds in Hydrogen GC SCD 5994 5864en Agilentnguyenthithanhthuy16061994No ratings yet

- AN212WA0420G Low S A4Document4 pagesAN212WA0420G Low S A4zanazeNo ratings yet

- An 42222 EA Oxygen Gasoline AN42222 enDocument3 pagesAn 42222 EA Oxygen Gasoline AN42222 enHUYQUYENNo ratings yet

- NDX - Ferroni at TOTALL GAS DETECTORDocument23 pagesNDX - Ferroni at TOTALL GAS DETECTORRoxxana Roxxana1990No ratings yet

- Method 10B - Determination of Carbon Monoxide Emissions From Stationary SourcesDocument8 pagesMethod 10B - Determination of Carbon Monoxide Emissions From Stationary SourcessimonclaudioNo ratings yet

- PKI - AN - 2016 - Analysis of Oil Additives Following ASTM D4951 With The Avio 200 ICPOESDocument3 pagesPKI - AN - 2016 - Analysis of Oil Additives Following ASTM D4951 With The Avio 200 ICPOESstrubingeraNo ratings yet

- Fundamentos Cromatografia de GasDocument4 pagesFundamentos Cromatografia de GasNicolassalgueroNo ratings yet

- AN44426 Lubricating Oil Analysis ASTM D5185 iCAP PRO XP ICP OES ST3Document4 pagesAN44426 Lubricating Oil Analysis ASTM D5185 iCAP PRO XP ICP OES ST3raimundo.gamelaNo ratings yet

- XRF5035-S in Oil LowS-Mini-Z SDocument4 pagesXRF5035-S in Oil LowS-Mini-Z SKu BonNo ratings yet

- Aromatic Content in Diesel Using 2D LCDocument8 pagesAromatic Content in Diesel Using 2D LCVaibhav AhujaNo ratings yet

- Avio 220 Max ICP-OES ASTM D4951 Oil Additives Application NoteDocument3 pagesAvio 220 Max ICP-OES ASTM D4951 Oil Additives Application NoteJuanjoNo ratings yet

- ASTM D5186 App Note AromaticsDocument8 pagesASTM D5186 App Note Aromaticsmustak kadivarNo ratings yet

- Real-Time Ppt-Level Analysis of CO, CO and CH in Semiconductor UHP GasDocument4 pagesReal-Time Ppt-Level Analysis of CO, CO and CH in Semiconductor UHP GasTanNo ratings yet

- 5991-4372ene Analysis of Oil in WaterDocument4 pages5991-4372ene Analysis of Oil in WaterAri CleciusNo ratings yet

- Oxygen, Nitrogen and Hydrogen Analyzer EMGA-930/EMGA-830: in Pursuit of High Performance, Speed and OperabilityDocument5 pagesOxygen, Nitrogen and Hydrogen Analyzer EMGA-930/EMGA-830: in Pursuit of High Performance, Speed and OperabilityDidit AndiatmokoNo ratings yet

- Omkar Catalog-1Document4 pagesOmkar Catalog-1manoj khaldeNo ratings yet

- ShimadzuDocument28 pagesShimadzupojiered100% (1)

- An1804 Crude Oil Astm d5708-d1548 Prodigyplus Icp OesDocument4 pagesAn1804 Crude Oil Astm d5708-d1548 Prodigyplus Icp OesyuliaNo ratings yet

- Ags 200Document2 pagesAgs 200dsimovicNo ratings yet

- Uop 987Document11 pagesUop 987pramod23septNo ratings yet

- D5599 617621-1Document8 pagesD5599 617621-1Fernando Cardeño LopezNo ratings yet

- Sulfur in Oil AnalyzerDocument2 pagesSulfur in Oil AnalyzerDan MatNo ratings yet

- The Analysis of CarbonDioxide in Natural GasDocument4 pagesThe Analysis of CarbonDioxide in Natural GasBimo Gunners RespatiNo ratings yet

- Total Nitrogen in Petroleum Products and Inorganic Materials by An Automated Micro-Dumas Nitrogen AnalyzerDocument10 pagesTotal Nitrogen in Petroleum Products and Inorganic Materials by An Automated Micro-Dumas Nitrogen AnalyzerGuisela Carbajal RomeroNo ratings yet

- Gas ChromatographyDocument24 pagesGas Chromatographysujiv_sujiv1278No ratings yet

- A System Simulation Study of The EnhanceDocument6 pagesA System Simulation Study of The Enhancekeltoma.boutaNo ratings yet

- Simple and Reliable Soil Analysis Using The Agilent 7800 ICP-MS With ISIS 3Document10 pagesSimple and Reliable Soil Analysis Using The Agilent 7800 ICP-MS With ISIS 3Nitesh SaxenaNo ratings yet

- J114ADocument2 pagesJ114AIrelena RomeroNo ratings yet

- AppNote ICPOES en Sewage SludgeDocument10 pagesAppNote ICPOES en Sewage Sludgeserena morenaNo ratings yet

- Refinerygasanalyzer - Brochure - Rev1-1115 - A4 PACDocument4 pagesRefinerygasanalyzer - Brochure - Rev1-1115 - A4 PACMiguelNo ratings yet

- Brochure ACCURA Design 2017.1 A4 HiRes PrintfileDocument4 pagesBrochure ACCURA Design 2017.1 A4 HiRes PrintfileAHMEDNo ratings yet

- Analysis of Biodiesel Oil (As Per ASTM D6751 & EN 14214) Using The Agilent 5100 SVDV Icp-OesDocument6 pagesAnalysis of Biodiesel Oil (As Per ASTM D6751 & EN 14214) Using The Agilent 5100 SVDV Icp-OesjulhamNo ratings yet

- Total Sulfur Analyzer CG ConditionsDocument8 pagesTotal Sulfur Analyzer CG ConditionsCristian ValenzuelaNo ratings yet

- Appnote Icpoes 0013 enDocument8 pagesAppnote Icpoes 0013 enejvelazcorNo ratings yet

- Halogenated Hydrocarbons C6H6 in Drinking WaterDocument9 pagesHalogenated Hydrocarbons C6H6 in Drinking WaterCristian CarrascoNo ratings yet

- Vapour Pressure TestingDocument2 pagesVapour Pressure TestinglbNo ratings yet

- Analytical Products: Sales Engineering Supercritical Fluid Chromatography For Process ControlDocument11 pagesAnalytical Products: Sales Engineering Supercritical Fluid Chromatography For Process Controltejasmodi21No ratings yet

- Application Report DMA 80 Evo Coal USREV061019Document4 pagesApplication Report DMA 80 Evo Coal USREV061019Roni GustiwaNo ratings yet

- Elizalde Solis2011Document6 pagesElizalde Solis2011jasontodd22031995No ratings yet

- AN 43158 ICP OES Lubricating Oil ASTM D5185 AN43158 EN PDFDocument4 pagesAN 43158 ICP OES Lubricating Oil ASTM D5185 AN43158 EN PDFwahyubudiutamaNo ratings yet

- Icap 4200 Icp OesDocument4 pagesIcap 4200 Icp Oeslahiru1983No ratings yet

- Procal 2000 IR Emissions AnalyserDocument4 pagesProcal 2000 IR Emissions AnalyserMeindert gerssenNo ratings yet

- DatasheetDocument16 pagesDatasheetmarcosNo ratings yet

- ChemiluminescenceDocument9 pagesChemiluminescencekir223No ratings yet

- AN40986 Trace Contaminant Analysis in Brine Using An Icap 6000 Series Duo IcpDocument6 pagesAN40986 Trace Contaminant Analysis in Brine Using An Icap 6000 Series Duo IcpNitisha RathoreNo ratings yet

- TS 61Document2 pagesTS 61mohamed aliNo ratings yet

- AA 7000 CatalogDocument28 pagesAA 7000 CatalogLuis Fernando Cáceres ChoqueNo ratings yet

- AdblueDocument6 pagesAdblueابراهيم السعيديNo ratings yet

- Varian TOGADocument3 pagesVarian TOGAKiran ChokshiNo ratings yet

- Metodo GCDocument6 pagesMetodo GCMatteo DMNo ratings yet

- 5991-hplc 1260 Mid DistDocument6 pages5991-hplc 1260 Mid Distمحمد محمودNo ratings yet

- DGA Whitepaper2Document6 pagesDGA Whitepaper2nooralhudNo ratings yet

- Avio 550 Max ICP-OES ASTM D5185 In-Service Oils Application NoteDocument4 pagesAvio 550 Max ICP-OES ASTM D5185 In-Service Oils Application Notec1nthiacruzNo ratings yet

- TransportX SPDocument2 pagesTransportX SPtalaporriNo ratings yet

- Charged Aerosol Detection for Liquid Chromatography and Related Separation TechniquesFrom EverandCharged Aerosol Detection for Liquid Chromatography and Related Separation TechniquesPaul H. GamacheNo ratings yet

- Application of IC-MS and IC-ICP-MS in Environmental ResearchFrom EverandApplication of IC-MS and IC-ICP-MS in Environmental ResearchRajmund MichalskiNo ratings yet

- GC/LC, Instruments, Derivatives in Identifying Pollutants and UnknownsFrom EverandGC/LC, Instruments, Derivatives in Identifying Pollutants and UnknownsNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo ratings yet

- Standard Specifications of Light Naphtha: Analysis Unit Limit Test MethodDocument1 pageStandard Specifications of Light Naphtha: Analysis Unit Limit Test MethodIman Moghadam100% (1)

- 0009b An Lowox in Lpg.1Document3 pages0009b An Lowox in Lpg.1Iman MoghadamNo ratings yet

- 0009b An Lowox in Lpg.1Document3 pages0009b An Lowox in Lpg.1Iman MoghadamNo ratings yet

- 0009b An Lowox in Lpg.1Document3 pages0009b An Lowox in Lpg.1Iman MoghadamNo ratings yet

- CLASS - 12th CAMPION SCHOOL, BHOURI, BHOPAL PT-2 EXAMINATION SUBJECT - CHEMISTRY MM - 50Document22 pagesCLASS - 12th CAMPION SCHOOL, BHOURI, BHOPAL PT-2 EXAMINATION SUBJECT - CHEMISTRY MM - 50Harshil NagwaniNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument12 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingalexNo ratings yet

- Brochure - Unitox PlusDocument4 pagesBrochure - Unitox PlusjayashreeNo ratings yet

- TDS of SP7154 0002Document2 pagesTDS of SP7154 0002kashyappathak01No ratings yet

- Alkene Preparation and ReactionsDocument46 pagesAlkene Preparation and Reactionsnlprofessional07No ratings yet

- The Chemical Elements and Their Compounds v2Document853 pagesThe Chemical Elements and Their Compounds v2techkasambaNo ratings yet

- Lab Report Experiment 2 - Sodium Borohydride Reduction of CyclohexanoneDocument11 pagesLab Report Experiment 2 - Sodium Borohydride Reduction of CyclohexanoneSITI NUR AFIQAH MAHAZANNo ratings yet

- 3 Carbamates InsecticidesDocument13 pages3 Carbamates InsecticidesAmit SharmaNo ratings yet

- Fabric Conveyor Belts Installation and Maintenance Guide: Habasit - Solutions in MotionDocument16 pagesFabric Conveyor Belts Installation and Maintenance Guide: Habasit - Solutions in MotionAbdul Kani Ahamed MNo ratings yet

- Electrocyclic ReactionDocument5 pagesElectrocyclic ReactionfareehaNo ratings yet

- Biofuel: Name-Swati Subhada Mohapatra Sec-A Roll No - 63 BSC Biotech 3 YearDocument19 pagesBiofuel: Name-Swati Subhada Mohapatra Sec-A Roll No - 63 BSC Biotech 3 YearNayak Alok RanjanNo ratings yet

- Alternate Fules Report-HariDocument20 pagesAlternate Fules Report-Hari18-331 YUGANDHARNo ratings yet

- FRP Catalogue 04.2021Document84 pagesFRP Catalogue 04.2021Bilel MahjoubNo ratings yet

- Cosmetics Microbiology: GlossaryDocument11 pagesCosmetics Microbiology: GlossaryAngelica Alejandra De La Torre AnayaNo ratings yet

- Vitamins, Minerals Plus Iron, Iodine, Taurine, and Zinc: Nutrition InformationDocument1 pageVitamins, Minerals Plus Iron, Iodine, Taurine, and Zinc: Nutrition InformationWonder PsychNo ratings yet

- Proposal Final Year ProjectDocument13 pagesProposal Final Year Projectnora azizNo ratings yet

- Solid Phase Extraction Technique - Trends, Opportunities and ApplicationsDocument15 pagesSolid Phase Extraction Technique - Trends, Opportunities and ApplicationsRohimah NHNo ratings yet

- FEVE Fluoropolymer Emulsions For Performance Improvement in Architectural CoatingsDocument32 pagesFEVE Fluoropolymer Emulsions For Performance Improvement in Architectural CoatingsThanh VuNo ratings yet

- Eco. Exp. 1 Determination of Free CO2Document3 pagesEco. Exp. 1 Determination of Free CO2Faneeshwar PatelNo ratings yet

- MSDS NaOCH3-Sodium MethylateDocument15 pagesMSDS NaOCH3-Sodium MethylateNasrulNo ratings yet

- TSR 131Document14 pagesTSR 131Prad1979No ratings yet

- Candlenut Oil: Review On Oil Properties and Future Liquid Biofuel ProspectsDocument24 pagesCandlenut Oil: Review On Oil Properties and Future Liquid Biofuel ProspectsdesniaNo ratings yet

- Safer Modified Hummers' Method For The Synthesis of Graphene Oxide With High Quality and High YieldDocument11 pagesSafer Modified Hummers' Method For The Synthesis of Graphene Oxide With High Quality and High YieldManu PriyaNo ratings yet

- LECTURE 2: Continuation Magnification vs. Resolution: Microbio (Midterms Reviewer)Document13 pagesLECTURE 2: Continuation Magnification vs. Resolution: Microbio (Midterms Reviewer)Entris AlcNo ratings yet

- Free Download Controlled Release Fertilizers For Sustainable Agriculture F B Lewu Full Chapter PDFDocument45 pagesFree Download Controlled Release Fertilizers For Sustainable Agriculture F B Lewu Full Chapter PDFellen.clark485100% (12)

- QueryDocument8 pagesQuerysubhash221103No ratings yet

- 1 s2.0 S2405844019363923 MainDocument10 pages1 s2.0 S2405844019363923 MainHagere EthiopiaNo ratings yet

- Hardin S.Si, S.PD, M.PDDocument26 pagesHardin S.Si, S.PD, M.PDRadiatul Awalia AmirNo ratings yet

Low Level Oxygenates Analyser: Astm D7423, Astm D7754, Uop 960 Robust Highest Uptime 99% Optional Ms Detection

Low Level Oxygenates Analyser: Astm D7423, Astm D7754, Uop 960 Robust Highest Uptime 99% Optional Ms Detection

Uploaded by

Iman MoghadamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Low Level Oxygenates Analyser: Astm D7423, Astm D7754, Uop 960 Robust Highest Uptime 99% Optional Ms Detection

Low Level Oxygenates Analyser: Astm D7423, Astm D7754, Uop 960 Robust Highest Uptime 99% Optional Ms Detection

Uploaded by

Iman MoghadamCopyright:

Available Formats

Low level oxygenates analyser

• astM D7423, astM D7754, uoP 960

• robust

• Highest uptime > 99%

• optional Ms detection

an 218Wa0420e

Global analyser solutions

GAS offers custom configured GC The low level oxygenates analyser from GAS

analysers for many application fields for analyses oxygen containing components like

over 40 years. GAS analysers are designed alcohols and ethers at (sub) ppm level. The

to meet many standardised methods from presence of these components in

GPA, ASTM, UOP, ISO, EN and others. The hydrocarbon feedstock reduces catalyst

efficient configurations are based on lifetime, even at low ppm level. Analysis at

proven GC technology, resulting in low levels is also demanded by

robust instruments with an optimal environmental requirements.

return on investment.

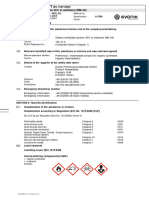

ASTM D7423, UOP 960 Figure 1. Diagram ASTM

Methods ASTM D4815 and EN 13132 (see application notes) cover the D7423 analyser with SSL

analysis of oxygenated components in finished products at % level, injection.

while below described methods ASTM D7423 and UOP 960 cover 0.1-

1000 ppm range. Oxygen containing compounds with boiling points up

to 100 oC are analysed in hydrocarbon streams with final boiling point

below 250 oC.

The instrument diagram is shown in figure 1. A highly selective

capillary column (Lowox) separates the components of interest from

the hydrocarbon matrix. Heavier components are backflushed using a

Deans column switch configuration. The diagram shows injection using

SSL (liquid sample injector). GSV (Gas Sampling Valve) and LSV

(Liquid Sampling Valve) with Pressure Facility for analysing LPG

samples are available as well (figure 9). Figure 2 and 3 show

chromatograms of 100 ppm calibration standard and real sample.

Figure 8 demonstrates good repeatability.

LOWOX CALIBRATION STANDARD

(100 ppm for each component)

Dimethylether

Acetaldehyde

Methanol

Ethanol

Propylether

Propionaldehyde

iso-propanol

T-Butanol

Propanol

Methyl Ethyl Ketone

Diethylether

Iso-Butanol

N-Butanol

Iso-Butanal

Buteraldehyde

Ethyl Tert Butyl Ether

Di-Isopropylether

Methyl Tert Butyl Ether

Tert Amyl Methyl Ether TAME

Acetone

Valeraldehyde

Allyl Alcohol

Figure 2. Lowox calibration standard 100 ppm

Global analyser solutions

Figure 3. Chromatogram: Pygas sample

Figure 5. Trace 1310 GC with InstantConnect

injector and detector technology

ASTM D7754

The GAS low level oxygenates analyser covers ASTM D7754 as well, for samples

containing 1-15% Ethanol.

Trace GC 1300

The low level oxygenates analyser is based on Thermo Trace GC 1300 with modular

injector and detector technology, providing low maintenance costs and high uptime

(figure 5, 6).

Lowox analysis using GC-MS

High yield catalyst are extremely prone to poisoning by feedstock impurities like Figure 6. Swift exchange of injector and detector

oxygenated components. Therefore a solution based on GC-MS was developed for

substantial increase in identification and sensitivity compared to GC-FID analyses.

Figure 4 demonstrates sensitivity gain factors of individual oxygenated components in

naphta. The gain is particularly significant when SIM mode is used. The ISQ mass

spectrometer (figure 7) conveniently combines full scan and SIM in a single run for both

increased sensitivity and reliable identification.

Figure 4. Average sensitivity gain factors in different MS detection modes. FS=full scan; Figure 7. Trace 1310 GC with ISQ Mass

EIC=extracted ion chromatogram; SIM= selected ion monitoring. %RSD at 10 ppm level (n=6). Spectrometer and RSH autosampler

Global analyser solutions

Specifications

standardised method: astM D7423, uoP 960

astM D7754 (for samples containing 1-15% v/v ethanol)

application: Analysis of oxygenated components (alcohols, ethers, ketones) in liquids, liquefied gases and gases

Configuration: single channel instrument based on thermo trace 1300 GC series using FiD detection.

Injection: SSL (Liquid Injection), GSV (Gas Sampling Valve) or LSV (Liquid Sampling Valve);

all three injection techniques can be combined

optional: Automated liquid sample injector

Pressure Facility for highly quantitative injection of liquefied gas samples using LSV

Mass Spectrometer for enhanced identification and sensitivity gain factor up to 177 (see page 3)

tubing: Sulfinert ® tubing for inert sample path

analytes: see table (page 2).

Calibration standards: 1, 10, and 100 ppm per individual component in n-Hexane

Dynamic range: 0.1-1000ppm (FiD)

sample requirements: Liquid, liquefied gas or gas sample

analysis time: 25 minutes

Minimum Detectability: 0.1 ppm for all individual components.

repeatability: 2% RSD (n=10)

Data systems Chromeleon, openlab

Figure 8. repeatability lowox

analysis (GC-FiD, 100pmm

calibration standard)

Figure 9. low level oxygenates analyser with optional

Pressure Facility for injection of Liquefied Gas

(using Liquid Sampling Valve)

M a De

in

Ho ll a nD

G. a .s is an

Gas is an

interscience company

Global analyser solutions WWW.Gassite.CoM

You might also like

- Aldehyde, Ketones and Carboxylic AcidDocument18 pagesAldehyde, Ketones and Carboxylic AcidPRADEEP CNo ratings yet

- Astm - D6277Document10 pagesAstm - D6277Sofia Fasolo CunhaNo ratings yet

- Measuring Hydrocarbon Oil Index PDFDocument4 pagesMeasuring Hydrocarbon Oil Index PDFMukhtiar Ahmed LakhanNo ratings yet

- 9 Dna Replication Scramble KeyDocument2 pages9 Dna Replication Scramble KeyTy Neal25% (4)

- An Sulfur Compounds in Hydrogen GC SCD 5994 5864en AgilentDocument6 pagesAn Sulfur Compounds in Hydrogen GC SCD 5994 5864en Agilentnguyenthithanhthuy16061994No ratings yet

- AN212WA0420G Low S A4Document4 pagesAN212WA0420G Low S A4zanazeNo ratings yet

- An 42222 EA Oxygen Gasoline AN42222 enDocument3 pagesAn 42222 EA Oxygen Gasoline AN42222 enHUYQUYENNo ratings yet

- NDX - Ferroni at TOTALL GAS DETECTORDocument23 pagesNDX - Ferroni at TOTALL GAS DETECTORRoxxana Roxxana1990No ratings yet

- Method 10B - Determination of Carbon Monoxide Emissions From Stationary SourcesDocument8 pagesMethod 10B - Determination of Carbon Monoxide Emissions From Stationary SourcessimonclaudioNo ratings yet

- PKI - AN - 2016 - Analysis of Oil Additives Following ASTM D4951 With The Avio 200 ICPOESDocument3 pagesPKI - AN - 2016 - Analysis of Oil Additives Following ASTM D4951 With The Avio 200 ICPOESstrubingeraNo ratings yet

- Fundamentos Cromatografia de GasDocument4 pagesFundamentos Cromatografia de GasNicolassalgueroNo ratings yet

- AN44426 Lubricating Oil Analysis ASTM D5185 iCAP PRO XP ICP OES ST3Document4 pagesAN44426 Lubricating Oil Analysis ASTM D5185 iCAP PRO XP ICP OES ST3raimundo.gamelaNo ratings yet

- XRF5035-S in Oil LowS-Mini-Z SDocument4 pagesXRF5035-S in Oil LowS-Mini-Z SKu BonNo ratings yet

- Aromatic Content in Diesel Using 2D LCDocument8 pagesAromatic Content in Diesel Using 2D LCVaibhav AhujaNo ratings yet

- Avio 220 Max ICP-OES ASTM D4951 Oil Additives Application NoteDocument3 pagesAvio 220 Max ICP-OES ASTM D4951 Oil Additives Application NoteJuanjoNo ratings yet

- ASTM D5186 App Note AromaticsDocument8 pagesASTM D5186 App Note Aromaticsmustak kadivarNo ratings yet

- Real-Time Ppt-Level Analysis of CO, CO and CH in Semiconductor UHP GasDocument4 pagesReal-Time Ppt-Level Analysis of CO, CO and CH in Semiconductor UHP GasTanNo ratings yet

- 5991-4372ene Analysis of Oil in WaterDocument4 pages5991-4372ene Analysis of Oil in WaterAri CleciusNo ratings yet

- Oxygen, Nitrogen and Hydrogen Analyzer EMGA-930/EMGA-830: in Pursuit of High Performance, Speed and OperabilityDocument5 pagesOxygen, Nitrogen and Hydrogen Analyzer EMGA-930/EMGA-830: in Pursuit of High Performance, Speed and OperabilityDidit AndiatmokoNo ratings yet

- Omkar Catalog-1Document4 pagesOmkar Catalog-1manoj khaldeNo ratings yet

- ShimadzuDocument28 pagesShimadzupojiered100% (1)

- An1804 Crude Oil Astm d5708-d1548 Prodigyplus Icp OesDocument4 pagesAn1804 Crude Oil Astm d5708-d1548 Prodigyplus Icp OesyuliaNo ratings yet

- Ags 200Document2 pagesAgs 200dsimovicNo ratings yet

- Uop 987Document11 pagesUop 987pramod23septNo ratings yet

- D5599 617621-1Document8 pagesD5599 617621-1Fernando Cardeño LopezNo ratings yet

- Sulfur in Oil AnalyzerDocument2 pagesSulfur in Oil AnalyzerDan MatNo ratings yet

- The Analysis of CarbonDioxide in Natural GasDocument4 pagesThe Analysis of CarbonDioxide in Natural GasBimo Gunners RespatiNo ratings yet

- Total Nitrogen in Petroleum Products and Inorganic Materials by An Automated Micro-Dumas Nitrogen AnalyzerDocument10 pagesTotal Nitrogen in Petroleum Products and Inorganic Materials by An Automated Micro-Dumas Nitrogen AnalyzerGuisela Carbajal RomeroNo ratings yet

- Gas ChromatographyDocument24 pagesGas Chromatographysujiv_sujiv1278No ratings yet

- A System Simulation Study of The EnhanceDocument6 pagesA System Simulation Study of The Enhancekeltoma.boutaNo ratings yet

- Simple and Reliable Soil Analysis Using The Agilent 7800 ICP-MS With ISIS 3Document10 pagesSimple and Reliable Soil Analysis Using The Agilent 7800 ICP-MS With ISIS 3Nitesh SaxenaNo ratings yet

- J114ADocument2 pagesJ114AIrelena RomeroNo ratings yet

- AppNote ICPOES en Sewage SludgeDocument10 pagesAppNote ICPOES en Sewage Sludgeserena morenaNo ratings yet

- Refinerygasanalyzer - Brochure - Rev1-1115 - A4 PACDocument4 pagesRefinerygasanalyzer - Brochure - Rev1-1115 - A4 PACMiguelNo ratings yet

- Brochure ACCURA Design 2017.1 A4 HiRes PrintfileDocument4 pagesBrochure ACCURA Design 2017.1 A4 HiRes PrintfileAHMEDNo ratings yet

- Analysis of Biodiesel Oil (As Per ASTM D6751 & EN 14214) Using The Agilent 5100 SVDV Icp-OesDocument6 pagesAnalysis of Biodiesel Oil (As Per ASTM D6751 & EN 14214) Using The Agilent 5100 SVDV Icp-OesjulhamNo ratings yet

- Total Sulfur Analyzer CG ConditionsDocument8 pagesTotal Sulfur Analyzer CG ConditionsCristian ValenzuelaNo ratings yet

- Appnote Icpoes 0013 enDocument8 pagesAppnote Icpoes 0013 enejvelazcorNo ratings yet

- Halogenated Hydrocarbons C6H6 in Drinking WaterDocument9 pagesHalogenated Hydrocarbons C6H6 in Drinking WaterCristian CarrascoNo ratings yet

- Vapour Pressure TestingDocument2 pagesVapour Pressure TestinglbNo ratings yet

- Analytical Products: Sales Engineering Supercritical Fluid Chromatography For Process ControlDocument11 pagesAnalytical Products: Sales Engineering Supercritical Fluid Chromatography For Process Controltejasmodi21No ratings yet

- Application Report DMA 80 Evo Coal USREV061019Document4 pagesApplication Report DMA 80 Evo Coal USREV061019Roni GustiwaNo ratings yet

- Elizalde Solis2011Document6 pagesElizalde Solis2011jasontodd22031995No ratings yet

- AN 43158 ICP OES Lubricating Oil ASTM D5185 AN43158 EN PDFDocument4 pagesAN 43158 ICP OES Lubricating Oil ASTM D5185 AN43158 EN PDFwahyubudiutamaNo ratings yet

- Icap 4200 Icp OesDocument4 pagesIcap 4200 Icp Oeslahiru1983No ratings yet

- Procal 2000 IR Emissions AnalyserDocument4 pagesProcal 2000 IR Emissions AnalyserMeindert gerssenNo ratings yet

- DatasheetDocument16 pagesDatasheetmarcosNo ratings yet

- ChemiluminescenceDocument9 pagesChemiluminescencekir223No ratings yet

- AN40986 Trace Contaminant Analysis in Brine Using An Icap 6000 Series Duo IcpDocument6 pagesAN40986 Trace Contaminant Analysis in Brine Using An Icap 6000 Series Duo IcpNitisha RathoreNo ratings yet

- TS 61Document2 pagesTS 61mohamed aliNo ratings yet

- AA 7000 CatalogDocument28 pagesAA 7000 CatalogLuis Fernando Cáceres ChoqueNo ratings yet

- AdblueDocument6 pagesAdblueابراهيم السعيديNo ratings yet

- Varian TOGADocument3 pagesVarian TOGAKiran ChokshiNo ratings yet

- Metodo GCDocument6 pagesMetodo GCMatteo DMNo ratings yet

- 5991-hplc 1260 Mid DistDocument6 pages5991-hplc 1260 Mid Distمحمد محمودNo ratings yet

- DGA Whitepaper2Document6 pagesDGA Whitepaper2nooralhudNo ratings yet

- Avio 550 Max ICP-OES ASTM D5185 In-Service Oils Application NoteDocument4 pagesAvio 550 Max ICP-OES ASTM D5185 In-Service Oils Application Notec1nthiacruzNo ratings yet

- TransportX SPDocument2 pagesTransportX SPtalaporriNo ratings yet

- Charged Aerosol Detection for Liquid Chromatography and Related Separation TechniquesFrom EverandCharged Aerosol Detection for Liquid Chromatography and Related Separation TechniquesPaul H. GamacheNo ratings yet

- Application of IC-MS and IC-ICP-MS in Environmental ResearchFrom EverandApplication of IC-MS and IC-ICP-MS in Environmental ResearchRajmund MichalskiNo ratings yet

- GC/LC, Instruments, Derivatives in Identifying Pollutants and UnknownsFrom EverandGC/LC, Instruments, Derivatives in Identifying Pollutants and UnknownsNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo ratings yet

- Standard Specifications of Light Naphtha: Analysis Unit Limit Test MethodDocument1 pageStandard Specifications of Light Naphtha: Analysis Unit Limit Test MethodIman Moghadam100% (1)

- 0009b An Lowox in Lpg.1Document3 pages0009b An Lowox in Lpg.1Iman MoghadamNo ratings yet

- 0009b An Lowox in Lpg.1Document3 pages0009b An Lowox in Lpg.1Iman MoghadamNo ratings yet

- 0009b An Lowox in Lpg.1Document3 pages0009b An Lowox in Lpg.1Iman MoghadamNo ratings yet

- CLASS - 12th CAMPION SCHOOL, BHOURI, BHOPAL PT-2 EXAMINATION SUBJECT - CHEMISTRY MM - 50Document22 pagesCLASS - 12th CAMPION SCHOOL, BHOURI, BHOPAL PT-2 EXAMINATION SUBJECT - CHEMISTRY MM - 50Harshil NagwaniNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument12 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingalexNo ratings yet

- Brochure - Unitox PlusDocument4 pagesBrochure - Unitox PlusjayashreeNo ratings yet

- TDS of SP7154 0002Document2 pagesTDS of SP7154 0002kashyappathak01No ratings yet

- Alkene Preparation and ReactionsDocument46 pagesAlkene Preparation and Reactionsnlprofessional07No ratings yet

- The Chemical Elements and Their Compounds v2Document853 pagesThe Chemical Elements and Their Compounds v2techkasambaNo ratings yet

- Lab Report Experiment 2 - Sodium Borohydride Reduction of CyclohexanoneDocument11 pagesLab Report Experiment 2 - Sodium Borohydride Reduction of CyclohexanoneSITI NUR AFIQAH MAHAZANNo ratings yet

- 3 Carbamates InsecticidesDocument13 pages3 Carbamates InsecticidesAmit SharmaNo ratings yet

- Fabric Conveyor Belts Installation and Maintenance Guide: Habasit - Solutions in MotionDocument16 pagesFabric Conveyor Belts Installation and Maintenance Guide: Habasit - Solutions in MotionAbdul Kani Ahamed MNo ratings yet

- Electrocyclic ReactionDocument5 pagesElectrocyclic ReactionfareehaNo ratings yet

- Biofuel: Name-Swati Subhada Mohapatra Sec-A Roll No - 63 BSC Biotech 3 YearDocument19 pagesBiofuel: Name-Swati Subhada Mohapatra Sec-A Roll No - 63 BSC Biotech 3 YearNayak Alok RanjanNo ratings yet

- Alternate Fules Report-HariDocument20 pagesAlternate Fules Report-Hari18-331 YUGANDHARNo ratings yet

- FRP Catalogue 04.2021Document84 pagesFRP Catalogue 04.2021Bilel MahjoubNo ratings yet

- Cosmetics Microbiology: GlossaryDocument11 pagesCosmetics Microbiology: GlossaryAngelica Alejandra De La Torre AnayaNo ratings yet

- Vitamins, Minerals Plus Iron, Iodine, Taurine, and Zinc: Nutrition InformationDocument1 pageVitamins, Minerals Plus Iron, Iodine, Taurine, and Zinc: Nutrition InformationWonder PsychNo ratings yet

- Proposal Final Year ProjectDocument13 pagesProposal Final Year Projectnora azizNo ratings yet

- Solid Phase Extraction Technique - Trends, Opportunities and ApplicationsDocument15 pagesSolid Phase Extraction Technique - Trends, Opportunities and ApplicationsRohimah NHNo ratings yet

- FEVE Fluoropolymer Emulsions For Performance Improvement in Architectural CoatingsDocument32 pagesFEVE Fluoropolymer Emulsions For Performance Improvement in Architectural CoatingsThanh VuNo ratings yet

- Eco. Exp. 1 Determination of Free CO2Document3 pagesEco. Exp. 1 Determination of Free CO2Faneeshwar PatelNo ratings yet

- MSDS NaOCH3-Sodium MethylateDocument15 pagesMSDS NaOCH3-Sodium MethylateNasrulNo ratings yet

- TSR 131Document14 pagesTSR 131Prad1979No ratings yet

- Candlenut Oil: Review On Oil Properties and Future Liquid Biofuel ProspectsDocument24 pagesCandlenut Oil: Review On Oil Properties and Future Liquid Biofuel ProspectsdesniaNo ratings yet

- Safer Modified Hummers' Method For The Synthesis of Graphene Oxide With High Quality and High YieldDocument11 pagesSafer Modified Hummers' Method For The Synthesis of Graphene Oxide With High Quality and High YieldManu PriyaNo ratings yet

- LECTURE 2: Continuation Magnification vs. Resolution: Microbio (Midterms Reviewer)Document13 pagesLECTURE 2: Continuation Magnification vs. Resolution: Microbio (Midterms Reviewer)Entris AlcNo ratings yet

- Free Download Controlled Release Fertilizers For Sustainable Agriculture F B Lewu Full Chapter PDFDocument45 pagesFree Download Controlled Release Fertilizers For Sustainable Agriculture F B Lewu Full Chapter PDFellen.clark485100% (12)

- QueryDocument8 pagesQuerysubhash221103No ratings yet

- 1 s2.0 S2405844019363923 MainDocument10 pages1 s2.0 S2405844019363923 MainHagere EthiopiaNo ratings yet

- Hardin S.Si, S.PD, M.PDDocument26 pagesHardin S.Si, S.PD, M.PDRadiatul Awalia AmirNo ratings yet