Professional Documents

Culture Documents

Aeroshell Grease 22: Main Applications Specifications, Approvals & Recommendations

Uploaded by

yierbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aeroshell Grease 22: Main Applications Specifications, Approvals & Recommendations

Uploaded by

yierbCopyright:

Available Formats

Technical Data Sheet

AeroShell Grease 22

AeroShell Grease 22 is a versatile advanced general purpose grease composed of a synthetic hydrocarbon oil

thickened with Microgel®, with outstanding performance characteristics. Appropriate additives are included to

achieve the necessary oxidation and corrosion resistance, anti-wear properties and load carrying properties.

The useful operating temperature range is –540C to +1770C.

Main Applications Specifications, Approvals & Recommendations

· AeroShell Grease 22 is especially recommended for use · MIL-PRF-81322G

wherever severe operating conditions are encountered as

· DOD-G-24508A

in high bearing loads, high speeds, wide operating

· DEF STAN 91-52 (British)

temperature range, and particularly where long grease

· COMAC QPL-CMS-OL-301

·

retention and high resistance to water washout are

required. DCSEA 395/A (French)

· The wide range of applications include aircraft wheel · Russian : Analogue of CIATIM 201 and 203, VNII NP 207,

ERA (VNII NP 286M) and ST (NK-50)

bearings, engine accessories, control systems, actuators,

screw-jacks, servo mechanisms and electric motors, · NATO Code G-395

helicopter rotor bearings, instruments, airframe lubrication,

hinge pins, static joints, landing gears.

· Joint Service Designation : XG-293

For a full listing of equipment approvals and

· AeroShell Grease 22 contains a synthetic hydrocarbon oil

and should not be used in contact with incompatible seal

recommendations, please consult your local Shell Technical

Helpdesk.

materials.

Typical Physical Characteristics

Properties Method MIL-PRF-81322G Typical

Oil type Synthetic Hydrocarbon

Thickener type Microgel

Colour Visual Amber

Base Oil viscosity @-40 C 0

mm /s 2 7 500

Base Oil viscosity @40 C0

mm /s 2 30.5

Base Oil viscosity @100 C 0

mm /s 2 5.7

Useful operating temperature 0

C -54 to +177

range

Dropping point 0

C ASTM D2265 232 min >300

Worked penetration @25 C0 ASTM D217 256 to 320 283

Bomb Oxidation pressure @99 C0

kPa ASTM D942 83 max 14

drop 100 hrs

Bomb Oxidation pressure @990C kPa ASTM D942 172 max 21

drop 500 hrs

Oil separation 30 hrs @1770C %m ASTM D6184 2.0 to 8.0 5.8

Water washout @41 C0

%m ASTM D1264 20 max 2.0

Evaporation loss (22 hrs) @177 C 0

%m ASTM D2595 10 max 1.1

Anti-friction bearing @177 C 0

hrs ASTM D3336 400 min >400

performance

Page 1 of 2 AeroShell Grease 22, v 1.5 28.01.2020.16.24

Properties Method MIL-PRF-81322G Typical

Load carrying capacity kg ASTM D2596 30min 40

Copper corrosion 24 hrs 0

@100 C ASTM D4048 Must pass Passes

FED-STD-791

5309

These characteristics are typical of current production. Whilst future production will conform to Shell's specification,

variations in these characteristics may occur.

Health, Safety & Environment

· Health and Safety

This product is unlikely to present any significant health or safety hazard when properly used in the recommended

application and good standards of personal hygiene are maintained.

Avoid contact with skin. Use impervious gloves with used oil. After skin contact, wash immediately with soap and water.

Guidance on Health and Safety is available on the appropriate Safety Data Sheet, which can be obtained from

https://www.epc.shell.com

· Protect the Environment

Take used oil to an authorised collection point. Do not discharge into drains, soil or water.

Additional Information

· Advice

Advice on applications not covered here may be obtained from your Shell representative.

Page 2 of 2 AeroShell Grease 22, v 1.5 28.01.2020.16.24

You might also like

- FT Grease 22Document2 pagesFT Grease 22Edgar Leonel CortésNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- AeroShell Grease 22Document2 pagesAeroShell Grease 22Anonymous oAbjbl4HNo ratings yet

- Aeroshell Fluid 31Document2 pagesAeroshell Fluid 31mertaktayNo ratings yet

- Aeroshell Grease 64: Main Applications Specifications, Approvals & RecommendationsDocument3 pagesAeroshell Grease 64: Main Applications Specifications, Approvals & RecommendationsNICKYNo ratings yet

- MDS SHELL Turbo Oil T68Document2 pagesMDS SHELL Turbo Oil T68Antonio CardosoNo ratings yet

- Shell Turbo Oil T 68Document2 pagesShell Turbo Oil T 68Muhammad SaputraNo ratings yet

- Shell GT32 1451468381Document2 pagesShell GT32 1451468381Pramod SokhariyaNo ratings yet

- Aeroshell Grease 64Document2 pagesAeroshell Grease 64S. MadaniNo ratings yet

- Aeroshell Grease 58: Main ApplicationsDocument2 pagesAeroshell Grease 58: Main ApplicationsSophia RoseNo ratings yet

- Grasa AeroShell 5Document2 pagesGrasa AeroShell 5epesanoNo ratings yet

- Gpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsDocument2 pagesGpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsBar AvaitNo ratings yet

- Shell Turbo Oil T32: Performance, Features & BenefitsDocument2 pagesShell Turbo Oil T32: Performance, Features & BenefitsCertified Rabbits LoverNo ratings yet

- Shell Turbo T 68Document2 pagesShell Turbo T 68Eid EeidNo ratings yet

- Shell Gadus S3 V220C 2: Performance, Features & BenefitsDocument2 pagesShell Gadus S3 V220C 2: Performance, Features & BenefitsDaniel PrecupNo ratings yet

- Mobilgrease 28Document2 pagesMobilgrease 28Jeef100% (1)

- Shell Gadus S3 V220C 2Document2 pagesShell Gadus S3 V220C 2Xavier DiazNo ratings yet

- Shell Gadus S3 V220 C2Document2 pagesShell Gadus S3 V220 C2regisNo ratings yet

- TDS - Shell Gadus S3 V220C 2 - ENDocument2 pagesTDS - Shell Gadus S3 V220C 2 - ENdtcuongNo ratings yet

- Shell Turbo Oil T32: Performance, Features & BenefitsDocument2 pagesShell Turbo Oil T32: Performance, Features & BenefitsHANIF AKBARNo ratings yet

- Shell Turbo Oil T32: Performance, Features & BenefitsDocument2 pagesShell Turbo Oil T32: Performance, Features & BenefitsElias GabrielNo ratings yet

- Shell Turbo Oil T 32Document2 pagesShell Turbo Oil T 32Muhammad SaputraNo ratings yet

- Gengear Series SPL-A Up To 320Document3 pagesGengear Series SPL-A Up To 320Hakim AmmorNo ratings yet

- Shell Turbo T32: Performance, Features & Benefits Main ApplicationsDocument3 pagesShell Turbo T32: Performance, Features & Benefits Main ApplicationsPandu SatrioNo ratings yet

- Shell Turbo T 32 PDFDocument2 pagesShell Turbo T 32 PDFaqas_khanNo ratings yet

- Shell Turbo Oil T46: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Turbo Oil T46: Performance, Features & Benefits Main ApplicationsMOHAMED GamalNo ratings yet

- GPCDOC Local TDS Pakistan Shell Turbo Oil T 46 (ur-PK) TDS PDFDocument2 pagesGPCDOC Local TDS Pakistan Shell Turbo Oil T 46 (ur-PK) TDS PDFSefa yıldızNo ratings yet

- Aeroshell Fluid 3Document2 pagesAeroshell Fluid 3mertaktayNo ratings yet

- Shell Spirax S5 DCT 11: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Spirax S5 DCT 11: Performance, Features & Benefits Main ApplicationsFernando Yupa SalazarNo ratings yet

- Gpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) TdsDocument3 pagesGpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) Tds100impianNo ratings yet

- Repsol Maker Hydroflux EP 32,46,68Document1 pageRepsol Maker Hydroflux EP 32,46,68ibrahim maulanaNo ratings yet

- Nyco Grease GN 22 Air4222Document1 pageNyco Grease GN 22 Air4222muhammad_andinovaNo ratings yet

- Gadus S3 V 220 C 2Document2 pagesGadus S3 V 220 C 2AMITNo ratings yet

- Shell Turbo Oil T 32 TDSDocument2 pagesShell Turbo Oil T 32 TDSBahim BahimanNo ratings yet

- GT 32 - High Performance Industrial Gas Turbine LubricantDocument2 pagesGT 32 - High Performance Industrial Gas Turbine LubricantRaden ArdyNo ratings yet

- TDS Gadus S5 V220 2Document2 pagesTDS Gadus S5 V220 2Nokiabhre WijayaNo ratings yet

- Techinical Data-Proton X70 DCT FluidDocument2 pagesTechinical Data-Proton X70 DCT Fluidjasonccw.pqholdingsNo ratings yet

- Repsol Telex E 46,68Document2 pagesRepsol Telex E 46,68ibrahim maulanaNo ratings yet

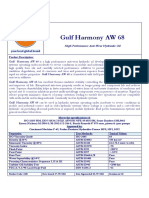

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 DataHitesh MahajanNo ratings yet

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 Datakatty_89No ratings yet

- Helix Ultra Professional AG 5W-30 (Dexos 2)Document2 pagesHelix Ultra Professional AG 5W-30 (Dexos 2)rstec pyNo ratings yet

- Aircol SR 68Document2 pagesAircol SR 68nauta007No ratings yet

- TDS - Shell Gadus S3 V220C 3 - ENDocument2 pagesTDS - Shell Gadus S3 V220C 3 - ENdtcuongNo ratings yet

- Shell Turbo: Premium Based Industrial Steam, Gas and Combined Cycle Turbine LubricantDocument2 pagesShell Turbo: Premium Based Industrial Steam, Gas and Combined Cycle Turbine Lubricantfaisalnadim100% (1)

- Turbo Oil T 46Document2 pagesTurbo Oil T 46Parthiban SowndararajanNo ratings yet

- Gadus S2 V 100 3Document2 pagesGadus S2 V 100 3Anonymous ABPUPbKNo ratings yet

- Shell Turbo Oil T46: Performance, Features & Benefits Main ApplicationsDocument4 pagesShell Turbo Oil T46: Performance, Features & Benefits Main Applicationshaider100% (1)

- Shell Turbo T 46Document2 pagesShell Turbo T 46Salem IereebiNo ratings yet

- Shell Turbo Oil T 46Document2 pagesShell Turbo Oil T 46Muhammad SaputraNo ratings yet

- Perfecto T RangeDocument2 pagesPerfecto T RangecarmaNo ratings yet

- Gpcdoc Gtds Shell Gadus s3 v460xd 2 (En) TdsDocument2 pagesGpcdoc Gtds Shell Gadus s3 v460xd 2 (En) TdsRoger ObregonNo ratings yet

- EfekDocument2 pagesEfekGasa RafliNo ratings yet

- BP Energrease LSDocument2 pagesBP Energrease LSsaddamNo ratings yet

- UAE Shell Turbo Oil T 46Document3 pagesUAE Shell Turbo Oil T 46diego lizaldes valarezoNo ratings yet

- GPCDOC Local TDS United Kingdom AeroShell Grease 14 (en-GB) TDSDocument2 pagesGPCDOC Local TDS United Kingdom AeroShell Grease 14 (en-GB) TDSTaher HriziNo ratings yet

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SNo ratings yet

- Shell Helix Ultra SN 0W-20: Performance, Features & BenefitsDocument2 pagesShell Helix Ultra SN 0W-20: Performance, Features & BenefitsCristiBvNo ratings yet

- Repsol Telex HVLP 32Document2 pagesRepsol Telex HVLP 32ibrahim maulanaNo ratings yet

- Tax Deduction at Source (TDS)Document15 pagesTax Deduction at Source (TDS)yierbNo ratings yet

- Details of TDS AOs As Reffered To in CBDTscribd5Document24 pagesDetails of TDS AOs As Reffered To in CBDTscribd5yierbNo ratings yet

- Mobilux™ EP 0, 1, 2, 3, 004 and 023: GreaseDocument2 pagesMobilux™ EP 0, 1, 2, 3, 004 and 023: GreaseyierbNo ratings yet

- What Is TDS?: Usage Instructions Temperature Conversion ChartDocument2 pagesWhat Is TDS?: Usage Instructions Temperature Conversion ChartyierbNo ratings yet

- CTT Pot BearingsDocument16 pagesCTT Pot Bearingslabsot100% (1)

- Katalog 2022 EngDocument232 pagesKatalog 2022 EngtechniciandpaNo ratings yet

- Still FM14, 17 y 20 Tipo429 (Ingles 09-1997) PDFDocument207 pagesStill FM14, 17 y 20 Tipo429 (Ingles 09-1997) PDFJuan Carlos Rubio Fresco50% (4)

- Scrambler 800Document873 pagesScrambler 800Fmracing OfficinamotoNo ratings yet

- Manuals For Lifeboat SystemsDocument31 pagesManuals For Lifeboat SystemsH_CrisostomoNo ratings yet

- Molykote AerossoisDocument6 pagesMolykote AerossoisMarcos Tati CunhaNo ratings yet

- 21st Lubricating Grease Conference BrochureDocument11 pages21st Lubricating Grease Conference Brochuremaheshgir5844No ratings yet

- ALIA Manual AUT8500A Thickness GaugeDocument12 pagesALIA Manual AUT8500A Thickness GaugeRexCrazyMindNo ratings yet

- TeboilDocument40 pagesTeboilAmjedNo ratings yet

- Lube Order 1987 - 45Document6 pagesLube Order 1987 - 45Surya IntlNo ratings yet

- Demolition Hammer: GSH 11 E - 3 611 C16 8K0Document8 pagesDemolition Hammer: GSH 11 E - 3 611 C16 8K0sanjoy PaulNo ratings yet

- TUCSON (JM) 2008 G 2.7 DOHC Clutch SystemDocument20 pagesTUCSON (JM) 2008 G 2.7 DOHC Clutch Systemrobin machadoNo ratings yet

- Tds CA 1000 Mastinox PPGDocument2 pagesTds CA 1000 Mastinox PPGAstari Putri NuarisaNo ratings yet

- Shell Gadus Product Family BrochureDocument6 pagesShell Gadus Product Family BrochurefahreezNo ratings yet

- Aral Industrial LubricantsDocument55 pagesAral Industrial LubricantsAnonymous oAbjbl4H100% (1)

- Klübersynth UH1 64-62 EN enDocument2 pagesKlübersynth UH1 64-62 EN enKamila AriasNo ratings yet

- Catalogue: Products For Oil&gas IndustryDocument39 pagesCatalogue: Products For Oil&gas Industryfarid said errahmaniNo ratings yet

- D3276 15 115 1 Standard GuidDocument14 pagesD3276 15 115 1 Standard GuidDavid SalgueroNo ratings yet

- Ac Dur Sba G PDFDocument2 pagesAc Dur Sba G PDFbhagwatpatilNo ratings yet

- Katalog Podshipnikovye Uzly LINK BELTDocument508 pagesKatalog Podshipnikovye Uzly LINK BELTYan D PutraNo ratings yet

- NM-238 GBDocument27 pagesNM-238 GBShania GintingNo ratings yet

- Atlas Copco Breakers1-1Document4 pagesAtlas Copco Breakers1-1theunauthorisedNo ratings yet

- Maintenance For Progressive Cavity Pump PDFDocument120 pagesMaintenance For Progressive Cavity Pump PDFmtfrvtNo ratings yet

- Bada Heavy Industries Co., LTDDocument50 pagesBada Heavy Industries Co., LTDCleverson SchmidtNo ratings yet

- 2018 Club Cadet Challenger 750 ManualDocument255 pages2018 Club Cadet Challenger 750 ManualKrista CvarNo ratings yet

- Volvo Ew 160BDocument60 pagesVolvo Ew 160BApexiNo ratings yet

- Shell Alvania Grease HDX 2: High Perfomrance Heavy Duty Grease Containing Solid LubricantsDocument2 pagesShell Alvania Grease HDX 2: High Perfomrance Heavy Duty Grease Containing Solid LubricantsJoko SusiloNo ratings yet

- ThesisDocument82 pagesThesisJango69No ratings yet

- 04 BRCE 2017 Jens Kammann Bearing Maintenance and The Right ToolsDocument36 pages04 BRCE 2017 Jens Kammann Bearing Maintenance and The Right ToolsHojaAmarillaNo ratings yet

- Mahula de PeçasDocument411 pagesMahula de PeçasRUBSONMOTANo ratings yet

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- The Engineer's Guide to Plant Layout and Piping Design for the Oil and Gas IndustriesFrom EverandThe Engineer's Guide to Plant Layout and Piping Design for the Oil and Gas IndustriesRating: 4 out of 5 stars4/5 (16)

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationFrom EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationRating: 4.5 out of 5 stars4.5/5 (2)

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbFrom EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Offshore Projects and Engineering ManagementFrom EverandOffshore Projects and Engineering ManagementRating: 5 out of 5 stars5/5 (2)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Oil: An Overview of the Petroleum IndustryFrom EverandOil: An Overview of the Petroleum IndustryRating: 4.5 out of 5 stars4.5/5 (3)

- Reservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesFrom EverandReservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesRating: 5 out of 5 stars5/5 (7)

- Deepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticeFrom EverandDeepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticeNo ratings yet

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Ship and Mobile Offshore Unit Automation: A Practical GuideFrom EverandShip and Mobile Offshore Unit Automation: A Practical GuideNo ratings yet

- The Offshore Pipeline Construction Industry: Activity Modeling and Cost Estimation in the U.S Gulf of MexicoFrom EverandThe Offshore Pipeline Construction Industry: Activity Modeling and Cost Estimation in the U.S Gulf of MexicoNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Practical Engineering Management of Offshore Oil and Gas PlatformsFrom EverandPractical Engineering Management of Offshore Oil and Gas PlatformsRating: 4 out of 5 stars4/5 (7)