Professional Documents

Culture Documents

Brochure - Superfloc RH4832 Rheology Modifier For Mining

Uploaded by

Metalurgista SosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brochure - Superfloc RH4832 Rheology Modifier For Mining

Uploaded by

Metalurgista SosCopyright:

Available Formats

Superfloc® RH4832 Rheology Modifier for

Mining Operations

IMPROVED PERFORMANCE OF KEY BENEFITS

TAILINGS THICKENER OPERATIONS

IMPROVED THICKENER

Mining is a very water-intensive industry and the availability of water

OPERATION

is critical to the sustainability of its operations. As mines become

more environmentally proactive with water conservation and tailings’

management, the need to improve the thickening process is becoming a

HIGHER THROUGHPUT

growing concern. An optimally performing thickener can provide higher

underflow solids, higher throughput, improved energy consumption, while

also improving the mine’s water recovery. Effective chemical technology is

INCREASED WATER

critical in achieving these benefits.

RECOVERY

SUPERFLOC® RH4832 TECHNOLOGY

Kemira has developed Superfloc RH4832 technology to improve the IMPROVED SETTLING IN

performance of tailings thickener operations and meet the needs of most POOR QUALITY ORES

sensitive operating conditions, such as varied pH and water conditions.

Superfloc RH4832 was evaluated in a mine using over 280,000 tons of

water to process approximately 120,000 – 160,000 tons of ore per day.

The primary ore processed was chalcopyrite/pyrite, containing an initial

concentration of 0.95% copper, thus more than 96% of the ore ended Kemira is the right

up in the tailings pond. With the high gangue production processed partner for your mining

through the tailings thickener, there was a need to recover and recycle operations. We offer

as much of the water as possible. However, recovery was limited by the state-of-the-art polymer

solids content due to the amount of torque introduced to the rake in the technology, applications

thickener, as well as the energy required to pump these concentrated expertise, along with

tailings to the tailings dam. The challenge was to increase the underflow polymer manufacturing

solids while maintaining a set yield stress and overflow turbidity. and synthesis capabilities

Superfloc RH4832 rheology modifier met the demands of the thickener to meet your most

operation and achieved improved results over conventional polymers. demanding needs.

SUPERFLOC RH4832 RESULTS

Superfloc RH4832 rheology modifier was tested in the field and the laboratory to understand its performance

benefits in varied water conditions.

Settling FIGURE 1. SUPERFLOC RH4832

An increase in the settling rate allows for higher SETTLING RESPONSE OVER TIME

throughputs through the thickener. Field and laboratory pH8 pH10

O Superfloc RH4832

evaluations demonstrate that Superfloc RH4832 can 15

(Dosage (gton)=3)

MINE WATER

achieve superior settling rates compared to conventional 10 + Conv. Flocculant

(Dosage (g/ton)=3)

flocculants (Figure 1). The chemistry of this rheology

5

SETTLING (cm)

modifier also allows for water quality variations and O Superfloc RH4832

0 (Dosage (g/ton)=3.5)

fewer upsets in settling as a result of these variations. + Conv. Flocculant

Tailings treated with Superfloc RH4832 maintain 15 (Dosage (g/ton)=3.5)

SEA WATER

a settling rate as the pH is reduced. Likewise, with 10 O Superfloc RH4832

seawater-tailings and the use of our technology, a (Dosage (g/ton)=4)

5 + Conv. Flocculant

good settling rate is maintained. The minimization (Dosage (gton)=4)

0

of settling rate upsets is especially important with

0 20 40 60 0 20 40 60

capacity limited thickeners. An additional benefit TIME (min)

is that optimized settling can be achieved, typically

with much reduced dosage compared to conventional

flocculants, which can have a number of benefits, not FIGURE 2. YIELD STRESS RESULTS FOR

SUPERFLOC RH4832 VS. CONVENTIONAL POLYMER

withstanding chemical cost-efficiency improvement.

Conventional Polymer

Yield Stress

YIELD STRESS (Pa)

Performance

A lower yield stress is preferred as this relates to

lower torque on the rake and lower pumping energy to Superfloc RH4832

Performance at the

transport the underflow to the tailings pond. The goal is same settling rate

to have elevated underflow solids without increasing the dose

yield stress over 100 pa. Superfloc RH4832 was able to 100 Pa High Rate Thickeners (Hi-cap)

maintain target yield stress at an improved underflow

density (Figure 2.) An increase of solids content from

58% to 62% was achieved, which will result in a tangible 58% U/F 62% U/F

benefit on water reuse. UNDERFLOW DENSITY (%wt/wt)

WATER CONSERVATION AND COST REDUCTION TO THE MINE OPERATION

Superfloc RH4832 technology can improve your tailings thickeners operations with the following benefits:

• Underflow solids – increased to improve water consumption

• Yield stress – maintained under set target to ensure no negative impact on rake torque, even with higher solids

• Settling rate – increased to allow higher throughputs and fewer operational upsets

• Stability - improved ability to handle changing ores and water chemistry

Kemira makes this information available as an accommodation to its customers and it is intended to be solely a guide in customers’ evaluation of the products. You must test our products

v. 5.4

to determine if they are suitable for your intended uses and applications, as well as from the health, safety and environmental standpoint. You must also instruct your employees, agents,

contractors, customers or any third party which may be exposed to the products about all applicable precautions. All information and technical assistance is given without warranty or guarantee

and is subject to change without notice. You assume full liability and responsibility for compliance with all information and precautions, and with all laws, statutes, ordinances and regulations

of any governmental authority applicable to the processing, transportation, delivery, unloading, discharge, storage, handling, sale and use of each product. Nothing herein shall be construed as a

recommendation to use any product in conflict with patents covering any material or its use.

Superfloc is a registered trademark of Kemira Oyj or its subsidiaries.

Kemira Oyj Europe, Middle East and Africa Americas

Porkkalankatu 3 Tel. +358 10 8611 North America

P.O. Box 330 Tel. +1 770 436 1542

FI-00101 Helsinki

Finland Asia - Pacific South America

www.kemira.com Tel. + 86 21 6037 5999 Tel. +55 11 2189 4900

You might also like

- Thickener Experiences at Langer Heinrich MineDocument14 pagesThickener Experiences at Langer Heinrich MineEddo Rafael Carrion ValerioNo ratings yet

- Diagrama de Flujo Circuito Chancado Minera Condestable S.ADocument1 pageDiagrama de Flujo Circuito Chancado Minera Condestable S.AdonaldoNo ratings yet

- Flowsheet Circuito ChipmoDocument1 pageFlowsheet Circuito ChipmoYusep Ronal Segura VillarrealNo ratings yet

- Zambia DRC Training Plant SideDocument67 pagesZambia DRC Training Plant SideMetalurgista Sos100% (1)

- Terminator TableDocument3 pagesTerminator TableSantiago PomasoncoNo ratings yet

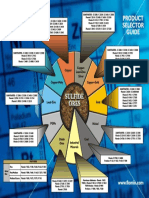

- SNF-Flomin Product Selection WheelDocument1 pageSNF-Flomin Product Selection WheelGerman Van der Olguin50% (2)

- FlotacionDocument2 pagesFlotacionJose Ariel TorrezNo ratings yet

- Mineral reception plant flowchartDocument12 pagesMineral reception plant flowchartrwtoorresdNo ratings yet

- 3043 FTP 001,002&003 - IomDocument189 pages3043 FTP 001,002&003 - IomMiguel Angel RodriguezNo ratings yet

- Hoja Tecnica Aerofroth 65 FrotherDocument2 pagesHoja Tecnica Aerofroth 65 FrotherEduardoHS67% (3)

- Minerals Engineering: Jian Liu, Yu Wang, Deqiang Luo, Yong ZengDocument8 pagesMinerals Engineering: Jian Liu, Yu Wang, Deqiang Luo, Yong ZengLuisito Mayhua PaucarNo ratings yet

- Steimour Rate of Sedimentation Suspensions of Uniform-Size Angular Particles PDFDocument8 pagesSteimour Rate of Sedimentation Suspensions of Uniform-Size Angular Particles PDFpixulinoNo ratings yet

- Hidrocilon D 15Document3 pagesHidrocilon D 15Metalurgista SosNo ratings yet

- DENVER Mineral CharacteristicsDocument8 pagesDENVER Mineral CharacteristicsTsakalakis G. Konstantinos100% (1)

- Mineral Processing Circuits - Detection of The Appropriate Sampling SchemeDocument19 pagesMineral Processing Circuits - Detection of The Appropriate Sampling SchemeTsakalakis G. KonstantinosNo ratings yet

- Determination of Calcium Fluoride in Fluorspar by Complexometric TitrationDocument3 pagesDetermination of Calcium Fluoride in Fluorspar by Complexometric TitrationEduardoNo ratings yet

- Peristaltic Pump: Sistemas HidráulicosDocument29 pagesPeristaltic Pump: Sistemas HidráulicosClaret JVNo ratings yet

- CMP2015 - Assessing Vertimill Ultrafine Grinding PerformanceDocument7 pagesCMP2015 - Assessing Vertimill Ultrafine Grinding PerformancerodrigoNo ratings yet

- Lecture3 Flotation Reagents1Document28 pagesLecture3 Flotation Reagents1vince coNo ratings yet

- Michaels Bolger Settling Rates and Sediment Volumes of Flocculated Kaolin Suspensions PDFDocument10 pagesMichaels Bolger Settling Rates and Sediment Volumes of Flocculated Kaolin Suspensions PDFpixulinoNo ratings yet

- 5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForceDocument4 pages5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForcejlfyNo ratings yet

- Fundamental Principles of Froth FlotationDocument30 pagesFundamental Principles of Froth FlotationAlagu RamNo ratings yet

- Watson Marlow 630 Datasheet PDFDocument6 pagesWatson Marlow 630 Datasheet PDFDarwin Sucasaca pilcoNo ratings yet

- Flotation Cell Froth Area Optimization by Crowding PDFDocument22 pagesFlotation Cell Froth Area Optimization by Crowding PDFPili Torres OrregoNo ratings yet

- Manual Columna de FlotaciónDocument40 pagesManual Columna de FlotaciónpaulinaNo ratings yet

- CLD1609-DA-586054-05-RL-002 Rev.1 LISTADO DE REPUESTOS CAPITALDocument3 pagesCLD1609-DA-586054-05-RL-002 Rev.1 LISTADO DE REPUESTOS CAPITALkevinzzzxd1No ratings yet

- SGS MIN TP2008 50 IOCG Recovery in Scandinavia PDFDocument8 pagesSGS MIN TP2008 50 IOCG Recovery in Scandinavia PDFPedro PabloNo ratings yet

- Mediacharge OptimalballsizeDocument4 pagesMediacharge OptimalballsizeHoàng HùngNo ratings yet

- Kinch - A Theory of SedimentationDocument11 pagesKinch - A Theory of SedimentationpixulinoNo ratings yet

- Zinn Stein FlotationDocument8 pagesZinn Stein Flotationalexander beltranNo ratings yet

- Design Considerations For Merrill-Crowe PlantsDocument5 pagesDesign Considerations For Merrill-Crowe PlantsLuis Miguel La Torre100% (1)

- Filtro Marco y PlatosDocument5 pagesFiltro Marco y PlatosCesar LapaNo ratings yet

- On Lifetime Cost of FlotationDocument5 pagesOn Lifetime Cost of FlotationPancho Arancibia MoralesNo ratings yet

- Denver Instruction & Operation ManualDocument24 pagesDenver Instruction & Operation ManualestramilsolutionNo ratings yet

- User - Manual - 3 Brinkmann Probe ColorimeterDocument4 pagesUser - Manual - 3 Brinkmann Probe ColorimeterRafiqul AlamNo ratings yet

- WTP Pilot Scale Testing High Density Sludge ProcessDocument126 pagesWTP Pilot Scale Testing High Density Sludge ProcessGeorgi SavovNo ratings yet

- Max rpm, impeller type, seal type effect on pump efficiencyDocument1 pageMax rpm, impeller type, seal type effect on pump efficiencyVf MauroNo ratings yet

- F.C. Bond Bico Ball Mill Operating InstructionsDocument25 pagesF.C. Bond Bico Ball Mill Operating InstructionsNataniel LinaresNo ratings yet

- Msds Rheomax DR 1030 enDocument9 pagesMsds Rheomax DR 1030 enBuenaventura Jose Huamani TalaveranoNo ratings yet

- Outotec OK-R and OK-U Flotation Cells: Optional Cells For Smaller Tank VolumesDocument4 pagesOutotec OK-R and OK-U Flotation Cells: Optional Cells For Smaller Tank VolumesAndrew HoyleNo ratings yet

- Liner Assembly-Antamina Project: .63 Total Gap Typical 16 423.21 Available Length 10750Document1 pageLiner Assembly-Antamina Project: .63 Total Gap Typical 16 423.21 Available Length 10750jhonNo ratings yet

- Flotacion Ppt-Flotación 2018 - Alexis CamposDocument23 pagesFlotacion Ppt-Flotación 2018 - Alexis CamposLuis Katsumoto Huere AnayaNo ratings yet

- 34-27-13 AutoBall Charger 301W Operations MaintenanceDocument28 pages34-27-13 AutoBall Charger 301W Operations Maintenanceerik masongNo ratings yet

- Analyzing The Applicability of Mining Turntable For Dumper Unloading at Crusher PDFDocument4 pagesAnalyzing The Applicability of Mining Turntable For Dumper Unloading at Crusher PDFSunny SouravNo ratings yet

- 5 Rene Orellana Codelco (Modulo II)Document18 pages5 Rene Orellana Codelco (Modulo II)Rodrigo BartoloNo ratings yet

- Brochure Paste ThickenerDocument8 pagesBrochure Paste ThickenerAndré BranchesNo ratings yet

- Flow Sheet (Solis Egusquiza Ronald)Document83 pagesFlow Sheet (Solis Egusquiza Ronald)Dan PerezNo ratings yet

- Balance San Expedito CarlosDocument36 pagesBalance San Expedito CarlosJordy Gallo BarretoNo ratings yet

- ChE65: Intro to Particle TechDocument31 pagesChE65: Intro to Particle Techکبری ادریس رسولNo ratings yet

- Dewatering Screens: Single-Deck Twin VibratorDocument8 pagesDewatering Screens: Single-Deck Twin Vibratorekrem0867No ratings yet

- APPENDIX A1 - 313L2 Specific ManualDocument41 pagesAPPENDIX A1 - 313L2 Specific ManualMiguel Angel RodriguezNo ratings yet

- Boehm Titration ExcelDocument8 pagesBoehm Titration ExcelAbraham Joel Mendoza FloresNo ratings yet

- Tankcell® Flotation Machine: Bolt ConnectionsDocument6 pagesTankcell® Flotation Machine: Bolt ConnectionsJulver Goyzueta ArceNo ratings yet

- Effect of clays on copper sulphide flotation recoveryDocument24 pagesEffect of clays on copper sulphide flotation recoveryNicolas MirandaNo ratings yet

- Outotec Flotation - TankCell E500Document2 pagesOutotec Flotation - TankCell E500jadetorresNo ratings yet

- Manual Falcon1Document2 pagesManual Falcon1Jorgebk SalazarNo ratings yet

- Jigs Gekko Con TrazadoresDocument18 pagesJigs Gekko Con TrazadoresVB JazminNo ratings yet

- Air RemovalDocument12 pagesAir RemovalwilxjNo ratings yet

- Instruction Manual Single Method - M318 - Phosphate Total HR TT - enDocument7 pagesInstruction Manual Single Method - M318 - Phosphate Total HR TT - enmoamen aliNo ratings yet

- Why Is The EmewDocument8 pagesWhy Is The EmewMetalurgista SosNo ratings yet

- Gold Investor S ManualDocument57 pagesGold Investor S Manualdrkwng100% (1)

- Copper Leaching Behavior From Waste Printed Circuit Board in Ammoniacal Alkaline SolutionDocument5 pagesCopper Leaching Behavior From Waste Printed Circuit Board in Ammoniacal Alkaline SolutionJhon Barzola PalominoNo ratings yet

- Fine Particle Processing Problems and SolutionsDocument10 pagesFine Particle Processing Problems and SolutionsMetalurgista SosNo ratings yet

- Hidrocilon D 15Document3 pagesHidrocilon D 15Metalurgista SosNo ratings yet

- Zambia DRC Flocculants and FlocculationDocument76 pagesZambia DRC Flocculants and FlocculationMetalurgista SosNo ratings yet

- Copper Recovery From Spent Ammoniacal EtchingDocument12 pagesCopper Recovery From Spent Ammoniacal EtchingMetalurgista SosNo ratings yet

- Real Statistics Examples Correlation ReliabilityDocument404 pagesReal Statistics Examples Correlation ReliabilityMetalurgista SosNo ratings yet

- Minerals 11 00385Document12 pagesMinerals 11 00385Metalurgista SosNo ratings yet

- Real Statistics Examples Goodness of FitDocument102 pagesReal Statistics Examples Goodness of FitMetalurgista SosNo ratings yet

- F EVALUACION CICLON Gmax-15 100% Relave (30 SETIEMBRE 2010)Document6 pagesF EVALUACION CICLON Gmax-15 100% Relave (30 SETIEMBRE 2010)Metalurgista SosNo ratings yet

- Corregida tabla de datos de hidrociclónDocument5 pagesCorregida tabla de datos de hidrociclónMetalurgista SosNo ratings yet

- Real Statistics Examples DistributionsDocument491 pagesReal Statistics Examples DistributionsMetalurgista SosNo ratings yet

- B EVALUACION CICLON Gmax-15 100% Relave (07 FEBRERO 2012)Document6 pagesB EVALUACION CICLON Gmax-15 100% Relave (07 FEBRERO 2012)Metalurgista SosNo ratings yet

- F EVALUACION CICLON Gmax-15 100% Relave (30 SETIEMBRE 2010)Document6 pagesF EVALUACION CICLON Gmax-15 100% Relave (30 SETIEMBRE 2010)Metalurgista SosNo ratings yet

- Corregida tabla de datos de hidrociclónDocument5 pagesCorregida tabla de datos de hidrociclónMetalurgista SosNo ratings yet

- Analisis Granulometrico Valorado Alimento Ciclon 15 B Analisis Granulometrico Valorado U/F Ciclon 15 BDocument3 pagesAnalisis Granulometrico Valorado Alimento Ciclon 15 B Analisis Granulometrico Valorado U/F Ciclon 15 BMetalurgista SosNo ratings yet

- D EVALUACION CICLON Gmax-15 100% Relave (28 NOVIEMBRE 2011)Document9 pagesD EVALUACION CICLON Gmax-15 100% Relave (28 NOVIEMBRE 2011)Metalurgista SosNo ratings yet

- F EVALUACION CICLON Gmax-15 100% Relave (30 SETIEMBRE 2010)Document6 pagesF EVALUACION CICLON Gmax-15 100% Relave (30 SETIEMBRE 2010)Metalurgista SosNo ratings yet

- Minerals 11 00385Document12 pagesMinerals 11 00385Metalurgista SosNo ratings yet

- TACO - Free On Demand TrainingDocument18 pagesTACO - Free On Demand TrainingVinicius Paschoal NatalicioNo ratings yet

- Mechanical Vibrations (ME 65) Chapter-8 Multi Degree of Freedom SystemsDocument36 pagesMechanical Vibrations (ME 65) Chapter-8 Multi Degree of Freedom SystemsGURUPRASAD KADAGADNo ratings yet

- Tricentis Tosca Powered by Vision AI Data Sheet 30.10.20Document2 pagesTricentis Tosca Powered by Vision AI Data Sheet 30.10.20nitomac608No ratings yet

- Dowec Electrical System Baseline Design: WP1 Task 7 DOWEC 045 Rev. 2Document30 pagesDowec Electrical System Baseline Design: WP1 Task 7 DOWEC 045 Rev. 2Rui TimóteoNo ratings yet

- Trihal Cast Resin dry type transformer 2000 kVA 20 kV IEC Dyn5 IP21 specificationsDocument2 pagesTrihal Cast Resin dry type transformer 2000 kVA 20 kV IEC Dyn5 IP21 specificationsadefaizalmaizar12No ratings yet

- Connection and Blowing Units HJF - TPF: Pharmaceutical and Food SectorsDocument8 pagesConnection and Blowing Units HJF - TPF: Pharmaceutical and Food SectorsAlper SakalsizNo ratings yet

- Automatic Transfer Switch (ATS) OR Automatic Mains Failure (AMF) PanelDocument9 pagesAutomatic Transfer Switch (ATS) OR Automatic Mains Failure (AMF) PanelKishore KumarNo ratings yet

- Method Statement of Tiling Works: ContentDocument4 pagesMethod Statement of Tiling Works: ContentChezy629No ratings yet

- A-Class Chambers - FBBCIDocument10 pagesA-Class Chambers - FBBCIJubaer INo ratings yet

- Unit Cost of Labor & Materials Material Unit Cost 1.00 Earthworks Item NoDocument54 pagesUnit Cost of Labor & Materials Material Unit Cost 1.00 Earthworks Item NoEricson Badua CorpuzNo ratings yet

- A Study On The Impact of Social Media On Consumer Buying Behaviour of Mobile Phones in ChennaiDocument6 pagesA Study On The Impact of Social Media On Consumer Buying Behaviour of Mobile Phones in ChennaiHeba AliNo ratings yet

- Datasheet DT35S-B15551 1122103 enDocument8 pagesDatasheet DT35S-B15551 1122103 enROSSNo ratings yet

- PE CurriculamDocument145 pagesPE Curriculamavula43No ratings yet

- M-17211-2 Avio FAST Method Guide - Syngistix - ESIDocument16 pagesM-17211-2 Avio FAST Method Guide - Syngistix - ESIta quang khanhNo ratings yet

- CAT 32 Operation Maintenance ManualDocument148 pagesCAT 32 Operation Maintenance Manualpakmarineeng96% (71)

- PHD Entrance MCQDocument11 pagesPHD Entrance MCQvandyNo ratings yet

- 1.overview of Operating SystemDocument50 pages1.overview of Operating SystemNisarg GugaleNo ratings yet

- 731 Loss On Drying: Water Determination 921Document1 page731 Loss On Drying: Water Determination 921wilNo ratings yet

- RE - 630 - Technical Manual PDFDocument1,276 pagesRE - 630 - Technical Manual PDFjenskgNo ratings yet

- MBA Research Project GuidelinesDocument7 pagesMBA Research Project GuidelinesAnsari WarisNo ratings yet

- SS 4r3a5 EpDocument2 pagesSS 4r3a5 EpangelroNo ratings yet

- 006 Amlh FR 2023Document20 pages006 Amlh FR 2023sebicapilneanNo ratings yet

- JNTUA R20 B.tech - ECE III IV Course Structure SyllabusDocument112 pagesJNTUA R20 B.tech - ECE III IV Course Structure SyllabusNaveenNo ratings yet

- DH WorkshopDocument17 pagesDH Workshopaan monNo ratings yet

- Annex II - Inspection Check ListsDocument15 pagesAnnex II - Inspection Check ListsKidanemariamNo ratings yet

- Machine Learning in Healthcare Management For Medical Insurance Cost PredictionDocument11 pagesMachine Learning in Healthcare Management For Medical Insurance Cost PredictionKumara SNo ratings yet

- Garry Owen. - Learn To Code Learn HTML, CSS & JavaScript & Build A Website, App and Game (2022)Document247 pagesGarry Owen. - Learn To Code Learn HTML, CSS & JavaScript & Build A Website, App and Game (2022)Saju George100% (1)

- C 0.8 Reference Manual: ArdpeekDocument60 pagesC 0.8 Reference Manual: ArdpeekMarcos FidelisNo ratings yet

- Operator - Brewing - Port HarcourtDocument2 pagesOperator - Brewing - Port HarcourtIsrael AdegboyegaNo ratings yet

- Rooftop Trane Voyager tch180 tch150 tch240Document108 pagesRooftop Trane Voyager tch180 tch150 tch240Leandro P SilvaNo ratings yet