Professional Documents

Culture Documents

US-JAPAN Research On Seismic Design

Uploaded by

vardhangargOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

US-JAPAN Research On Seismic Design

Uploaded by

vardhangargCopyright:

Available Formats

TECHNICAL NOTES

Overview of U.S.–Japan Research on the Seismic Design of

Composite Reinforced Concrete and Steel Moment Frame

Structures

Downloaded from ascelibrary.org by NIRMA INSTITUTE OF TECHNOLOGY on 02/04/17. Copyright ASCE. For personal use only; all rights reserved.

Gregory G. Deierlein, F.ASCE,1 and Hiroshi Noguchi, M.ASCE2

Abstract: Extensive research over the past 15 years has led to improved models and criteria for seismic design of composite steel–

concrete moment frames and their components. Much of this research has been conducted through the U.S.–Japan Cooperative Research

Program on Composite and Hybrid Structures. Research on reinforced concrete and steel moment frame structures includes 共a兲 tests and

analyses of over 50 composite beam–column connections, 共b兲 tests and analyses of two composite frames, and 共c兲 performance-based

seismic design and simulation studies of prototype composite frame buildings. These projects, together with prior research, demonstrate

that composite frames can be designed with seismic deformation capacity and toughness comparable to traditional steel or reinforced

concrete construction.

DOI: 10.1061/共ASCE兲0733-9445共2004兲130:2共361兲

CE Database subject headings: Composite structures; Framed structures; Steel construction; Concrete construction; Seismic design;

Research.

Introduction tion except that the steel columns are replaced by high strength

reinforced concrete with the incentive to reduce material cost

One of the four thrust areas of the U.S.–Japan Cooperative Re- 共Griffis 1992兲. Innovative construction sequencing and connec-

search Program on Composite and Hybrid Structures concerns the tion detailing add to the attractiveness of RCS construction. In

seismic design of moment frames consisting of reinforced con- Japan, RCS frames developed as an alternative to conventional

crete 共RC兲 columns and steel 共S兲 beams—the so-called composite reinforced concrete construction for low-rise office and retail

RCS frames. Composite RCS frames can provide cost-effective buildings 共Yamanouchi et al. 1998兲. Here, steel beams are utilized

alternatives to traditional steel or reinforced concrete framing sys- to permit long span floor framing and to minimize field labor,

tems, however, their use in high seismic regions has been hin- while still achieving the material cost savings provided by rein-

dered by a lack of comprehensive design criteria and experience forced concrete columns. Another contributing factor to RCS de-

with the systems. The coordinated U.S.–Japan research has velopment in Japan is the prevalence of another type of composite

helped to develop improved seismic design models and criteria construction called, steel reinforced concrete 共SRC兲, which be-

for RCS systems through a broad investigation involving 共1兲 tests came popular after SRC structures performed well in the 1923

and analyses of RCS beam–column connection subassemblies, Kanto earthquake. While both SRC and RCS combine structural

共2兲 tests and analyses of RCS moment frames, 共3兲 seismic design steel and reinforced concrete, there are significant differences in

studies and simulations of RCS building systems, and 共4兲 devel- the two methods, which are reflected in construction methods and

opment of design guidelines. design codes for the two systems. In SRC frames, steel beams and

In the United States, RCS moment frame construction was steel columns are both encased in concrete, essentially forming a

introduced during the late 1970’s and 1980’s as a variation of complete steel frame encased in a complete concrete frame,

conventional steel frames in mid- to high-rise buildings. These whereas in modern RCS construction bare steel beams act in se-

composite systems resemble conventional steel frame construc- ries with reinforced concrete columns.

1

Professor and Director, John A. Blume Earthquake Engineering

Center, Terman Engineering Building, Stanford Univ., Stanford, CA Connection Behavior and Design

94305-4020. E-mail: ggd@stanford.edu

2

Professor, Dept. of Architecture, Chiba Univ., Yayoi, Inage, Chiba In general, the design of steel beams and reinforced concrete col-

263-0022, Japan. E-mail: noguchi@archi.ta.chiba-u.ac.jp umns in RCS frames follows established practice for conventional

Note. Associate Editor: Joseph M. Bracci. Discussion open until July steel or reinforced concrete construction. Therefore, much of the

1, 2004. Separate discussions must be submitted for individual papers. To

research emphasis has been on the design and behavior of the

extend the closing date by one month, a written request must be filed with

the ASCE Managing Editor. The manuscript for this technical note was composite RCS beam–column connections, which pose unique

submitted for review and possible publication on September 24, 2002; challenges that are not addressed by traditional design standards.

approved on August 25, 2003. This technical note is part of the Journal During the 1980’s and early 1990’s, over 400 RCS connection

of Structural Engineering, Vol. 130, No. 2, February 1, 2004. ©ASCE, subassemblies were tested in Japan, and 36 were tested in the

ISSN 0733-9445/2004/2-361–367/$18.00. United States. Many of these early Japanese tests were of propri-

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / FEBRUARY 2004 / 361

J. Struct. Eng., 2004, 130(2): 361-367

Downloaded from ascelibrary.org by NIRMA INSTITUTE OF TECHNOLOGY on 02/04/17. Copyright ASCE. For personal use only; all rights reserved.

Fig. 1. Examples of reinforced concrete and steel beam–column connection details

etary details, which are interesting but of limited research value A summary of composite joint subassemblies, which were

since they were primarily intended as proof tests and were not tested through the U.S.–Japan program and prior National Sci-

designed to interrogate internal force transfer mechanisms in the ence Foundation supported research, is presented in Table 1. In-

joint. Through the U.S.–Japan Cooperative Research Program cluded are 63 tests of through-beam connections and 21 tests of

about 56 more connection subassemblies were tested to fill through-column connections. Among these, 12 tests were of

knowledge gaps for certain connection configurations and force– three-dimensional space–frame configurations, where beams

transfer mechanisms. Researchers with the Building Contractors were loaded in the two orthogonal directions. The test specimens

Society of Japan 共BCS 1998兲 have compiled much of these test are roughly one-half to two-thirds of full scale, with typical RC

data in an electronic database. column sizes ranging from 300 to 500 mm square and W-shaped

Examples of the wide variety of RCS connection details, steel beam sizes from 250 to 450 mm deep. Tests were generally

which have been investigated, are shown in Fig. 1. Details 1–7 conducted under cyclic loading to simulate forces and deforma-

are so-called ‘‘through-beam’’ type connections where the beam tions induced by earthquake effects. Several of the tests included

runs continuous through the joint. By not interrupting 共splicing兲

axial loading of the RC columns to represent gravity loads and

the beam at the point of maximum moment at the column face,

earthquake-induced overturning. Typical yield strengths of steel

the through-beam details avoid the fracture-critical joints that are

beams were F y ⫽345 MPa (50 ksi) and concrete compression

of concern in conventional steel construction. Details 8 –11 are

‘‘through-column’’ type, where the beam flanges are interrupted at strengths ranged from f ⬘c ⫽30 to 100 MPa 共4 to 15 ksi兲. A few test

the joint, so as to minimize the impact on the column reinforcing specimens had fiber-reinforced concrete in the joint region. Nogu-

bar arrangement and to facilitate concrete placement in the joint. chi and Kim 共1997 and 1998兲 conducted detailed three-

Detail 12 is an example of hybrid detail, combining conventional dimensional nonlinear finite element simulations to supplement

SRC concepts by encasing the end of the steel beam where it the tests and examine internal force transfer mechanisms.

connects to the concrete column. Through-beam type connections Overall, the tests show that, when properly detailed to mobi-

have been the preferred detail in the United States, whereas both lize internal force transfer mechanisms, RCS connections provide

types have been used in Japan. Apart from the major distinction reliable strength and ductility for seismic design. For research

of ‘‘through-beam’’ versus ‘‘through-column’’ type connections, purposes to understand the internal force transfer mechanisms,

the chief differences among the details of Fig. 1 lie in attachments most of the connection test assemblies were intentionally de-

of various stiffener plates, cover plates, and bearing plates, which signed to fail in the joint. This is counter to design practice where

act together with reinforcing bars to mobilize force transfer be- the joints are typically designed to be stronger than the beams. In

tween the steel and concrete. order to fail the joints, the test specimens often had specially

362 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / FEBRUARY 2004

J. Struct. Eng., 2004, 130(2): 361-367

Table 1. Summary of Composite Joint Tests

Organization Test description References

Building Research Institute 10 planar, through-column joints Kuramoto and Noguchi 共1997兲

Building Contractors Society 6 three-dimensional, through-column joints Nishiyama et al. 共1998, 2000兲

Kuramoto and Nishiyama 共2004兲

Chiba Univ. 6 planar through-beam joints Kuramoto and Noguchi 共1997兲

5 planar through-column joints Noguchi and Kim 共1997, 1998兲

Osaka Institute of Technology 6 planar through-beam joints, investigation of specific internal Baba and Nishimura 共2000b兲

Downloaded from ascelibrary.org by NIRMA INSTITUTE OF TECHNOLOGY on 02/04/17. Copyright ASCE. For personal use only; all rights reserved.

force transfer mechanisms

Univ. of Michigan 15 through-beam joints 共9 exterior configurations, Parra-Montesinos et al. 共2000a,b, 2001a,b, 2003兲

4 with composite slab, and 2 post-earthquake repairs兲

Liang et al. 共2004兲

Texas A&M 6 three-dimensional through-beam joints, with composite slab Bugeja et al. 共1999, 2000兲

Bracci et al. 共1999兲

Eshe et al. 共1999兲

U.C. San Diego 2 planar tests of steel beams to composite column Chou and Uang 共2002兲

with reduced beam sections

Cornell Univ.a 19 through-beam joints Kanno et al. 共1993, 1997兲

a

Univ. of Texas 17 through-beam joints Sheikh et al. 共1989兲

Deierlein et al. 共1989兲

a

Connection tests at Univ. of Texas and Cornell Univ. were conducted prior to the formal U.S.–Japan cooperative program, but are included here since

they formed the basis of the first design guidelines 共ASCE Task Committee 1994兲 in the United States.

fabricated beams with thick flanges and thin webs, which pro- crete construction. Shown in Fig. 2, for example, is the hysteretic

vided large moment capacity while limiting the joint panel shear load-deformation response of two RCS joints with band plates.

strength. Studies show that when using standard rolled W-shaped The joint detail in both tests is similar to that of detail 4 of Fig. 1,

beams, fairly simple joint details are sufficient to develop joint except that these test specimens did not have stirrups in the joint.

strengths that force inelastic hinging into the steel beam adjacent The response in Fig. 2共a兲 is of a specimen where inelastic defor-

to the joint. These points are important to keep in mind as the mations occurred in the joint; whereas the response in Fig. 2共b兲 is

observations made below are for cases where the joint is inten- for a specimen where the majority of inelastic action occurs

tionally weaker than the beam and damage to the RCS joint is through beam hinging. In general, for specimens with inelastic

more extensive than is expected to occur in actual buildings sub- action in the joint 关e.g., Fig. 2共a兲兴, the connection damage begins

jected to strong earthquakes. with diagonal cracking and localized crushing due to beam bear-

Even when designed to force all inelastic action into the joint, ing at joint shear deformations of roughly 0.005 rad to 0.007 rad,

the RCS subassemblies exhibit reliable strength, stiffness, ductil- followed by steel web and/or cover panel yielding at 0.01–0.015

ity, and energy dissipation, which is at least on par with seismi- rad 共corresponding to drift ratios of about 0.02兲. Maximum

cally detailed connections for traditional steel or reinforced con- strength is typically reached at joint deformation angles of about

Fig. 2. Typical reinforced concrete and steel through-beam-type connection test response 共a兲 exterior configuration with inelastic deformations

in joint 共Parra-Montesinos and Wight 2000a兲; 共b兲 interior configuration with beam hinging 共Liang and Parra-Montesinos 2004兲

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / FEBRUARY 2004 / 363

J. Struct. Eng., 2004, 130(2): 361-367

0.02–0.03 rad, which correspond to drift ratios of 0.03–0.04. Be- reinforcement in the connection could be significantly reduced

yond this, the joint subassemblies experience gradual strength and from values specified in current design guidelines 共e.g., ASCE

stiffness degradation under cyclic loading to maximum drift ratios 1994兲, or in some cases eliminated, while still achieving ac-

of 0.04 –0.05. The maximum imposed deformations were usually ceptable seismic performance. This was especially true for de-

limited by the experimental apparatus, rather than by any sudden tails with band plates above and below the joint 共detail 4 in

change in connection response. In tests with beam proportions Fig. 1兲, where the band plates provided confinement to critical

more representative of design practice, where the forces imposed bearing regions and, by restraining large diameter longitudinal

on the joints are limited by beam hinging 关Fig. 2共b兲兴, the subas- bars, to the entire joint 共Kanno and Deierlein 1993, 1997;

semblies exhibit similar response to well-detailed steel connec- Parra-Montesinos et al. 2000a,b, 2001a,b; Noguchi and Kim

tions where, at large deformations, the strength degrades gradu- 1997, 1998兲. Additionally, tests with fiber concrete and epoxy

ally due to local flange and web buckling in the plastic hinge carbon fiber bands showed promise to reduce or eliminate tie

Downloaded from ascelibrary.org by NIRMA INSTITUTE OF TECHNOLOGY on 02/04/17. Copyright ASCE. For personal use only; all rights reserved.

region with only modest damage to the beam–column joint. reinforcement requirements in the joint 共Parra-Montesinos

In addition to general understanding of internal force transfer et al. 2000a,b, 2001a,b兲.

mechanisms and validation of design models, the tests offer de-

tailed insights into the following configuration and design param-

Reinforced Concrete and Steel Joint Design

eters:

Guidelines

• Tests confirm that axial column compression tends to improve

the joint behavior by resisting concrete flexural and shear Test results for RCS connections have demonstrated the general

cracking and, thereby, increasing the joint strength and stiff- robustness of the connections and identified practical details 共face

ness. This observation is based on connection tests with ap- bearing plates, vertical joint reinforcement, web doubler plates,

plied column loads up to about 30% of the column crushing etc.兲 to enhance the strength and stiffness of the connection. Mod-

strength 共Nishiyama et al. 1998, 2000兲, supplemented by other els to calculate the strength and stiffness of RCS joints have been

data 共e.g., Kanno and Deierlein 1993兲, which suggest that previously proposed 共Deierlein et al. 1989兲 and synthesized into

compression has a positive effect for forces up to 70% of the guidelines by a task committee of the ASCE Committee on Com-

column crushing strength. posite Construction 共ASCE 1994兲. Through new data and under-

• Comparisons between moderate- and high-strength concrete standing developed through the U.S.–Japan Cooperative Re-

indicate that standard design equations and detailing rules search, the ASCE guidelines have been validated for seismic

apply equally well to joints with concrete compression design and several proposals have been made for improvements

strengths up to 100 MPa 共the maximum concrete strength in- to these guidelines 共e.g., Parra-Montesinos et al. 2001a, 2003;

vestigated兲. Kanno and Deierlein 1997, 2002; Kuramoto and Nishiyama 2004;

• Tests of alternative configurations show that the differences in Kuramoto 1996兲. Among the more important improvements and

behavior between interior and exterior joints are not as signifi- revisions are those suggested for 共a兲 reduced requirements for

cant as for reinforced concrete joints, but there are modest transverse ties in joints, 共b兲 modifications to address interior ver-

differences in joint shear strength that need to be considered in sus exterior joints, and 共c兲 performance-based requirements to

design 共Nishiyama et al. 1998, 2000; Parra-Montesinos et al. limit expected deformations and damage.

2000a,b, 2001a,b兲. Tests of corner details 共with the RC column

only below the beam兲 demonstrate the need for special details

to transfer vertical tension from the beam into the longitudinal Frame Behavior and System Analysis

column bars 共Nishiyama et al. 1998, 2000兲.

• Data from three-dimensional tests 共Nishiyama et al. 1998, Frame Tests

2000兲 show that joint strengths are not very sensitive to differ-

ences in two- versus three-dimensional loading, e.g., unidirec- Two RCS frames were tested and analyzed as part of the U.S.–

tional in-plane, unidirectional diagonal, and two-component Japan program—one at the Osaka Institute of Technology 共Baba

orbital loading. Compared to unidirectional in-plane and diag- and Nishimura 2000a兲 and the second at Chiba University 共Nogu-

onal loading, the orbital loading reduced the maximum chi and Uchida 2004兲. Both are one-third scale planar frames with

strength by about 10% and increased pinching in the hysteretic two bays, two stories, and through-beam type RCS connections.

response. In the Chiba frame the predominant failure mechanism was beam

• Subassembly tests with floor slabs provide data on slab par- hinging, whereas in the Osaka frame the predominant mechanism

ticipation where the increase in ultimate strength 共for the slab was joint shear yielding and column hinging.

loaded in compression兲 was significant. Tests of planar speci- Shown in Fig. 3 is an overview of results from the Osaka

mens indicate that the effective slab participation at the beam– frame test by Baba and Nishimura 共2000a兲. This frame was de-

column joint can be taken as the sum of the slab steel in signed with the plastic strength of the beams roughly equal to the

negative bending combined with compression bearing over the calculated shear strength of the joints, with the goal to investigate

column width 共Liang et al. 2004兲. Tests of space frame con- the interaction between frame and connection response. Columns

nections indicate that the effective slab width is larger than the were designed with nominal flexural strengths about 1.24 times

column width due to force transfer from the slab to the column that of the steel beams. Axial column loads equal to about 10–

through bearing and torsion of orthogonal beams 共Bracci et al. 20% of the column compressive strengths were applied and held

1999; Bugeja et al. 1999, 2000; Nishiyama et al. 1998, 2000兲. constant, while cyclic lateral loading was applied to the top story.

In such cases, the effective slab width is roughly equal to that Overall, the frame performed quite well, with the connections

calculated using standard provisions for composite steel beams performing better than intended. Visible damage began at a drift

共e.g., such as those in Chap. I of the AISC-LRFD Specification ratio of 0.003 with flexural cracking near column bases. At a drift

1999兲. ratio of 0.01 there was extensive flexural cracking near column

• Tests by several researchers demonstrate that the transverse bases, flexural cracking above and below beam-column joints,

364 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / FEBRUARY 2004

J. Struct. Eng., 2004, 130(2): 361-367

Downloaded from ascelibrary.org by NIRMA INSTITUTE OF TECHNOLOGY on 02/04/17. Copyright ASCE. For personal use only; all rights reserved.

Fig. 3. Results of reinforced concrete and steel frame test 共Baba and Nishimura 2000a兲

some localized concrete crushing below joints at interior connec- research are summarized by Mehanny et al. 共2001, 2002兲, Bracci

tion, and shear yielding of steel web panels in connections at et al. 共1998兲, Bugeja et al. 共1999兲, and Noguchi et al. 共1998兲.

second floor. At a drift ratio of 0.02 共see the cracking pattern in One example of these studies is a six-story building designed

Fig. 3兲, there was flexural yielding of column reinforcement at by Mehanny et al. 共2002兲 using provisions of the International

base and the frame reached its calculated mechanism strength, Building Code 共ICC 2000兲. Sited in a high seismic region, the

P u . The frame continued to pick up about 10% more base shear building is designed for an equivalent lateral base shear ratio of

until the maximum strength was reached at a drift ratio of about roughly 13% gravity, resulting in a frame with 600-mm-square

0.04. The strength dropped off slightly at a drift ratio of 0.05, at reinforced columns and 400– 610 mm deep W-shaped steel

which point the loading apparatus reached its maximum displace- beams. Comparative studies with steel framed buildings indicate

ment capacity and the test was stopped. that the beam sizes are roughly the same in both types of systems

Finite element analyses of both the Osaka and Chiba frame and that the main differences lie in the column and connection

tests demonstrate that the nonlinear pushover analyses can predict designs. Since the reinforced concrete columns generally have a

the frame behavior and progression of damage. Noguchi and larger stiffness to strength ratio than steel columns, the RCS

Uchida 共2004兲 modeled the frames with continuum elements, in- frames tend to be controlled more by minimum strength require-

cluding discrete nonlinear modeling of reinforcing bars, concrete, ments and less by seismic drift requirements, as compared to steel

and bond slip. The analyses captured the frame response well and frames. Seismic performance assessments of the trial designs

provided insights on localized deformations and internal force- using nonlinear static and dynamic time history analyses revealed

transfer mechanisms that were not readily observable in the tests. large variations in static over strengths 共the ratio of the static

inelastic limit point to the design strength兲 for alternative framing

configurations designed according to the same criteria. Results of

Trial Design Studies of System Performance

this sort from Mehanny et al. 共2002兲, and the other studies cited

Several teams of investigators developed trial designs of RCS previously, suggest areas of needed improvements to current

frames modeled after a theme building devised for the U.S.– building code requirements for seismic design of moment frame

Japan Program. The objectives of the trial design studies were to systems.

exercise proposed seismic design provisions for RCS systems and

then, through nonlinear analyses, evaluate the performance of

Reinforced Concrete and Steel System Design

these systems. The trial design studies contrasted space-frame and

Standards

perimeter framing systems, steel and composite 共RCS兲 frames,

and buildings of varying heights. Apart from the design implica- In the United States, seismic design criteria for composite frames

tions for RCS systems, the studies provided opportunities to ad- are distributed amongst several codes and standards 共Deierlein

vance the state of the art in applying nonlinear analysis methods 2000兲. General seismic loading and design requirements are in-

for performance-based earthquake engineering. Examples of this cluded in the International Building Code 共ICC 2000兲, which ref-

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / FEBRUARY 2004 / 365

J. Struct. Eng., 2004, 130(2): 361-367

erence Part II of the AISC Seismic Provisions 共2002兲 for specific American Institute of Steel Construction 共AISC兲. 共2002兲. Seismic provi-

detailing requirements for composite special moment frames. The sions for structural steel buildings, American Institute of Steel Con-

AISC Seismic Provisions, in turn, reference underlying require- struction, Chicago.

ments for reinforced concrete and steel structures 共ACI 2002; American Society of Civil Engineers 共ASCE兲. 共1994兲. ‘‘Guidelines for

AISC 1999兲. Specific guidance on the design of RCS beam- design of joints between steel beams and reinforced concrete col-

umns.’’ J. Struct. Eng., 120共8兲, 2330–2357.

column connection design is available in the ASCE guidelines

Baba, N., and Nishimura, Y. 共2000a兲. ‘‘Seismic behavior of RC column to

mentioned previously 共ASCE 1994兲. Technical committees of all

S beam moment frames.’’ Proc., 12WCEE, Paper Ref. 0352, 6 pp.

these organizations are continuing work to update these criteria Baba, N., and Nishimura, Y. 共2000b兲. ‘‘Stress transfer on through beam

and guidelines based on the research findings of the U.S.–Japan type steel beam-reinforced concrete column joints.’’ Proc., 6th ASCCS

Program. Int. Conf. on Steel–Concrete Composite Structures, Y. Xiao and S.

In Japan, requirements for composite SRC structures have

Downloaded from ascelibrary.org by NIRMA INSTITUTE OF TECHNOLOGY on 02/04/17. Copyright ASCE. For personal use only; all rights reserved.

Mahin, eds., 2, 753–760.

been available for several years 共AIJ 1987兲, but these do not Bracci, J. M., Atahan, A. O., and Kunnath, S. K. 共1998兲. ‘‘Analytical

address RCS systems. As described by Nishiyama and Kuramoto modeling of composite SRC structural frame systems.’’ ACI SP-174,

共2004兲, work conducted through the U.S.–Japan program has re- 197–212.

sulted in the development new seismic design guidelines for RCS Bracci, J. M., Moore, W. P., Jr., and Bugeja, M. N. 共1999兲. ‘‘Seismic

buildings. These provisions include requirements that outline ma- design and constructability of RCS special moment frames.’’ J. Struct.

terial requirements, overall design principles, detailed models and Eng., 125共4兲, 385–392.

requirements for beam-column joints, and general principles for Bugeja, M., Bracci, J. M., and Moore, W. P. 共1999兲. ‘‘Seismic behavior of

analysis and design. The provisions are implemented through a composite moment resisting frame systems.’’ Tech. Rep. No. CBDC-

two-step design procedure, consisting of an allowable stress and 99-01, Dept. of Civil Eng., Texas A & M Univ., 193 pp.

Bugeja, M., Bracci, J. M., and Moore, W. P. 共2000兲. ‘‘Seismic behavior of

ultimate load check, along the lines currently employed in Japan

composite RCS frame systems.’’ J. Struct. Eng., 126共4兲, 429– 436.

for other materials and framing systems. Work is continuing to

Building Codes and Standards 共BCS兲. 共1998兲. ‘‘Compilation based on

develop a performance-based design approach that employs non- data base on RCJ joint.’’ Sakaguchi, N., Yoshimatu, K., Masuda, Y.,

linear pushover analysis and capacity spectrum concepts 共Kura- Iizuka, S., and Miyano, Y., Presentation at 5th JTCC Meeting of the

moto et al. 2000兲. U.S.–Japan Program.

Chou, C. C., and Uang, C. M. 共2002兲. ‘‘Cyclic performance of a type of

steel beam to steel-encased reinforced concrete column moment con-

Concluding Remarks nection.’’ JCSR, 58共5-8兲, 637– 663.

Deierlein, G. G. 共2000兲. ‘‘New provisions for the seismic design of com-

Research conducted through the U.S.–Japan Program on RCS posite structures.’’ Earthquake Spectra, 16共1兲, 163–178.

structures provides valuable information on the behavior of com- Deierlein, G. G., Sheikh, T. M., Yura, J. A., and Jirsa, J. O. 共1989兲.

posite connections, members, and systems. These data and the ‘‘Beam–column moment connections for composite frames: Part 2.’’

resulting seismic design guidelines help enable the use of RCS J. Struct. Eng., 115共11兲, 2877–2896.

Esche, C. D., Bracci, J. M., and Moore, W. P. 共1999兲. ‘‘Joint strength in

frames as cost-effective and reliable alternatives to conventional

RCS frames.’’ Tech. Rep. No. CBDC-99-02, Dept. of Civil Eng., Texas

steel and reinforced concrete construction. The analytical and sys-

A & M Univ., 131 pp.

tems design research conducted under the U.S.–Japan Program Griffis, L. G. 共1992兲. ‘‘Composite frame construction.’’ Constructional

have also advanced the development of new performance-based steel design—An Int. guide, P. Dowling, J. Harding, and R. Bjorhovde,

earthquake engineering concepts. eds., Elsevier Applied Science, New York, 523–554.

International Code Council 共ICC兲. 共2000兲. International building code,

International Code Council, BOCA, Country Club Hills, Ill.

Acknowledgments Kanno, R., and Deierlein, G. G. 共1993兲. ‘‘Strength, deformation, seismic

resistance of joints between steel beams and reinforced concrete col-

The writers would like to acknowledge the contributions by many umns.’’ Struct. Eng. Rep. No. 93-6, Cornell Univ., Ithaca, N.Y.

investigators from Japan and the United States, many of whom Kanno, R., and Deierlein, G. G. 共1997兲. ‘‘Seismic behavior of composite

are identified through the referenced papers and reports. Research 共RCS兲 beam–column joint subassemblies.’’ Composite construction in

steel and concrete III, ASCE, New York, 236 –249.

conducted in the United States was primarily supported by the

Kanno, R., and Deierlein, G. G. 共2002兲. ‘‘Design model of joints for RCS

Earthquake Hazards Mitigation Program of the National Science

frames.’’ Composite Construction in Steel and Concrete IV, ASCE

Foundation under the direction of Dr. Chi Liu. In Japan, support Reston, Va., 947–958.

was provided by the Building Research Institute of the Ministry Kuramoto, H. 共1996兲. ‘‘Seismic resistance of through column type con-

of Construction along with university and industry groups. nections for composite RCS systems.’’ Proc., 11 WCEE, Paper No.

1755, Elsevier Science.

Kuramoto, H., and Nishiyama, I. 共2000兲. ‘‘Equivalent damping factor of

References composite RCS frames.’’ SP 196-6, ACI, Farmington Hills, Mich.,

109–123.

American Concrete Institute 共ACI兲. 共2002兲. Building code requirements Kuramoto, H., and Nishiyama, I. 共2004兲. ‘‘Seismic performance and

for structural concrete, ACI-318-02, American Concrete Institute, stress transferring mechanism of through-column-type joints for com-

Farmington Hills, Mich. posite reinforced concrete and steel frames.’’ J. Struct. Eng., 130共2兲,

Architectural Institute of Japan 共AIJ兲. 共1987兲. ‘‘AIJ standards for calcu- 352–360.

lation of steel reinforced concrete structures.’’ Architectural Institute Kuramoto, H., and Noguchi, H. 共1997兲. ‘‘An overview of Japanese re-

of Japan, Tokyo 共original in Japanese, but English translation avail- search on RCS systems.’’ Proc., ASCE Structures Congress XV,

able from AIJ兲. ASCE, Reston, Va., 716 –720.

American Institute of Steel Construction 共AISC兲. 共1999兲. Load and resis- Liang, X., and Parra-Montesinos, G. J. 共2004兲. ‘‘Seismic behavior of

tance design specification for structural steel buildings, 2nd Ed., reinforced concrete column-steel beam subassemblies and frame sys-

American Institute of Steel Construction, Chicago. tems.’’ J. Struct. Eng., 130共2兲, 310–319.

366 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / FEBRUARY 2004

J. Struct. Eng., 2004, 130(2): 361-367

Mehanny, S. S. F., Cordova, P., and Deierlein, G. G. 共2002兲. ‘‘Seismic Noguchi, H., and Uchida, K. 共2004兲. ‘‘Finite element method analysis of

design of composite moment frame buildings—Case studies and code hybrid structural frames with reinforced concrete columns and steel

implications.’’ Composite Construction in Steel and Concrete IV, beams.’’ J. Struct. Eng., 130共2兲, 328 –335.

ASCE, Reston, Va., 551–563. Parra-Montesinos, G., Liang, X., and Wight, J. K. 共2003兲. ‘‘Towards

Mehanny, S. S. F., and Deierlein, G. G. 共2001兲. ‘‘Seismic damage and deformation-based capacity design of RCS beam–column connec-

collapse assessment of composite moment frames.’’ J. Struct. Eng., tions.’’ Eng. Struct., 25共5兲, 681– 690.

127共9兲, 1045–1053. Parra-Montesinos, G., and Wight, J. K. 共2000a兲. ‘‘Seismic behavior,

Nishiyama, I., Itadani, H., and Sugihiro, K. 共1998兲. ‘‘Bidirectional seis- strength, and retrofit of exterior RC column-to-steel beam connec-

tions.’’ UMCEE 00-09, Dept. of CEE, Univ. of Michigan.

mic response of reinforced concrete column and structural steel beam

Parra-Montesinos, G., and Wight, J. K. 共2000b兲. ‘‘Seismic response of

subassemblies.’’ Proc., Struct. Engineers World Congress, ASCE, Re-

exterior RC column-to-steel beam connections.’’ J. Struct. Eng.,

ston, Va., Paper Ref. T177-2, 8 pp.

126共10兲, 1113–1121.

Downloaded from ascelibrary.org by NIRMA INSTITUTE OF TECHNOLOGY on 02/04/17. Copyright ASCE. For personal use only; all rights reserved.

Nishiyama, I., Kuramoto, H., Itadani, H., and Sugihiro, K. 共2000兲. ‘‘Bi-

Parra-Montesinos, G., and Wight, J. K. 共2001a兲. ‘‘Modeling shear behav-

directional behavior of interior, exterior, and corner joints of RCS ior of hybrid RCS beam–column connections.’’ J. Struct. Eng.,

system.’’ Proc., 12 WCEE, Paper No. 1911/6/A, 8 pp. 127共1兲, 3–11.

Nishiyama, I., Kuramoto, H., and Noguchi, H. 共2004兲. ‘‘Guidelines: Seis- Parra-Montesinos, G., and Wight, J. K. 共2001b兲. ‘‘Seismic repair of hy-

mic design of composite reinforced concrete and steel buildings.’’ J. brid RCS beam–column connections.’’ ACI Struct. J., 98共5兲, 762–

Struct. Eng., 130共2兲, 336 –342. 770.

Noguchi, H., and Kim, K. 共1997兲. ‘‘Analysis of beam–column joints in Sheikh, T. M., Deierlein, G. G., Yura, J. A., and Jirsa, J. O. 共1989兲.

hybrid structures.’’ Proc., ASCE Structures Congress XV, ASCE, Re- ‘‘Beam–column moment connections for composite frames: Part 1.’’

ston, Va., 726 –730. J. Struct. Eng., 115共11兲, 2858 –2876.

Noguchi, H., and Kim, K. 共1998兲. ‘‘Shear strength of beam-to-column Yamanouchi, H., Nishiyama, I., and Kobayashi, J. 共1998兲. ‘‘Development

connections in RCS system.’’ Proc., Struct. Engineers World Con- and usage of composite and hybrid building structure in Japan.’’ ACI

gress, ASCE, Reston, Va., Paper Ref. T177-3, 7 pp. SP-174, 151–174.

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / FEBRUARY 2004 / 367

J. Struct. Eng., 2004, 130(2): 361-367

You might also like

- Rectangular Concrete-Filled Steel Tubular Beam-Columns Using High-Strength Steel - Experiments and Design, 2017 (Yansheng Du)Document18 pagesRectangular Concrete-Filled Steel Tubular Beam-Columns Using High-Strength Steel - Experiments and Design, 2017 (Yansheng Du)Phan Đào Hoàng HiệpNo ratings yet

- Finite Element Analysis of Concrete-Filled Steel Tube (CFST) Columns With Circular Sections Under Eccentric LoadDocument12 pagesFinite Element Analysis of Concrete-Filled Steel Tube (CFST) Columns With Circular Sections Under Eccentric LoadvardhangargNo ratings yet

- Composite Action of Octagonal Concrete-Filled Steel Tubular StubDocument9 pagesComposite Action of Octagonal Concrete-Filled Steel Tubular StubvardhangargNo ratings yet

- Meso-Scale Modeling of Size Effect in Eccentrically-Loaded Squared CFST Influence of Eccentricity and ConfinementDocument19 pagesMeso-Scale Modeling of Size Effect in Eccentrically-Loaded Squared CFST Influence of Eccentricity and ConfinementvardhangargNo ratings yet

- Concrete-Filled Steel Tube Columns of Different Cross-Sectional Shapes Under Axial Compression: A ReviewDocument18 pagesConcrete-Filled Steel Tube Columns of Different Cross-Sectional Shapes Under Axial Compression: A ReviewvardhangargNo ratings yet

- Design Aid For Composite ColumnsDocument92 pagesDesign Aid For Composite ColumnsNikkiPopaNo ratings yet

- Optimization of Steam-CuringDocument15 pagesOptimization of Steam-CuringvardhangargNo ratings yet

- 8844 U 121433Document10 pages8844 U 121433Dorin LazarNo ratings yet

- Theoretical and Experimental Analyses of Composite Columns With The Use of High Strength ConcreteDocument10 pagesTheoretical and Experimental Analyses of Composite Columns With The Use of High Strength ConcretevardhangargNo ratings yet

- Effect of Accelerated Curing On Compressive Strength of High Strength Concrete With Nano - SilicaDocument14 pagesEffect of Accelerated Curing On Compressive Strength of High Strength Concrete With Nano - SilicavardhangargNo ratings yet

- 8844 U 121433Document10 pages8844 U 121433Dorin LazarNo ratings yet

- Development of P-M Curve for Composite ColumnsDocument322 pagesDevelopment of P-M Curve for Composite ColumnsvardhangargNo ratings yet

- VALIDATION OF ACCELERATED CURING TANKDocument13 pagesVALIDATION OF ACCELERATED CURING TANKvardhangargNo ratings yet

- Effects of Different Types of Curing OnDocument7 pagesEffects of Different Types of Curing OnvardhangargNo ratings yet

- Development of Mathematical Model To PredictDocument6 pagesDevelopment of Mathematical Model To PredictvardhangargNo ratings yet

- Comparative Study of Accelerated and Normal Curing of Silica Fume ConcreteDocument5 pagesComparative Study of Accelerated and Normal Curing of Silica Fume ConcretevardhangargNo ratings yet

- Optimization of Steam-CuringDocument15 pagesOptimization of Steam-CuringvardhangargNo ratings yet

- Supplementary Cementitious Materials Strength Development ofDocument6 pagesSupplementary Cementitious Materials Strength Development ofvardhangargNo ratings yet

- The Accelerated Curing of Concrete Test CubesDocument22 pagesThe Accelerated Curing of Concrete Test CubesvardhangargNo ratings yet

- The Effact of Acce. CuringDocument26 pagesThe Effact of Acce. CuringvardhangargNo ratings yet

- Comparison of Strength For Concrete With GGBS and Cement Using Accelerated Curing MethodDocument5 pagesComparison of Strength For Concrete With GGBS and Cement Using Accelerated Curing MethodvardhangargNo ratings yet

- EA 15. Residual Stress Measurements On Cold-Formed HSS Hollow Section ColumnsDocument15 pagesEA 15. Residual Stress Measurements On Cold-Formed HSS Hollow Section ColumnsvardhangargNo ratings yet

- Application of Acce. Curing To HSCDocument3 pagesApplication of Acce. Curing To HSCvardhangargNo ratings yet

- PM Envelope Buckling Effect PDFDocument703 pagesPM Envelope Buckling Effect PDFprajjwal patidarNo ratings yet

- EA 16. Material Properties and Residual Stresses of Cold-Formed High Strength Steel Hollow SectionsDocument14 pagesEA 16. Material Properties and Residual Stresses of Cold-Formed High Strength Steel Hollow SectionsvardhangargNo ratings yet

- Curing ReportDocument22 pagesCuring ReportNagesh ChitariNo ratings yet

- Seismic Behavior, Analysis, AnDocument467 pagesSeismic Behavior, Analysis, AnvardhangargNo ratings yet

- EA 15. Residual Stress Measurements On Cold-Formed HSS Hollow Section ColumnsDocument15 pagesEA 15. Residual Stress Measurements On Cold-Formed HSS Hollow Section ColumnsvardhangargNo ratings yet

- EA 14. Modelling and Probabilistic Study of The Residual Stress of Cold-Formed Hollow Steel SectionsDocument10 pagesEA 14. Modelling and Probabilistic Study of The Residual Stress of Cold-Formed Hollow Steel SectionsvardhangargNo ratings yet

- Reliability-Based PerformanceDocument423 pagesReliability-Based PerformancevardhangargNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2019.0096-0400-R-011-R0-A - Segmental Lining ConceptDocument36 pages2019.0096-0400-R-011-R0-A - Segmental Lining Concepthaureta_novaNo ratings yet

- Pavement Materials SyllabusDocument13 pagesPavement Materials SyllabusZuhaib KaziNo ratings yet

- Codes of Seismic BuildingDocument29 pagesCodes of Seismic Buildingutkarsh pandeyNo ratings yet

- Recommendations For The Design of Segmental Bridges - 1996Document66 pagesRecommendations For The Design of Segmental Bridges - 1996Marwan MokhadderNo ratings yet

- Caterpillar: Door & Tilt LatchDocument4 pagesCaterpillar: Door & Tilt LatchJason Del Rio100% (1)

- Site and Temporary WorksDocument11 pagesSite and Temporary Worksbaluku samuelNo ratings yet

- History of ArchitectureDocument2 pagesHistory of ArchitectureDivya Varghese KurumuttathuNo ratings yet

- J910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)Document13 pagesJ910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)rudi sarifudinNo ratings yet

- Senior Engineer Resume Lyst3178Document2 pagesSenior Engineer Resume Lyst3178Asif khanNo ratings yet

- Proposed Sewage Treatment Plant 100CmD (Civil)Document1 pageProposed Sewage Treatment Plant 100CmD (Civil)John Axl LajomNo ratings yet

- Milestone 1Document4 pagesMilestone 1Abhishek KumarNo ratings yet

- Understanding Arch TypesDocument185 pagesUnderstanding Arch Typesaysha hannaNo ratings yet

- 2019 Dec. CE401-CDocument3 pages2019 Dec. CE401-CAKHIL.S1822 CE A 18-22No ratings yet

- Structural Analysis and Design of Residential Using EtabsDocument1 pageStructural Analysis and Design of Residential Using Etabsinnovative technologiesNo ratings yet

- NBC - Fire SafetyDocument200 pagesNBC - Fire Safetyvenkin84507486% (7)

- The Building Commissioning Guide: GSA Public Buildings ServiceDocument100 pagesThe Building Commissioning Guide: GSA Public Buildings ServiceMai Tuan AnhNo ratings yet

- GOLDEN DAWN 4 7 Construction and Symbolism of The Fire WandDocument4 pagesGOLDEN DAWN 4 7 Construction and Symbolism of The Fire WandF_RC100% (3)

- Astm - C1579Document7 pagesAstm - C1579Diego Bonadiman100% (1)

- 3 Vetonit BOND2 PDFDocument2 pages3 Vetonit BOND2 PDFengrrahman3135No ratings yet

- Heat Load CalculationDocument2 pagesHeat Load CalculationburhanNo ratings yet

- 4 Training AK0303001 Delta P-C01 IOM - Rev3Document22 pages4 Training AK0303001 Delta P-C01 IOM - Rev3Nad DaniNo ratings yet

- Wattstopper: Specifications Description and OperationDocument2 pagesWattstopper: Specifications Description and OperationTyrael TyraelNo ratings yet

- Gallows Brackets TecoDocument1 pageGallows Brackets TecoAdil MaqsoodNo ratings yet

- Drilling Workover ManualDocument187 pagesDrilling Workover Manualmohammed100% (1)

- MS-0001 Mobilization of Portacabin.Document31 pagesMS-0001 Mobilization of Portacabin.Abdul LatheefNo ratings yet

- Basic MaterialsDocument7 pagesBasic MaterialsCristina Marie BatoNo ratings yet

- Concrete Bridge Bearing Technical SpecificationDocument3 pagesConcrete Bridge Bearing Technical SpecificationFaikar Luthfi AndrishaNo ratings yet

- Police Station PresentationDocument19 pagesPolice Station Presentationsokil_danNo ratings yet

- 2 OF 7 - Sep3,2020 - P8 - Balaji at Vandhavasi West Elevation WD PDFDocument1 page2 OF 7 - Sep3,2020 - P8 - Balaji at Vandhavasi West Elevation WD PDFepe civil1No ratings yet

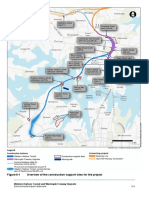

- Overview of Construction Activities and Construction FootprintDocument24 pagesOverview of Construction Activities and Construction FootprintShubham BaderiyaNo ratings yet