Professional Documents

Culture Documents

Chapter 4 - Vertical Alignment Optimization

Uploaded by

Roberto JoaquinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 4 - Vertical Alignment Optimization

Uploaded by

Roberto JoaquinCopyright:

Available Formats

Chapter 4 - Vertical Alignment Optimization

4. Vertical Alignment Optimization

Alignment design is a fundamental part of any corridor engineering project. The alignment position

directly affects the cost of the project. Softree Optimal can be used to create new designs or refine

and verify existing designs.

Three-dimensional alignment design is a complicated geometric problem. In addition to standards

such as design speed curvatures and maximum grade, engineers must contend with a variety of

conditions and restrictions such as right of way, utilities and crossing grades. These constraints often

make the alignment problem even more challenging.

Softree Optimal can quickly calculate the earthwork cost of any alignment (see previous exercises);

in mathematical optimization terminology, this is called the cost function. To optimize a vertical

alignment, Softree Optimal minimizes the cost function over all possible alignments. Your job as an

engineer/designer is to constrain Softree Optimal to reasonable alignments.

Vertical alignment optimization is based on the following parameters and constraints:

• Earthwork Costs - Excavation, embankment and haul costs (see previous section).

• Pit Locations - Waste and borrow locations and associated costs (see previous section).

• Design Standards - Maximum curvature (minimum K values), minimum and maximum grades.

• Control Points - Elevation and grade constraints:

o Terminating Conditions - Starting and ending elevations and grades.

o Control Points - Defined station, elevation points (intersections, driveways, etc.).

• Special Constraints:

o Cut or fill depth constraints – for example minimum fill requirements in wet areas.

o Preferred direction for earth movement.

o Full Bench Cut requirement.

Softree Optimal allows you to create multiple vertical alignments in one document. This lets you to

try different constraints and scenarios. To work with and compare multiple horizontal alignments, it

is necessary to create multiple documents (DSN files); in this event, it is sometimes convenient to

open two instances of the Location module.

An optimal vertical alignment is based on all the current design settings, e.g. horizontal alignment,

sub-surface layers, template assignments, ground types, etc.

Note (for those familiar with RoadEng®): Vertical optimization is not recommended if you have fixed sections

defined. A change in vertical position may produce unwanted results on a fixed section. Fixing sections (if

desired) can be done later once both the horizontal and vertical alignments are finalized.

P A G E | 26

You might also like

- v2 CI2541 ChappellDocument10 pagesv2 CI2541 ChappellAbdelkrim JomaaNo ratings yet

- AppNote 07 FPSO and Offshore PlatformsDocument4 pagesAppNote 07 FPSO and Offshore PlatformsRao MadepalliNo ratings yet

- Geometry: ICEM CFD Introductory CourseDocument17 pagesGeometry: ICEM CFD Introductory CourseCarlos GomezNo ratings yet

- 8.0 Vertical Allignment DesignDocument16 pages8.0 Vertical Allignment DesignalexiusfaustineNo ratings yet

- ADAPT Builder2012Document2 pagesADAPT Builder2012Partho PRATIMNo ratings yet

- Attributes of Good Car Park DesignDocument30 pagesAttributes of Good Car Park DesignRiza ArceñoNo ratings yet

- Class Handout CES500056 ClassHandout-CES500056-DIEZIGER-AU2021Document40 pagesClass Handout CES500056 ClassHandout-CES500056-DIEZIGER-AU2021Danny NguyenNo ratings yet

- Site Grading and Quantities: Autocad Civil 3D 2010 Education Curriculum Unit 3: Land DevelopmentDocument42 pagesSite Grading and Quantities: Autocad Civil 3D 2010 Education Curriculum Unit 3: Land DevelopmentNathan HeinNo ratings yet

- PROKON General ColumnDocument4 pagesPROKON General Columnsusan87No ratings yet

- AU09 SpeakerHandout CV122-31Document19 pagesAU09 SpeakerHandout CV122-313dycsaNo ratings yet

- Selection of Part Build OrientationDocument10 pagesSelection of Part Build OrientationShubham SharmaNo ratings yet

- 8.0 Vertical Allignment DesignDocument18 pages8.0 Vertical Allignment DesignChris AdaminovicNo ratings yet

- Flexible Pavements - Evolution of IRC 37Document85 pagesFlexible Pavements - Evolution of IRC 37DIT TRAFFIC100% (2)

- Structural Design of Hangar For AirportDocument18 pagesStructural Design of Hangar For Airportsanusi69100% (3)

- Skid Design and AnalysisDocument4 pagesSkid Design and AnalysisBiswajeet PandaNo ratings yet

- Super Elevation RulesDocument50 pagesSuper Elevation RulesBabulal SahuNo ratings yet

- Die Face StageDocument14 pagesDie Face StageRavindra KurisettiNo ratings yet

- Fatigue AASHTO 8th EdDocument33 pagesFatigue AASHTO 8th EdHenry Burgos N.No ratings yet

- Flexible Pavement Aspects of Basic DesignDocument92 pagesFlexible Pavement Aspects of Basic DesignGanesh Gupta100% (1)

- Batch 1 Parer Publish ofDocument16 pagesBatch 1 Parer Publish ofAbdul RazzakNo ratings yet

- MIDAS Advanced Gen WebinarDocument31 pagesMIDAS Advanced Gen Webinarpradeepjoshi007No ratings yet

- CSG Brep Solid ModelingDocument64 pagesCSG Brep Solid ModelingHariNo ratings yet

- Basic Highway Design ChecklistDocument13 pagesBasic Highway Design ChecklistSyed Ali Raza ShahNo ratings yet

- TCAA Geometry ControlDocument4 pagesTCAA Geometry ControlShaileshRastogiNo ratings yet

- Exam Preparation Chartered Member Solutions 20150710Document33 pagesExam Preparation Chartered Member Solutions 20150710MartinNo ratings yet

- Modeling Roundabout IntersectionsDocument13 pagesModeling Roundabout IntersectionsAllexby C. EstardoNo ratings yet

- Flexible Pavement - Aspects of Basic Design As Per IRC MethodDocument87 pagesFlexible Pavement - Aspects of Basic Design As Per IRC Methodrajibchattaraj100% (2)

- A Practical System For Hydrodynamic Optimization of Ship Hull FormsDocument7 pagesA Practical System For Hydrodynamic Optimization of Ship Hull FormsSalma SherbazNo ratings yet

- Methodology For Part Building Orientation in Additive ManufacturingDocument16 pagesMethodology For Part Building Orientation in Additive ManufacturingziatNo ratings yet

- ADAPT PT Training ManualDocument22 pagesADAPT PT Training Manualgoblue11112100% (2)

- 0 STAR-CCM+ - Reference Guide2012Document8 pages0 STAR-CCM+ - Reference Guide2012triya_vadgamaNo ratings yet

- Lecture 1: Introduction To Aircraft DesignDocument61 pagesLecture 1: Introduction To Aircraft DesignAgostino De GiuseppeNo ratings yet

- Surface QualityDocument35 pagesSurface Qualityroyce_ss75% (4)

- Computer-Aided Manufacturing: Computer-Aided Manufacturing (CAM) Is The Use of Computer Software To ControlDocument4 pagesComputer-Aided Manufacturing: Computer-Aided Manufacturing (CAM) Is The Use of Computer Software To Controlvarma511No ratings yet

- ETABS & SAP Step by StepDocument25 pagesETABS & SAP Step by StepAvishek Acharya100% (1)

- Highway Geometric Alignment and Design LectureDocument98 pagesHighway Geometric Alignment and Design LectureMatthew MazivanhangaNo ratings yet

- Generative Design Essentials of Convergent Modeling Topology OptimizationDocument10 pagesGenerative Design Essentials of Convergent Modeling Topology Optimizationcad cadNo ratings yet

- Fluent Introduction - Some Best Practice...Document29 pagesFluent Introduction - Some Best Practice...TestNo ratings yet

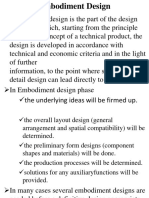

- Embodiment DesignDocument46 pagesEmbodiment Designabel shimelisNo ratings yet

- Falling Weight DeflectometerDocument4 pagesFalling Weight DeflectometerAsif Ali100% (1)

- Selecting and Using Appropriate Truck Data in Design GuidelinesDocument3 pagesSelecting and Using Appropriate Truck Data in Design GuidelinesAlioune PAYENo ratings yet

- CWK Preliminary 1Document12 pagesCWK Preliminary 1Mohammad MohammadPourNo ratings yet

- KISSsoft Book 2015Document108 pagesKISSsoft Book 2015Anonymous SYqjuakwzP100% (2)

- Air-Bearing Design Based On Global Approximation Concepts: Sang-Joon Yoon and Dong-Hoon Choi, Member, IEEEDocument3 pagesAir-Bearing Design Based On Global Approximation Concepts: Sang-Joon Yoon and Dong-Hoon Choi, Member, IEEEDeepak SharmaNo ratings yet

- Safe BrochureDocument21 pagesSafe BrochuremindoiuNo ratings yet

- 20.cedrus 5h enDocument7 pages20.cedrus 5h entrannguyenvietNo ratings yet

- CM 2laneDocument21 pagesCM 2lanerammirisNo ratings yet

- Part Orientation and Support GenerationDocument22 pagesPart Orientation and Support GenerationVivek DesaleNo ratings yet

- 9.0 General Design ControlsDocument24 pages9.0 General Design ControlsChris AdaminovicNo ratings yet

- Advanced ModellingDocument4 pagesAdvanced ModellingJavadNo ratings yet

- Plant Layout ProblemDocument52 pagesPlant Layout Problemtony_njNo ratings yet

- Concrete Construction Article PDF - Coordinating Formwork Plans With Overall Project PlanningDocument3 pagesConcrete Construction Article PDF - Coordinating Formwork Plans With Overall Project PlanningKiranNo ratings yet

- Race Car Designing ProcedureDocument5 pagesRace Car Designing ProcedureBalaji AeroNo ratings yet

- CFDDocument13 pagesCFDMurali S SaranglaNo ratings yet

- Track Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part15Document6 pagesTrack Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part15linghuchongNo ratings yet

- Planar Linkage Synthesis: A modern CAD based approachFrom EverandPlanar Linkage Synthesis: A modern CAD based approachNo ratings yet

- Build Your Own Garage Manual: More Than 175 PlansFrom EverandBuild Your Own Garage Manual: More Than 175 PlansRating: 4 out of 5 stars4/5 (2)

- NX 9 for Beginners - Part 2 (Extrude and Revolve Features, Placed Features, and Patterned Geometry)From EverandNX 9 for Beginners - Part 2 (Extrude and Revolve Features, Placed Features, and Patterned Geometry)No ratings yet

- Accessing Regional Settings and Language Details in MapInfo Pro v2019 - MapInfo ProDocument7 pagesAccessing Regional Settings and Language Details in MapInfo Pro v2019 - MapInfo ProRoberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers13 13Document1 page348714276-Openroads-Manual-for-Designers13 13Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers15 15Document1 page348714276-Openroads-Manual-for-Designers15 15Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers16 16Document1 page348714276-Openroads-Manual-for-Designers16 16Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers14 14Document1 page348714276-Openroads-Manual-for-Designers14 14Roberto JoaquinNo ratings yet

- Openroads Manual For Designers3 3Document1 pageOpenroads Manual For Designers3 3Roberto JoaquinNo ratings yet

- Openroads Manual For Designers1 1Document1 pageOpenroads Manual For Designers1 1Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers4 4Document1 page348714276-Openroads-Manual-for-Designers4 4Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers5 5Document1 page348714276-Openroads-Manual-for-Designers5 5Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers2 2Document1 page348714276-Openroads-Manual-for-Designers2 2Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers8 8Document1 page348714276-Openroads-Manual-for-Designers8 8Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers6 6Document1 page348714276-Openroads-Manual-for-Designers6 6Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers7 7Document1 page348714276-Openroads-Manual-for-Designers7 7Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers9 9Document1 page348714276-Openroads-Manual-for-Designers9 9Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers11 11Document1 page348714276-Openroads-Manual-for-Designers11 11Roberto JoaquinNo ratings yet

- V8 - Softree Optimal (1) 80 80Document1 pageV8 - Softree Optimal (1) 80 80Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers10 10Document1 page348714276-Openroads-Manual-for-Designers10 10Roberto JoaquinNo ratings yet

- Openroads Manual For Designers3 3Document1 pageOpenroads Manual For Designers3 3Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers12 12Document1 page348714276-Openroads-Manual-for-Designers12 12Roberto JoaquinNo ratings yet

- 348714276-Openroads-Manual-for-Designers2 2Document1 page348714276-Openroads-Manual-for-Designers2 2Roberto JoaquinNo ratings yet

- Openroads Manual For Designers1 1Document1 pageOpenroads Manual For Designers1 1Roberto JoaquinNo ratings yet

- Chapter 10 - Civil 3D Export Corridor Plug-In: Figure 10-3: Increments and StationsDocument1 pageChapter 10 - Civil 3D Export Corridor Plug-In: Figure 10-3: Increments and StationsRoberto JoaquinNo ratings yet

- V8 - Softree Optimal (1) 78 78Document1 pageV8 - Softree Optimal (1) 78 78Roberto JoaquinNo ratings yet

- V8 - Softree Optimal (1) 84 84Document1 pageV8 - Softree Optimal (1) 84 84Roberto JoaquinNo ratings yet

- Understanding The .CSX File: Chapter 10 - Civil 3D Export Corridor Plug-InDocument1 pageUnderstanding The .CSX File: Chapter 10 - Civil 3D Export Corridor Plug-InRoberto JoaquinNo ratings yet

- Index: Civil 3D Export Corridor Plug-InDocument1 pageIndex: Civil 3D Export Corridor Plug-InRoberto JoaquinNo ratings yet

- V8 - Softree Optimal (1) 77 77Document1 pageV8 - Softree Optimal (1) 77 77Roberto JoaquinNo ratings yet

- V8 - Softree Optimal (1) 79 79Document1 pageV8 - Softree Optimal (1) 79 79Roberto JoaquinNo ratings yet

- Chapter 9 - Working With External Design Software: Figure 9-7: Landxml Options DialogueDocument1 pageChapter 9 - Working With External Design Software: Figure 9-7: Landxml Options DialogueRoberto JoaquinNo ratings yet

- Part 2: Importing Civil 3D Into Location: Chapter 9 - Working With External Design SoftwareDocument1 pagePart 2: Importing Civil 3D Into Location: Chapter 9 - Working With External Design SoftwareRoberto JoaquinNo ratings yet

- 2003 - QRS Detection Using Zero Crossing CountsDocument8 pages2003 - QRS Detection Using Zero Crossing CountsIrfan IrfanNo ratings yet

- Csi 5155 ML Project ReportDocument24 pagesCsi 5155 ML Project Report77Gorde Priyanka100% (1)

- Unit 6-Case Studies of Data ScienceDocument19 pagesUnit 6-Case Studies of Data Scienceshahidshaikh9936No ratings yet

- Further Pure Mathematics F3 Wfm03-01-Que-20230616Document32 pagesFurther Pure Mathematics F3 Wfm03-01-Que-20230616asafNo ratings yet

- Graph SamplingDocument16 pagesGraph SamplingOri RazNo ratings yet

- Algorithm Design: GCDDocument21 pagesAlgorithm Design: GCDUdtaParindaNo ratings yet

- Transshipment ProblemDocument3 pagesTransshipment ProblemIra Grace De CastroNo ratings yet

- Activity - CODINGDocument4 pagesActivity - CODINGLila MiclatNo ratings yet

- Automation & RoboticsDocument1 pageAutomation & RoboticsHarish HNo ratings yet

- Mscit (It) 1 Sem Paper - MS11 Computer Programming M.M. - 25Document6 pagesMscit (It) 1 Sem Paper - MS11 Computer Programming M.M. - 25Allho AllobeNo ratings yet

- Prak. Robotika Cerdas Tugas 2Document7 pagesPrak. Robotika Cerdas Tugas 2Rifqi Ramadhan0% (1)

- Assignment1 1Document3 pagesAssignment1 1ARUOS SouraNo ratings yet

- Topic: Warshall Algorithm, Floyd AlgorithmDocument10 pagesTopic: Warshall Algorithm, Floyd Algorithmnoob gamingNo ratings yet

- OR - 6 - Queuing Theory - EMBA-2020-22Document40 pagesOR - 6 - Queuing Theory - EMBA-2020-22Saba MullaNo ratings yet

- Comparing Clustering Algorithms Using Financial Time-Series DataDocument21 pagesComparing Clustering Algorithms Using Financial Time-Series Dataijsab.comNo ratings yet

- Frequency Response of LTI Systems: HapterDocument23 pagesFrequency Response of LTI Systems: HapterclaielloNo ratings yet

- Amstext 54.eDocument647 pagesAmstext 54.ePaul PerezNo ratings yet

- Motor Imagery Classification Via Temporal Attention Cues of Graph Embedded EEG SignalsDocument10 pagesMotor Imagery Classification Via Temporal Attention Cues of Graph Embedded EEG SignalsChrisilla SNo ratings yet

- 03 - K Means Clustering On Iris DatasetsDocument4 pages03 - K Means Clustering On Iris DatasetsJohn WickNo ratings yet

- ELM Workshop NUSDocument66 pagesELM Workshop NUSMurdoko RagilNo ratings yet

- Subtopic 1 - Overview of Time SeriesDocument30 pagesSubtopic 1 - Overview of Time SeriesKim VincereNo ratings yet

- Grafcet ECC95Document7 pagesGrafcet ECC95Valkure OmegaNo ratings yet

- Hightec Inc.Document10 pagesHightec Inc.anurag4u10No ratings yet

- Cyclic CodesDocument20 pagesCyclic Codesamit mahajan100% (7)

- Memory - Management - Exercises and SolutionDocument21 pagesMemory - Management - Exercises and Solutionkz33252000No ratings yet

- Analisis de Datos MITDocument340 pagesAnalisis de Datos MITAnonymous lIJl27QBXLNo ratings yet

- Econ 329 - Statistical Properties of The Ols Estimator: Sanjaya DesilvaDocument12 pagesEcon 329 - Statistical Properties of The Ols Estimator: Sanjaya DesilvaArchivo RCNo ratings yet

- Analysis Sports Obermeyer PDFDocument16 pagesAnalysis Sports Obermeyer PDFSinem DüdenNo ratings yet

- DAA - Unit IV - Greedy Technique - Lecture Slides PDFDocument50 pagesDAA - Unit IV - Greedy Technique - Lecture Slides PDFkennygoyalNo ratings yet

- Polynomial Time ReductionDocument17 pagesPolynomial Time Reductionendu wesenNo ratings yet