Professional Documents

Culture Documents

Cooling, Exhaust, Fuel & Electrical Systems

Uploaded by

Md ShOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cooling, Exhaust, Fuel & Electrical Systems

Uploaded by

Md ShCopyright:

Available Formats

Cooling system Exhaust system

Radiator Maximum back pressure .. ... ... .. ... ... ... ... ... . ... ... ... .. 10.2 kPa

-face area. ... ... ... ... ... ... ... ... ... ... ... ... . ... ... ... ... ... . 0.167 m² Exhaust outlet size... ... ... ... ... ... . . ... ... ... .. ... ... ... ... ... . 42 mm

-rows and materials.. ... ... ... ... ... ... ... ... ... ... .2 rows, Aluminium

-matrix density and material ... ... ... ... 4.5 fins per inch, Aluminium

-width of matrix... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 334.2 mm Fuel system

-height of matrix . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 500.0 mm

-pressure cap setting ... ... ... ... ... ... . ... ... ... ... .. ... ... ... ..90 kPa Type of injection .. ... ... ... ... ... ... ... ... ... ... ... ... . Indirect injection

Estimated cooling air flow reserve ... ... ... ... ... ... ... ... .. 0.125 kPa Fuel injection pump . ... ... ... ... ... ... ... ... ... ... ... ... . Cassette type

Fuel injector. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...Pintle nozzle

Fan Nozzle opening pressure ... ... ... ... ... ... ... ... ... ... ... ... 14.7 MPa

-diameter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 320 mm Max particle size.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 25 microns

-drive ratio .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 1.25:1

-number of blades .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 6 Fuel lift pump

-material . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..Plastic -type ... ... ... ... ... ... ... ... ... ... ... ... mechanical (camshaft driven)

-type ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .Pusher -flow/hour. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 63 litres/hr

Airflow at rated speed ... ... ... ... ... ... ... ... ... ... ... ... ... 49 m³/min -pressure .. ... ... ... ... ... ... ... ... ... ... .. ... ... ... ... ... ... ... ...10 kPa

Power absorbed @ Max. rated speed ... ... ... ... ... ... ... ... ... . 0.20 Maximum suction head ... ... ... ... ... ... .. ... ... .. . ... ... ... ... ..0.8 m

Maximum static pressure head ... ... ... ... . . ... ... .. ... ... ... ...3.0 m

Coolant Max. fuel temperature at lift pump inlet. .. ... ... ... ... ... ... ... ... 40°C

Total system capacity Max. fuel filter service interval . ... ... ... ... ... ... ... ... ... ... . 1000 hrs

-with radiator .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...6.0 litres Governor type.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .Mechanical

-without radiator . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...2.6 litres Speed control conforms to .. ... ... ... ... ... ... ... ... ... ... ... ... ... .. G2

Maximum top tank temperature ... ... . ... ... ... . .. ... ... ... ... . 112°C

Max static pressure head on pump ... ... ... ... ... ... ... ... .. 30.4 kPa Fuel specification

Temperature rise across engine .. ... .. .. ... ... ... . . ... ... ... ... 5.1°C BS2869 CLASS 2 (off highway, gas oil), DIN EN590 DERV (Class

Max permissible external system resistance . ... ... ... ... .. TBA kPa A to F and 0 to 4).

Thermostat operation range. ... ... ... . ... ... ... ... ... ... .. ...82 - 95°C For further information on fuel specifications and restrictions, refer

Recommended coolant: to the OMM Fuels section for this engine model.

Recommended coolant: 50% anti freeze / 50% water. For complete

details of recommended coolant specifications, refer to the Fuel consumption

Operation and Maintenance Manual for this engine model Power rating%

g/kWh (litres/hr)

Duct allowance

110 100 75 50 25

Maximum additional restriction (duct allowance) to cooling 270 (5.90) 253 (4.90) TBA TBA TBA

airflow and resultant minimum airflow

Ambient clearance Duct allowance

m³/sec

50% Glycol Pa

53°C 65 48.6

46°C 125 48.6

Electrical System

-alternator... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 15 amps, 12 V

-starter motor . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 2 kW, 12 V

Number of teeth on flywheel .. ... ... ... ... ... ... ... ... ... ... ... ... .. 109

Number of teeth on starter pinion .. ... ... ... ... ... ... ... ... ... ... ... .. 9

Engine stop method ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. Solenoid

Cold start recommendations

Minimum cranking speed ... ... ... ... ... ... ... ... ... ... ... . 150 rev/min

Minimum

starting Battery specifications

temperature Grade of

engine

lubricating BS3911 SAEJ537 Number

oil Cold Cold of Commercial

°C

start cranking batteries ref number

amps amps needed

0 20W 420 590 1 072

-15 10W 420 590 1 072

-20 5W 540 740 1 647

Note: Additional information for battery and cable limits can be

found in Chapter 6 of the 400 Series Engine Sales Manual.

Induction system Load acceptance

Maximum air intake restriction The below complies with the requirements of classification 3 and 4

-clean filter. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 3.0 kPa of ISO 8528-12 and G2 operating limits stated in ISO 8528-5

-dirty filter .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 6.4 kPa Initial load application: When engine reaches rated speed

-air filter type.. ... ... ... ... ... ... ... ... ... ... ... ... ... .. dry element type

(15 seconds maximum after engine starts to crank)

Descriptor Units 60Hz

Lubrication system % of prime power % 60

Transient frequency

% <10

Lubricating oil capacity deviation

Maximum sump capacity... ... ... ... ... ... ... ... ... ... ... ... ... 6.0 litres Frequency recovery Seconds 5

Minimum sump capacity ... ... ... ... ... ... ... ... ... ... ... ... ... 4.5 litres The above figures were obtained under the following test

Maximum engine operating angles

conditions:

-front up, front down, right side or left side ... ... ... . 35° continuous

-minimum engine block temperature .. ... ... ... ... ... ... ... ... TBA°C

Lubricating oil pressure -ambient temperature . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 25°C

-governing mode ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 5%

-relief valve opens . ... ... ... ... ... ... ... ... ... ... ... ... ...262 - 359 kPa

-alternator inertia ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... TBA kgm²

Minimum oil pressure ... ... ... ... ... ... ... ... ... ... ... ... ... ... 120 kPa

-at maximum no-load speed.. ... ... ... ... ... ... ... ... ... ... ... ... .. TBA -under frequency roll off (UFRO) point set to2% Volt / 1% frequency

-UFRO rate set to ... ... ... ... ... ... ... ... ... .. 1 Hz below rated speed

Max. oil temperature - continuous operation. ... ... ... ... ... ... 125°C

LAM on/off .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... off

Max. oil temperature - intermittent operation ... ... ... ... ... ... 135°C

Oil flow at rated speed .. ... ... ... ... ... ... ... ... ... ... ...10.9 litres/min All tests were conducted using an engine which was installed and

serviced to Perkins Engines Company Limited recommendations.

Recommended SAE viscosity

A single or multigrade oil must be used which conforms API-CH-4

Derate Curves

Derate curves for altitude and humidity can be found in Chapter 6

or ACEA E5.

of the 400 Series Engine Sales Manual.

Viscostiy grade

15W-40 The general arrangement drawings shown in this data sheet are for

guidance only. For installation purposes, latest versions should be

10W-40

requested from the Applications Dept., Perkins Engines Stafford,

10W-30 ST16 3UB United Kingdom.

5W-40

5W-30

0W-40

0W-30

0W-20

-50 -40 -30 -20 -10 0 10 20 30 40 50 60

Ambient Temperature Deg C

Maximum static bending moment

at rear face of block .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... .990 Nm

400 Series 403A-15G2

Notes

Publication No. TPD1800E1. 07 February 2012 Perkins Engines Company Limited.

Distributed by

Perkins Engines Company Limited

Peterborough PE1 5NA United Kingdom

Telephone +44 (0) 1733 583000

Fax +44 (0) 1733 582240

www.perkins.com

All information in the document is substantially correct at the time

of printing but may be subsequently altered by the company.

You might also like

- Cooling System Exhaust System: RadiatorDocument2 pagesCooling System Exhaust System: RadiatorMd ShNo ratings yet

- 404D-22G@1500 (Battery Specs)Document2 pages404D-22G@1500 (Battery Specs)Md ShNo ratings yet

- Cooling System Exhaust System: RadiatorDocument2 pagesCooling System Exhaust System: RadiatorMd ShNo ratings yet

- Cooling 1306ATAG6 TPD1827E2Document1 pageCooling 1306ATAG6 TPD1827E2Md ShNo ratings yet

- 1104C 44taDocument8 pages1104C 44taWilmerNo ratings yet

- New 625kva 2806d E18 Tag1aDocument12 pagesNew 625kva 2806d E18 Tag1aRohit BhattNo ratings yet

- New 625kVA 2806D E18 TAG1A PDFDocument12 pagesNew 625kVA 2806D E18 TAG1A PDFRohit BhattNo ratings yet

- 4008-30TAG3 TPD2011E2 Nov2015Document5 pages4008-30TAG3 TPD2011E2 Nov2015tienlamNo ratings yet

- TPD2076 1Document7 pagesTPD2076 1Alfonso RivasNo ratings yet

- Scania Engine Data 1588878Document20 pagesScania Engine Data 1588878Anderson Aguiar69% (16)

- 12M33G1100/6 PowerKit Engine SpecificationsDocument4 pages12M33G1100/6 PowerKit Engine SpecificationsZÁNCHON XDNo ratings yet

- 404D-22T Iopu (Tpd1717e2)Document10 pages404D-22T Iopu (Tpd1717e2)hecazorlaNo ratings yet

- Catalogue Perkins 404D 22TGDocument10 pagesCatalogue Perkins 404D 22TGDanh TrầnNo ratings yet

- Engine Data D12 PDFDocument20 pagesEngine Data D12 PDFFabio Junior100% (1)

- Technical Data: 400 Series 403D-15GDocument6 pagesTechnical Data: 400 Series 403D-15GOGNo ratings yet

- 404D 22Document8 pages404D 22aiulica20100% (2)

- Planta Panaven Modelo GMS22PX6SDocument6 pagesPlanta Panaven Modelo GMS22PX6Sfranklin velasco100% (1)

- Datasheet P2500 PDFDocument14 pagesDatasheet P2500 PDFElectro JC100% (1)

- Lehm20653-00 C4.4 Keel Cooled 50HZDocument3 pagesLehm20653-00 C4.4 Keel Cooled 50HZDedi MaryadiNo ratings yet

- TPD2127 1206D-E70TTAG1Document4 pagesTPD2127 1206D-E70TTAG1marwanqaisi85No ratings yet

- Case 570mxtspDocument4 pagesCase 570mxtspJesús PatiñoNo ratings yet

- Technical Data: 400 Series 403C-11GDocument6 pagesTechnical Data: 400 Series 403C-11Gmuhammad arifNo ratings yet

- 2506C E15tag2 PDFDocument14 pages2506C E15tag2 PDFIvan Dumont67% (3)

- TPD2158E2Document4 pagesTPD2158E2MohamedJaberKutkutMjkNo ratings yet

- Komatsu Pc210lc 10 Hydraulic Crawler Excavator SpecificationsDocument6 pagesKomatsu Pc210lc 10 Hydraulic Crawler Excavator SpecificationsHugo BelgraveNo ratings yet

- Catalogue Perkins 404A 22G1Document10 pagesCatalogue Perkins 404A 22G1ikhtiyar ali khan ikhtiyarNo ratings yet

- 1104C-44T IOPU Technical Data Sheet PDFDocument8 pages1104C-44T IOPU Technical Data Sheet PDFBob100% (2)

- LEHM20671-00 - C4.4 Electronic Data SheetDocument3 pagesLEHM20671-00 - C4.4 Electronic Data Sheetkman548No ratings yet

- 2806A-E18TAG2A Technical DataDocument10 pages2806A-E18TAG2A Technical DatabereketNo ratings yet

- 404A-22G1 Technical SpecsDocument10 pages404A-22G1 Technical SpecsDEEPAKNo ratings yet

- TPD1943Document5 pagesTPD1943Mazen SalibaNo ratings yet

- 1506a E88tag5 - 300 KvaDocument12 pages1506a E88tag5 - 300 KvaRizki Heru HermawanNo ratings yet

- Tpd2157en-04 (08-23)Document5 pagesTpd2157en-04 (08-23)ccssaa123No ratings yet

- 3 1524 (1500)Document6 pages3 1524 (1500)mkNo ratings yet

- Perkins 4008tag1a & Tag2a (Tsl4252e-6)Document16 pagesPerkins 4008tag1a & Tag2a (Tsl4252e-6)Cris_eu09No ratings yet

- Thông số Perkins 4008TAG1A PDFDocument16 pagesThông số Perkins 4008TAG1A PDFBắc NhậtNo ratings yet

- Gep110 1104C Tag2 LL3014BDocument6 pagesGep110 1104C Tag2 LL3014BDaniel EvansNo ratings yet

- General Engine Specifications: 3000 BKW at 1800 RPM Diesel Propulsion RatingDocument5 pagesGeneral Engine Specifications: 3000 BKW at 1800 RPM Diesel Propulsion RatingJoko Susilo0% (1)

- 2.1. Excav PC200 - 200LC-8 - CEN00049-09Document5 pages2.1. Excav PC200 - 200LC-8 - CEN00049-09adityadhNo ratings yet

- Dvigatel Perkins 4016 61trg3Document14 pagesDvigatel Perkins 4016 61trg3mohammed khadrNo ratings yet

- 4016T 61TRG32250kVA For 50Hz PDFDocument13 pages4016T 61TRG32250kVA For 50Hz PDFParinya100% (1)

- Electropak: 1206A-E70Ttag2Document4 pagesElectropak: 1206A-E70Ttag2Andres SorinNo ratings yet

- EMI4050T18 WebDocument1 pageEMI4050T18 WebJuli B.No ratings yet

- Technical Data: 400 Series 404D-22GDocument6 pagesTechnical Data: 400 Series 404D-22Grofaria100100% (1)

- 1104a 44tg2perkinsDocument8 pages1104a 44tg2perkinsEdilson Matias CastroNo ratings yet

- 4006-23tag2a - Tag3aDocument14 pages4006-23tag2a - Tag3aImran MazharNo ratings yet

- Perkins 1100 Series HDDocument8 pagesPerkins 1100 Series HDSaadNo ratings yet

- 1106a-70tg1 TPD1857Document10 pages1106a-70tg1 TPD1857Genset GensetNo ratings yet

- GMS130CS in B S e PDocument7 pagesGMS130CS in B S e Pcertificacionesequiposmb mbNo ratings yet

- Perkins 4 0 3Document6 pagesPerkins 4 0 3Rizki HermawanNo ratings yet

- PD750-01 Engine Data Sheet 12-29-20Document4 pagesPD750-01 Engine Data Sheet 12-29-20Service Brags & Hayes, Inc.No ratings yet

- Industrial Open Power Unit: SeriesDocument9 pagesIndustrial Open Power Unit: Serieseli abdul rohimNo ratings yet

- Electropak: SeriesDocument10 pagesElectropak: SeriesChristian Rivera FloverNo ratings yet

- Ficha Tecnica C 40Document1 pageFicha Tecnica C 40Abrar HussainNo ratings yet

- 2.2. DAF EQUIPMENT (Flow 15 M /H) : Flocculation PipeDocument4 pages2.2. DAF EQUIPMENT (Flow 15 M /H) : Flocculation PipeAna QueenNo ratings yet

- Part. B.thermal DesignDocument8 pagesPart. B.thermal DesignAhmed GadNo ratings yet

- Catalogue Perkins 1104C 44TAG2Document8 pagesCatalogue Perkins 1104C 44TAG2RobNo ratings yet

- WPS30S in D S e PDocument8 pagesWPS30S in D S e PMesfin MamoNo ratings yet

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- 1103 (Battery Specs)Document1 page1103 (Battery Specs)Md ShNo ratings yet

- Perkins 30kW Motor DatasheetDocument10 pagesPerkins 30kW Motor DatasheetOmar Orlando Rincon FigueroaNo ratings yet

- Cooling of 1103A-33GDocument2 pagesCooling of 1103A-33GMd ShNo ratings yet

- Perkins 404D-22G Model - DataDocument8 pagesPerkins 404D-22G Model - DataKrishNo ratings yet

- Basic Technical Data Centre of Gravity (Dry)Document8 pagesBasic Technical Data Centre of Gravity (Dry)Md ShNo ratings yet

- Flow DiagramDocument3 pagesFlow DiagramMd ShNo ratings yet

- Perkins 4 0 3Document6 pagesPerkins 4 0 3Rizki HermawanNo ratings yet

- Product Bulletin: Overhead Charge Air Pipes On 4012-46TAG ProductsDocument2 pagesProduct Bulletin: Overhead Charge Air Pipes On 4012-46TAG ProductsMd ShNo ratings yet

- Technical Data: 400 Series 403D-11GDocument6 pagesTechnical Data: 400 Series 403D-11GMd ShNo ratings yet

- 404 D22 TAG1800 TPD1711 E5 Technical Data SheetDocument11 pages404 D22 TAG1800 TPD1711 E5 Technical Data SheetOmar Orlando Rincon FigueroaNo ratings yet

- Variable Speed Generator Set: SeriesDocument9 pagesVariable Speed Generator Set: SeriesMd ShNo ratings yet

- Engine Fuel Oil SystemDocument1 pageEngine Fuel Oil SystemMd ShNo ratings yet

- 403D - 15 Industrial TPD1764E1Document8 pages403D - 15 Industrial TPD1764E1Md ShNo ratings yet

- In Line Lubrication SystemDocument1 pageIn Line Lubrication SystemMd ShNo ratings yet

- Hearing ProtectionDocument1 pageHearing ProtectionMd ShNo ratings yet

- C 10809824Document1 pageC 10809824Mohamed HamdallahNo ratings yet

- Jacket Water Circulation DiagramDocument1 pageJacket Water Circulation DiagramMd ShNo ratings yet

- Toolbox Talk - Safety Around High VoltageDocument1 pageToolbox Talk - Safety Around High Voltagesl1828No ratings yet

- Diesel Fuel TipsDocument1 pageDiesel Fuel TipsMd ShNo ratings yet

- Shop Safety Tools - Water PressureDocument1 pageShop Safety Tools - Water PressureMd ShNo ratings yet

- Carbon Monoxide PoisoningDocument1 pageCarbon Monoxide PoisoningMd ShNo ratings yet

- TOPIC: Personal Protective Equipment ChecklistDocument1 pageTOPIC: Personal Protective Equipment ChecklistMd ShNo ratings yet

- Battery Care and Tips2Document1 pageBattery Care and Tips2SCCstudent99No ratings yet

- Head Protection - Hard HatsDocument1 pageHead Protection - Hard HatsMd ShNo ratings yet

- 1062 16 1222Document1 page1062 16 1222Md ShNo ratings yet

- 1110 HTS Dec06Document2 pages1110 HTS Dec06Md ShNo ratings yet

- Scania Diesel Engine Parts CatalogDocument3 pagesScania Diesel Engine Parts CatalogTarek MassimoNo ratings yet

- Photoelectric Effect: Classical PredictionDocument7 pagesPhotoelectric Effect: Classical PredictionOliver58No ratings yet

- Purepro Color Catalogs PDFDocument52 pagesPurepro Color Catalogs PDFArlex Ricardo Guillen PetitNo ratings yet

- DTFS Project 1Document9 pagesDTFS Project 1ridaNo ratings yet

- How Are Supercritical Boilers Different From Subcritical BoilersDocument2 pagesHow Are Supercritical Boilers Different From Subcritical BoilerssbmmlaNo ratings yet

- M-33 Diesel Generator Engine ManualDocument847 pagesM-33 Diesel Generator Engine ManualJibu George Thomas100% (7)

- 1TGG909017 ABB NeoGear LBP WhitepaperDocument12 pages1TGG909017 ABB NeoGear LBP WhitepaperJohn VernonNo ratings yet

- Barangay Salawag: Far Eastern UniversityDocument24 pagesBarangay Salawag: Far Eastern UniversityMark Benson CasaclangNo ratings yet

- Internal Rotary Inspection System (IRIS) Tubular TestingDocument3 pagesInternal Rotary Inspection System (IRIS) Tubular Testingநந்த குமார் சம்பத் நாகராஜன்100% (1)

- Features: Power Isolation TransformersDocument8 pagesFeatures: Power Isolation TransformersLKGNo ratings yet

- CY2161 - Engineering Chemistry - IIDocument186 pagesCY2161 - Engineering Chemistry - IIPushpavalli MohanNo ratings yet

- ZN 375 M PERC - Certificado - 1 PDFDocument2 pagesZN 375 M PERC - Certificado - 1 PDFJosé Luis González MartínezNo ratings yet

- Rotary Evaporator Instruction ManualDocument38 pagesRotary Evaporator Instruction Manualkieuthu leNo ratings yet

- Test Relief Valves up to 6,000 PSI with Barbee's Model HP-6000 Test StandDocument27 pagesTest Relief Valves up to 6,000 PSI with Barbee's Model HP-6000 Test StandNam TranNo ratings yet

- Company Profile - AG NutriceuticalDocument5 pagesCompany Profile - AG NutriceuticalNorina GenistonNo ratings yet

- LM 1117Document38 pagesLM 1117Miguel MejíaNo ratings yet

- Corrosion Resistant Fiberglass Piping Systems BrochureDocument6 pagesCorrosion Resistant Fiberglass Piping Systems BrochureDavid MayNo ratings yet

- Election Manifesto of Bangladesh Awami League-2008Document15 pagesElection Manifesto of Bangladesh Awami League-2008api-3709098No ratings yet

- CA Vd4 40ka (En) M 1vcp000001 CatalogDocument86 pagesCA Vd4 40ka (En) M 1vcp000001 Catalogdorin serbanNo ratings yet

- 6.high-Temperature Cl-Induced CorrosionDocument18 pages6.high-Temperature Cl-Induced CorrosionPrakash WarrierNo ratings yet

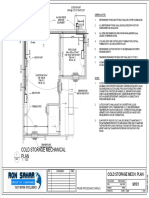

- M101 - Cold Storage Mech - PlanDocument1 pageM101 - Cold Storage Mech - PlanLiaqatSrakNo ratings yet

- Pacific Scirocco 2017-08-03 Revision 7Document2 pagesPacific Scirocco 2017-08-03 Revision 7wangnaNo ratings yet

- EI-LOTO Safety ProceduresDocument3 pagesEI-LOTO Safety ProceduresFabian Martin Nunes OrellanaNo ratings yet

- Flexicoking ProcessDocument4 pagesFlexicoking ProcessJHONNY100% (2)

- Data Sheets, Approved VendorsDocument213 pagesData Sheets, Approved Vendorsapi-3698996100% (7)

- Oxygen Sensor OOM101: Use The AdvantagesDocument2 pagesOxygen Sensor OOM101: Use The AdvantagesDaniel FalconNo ratings yet

- Sr Instrument Engineer Israr Ali ResumeDocument4 pagesSr Instrument Engineer Israr Ali ResumeOwais Manzoor MalikNo ratings yet

- HVAC Water Chillers and Cooling Towers: Second EditionDocument48 pagesHVAC Water Chillers and Cooling Towers: Second EditionRoger MartinsNo ratings yet

- Tac, Fire Protection ManulDocument81 pagesTac, Fire Protection ManulVijay PatelNo ratings yet

- Underground Works: Projek Mass Rapid Transit Laluan 2: Sg. Buloh - Serdang - PutrajayaDocument21 pagesUnderground Works: Projek Mass Rapid Transit Laluan 2: Sg. Buloh - Serdang - PutrajayaMohd FadliNo ratings yet