Professional Documents

Culture Documents

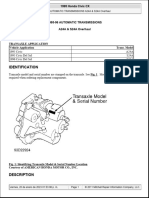

Asian Warner 55-50SN Seminar General Description

Uploaded by

Tawatchai BoonpermOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asian Warner 55-50SN Seminar General Description

Uploaded by

Tawatchai BoonpermCopyright:

Available Formats

Focus Technology Ltd 2003

Asian Warner 55-50SN Seminar

General Description

This transmission is manufactured by

Asian Warner. It can be found in many There is a four element torque converter

different vehicles such as General in this transmission. In incorporates a,

Motors, Volvo, Saab, Renault and Fiat. Pump. b, Turbine. c, pressure plate

Although it looks the same, there are which is located by the spline on the

subtle differences. We will look at some shaft of the turbine, and d, the stator

of them later but it is important to note assembly.

that not all parts are interchangeable.

The TCM (Transmission Control

The 55-50SN is also referred to as the Module) commands the solenoids to

AF23/33-5 transmission by some obtain the required ratio. It also controls

manufacturers such as GM. the line pressure and the apply and

release pressure for the torque converter

This transmission incorporates the final clutch. The input signals from the

drive unit and therefore it is known as a sensors act to feed information to the

Transaxle. It is a fully operational TCM so that it can obtain the best ratio

automatic transmission which has five to give maximum fuel efficiency.

forward gears and is electronically

Controlled.

Copyright Focus Technology Ltd 1

Focus Technology Ltd 2003

The park neutral switch is of a

General Description continued sliding contact type that is

connected directly to the manual

The hydraulic system follows the shift lever. It is fitted externally on

normal transmission requirements the transmission and it is

utilizing a pump along with the adjustable There are four positions

valve body case cover and in the switch that inform the TCM

converter housing. The pump which position the gear lever is in.

produces a variable pressure The information is used for control

dependent on engine speed. This is of the engines as well as the

then regulated to produce the transmission. If you are using a

working pressure. This pressure scanner, you will see the positions

works to apply the servo and displayed as Modes, A, B C and

pistons that apply and release the PA. The switches on each vehicle

friction components. look the same but are not. Make

sure that you have the correct on

Model Differences fitted.

As we have seen, this transmission

is fitted to vehicles of many

different manufacturers. Although

there are similarities with this

transmission, it should be noted

that there are distinct operational

differences. He control strategy for

solenoid operation varies from

manufacturer to manufacturer.

Even when a valve body looks the

same, it differs considerable so be

careful when changing parts that

you do not introduce a fault that

you will never fix.

A close study of the component

and solenoid application will show

that there is distinct differences.

Park, Neutral position switch

Copyright Focus Technology Ltd 2

Focus Technology Ltd 2003

range for this feature to be active.

Neutral control The gas pedal must not be

depressed as the accelerator pedal

Volvo vehicles using the 5 module (APM) will tell the PCM

cylinder engine since 2001 have a that the vehicle should be moving.

neutral control circuit fitted to

reduce emissions and fuel Re-engagement of first gear is

consumption. The TCM will done as the brake pedal sensor

operate the appropriate solenoids indicates that the brake is no

to place the transmission in neutral longer depressed.

when the car is standing with the

brakes applied in the “D” position.

Transmission fluid temperature

must be in the normal operating

Copyright Focus Technology Ltd 3

Focus Technology Ltd 2003

AW 55-50 SN with Modulated lock-up

This transmission is an electronically controlled five speed automatic

transmission. In Volvo it is fitted to the X70 series. It is derived from the

AW 50-42 transmission with the following differences.

• A fourth planetary gear. (P4)

• Free wheel F3 has been eliminated

• The TCC has a slip strategy

• A fifth brake (B5) has been added

• Four more solenoids

• Four small differential pinions in the final drive

• Accumulators have been removed

Copyright Focus Technology Ltd 4

Focus Technology Ltd 2003

Gear changes

The gear changes and lock up functions are controlled by the activation of

the solenoids as described in the patterns later. Be sure to remember that the

valve bodies are not interchangeable between models as the shift patterns

differ.

There are two change patterns available: Normal and Winter modes

In normal mode, shifts and lock-up take place relatively early to improve

fuel consumption. If the throttle is moved rapidly, the TCM will engage a

SPORT mode.

In the winter mode, the changes will be at lower engine speeds. 1st and 2nd

gear will also be available for kick down.

Selector position D,4,3….. The car will start off in 3rd gear

Selector position L………..The car will start off in 2nd gear.

Engine braking will be available in “L” by application of the B3 brake

Copyright Focus Technology Ltd 5

Focus Technology Ltd 2003

Copyright Focus Technology Ltd 6

Focus Technology Ltd 2003

AW 55-50SN 23/33.5

Copyright Focus Technology Ltd 7

Focus Technology Ltd 2003

Volvo

Solenoid and component application chart

Range Gear S1 S2 S3 S4 S5 C1 C2 C3 B1 B2 B3 B4 B5

Park P Off Off Off Off Off On

Reverse R Off Off On Off On On On On

Neutral N Off Off Off Off Off On

Drive 1 On On On Off Off On On

2 Off Off On Off Off On On On On

3 Off Off On On Off On On On On

4 Off Off Off On Off On On On On

5 Off On Off On Off On On On On

Limp

Mode Off Off Off Off Off On On On On

Copyright Focus Technology Ltd 8

Focus Technology Ltd 2003

GM Vauxhall

Solenoid and component application chart

Range Gear S1 S2 S3 S4 S5 C1 C2 C3 B1 B2 B3 B4 B5

Park P Off Off Off Off Off On

Reverse R Off Off On Off On On On On

Neutral N Off Off Off Off Off On

Drive 1 On Off On Off Off On On

2 Off On On Off Off On On On On

3 Off On On On Off On On On On

4 Off On Off On Off On On On On

5 Off Off Off On Off On On On On

Limp

Mode Off Off Off Off Off On On On On

You will note that the solenoid solenoids Named. a, SLT, b, SLU

shift pattern for these two and c, SLS. These solenoids are

transmissions is completely linear solenoids and work at

different although it will be seen variable states dependent on the

that the clutch and brake gear and load required from the

components remain the same. It is transmission.

therefore obvious that fitting the

wrong valve body will cause the

transmission to behave incorrectly.

As well as the five shift solenoids

S1 through to S5, this

transmissions also have three other

Copyright Focus Technology Ltd 9

Focus Technology Ltd 2003

Solenoid resistances are as change of speed of the

follows:- transmission input shaft during the

shifting process and comparing the

S1 to S5. 11 to 16 ohms values calculated in the TCM.

SLT, SLU and SLS are 5 – 5.6 Two shifting patterns can be

ohms. All readings are at 20C. commanded, Normal driving and

Winter mode. This is done by the

S1, S2 and S4 are normally Closed driver using a select switch or

solenoids button by the gear select lever.

S3 and S5 solenoids are normally In normal mode, shifting and lock-

open. up occur at a relatively low speed

to reduce fuel consumption. In the

The SL solenoids are run at 300 event of rapid accelerator

hz. movements, the TCM

automatically changes to a third,

Control of the solenoids sport mode.

The shift and lock-up function is SL solenoid function

controlled by activating the

solenoids in a specific pattern SLT

according to the manufacturer. The

solenoids S1 through to S5 This is the line pressure solenoid.

determine which gear is to be It is a normally open three port

selected and the SLS, SLU and type solenoid. The TCM controls

ALT solenoids determine the this transmission using 300 hz

engagement by adjusting the commanding current fro 0.0 to 1,1

hydraulic pressure. The basic amps. The TCM uses current

parameters for the different shift measurement to determine

point are the accelerator pedal and pressure.

the vehicle speed. The shift quality In the event of a serious electronic

is decided by the control of torque failure the solenoid is designed to

through the transmission. give maximum line pressure. A

DTC of P0962 or P0963 will be

Pressurization of the clutches and stored in the TCM memory.

brakes are adjusted by reading the

Copyright Focus Technology Ltd 10

Focus Technology Ltd 2003

feed to it and due to variants of

resistance caused by temperature,

SLS it feeds a variable voltage back to

the TCM. When the oil

This solenoid is the shift pressure temperature is cold, a high

solenoid. It is similar to the SLT resistance is evident. As the oil

solenoid in that it is a three way heats up the resistance lowers. The

ported solenoid and runs at the TCM uses this resistance to

same frequency and current calculate the oil temperature in the

characteristics. It is used to buffer transmission. This signal is used

the shift and is adjusted dependent by the TCM to modify the shift

on load requirements and driving quality and the TCC operation.

conditions.

In the event of an electronic failure

a DTC 0970 or 0971 will be stored Temperature in C Ohms reading

in the TCM memory. -40 77,480

-30 44,000

-20 25,880

SLU -10 15,730

0 9,846

The SLU solenoid is the Torque 10 6,445

converter lock-up pressure control 20 4,184

30 2,829

solenoid. It is similar to the other 40 1,955

two SL solenoids listed above 50 1,379

except that it is a normally closed 60 992

solenoid. 70 726

80 541

90 409

In the event of an electronic failure 100 314

a DTC of P0966 or P0967 will be 110 247

120 192

stored in the TCM memory.

130 153

140 124

TFT 150 101

The transmission fluid temperature

sensor is an integral part of the

transaxle internal wire harness

assembly The TFT is a NTC

thermister which changes its value

based on the transmission oil

temperature. The TFT has 5 volts

Copyright Focus Technology Ltd 11

Focus Technology Ltd 2003

Output shaft speed sensor.

The input and output shaft speed

The output shaft speed sensor is a sensors should give a reading of

Hall effect sensor. Hall effect > than 10 M ohms at 20 C. (68 F).

sensors usually have three wires

but in this case, the sensor only has

two wires. The sensor is mounted

in the case by the park gear by the

front differential transfer gear

assembly. The sensor is supplied

with 0.6 volts to activate it. As the

vehicle moves the toothed gear

passes the sensor and produces a

square wave or frequency. The

TCM uses this signal to calculate

the vehicle road speed.

Input shaft speed sensor.

The input shaft speed sensor is of

the same construction as the

Output shaft speed sensor.

The reluctor for this sensor is the

teeth on the forward / direct clutch

housing. The output from this

sensor is used by the TCM to

adjust and determine transaxle

shift patterns, line pressure TCC

apply pressure and gear ratios. It is

also used to determine TCC

slippage.

Copyright Focus Technology Ltd 12

Focus Technology Ltd 2003

Pressure relief valve the forward clutch oil circuit to

control the apply pressure to the

The pressure relief valve and forward clutch.

spring prevent the line pressure

from exceeding 360 psi. (2520 A stuck forward clutch valve would

kPa). Higher pressure moves the cause harsh engagement from

valve against the spring opening neutral to drive.

and exhaust.

Neutral relay valve.

A stuck valve or broken spring

would cause high or low line The neutral relay valve acts on the

pressure. neutral relay valve spring force.

The 1st SS valve state, the neutral

Solenoid modulator valve relay valve controls the route of

fluid into the forward clutch

The line pressure solenoid valve circuit.

(SLT), the shift pressure control A stuck neutral relay valve cause

solenoid valve (SLS) and the no drive or serious slip conditions.

torque converter lock up valve

solenoid (SLU) are only able to Cooler by-pass valve.

work with a given pressure.

Pressure that exceeds this will The cooler by-pass valve and

overload the valve causing spring prevent the cooler and lube

damage. The modulator valve pressure from exceeding 30 psi

spring produces the force to (210 kPa).

regulate the pressure. The pressure

should equal line pressure. A stuck cooler by-pass valve or

damaged spring could cause high

If the valve is stuck in the exhaust cooler and lube pressure.

position, it would result in the

transmission having only 5th gear TCC check valve

and low line pressure.

The TCC check valve and spring is

Forward clutch control valve. to prevent the cooler fluid

reversing directional flow.

The forward clutch control valve

responds directly to throttle signal. A stuck TCC check valve or

Depending on the gear selected, damaged spring would cause

the valve regulates drive fluid onto incorrect TCC operation.

Copyright Focus Technology Ltd 13

Focus Technology Ltd 2003

Volvo Tech notes

Model & year:- 2001 S60, V70, V70 XC

Subject:- Adaptation procedure

Description: This transmission relies on adaptive data to properly adjust the

shift pressure. If the adaptation is not complete, it may result in one or more

of the following:

• Harsh flare. Engine RPM will increase during a shift. This symptom

feel like the transmission has lost drive. It usually happens during the

2-3 shift.

• Harsh down shift. Bumpy down shift when the gas pedal is odd

(Zero).

• Harsh Garage shift. Sever bump when engaging forward or reverse

from park or neutral.

• Harsh engagement control. After coming to a complete stop in

drive, with the foot on the brake, the TCM waits for 2 seconds and

then disengages drive to reduce emissions. This disengagement is not

usually felt by the driver. If adaptation is not complete, then a “thud”

will be felt. A harsh re-engagement will also be felt.

Service. The TCM can sometimes take many miles to fully adapt. If you

do not have access to the factory tester or Volvo VADIS, then you

might try the following.

1. Drive the car forward in the “D” range at about 5 mph (8kph) and

bring to a gentle stop. Repeat this procedure at least 10 times.

2. With the engine at idle and your foot on the brake, shift from “N” to

“D”. Wait for about 30 seconds. Release the brake. Repeat this

procedure for 10 cycles.

If the above does not cure the fault, you will need to get access to a

factory tester to reset the adaptation. Remember though that the TCM is

constantly updating so not every shift will be the same.

Copyright Focus Technology Ltd 14

Focus Technology Ltd 2003

Model and Year: S60, V70, V70 XC

Subject: Harsh or delayed P<R<or N to D shift

This complaint is caused by a faulty valve body and, or solenoids. The

factory recommend that you replacethe valve body and down load the

new software number 30646691.

The two “O” rings and the suction cover gasket (Sealing kit # 274470)

must be replaced as part of the repair. The SLT and SLS solenoids have

been rotated 180 degrees on all new valve bodies. The S1 solenoid has

also been rotated to accommodate the change. The new solenoids and

bracket are available from your parts supplier and should get you out of

trouble without the need to purchase a new valve body.

If youdo this modification you will need to fit a new internal wiring

harness which is included in the kit.

Copyright Focus Technology Ltd 15

You might also like

- AW55-51 Troubleshooting LowDocument7 pagesAW55-51 Troubleshooting Lowalexcus1539100% (1)

- GM 4T65 e - VBL PDFDocument1 pageGM 4T65 e - VBL PDFanzorNo ratings yet

- Building a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendFrom EverandBuilding a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendNo ratings yet

- BTRDocument100 pagesBTRBartłomiej Kilian100% (1)

- Accord SE 2002 2.3LDocument338 pagesAccord SE 2002 2.3LJuan BaezNo ratings yet

- Oversized 3/5/reverse & Underdrive Pressure Control Valve KitDocument2 pagesOversized 3/5/reverse & Underdrive Pressure Control Valve KithidraulicNo ratings yet

- 41TE Accumulator PositionDocument10 pages41TE Accumulator PositionLula MarquesNo ratings yet

- Hydra-matic transmission overviewDocument56 pagesHydra-matic transmission overviewmihai_1957100% (1)

- Aw80-41le 2013Document2 pagesAw80-41le 2013Jeremi Jose Salero0% (1)

- Hydra-Matic Transmission Components 1956Document55 pagesHydra-Matic Transmission Components 1956stansracing100% (2)

- Introduction: An Automatic Gear Change Device Includes A FirstDocument65 pagesIntroduction: An Automatic Gear Change Device Includes A FirstGarg AgamNo ratings yet

- G1190bev11 353 PDFDocument33 pagesG1190bev11 353 PDFRogérioFreitasNo ratings yet

- SK Aw55 50 InstructionsDocument2 pagesSK Aw55 50 InstructionsAndrea Gutiérrez VidalNo ratings yet

- 2015 Ford Escape Specs ComparisonDocument1 page2015 Ford Escape Specs ComparisontouchvikrantNo ratings yet

- A760E F H VBL InteractiveDocument1 pageA760E F H VBL InteractivehaddadiNo ratings yet

- Technical Bulletin Listing: Transmission # # Pages SubjectDocument17 pagesTechnical Bulletin Listing: Transmission # # Pages SubjectAleNo ratings yet

- Dodge JourneyDocument387 pagesDodge Journeycesar alejandro scavoNo ratings yet

- Transmission SheetDocument2 pagesTransmission SheetДима ШамаевNo ratings yet

- 5HP30 CatalogDocument49 pages5HP30 Catalogferber107eNo ratings yet

- Service BulletinDocument17 pagesService BulletinСергій БоженкоNo ratings yet

- Clutchcontrolvalve PDFDocument1 pageClutchcontrolvalve PDFnoe dela vegaNo ratings yet

- MC 10171108 0001Document53 pagesMC 10171108 0001komputer domino100% (1)

- JF 404 eDocument4 pagesJF 404 evaskaserv100% (2)

- 5 HP 30Document104 pages5 HP 30RaulNo ratings yet

- Mercedes 722.5 AutoDocument2 pagesMercedes 722.5 Autocorie132100% (1)

- Aisin AW55-50SN ASTG Technical Information 07-26Document5 pagesAisin AW55-50SN ASTG Technical Information 07-26pmsgaspar100% (3)

- 521Document270 pages521ccbulgariaNo ratings yet

- A24a S24aDocument79 pagesA24a S24aluisridik3No ratings yet

- Sony SA-WM500 Subwoffer Activo Manual de ServicioDocument12 pagesSony SA-WM500 Subwoffer Activo Manual de Serviciodocetallico100% (1)

- 00 01 PDFDocument2 pages00 01 PDFКонстантин МалетинNo ratings yet

- Hf2av TransferDocument15 pagesHf2av TransferПавел КрыловNo ratings yet

- Overhauling The Studebaker Flightomatic GearboxDocument41 pagesOverhauling The Studebaker Flightomatic Gearboxbaccara150% (2)

- GEARBOX MANUAL AND OPERATIONDocument48 pagesGEARBOX MANUAL AND OPERATIONYarg NitramNo ratings yet

- Technical Service Information: Automatic Transmission Service GroupDocument9 pagesTechnical Service Information: Automatic Transmission Service GroupMario MastronardiNo ratings yet

- Wiring Diagram New Gen 500Document202 pagesWiring Diagram New Gen 500Ifan saputroNo ratings yet

- 5R110W Assembly PDFDocument16 pages5R110W Assembly PDFLuis VelazquezNo ratings yet

- Bw55 To Aw70 ConversionDocument17 pagesBw55 To Aw70 ConversionjbouzaNo ratings yet

- VW-095 Transmission BreakdownDocument1 pageVW-095 Transmission BreakdownLeo BurnsNo ratings yet

- Aw 50-40Document3 pagesAw 50-40Syahlah Indira HafizahNo ratings yet

- G4a El FallasDocument8 pagesG4a El FallasLogam Lopez100% (1)

- 2005 Mazda 3Document8 pages2005 Mazda 3Josmar MartinezNo ratings yet

- 308-03b-I Manual Transaxle/Transmission - TR6060 308-03b-IDocument21 pages308-03b-I Manual Transaxle/Transmission - TR6060 308-03b-IdavidNo ratings yet

- zf5hp19 PDFDocument6 pageszf5hp19 PDFReinaldo De Oliveira SilvaNo ratings yet

- Jatco/Nissan JF016E, JF017E: (RE0F10D) (RE0F10E)Document1 pageJatco/Nissan JF016E, JF017E: (RE0F10D) (RE0F10E)ak_adamNo ratings yet

- Mitsubishi F5A-51, Hyundai A5HF1/3: 5 SPEED FWD With Lock Up (Electronic Control)Document5 pagesMitsubishi F5A-51, Hyundai A5HF1/3: 5 SPEED FWD With Lock Up (Electronic Control)Ibrain MoranNo ratings yet

- A340 Catalog PDFDocument8 pagesA340 Catalog PDFWojtek KrzywickiNo ratings yet

- C 3Document2 pagesC 3Santiago Montoya100% (1)

- Transmission NoteDocument6 pagesTransmission Notesyariza ismailNo ratings yet

- Bravo-A Service Manual Vol3 PDFDocument868 pagesBravo-A Service Manual Vol3 PDFtester testNo ratings yet

- 6L45 6L90 VacTestLocationsDocument4 pages6L45 6L90 VacTestLocationsbyungchul kimNo ratings yet

- Jatco/Nissan JF011E (RE0F10A) : Click On Part Numbers For Product Details or VisitDocument1 pageJatco/Nissan JF011E (RE0F10A) : Click On Part Numbers For Product Details or VisitNEIL OTALORANo ratings yet

- Re5f22a PDFDocument297 pagesRe5f22a PDFnetralka.byyandex.ruNo ratings yet

- 09D-TG AtsgDocument75 pages09D-TG AtsgValdir Gomiero100% (1)

- TF 60 SNDocument5 pagesTF 60 SNyermain100% (1)

- Aw55-50 SNDocument15 pagesAw55-50 SNactiongb1100% (3)

- 8L90 IntroductionDocument66 pages8L90 IntroductionBrandon100% (5)

- Nissan Skyline R32 Engine ManualDocument580 pagesNissan Skyline R32 Engine ManualEminence Imports100% (6)

- PDFDocument1,976 pagesPDFEmilio BravoNo ratings yet

- M111 CAM SENSOR REPLACEMENT (Mercedes)Document4 pagesM111 CAM SENSOR REPLACEMENT (Mercedes)Tawatchai BoonpermNo ratings yet

- Automatic Transmission Adaptive Value Reset ProcedureDocument4 pagesAutomatic Transmission Adaptive Value Reset ProcedureGALERİ MUTLU EFENo ratings yet

- 2000 System Wiring Diagrams Volkswagen - PassatDocument55 pages2000 System Wiring Diagrams Volkswagen - PassatEsther KoltermanNo ratings yet

- 1jz-Ge 2wdDocument3 pages1jz-Ge 2wdTawatchai BoonpermNo ratings yet

- S11 - V4 - KIA'S Success Story in IndiaDocument3 pagesS11 - V4 - KIA'S Success Story in IndiaAkshay ChaudhryNo ratings yet

- Build Your Own Hydrogen Generator to Run Your Car on Tap Water FreeDocument51 pagesBuild Your Own Hydrogen Generator to Run Your Car on Tap Water FreeHakim OmerkhailNo ratings yet

- Training Workshop 2020Document10 pagesTraining Workshop 2020Carrasco AngelsNo ratings yet

- Catalogue Xe NângDocument8 pagesCatalogue Xe NângHoàng Anh PhạmNo ratings yet

- Pump maintenance standard documentDocument4 pagesPump maintenance standard documentNaing Min HtunNo ratings yet

- 560 940kwe 64 120kwe: - Generator Capacity - Generator CapacityDocument1 page560 940kwe 64 120kwe: - Generator Capacity - Generator CapacityTonex X-friendNo ratings yet

- 5.07.0t XF Series IC ForkliftDocument6 pages5.07.0t XF Series IC ForkliftBliblibloNo ratings yet

- YafmsDocument3 pagesYafmsJuan AguinigaNo ratings yet

- Vag ToolDocument43 pagesVag ToolSebastian Damian0% (1)

- PDSDetail PageDocument4 pagesPDSDetail Pagemgamal1080No ratings yet

- Beaver enDocument8 pagesBeaver enkeesNo ratings yet

- Pick Up The Most Appropriate Statement of The Multiple-Choice Answers by Comment On The Correct AnswersDocument8 pagesPick Up The Most Appropriate Statement of The Multiple-Choice Answers by Comment On The Correct Answersأحمد إبراهيم شواربNo ratings yet

- Volvo D6D Shop ArmedDocument45 pagesVolvo D6D Shop ArmedBASILIO JARA HUERTA100% (4)

- FGW9 Weichai Genset 12M26 Series 60HZ 700 1000kwe LTPDocument5 pagesFGW9 Weichai Genset 12M26 Series 60HZ 700 1000kwe LTPeichermguptaNo ratings yet

- Demu 1600Document38 pagesDemu 1600Love Todkar100% (1)

- Dimax Inyectores 2Document4 pagesDimax Inyectores 2Karen Tapia garciaNo ratings yet

- PDF c201 Diesel CompressDocument67 pagesPDF c201 Diesel CompressjbarcelocamachoNo ratings yet

- ACHIEVEMENT CHART AutomotiveDocument2 pagesACHIEVEMENT CHART AutomotiveCharis AbadNo ratings yet

- Manual Servicio FZ-16 PDFDocument267 pagesManual Servicio FZ-16 PDFaxpel calzadoNo ratings yet

- S20200416 - Seminario Excavadora Hidráulica CAT 336 GC - Parte 1Document39 pagesS20200416 - Seminario Excavadora Hidráulica CAT 336 GC - Parte 1DannyNo ratings yet

- Marine Engine: IMO Tier LL Programme 3rd Edition 2010Document140 pagesMarine Engine: IMO Tier LL Programme 3rd Edition 2010Cah Ndeso Klutuk100% (1)

- Manual Partes PDFDocument180 pagesManual Partes PDFRoberto Juniior Mendoza DiazNo ratings yet

- FLC Contisys Obd Application List Ver13!0!0 enDocument45 pagesFLC Contisys Obd Application List Ver13!0!0 enSOLID ENGENHARIA & PROJETOSNo ratings yet

- Crude Oil Processing at Petrojam RefineryDocument3 pagesCrude Oil Processing at Petrojam RefineryfedemochileroNo ratings yet

- Mitsubishi 6A1 SERIESDocument83 pagesMitsubishi 6A1 SERIESGabriel PehlsNo ratings yet

- Ih - 454 474 475 574 674 2400 2500 Tractors - Manual - Sec - WatDocument135 pagesIh - 454 474 475 574 674 2400 2500 Tractors - Manual - Sec - WatbenborzashNo ratings yet

- 0service Bulletin List For 2Document2 pages0service Bulletin List For 2Tolias Egw100% (1)

- W A U K E S H A: 96 FORM 6302 First EditionDocument2 pagesW A U K E S H A: 96 FORM 6302 First Editiondiego yecid millan mendozaNo ratings yet

- Detroit PartsDocument2 pagesDetroit PartsMazhar HussainNo ratings yet

- Terex Demag All Terrain Cranes Spec f2347fDocument18 pagesTerex Demag All Terrain Cranes Spec f2347fAravindhan KNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Biogas Production: Pretreatment Methods in Anaerobic DigestionFrom EverandBiogas Production: Pretreatment Methods in Anaerobic DigestionNo ratings yet

- DIY Free Home Energy Solutions: How to Design and Build Your own Domestic Free Energy SolutionFrom EverandDIY Free Home Energy Solutions: How to Design and Build Your own Domestic Free Energy SolutionRating: 5 out of 5 stars5/5 (1)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksFrom EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNo ratings yet

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyFrom EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyRating: 5 out of 5 stars5/5 (3)

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AFrom EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ARating: 5 out of 5 stars5/5 (1)