Professional Documents

Culture Documents

User Instructions TWIN80C: Wall Hung, Fan Flue, Room Sealed Gas Boiler

Uploaded by

buzdu85Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

User Instructions TWIN80C: Wall Hung, Fan Flue, Room Sealed Gas Boiler

Uploaded by

buzdu85Copyright:

Available Formats

User instructions TWIN80C

Wall hung, fan flue, room sealed gas boiler

2006 E000129017

(E000129017 - user instructions TWIN80C_EN - MV190805)

Downloaded from www.Manualslib.com manuals search engine

user instructions TWIN80C_EN

General

The TWIN 80C is a wall hung, fan flue, room sealed, high LED indication

efficiency condensing gas boiler for central heating and / or under

floor heating systems.

The type plate, which specifies the type of gas etc. to be used, for

which the unit is set, is on the left side of the unit.

The appliance is equipped with pre-set gas/air ratio regulators.

The purpose of this regulator is to keep the gas/air ratio in the

burner as optimal as possible at all times e.g. when modulating.

This ensures clean and reliable combustion across the entire

load range. In addition it achieves high part-load efficiency.

How the boiler works

Two LED’s have been placed under the appliance informing the

user the status of each unit individually.

The left hand side LED (L) is indicating the actual status of the

Left hand side heating unit.

• LED is ON = burner concerned is ON

• LED is OFF = burner concerned is OFF

• LED is FLASHING = unit concerned is LOCK-OUT

The TWIN 80C incorporates 2x heat units. Each heat burner The right hand side LED (r) is indicating the actual status of the

works independently, cascade controlled by two printed circuit right hand side heating unit.

boards. • LED is ON = burner concerned is ON

Master – Left hand side printed circuit board.

• LED is OFF = burner concerned is OFF

The Master is the leading board, calculates and divides the

• LED is FLASHING = unit concerned is LOCK-OUT

necessary power over both units. Therefore the regulation

controls will always be connected to the Master.

Slave – right hand side printed circuit board.

In most cases of a lock-out of the Master printed circuit board

the Slave is still able to operate correctly.

A fan sucks the air required for the combustion through the air

feed canal (A). Because the combustion air in the venturi sucks

an under pressure, the correct amount of gas (G) is

automatically added to the combustion air.

The flammable gas/air mixture thus obtained is fed to the

burner(s), via a mixing chamber, to be ignited at the surface of

the burner(s) by a ceramic glow plug. The hot combustion gases

are efficiently fed through the heat exchanger(s), where they

give their heat to the system water. The flue gases are fed

outdoor, through the flue tube (F), into a combined flue tube

exhaust canal.

The formed condensation water (H2O) is discharged through the

waste trap.

Burner is on

• when the room thermostat is closed (heat demand)

• and when the actual flow temperature is 5°C below the set

point (desired heating flow temperature)

• and after 3 minutes anti-reciprocital time, if applicable, after a

reciprocital stop

Burner is off

• when the room thermostat is open (end of heat demand)

• when the actual flow temperature is 3°C above the set point

(blocking)

• or when the actual flow temperature is 3°C above the

maximum permissible central heating temperature.

Downloaded from www.Manualslib.com manuals search engine

user instructions TWIN80C_EN

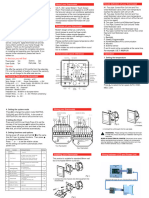

Display Status indication during normal operation

Display Description

To be able to read the codes of the, open the cover in front of

the appliance. - Initialisation after restoration of supply power

U Reversed neutral and line

O No heat demand, stand-by

A = Status

B = Reading C Central heating heat demand, burner off

C = “+ button” C. Central heating heat demand, burner on

D = “- button” P/C. (Central heating) heat demand, low load water

E = Set / Reset pressure

F = Flame A/C. (Central heating) heat demand, low load chimney

temperature

c Central heating pump post-running

The left 7-segment LED shows the status or the menu step. b HWS burner off/ pump post running

The two right 7-segment LED's show the temperature, the b. HWS burner on

pressure or the parameter value. P/b. HWS, low load by water pressure

What is a functional blocking? A/b. HWS, low load by chimney temperature

During blocking operation, the display status shows a O Frost protection burner off pump running 8C

continuous indication. The regulation blocks the burner till o. Frost protection burner on 3C

blocking conditions are within certain requirements. C Chimney sweeper function (temp display

Most blocking actions restore automatically in time. Some max/min/ionisation)

FLASHING

blocking operations need a reset of the 230V supply power or an

action manually. Status indication during “blocking” mode

Note that each blocking operation will stay at least with 3 (intermittent “L” for master and “r” for slave)

minutes anti-cycling time. Display Description

1 Flow sensor open circuit

What is a functional lock-out?

1. Flow sensor short circuit

During lock-out operation, the display status shows a flashing

indication. 2 Return sensor open circuit

Pump runs over the heating circuit (max 24 hr). 2. Return sensor short circuited

Fan post rinses for 1 minute at 2700 rpm (some lock-outs) 4 Flue gas sensor open circuit

Most lock-out operations can be restored by pressing the A Flue gas temperature > 80°C

‘Set/Reset’ button. It is advised to use this button not more than

H Flow sensor > 105°C while the burner was off

3 times in a row. Ask your installer for help.

Note that some lock-out operations need a reset of the 230V J Blocking flow temperature

supply power. (3 minutes anti-cycling time)

Pump test / Start function blocking / Water

P

pressure

nc Electronics interruption

(manual reset by interruption of electrical supply)

E No slave connected

b/r HWS right unit

9 Flow / Return temperature to high

Status indication of ”lock-out” mode (flashing)

(intermittent “L” for master and “r” for slave)

Display Description

1 Boiler does not pass start temperature test

2 Too many restarts

Internal regulation fault / A/D conversion fault /

3

external sensor fault /Too many restarts

4

5 Fan error

6

7 Gas valve error

8 Flame detected with closed gas valve

A Flue gas temperature > 95°C

E Internal interlock fault

H Flow sensor > 105°C with burner on

F Too many ignition attempts during

O Gas valve connection error

Downloaded from www.Manualslib.com manuals search engine

user instructions TWIN80C_EN

Menu structure

By pressing the set/reset button in for longer than 5 seconds, you go to the ‘mode’ menu.

To change the subsequent "Letter" parameter, the user must press the Set/Reset button.

To change the “Range” setting in the parameter, the user must press the “+” or the “–“ button.

Pressing the “+” button you will enter the “view mode” directly, starting at indicating the water pressure wth “8”.

U S E R / I N S T A L L E R S E T T I N G S (TWIN80C)

Letter Description Range Factory settings

C Heating: Max. flow temperature setting 25 – 90°C 82°C

O Heating: Pump post-running time 01-25 min, CO=24 hour 05

P Heating: Max. boiler output 33 – 100% 00 (100%)

h Extended adjustments for installer (password h= ) 10 – 99 10

r Factory setting return mode; excluded are the settings

= Factory setting

under Letter “h”

(note: for entering press “+” button 5 sec) = Customised setting

u 0-10V regulation 0 = Regulation on temperature (°C)

0 (4)

1 = Regulation on boiler input (kW)

o Configuration of TWIN

Power configuration = 01 (input 14,6 – 74.0 kW) 01 / 00 01 (4)

Comfort configuration = 00 (input 7,3 – 74.0 kW)

S Pump mode 00 = Software

= Always high 00 (4)

= Always low

L View mode of Left hand side unit 8 = Water pressure (in bar)

1 = Flow temperature (in °C)

2 = Return temperature (in °C)

3 = 0÷10V

4 = Outdoor temperature (in °C)

5 = TWIN flow temperature (in °C)

6 = Flue gas temperature (in °C)

7 = Flame signal (in μA DC)

9 = Last lock-out

A = Last blocking (internal coding)

d=

r View mode of right hand side unit 8 = Water pressure (in bar)

1 = Flow temperature (in °C)

2 = Return temperature (in °C)

6 = Flue gas temperature (in °C)

7 = Flame signal (in μA DC)

9 = Last lock-out

A = Last blocking (internal coding)

Note: (4) does not return to factory settings

Downloaded from www.Manualslib.com manuals search engine

user instructions TWIN80C_EN

Outdoor sensor

An outdoor temperature sensor (heating) must be an NTC with a resistance of 12kOhm at 25°C

(connected to terminals (3) and (4) of the green connector block)

Letter Description Range Factory settings

O/b (3) Basic temperature (outdoor sensor) 10°C – 70°C 40°C (4)

O/S (3) Slope (outdoor sensor) 1- 100 20 (4)

O/d (3) Day reference temperature (outdoor sensor) 0°C – 70°C 40°C (4)

Note: (3) Active when an outside sensor is connected, Note: (4) does not return to factory settings

Adjustment heating curve (in case of an outdoor temperature sensor)

By pressing the set/reset button in for longer than 5 seconds, you go to the ‘mode’ menu.

To change the subsequent "Letter in menu" parameter, the user must press the Set/Reset button.

To change the “Range” setting in the parameter, the user must press the “+” or the “–“ button.

Parameter „C“

Supply temperature [°C]

The setting in the menu „C“ makes the maximal heating flow

Parameter C=82°C [default] temperature (default 82°C).

O/b-value: The setting of the minimal Heating flow temperature

(value in °C).

O/S-value : The setting for the sloop of the curve.

( change of Flow temperature depending on the change of the

outside temperature).

O/S=20 [default]

O/d-value : The setting of the flow temperature at an outside

temperature of 20°C (value in °C).

O/d=20°C [default]

O/b=20°C [default]

Outside temperature [°C]

Letter in menu Description Range default

C Max. Flowtemp. for heating 25 –90 °C 82 °C

O/b Basic temperature 10 –70 °C 20 °C

O/S Slope 1 – 100 20

O/d Flow temperature at outside = 20°C 0 –70 °C 20 °C

Downloaded from www.Manualslib.com manuals search engine

user instructions TWIN80C_EN

Cascade options

Power mode (default) Comfort mode (field adjustable)

Both units run simultaneously. Menu parameter “o” = 1 Menu parameter “o” has to be set onto the value 0

At low and at high heat demand both units run simultaneously. At low heat demand a single unit runs independently.

At high heat demand both units run simultaneously.

Cascade selection : menu parameter “.o” = 1 Cascade selection : menu parameter “.o” = 0

Heat input (gross) 16.2 – 82.2 kW Heat input (gross) 8.1 – 82.2 kW

Heat input (net) 14.6 – 74.0 kW Heat input (net) 7.3 – 74.0 kW

Nominal output at 80/60ºC 14.1 – 72.0 kW Nominal output at 80/60ºC 7.0 – 72.0 kW

Nominal output at 50/30ºC 15.6 – 75.3 kW Nominal output at 50/30ºC 7.8 – 75.3 kW

Low load = 96.6 % Low load = 96.0 %

Efficiency at 80/60ºC (net) Efficiency at 80/60ºC (net)

High load = 97.2 % High load = 97.2 %

Low load = 106.9 % Low load = 106.3 %

Efficiency at 50/30ºC (net) Efficiency at 50/30ºC (net)

High load = 101.8 % High load = 101.8 %

When the room thermostat or space unit indicates that heat is When the room thermostat or space unit indicates that heat is

required for central or under floor heating, both units will heat required a single unit will start-up, while the other unit remains

simultaneously. The Master print calculates the system flow stand-by. The unit priority will change each 24 hours.

temperature and divides the necessary power over both units

equally. The speeds of both fans are automatically adapted to When the heat required is twice low fire, the second unit will be

the heat required, also with the use of an on/off thermostat. started as well. Both units will heat simultaneously. The Master

print calculates the system flow temperature and divides the

When the room thermostat or space unit indicates that the necessary power over both units equally. The speeds of both

desired temperature has been reached, the central heating fans are automatically adapted to the heat required, also with

water is no longer heated. The unit pumps will continue to run the use of an on/off thermostat.

for a previously set time to distribute the heat evenly over the

heating installation.

Downloaded from www.Manualslib.com manuals search engine

user instructions TWIN80C_EN

Fully open all radiator taps.

Tips Connect the water supply to the filling connection of the

Depending on how much you value optimum comfort and the installation.

lowest possible energy consumption, the following tips can help Open the tap to fill the system with water.

you make optimum use of your unit: When the water pressure is sufficient (> 1.3 bar), close the filling

To help limit the energy consumption, it is recommended to set tap again.

the room thermostat to a lower temperature a few hours before If there is air in the installation, the boiler can switch on, but the

going to bed. radiators remain cold.

Turn all radiator taps fully open in the rooms that you want to Follow the instructions from the manufacturer/installer for the

heat. venting of possible other elements of the heating installation,

Shut the radiator taps off in the rooms where you do not want such as floor heating.

any heating. Fully open all radiator taps.

Vent the radiators after the pump is switched off.

Cleaning the unit Open the air bleed cocks of the radiators one at a time. Use an

Regularly clean the outside of the unit with a soft, damp cloth. It air bleed key for this.

is not necessary to shut the gas tap off or switch the mains off As soon as water comes out of the air bleed cock, shut the cock

for this. off again.

Never use aggressive or flammable cleaning agents. If the central heating boiler is at the highest point of the

Take note that the pipes can be at a high temperature. installation, air can collect in the boiler. This can cause a

malfunction in the boiler. Also vent the internal tap pot (only with

Holidays a Combi-unit).

With long-term absence, for example in the holidays, it is

recommended to leave the unit continually switched on. The Other causes

reason is that the unit makes a number of checks every 24 There must be heat demand from the room thermostat or other

hours. control, otherwise the boiler will not switch on. Set the

If frost can be excluded, set the room thermostat to a lower thermostat to demand heat and check whether the boiler

temperature. switches on; this can take a minute or so.

If frost cannot be excluded, set the room thermostat to a

temperature of 12°C or higher. If there is little water circulation because too many radiator taps

Although the unit has an internal frost protection, this does not are closed, the boiler will not function or will function

protect the whole installation against freezing. insufficiently. In this case, open more radiator taps or ask your

installer to fit a bypass valve.

Brrrr, the central heating is not working

In the unlikely event that the central heating has let you down,

we have some tips for things that you can check and remedly

yourself before an installer.

The central heating boiler is a fairly complicated item that is

fitted with safety devices, which prevent a dangerous situation.

There can be many reasons why the central heating is not

working.

Electricity and gas

Is the connection of the green block in the green socket correct

connected?

Is the main switch on the unit in the right position?

Or is the circuit to which the boiler is connected out of operation

because the fuse has blown or the earth leakage switch has

activated?

Is there an (unusual) interruption in the gas supply? Check by

seeing whether a gas cooker in the kitchen is working. If it is not

working, call the gas company. The gas flow can also be

blocked because the gas filter of the boiler is contaminated; this

is a problem for the service man.

The unit also lets the pump regularly run outside the heating

season to prevent it from sticking. If the mains supply outside is

interrupted several times during the heating season, the pump

can stick. Solution: turn the shaft of the pump a few times by

hand (screwdriver).

Water and air

If the water pressure in the installation falls below a minimum

level, the burner will be off.

Solution: Top up with water.

It is possible to read the water pressure directly from the display.

Reading: Press the + button in for a minimum of 5 seconds.

From the menu back to normal operation: Press the - button in

briefly (or automatically after about 5 minutes).

During filling, the unit must be connected to the mains and be

switched on.

7

Downloaded from www.Manualslib.com manuals search engine

user instructions TWIN80C_EN

2006 Coopra Advanced Heating Technologies b.v.

All rights reserved.

The information supplied in this document is based on general data with regard to constructions, material characteristics and working

methods known at the time of going to print. Therefore, we reserve the right to make changes without notification. For this reason, the

instructions given serve only as a guideline for the use of the units shown on the cover of this document.

This document is valid for the unit in its standard version. Therefore, the manufacturer cannot be held liable for any damage arising

from specifications that deviate from the standard version of the unit delivered to you.

This document has been compiled with all possible care. However, the manufacturer cannot be held liable for any mistakes in this

document or for any consequences.

Take the time to read this document carefully before installing or using the unit. Always keep this document near the unit.

Coopra Advanced Heating Technologies b.v.

Vierlinghstraat 14

NL 3316 EL Dordrecht

Tel: +31 (0) 78 – 653 08 30

Fax: +31 (0) 78 – 653 08 33

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Manual Termostato Digitall t6812 FancoilDocument4 pagesManual Termostato Digitall t6812 FancoilaarroyofNo ratings yet

- Digital Thermostat T0140Document21 pagesDigital Thermostat T0140jondough56No ratings yet

- Power Vent / Intellivent With FVIR ClassroomDocument48 pagesPower Vent / Intellivent With FVIR ClassroomCarlos Sanchez RojasNo ratings yet

- A.O.smith Intellli Vent Control Information When Used On Gas Residential, Power Vented Water HDocument27 pagesA.O.smith Intellli Vent Control Information When Used On Gas Residential, Power Vented Water HDmitriy SemakovNo ratings yet

- Hotwater Heater Controller ManualDocument48 pagesHotwater Heater Controller Manualimateleporter247No ratings yet

- SET-002ALNE(2 pipe)-ELNE(4 pipe)-(3Speed OnOffValve)Document2 pagesSET-002ALNE(2 pipe)-ELNE(4 pipe)-(3Speed OnOffValve)jimmylo3224No ratings yet

- Four-Pipe Fan Coil Room Thermostat GuideDocument6 pagesFour-Pipe Fan Coil Room Thermostat GuideIONUT PRISECARUNo ratings yet

- T-Reg300 EngDocument12 pagesT-Reg300 EngFlorin BocanetNo ratings yet

- ΤΕΧΝΙΚΟ ΕΓΧΕΙΡΙΔΙΟ Ecomfort -UtDocument8 pagesΤΕΧΝΙΚΟ ΕΓΧΕΙΡΙΔΙΟ Ecomfort -UtHousambaNo ratings yet

- 450 RR 1Document18 pages450 RR 1aliNo ratings yet

- 30410a InstallDocument17 pages30410a InstallIBJSC.comNo ratings yet

- Manual de Operación de Placa de CalentamientoDocument24 pagesManual de Operación de Placa de CalentamientoAnonymous Se5IdneSpNo ratings yet

- BAC-002 ModbusDocument2 pagesBAC-002 ModbusAlfredo Ferrari Jr.No ratings yet

- T1010 Manual Install Rev 1Document15 pagesT1010 Manual Install Rev 1Eridy AntuanNo ratings yet

- 2HFF4 2Document12 pages2HFF4 2AhmmedNo ratings yet

- Wall-Hung Gas Boilers: EnglishDocument12 pagesWall-Hung Gas Boilers: EnglishwefeNo ratings yet

- Water Temperature Control Using Siemens PLC and HMIDocument9 pagesWater Temperature Control Using Siemens PLC and HMIMunimNo ratings yet

- Bac-1000mlnDocument2 pagesBac-1000mlndendincNo ratings yet

- LC 54Document16 pagesLC 54Christos ChristofiNo ratings yet

- Emos P5601N UputstvoDocument80 pagesEmos P5601N UputstvoXavier Xavierson100% (2)

- TP-N-511 TP-N-521: Non-Programmable ThermostatsDocument7 pagesTP-N-511 TP-N-521: Non-Programmable ThermostatsTheresa CoeNo ratings yet

- Anti Ice R 01 160820223916Document30 pagesAnti Ice R 01 160820223916Eddy JhetNo ratings yet

- E2EB Inter Therm Central AirDocument28 pagesE2EB Inter Therm Central AirJason D ClarkNo ratings yet

- CENTROPELET-ZV ZVB-serviseri-ENG N 03 2015Document22 pagesCENTROPELET-ZV ZVB-serviseri-ENG N 03 2015Miloš Stijelja75% (4)

- STC-1000 Temperature Controller Operating Manual: or or orDocument1 pageSTC-1000 Temperature Controller Operating Manual: or or orziandNo ratings yet

- Operating Manual: PRO 1000 SeriesDocument48 pagesOperating Manual: PRO 1000 SeriesWilfredo GutierrezNo ratings yet

- Digital Lab OvenDocument3 pagesDigital Lab Ovenananda_beloshe75No ratings yet

- Assembly Manual: Thermometer/ ThermostatDocument10 pagesAssembly Manual: Thermometer/ Thermostatsaric_terrill4785No ratings yet

- Termostat Ventiloconvector - Siemens - RAB31 - Modificat PDFDocument5 pagesTermostat Ventiloconvector - Siemens - RAB31 - Modificat PDFpriseNo ratings yet

- Termostat Ventiloconvector - Siemens - RAB31 - Modificat PDFDocument5 pagesTermostat Ventiloconvector - Siemens - RAB31 - Modificat PDFpriseNo ratings yet

- Heatec: Tec-NoteDocument11 pagesHeatec: Tec-Notepowerslave123No ratings yet

- TOL47WIFI Heating Thermostat ManualDocument3 pagesTOL47WIFI Heating Thermostat ManualJorge Juan MANRIQUENo ratings yet

- 2. ILR HBC-80 TrainingDocument24 pages2. ILR HBC-80 Trainingkasilibomani99No ratings yet

- Model: RT310RF: Installation ManualDocument15 pagesModel: RT310RF: Installation ManualbestducuNo ratings yet

- 1 Midea+mpk+09cen2+mpk+10er+Document21 pages1 Midea+mpk+09cen2+mpk+10er+victorjoseteixeiraNo ratings yet

- Heat Pump User Manual: Comprehensive Version (EVI Heat Pump and High Temp. Heat Pump)Document39 pagesHeat Pump User Manual: Comprehensive Version (EVI Heat Pump and High Temp. Heat Pump)vino ananditaNo ratings yet

- Foster Cold Room ManualDocument45 pagesFoster Cold Room Manualamerican_guy10100% (1)

- BAC-1000 Room ThermostatDocument2 pagesBAC-1000 Room ThermostatMd Amir Hossain0% (1)

- 20151210201922RC-112E User Manual220v10Document2 pages20151210201922RC-112E User Manual220v10Anonymous ZLmk6mPPnNo ratings yet

- Manual PDF REFRIGERACION 43154 PDFDocument7 pagesManual PDF REFRIGERACION 43154 PDFRodrigo PedrínNo ratings yet

- Manual Source1 S1-TheC11NS Rev 4Document25 pagesManual Source1 S1-TheC11NS Rev 4nichokolNo ratings yet

- Curing Oven Operation ManualDocument16 pagesCuring Oven Operation ManualWONG TS0% (1)

- UC8 Troubleshooting Guide v2 0715 2Document18 pagesUC8 Troubleshooting Guide v2 0715 2j.knightNo ratings yet

- Mitsubishi InterfaceDocument9 pagesMitsubishi Interfaceslather-faunas.0cNo ratings yet

- TopTech Value Series Non-Programmable ManualDocument7 pagesTopTech Value Series Non-Programmable ManualCassieNo ratings yet

- Product Specs, Diagrams, and Troubleshooting GuideDocument28 pagesProduct Specs, Diagrams, and Troubleshooting GuideAndres Araujo GarciaNo ratings yet

- SP1 ManualDocument13 pagesSP1 ManualAnonymous RCPxaonfvNo ratings yet

- SP 24 ManualDocument7 pagesSP 24 ManualOrlando Meza MachadoNo ratings yet

- Cooling Tower Basin Heater Control Panel: Installation, Operating, and Maintenance InstructionsDocument4 pagesCooling Tower Basin Heater Control Panel: Installation, Operating, and Maintenance InstructionspayNo ratings yet

- AT249PD - L'hermomatic Dimpling Control Unit - Operating and Maintenance ManualDocument8 pagesAT249PD - L'hermomatic Dimpling Control Unit - Operating and Maintenance ManualMARTY CARTERNo ratings yet

- MP908FCT-2: Fan Coil Unit On/Off Digital ThermostatDocument1 pageMP908FCT-2: Fan Coil Unit On/Off Digital ThermostatChhomNo ratings yet

- SHWZ001 Electric Heater User ManualDocument6 pagesSHWZ001 Electric Heater User ManualMiguel DuarteNo ratings yet

- Termostato Electronico EmersonDocument16 pagesTermostato Electronico Emersonaldariz201181No ratings yet

- Bếp Từ Panasonic Ky-c227absdDocument47 pagesBếp Từ Panasonic Ky-c227absdDientu-huy HieubangnbNo ratings yet

- Ekc 102 Rs8dy302Document12 pagesEkc 102 Rs8dy302alphyjayemilianoNo ratings yet

- AlthermaHT UKEPLEN13 724 Tcm511 277337Document2 pagesAlthermaHT UKEPLEN13 724 Tcm511 277337UrosGolubNo ratings yet

- Temperature Controlled Automatic DC Fan: Group MembersDocument17 pagesTemperature Controlled Automatic DC Fan: Group MembersAsad saeedNo ratings yet

- Digital LED Thermometer with Microcontroller AVR ATtiny13From EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Rating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Panasonic Pcz1104070ce Tx-P42st30e tx-p42st30j tx-pf42st30 tx-pr42st30 Chassis Gpf14d-EDocument138 pagesPanasonic Pcz1104070ce Tx-P42st30e tx-p42st30j tx-pf42st30 tx-pr42st30 Chassis Gpf14d-EnovyNo ratings yet

- Course On: Big Data AnalyticsDocument52 pagesCourse On: Big Data Analyticsmunish kumar agarwalNo ratings yet

- CCNA ACLsDocument14 pagesCCNA ACLsUsama Weince JuttNo ratings yet

- Edureka Data Science Masters Program CurriculumDocument41 pagesEdureka Data Science Masters Program CurriculumMeenal Luther NhürNo ratings yet

- Neutral Quick Installation Guide (For Dome CMIP70x2W-28MA) - 20210413Document1 pageNeutral Quick Installation Guide (For Dome CMIP70x2W-28MA) - 20210413Marvin Caballero ZelayaNo ratings yet

- (BURNDY) SectionD Grounding06Document94 pages(BURNDY) SectionD Grounding06María José CucanchonNo ratings yet

- CertusimDocument126 pagesCertusimemerson malafaiaNo ratings yet

- QuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERDocument14 pagesQuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERKrisman SimanjuntakNo ratings yet

- Testing of Magnetic Flow Meters in Nonideal Conditions: Conference PaperDocument13 pagesTesting of Magnetic Flow Meters in Nonideal Conditions: Conference PaperpinkcityNo ratings yet

- UTF-8'en'QRadar SIEM and ZscalerDocument20 pagesUTF-8'en'QRadar SIEM and ZscalerDens Can't Be PerfectNo ratings yet

- 9th ScienceDocument4 pages9th ScienceRam Prasad BismilNo ratings yet

- Offshore Floating Met MastDocument26 pagesOffshore Floating Met MastOnkar SinghNo ratings yet

- Design Review AI: ScopeDocument17 pagesDesign Review AI: ScopeAurunisbi Aldino AuliaNo ratings yet

- Baby Techni ReportDocument25 pagesBaby Techni Reportwww.timzbaba100% (1)

- CCN NOTS Final Unit - 2Document38 pagesCCN NOTS Final Unit - 2Suresha V SathegalaNo ratings yet

- GGHH 60 HZ Generator SetDocument9 pagesGGHH 60 HZ Generator SetDaniel RojasNo ratings yet

- Affan-Udemy RewriteDocument4 pagesAffan-Udemy RewriteAlexander Odge100% (1)

- Amjad Ali SoomroDocument3 pagesAmjad Ali SoomroAli SoomroNo ratings yet

- Lab 1 - Code Conversion.: A. IntroductionDocument22 pagesLab 1 - Code Conversion.: A. IntroductionAishwarya JSNo ratings yet

- Webrtc Book ExcerptDocument15 pagesWebrtc Book ExcerptAlan B. JohnstonNo ratings yet

- MCC - Assistant Computer Operator (01-07-2022)Document5 pagesMCC - Assistant Computer Operator (01-07-2022)Ajay AgarwalNo ratings yet

- Republic ActDocument4 pagesRepublic ActGwen CaldonaNo ratings yet

- Crypto TLSDocument11 pagesCrypto TLSAuliya RusyidaNo ratings yet

- Yawopay Pitch Desk v1Document15 pagesYawopay Pitch Desk v1Profil BasNo ratings yet

- Ayurveda ReportDocument75 pagesAyurveda ReportPrince GargNo ratings yet

- Data Sheet 3VA1580-5EF32-0AA0: ModelDocument7 pagesData Sheet 3VA1580-5EF32-0AA0: ModelFelipe FrancoNo ratings yet

- DocumentaryDocument3 pagesDocumentarymanoj ranathiiveNo ratings yet

- Introduction To TCL SCLDocument89 pagesIntroduction To TCL SCLStajic Milan100% (5)

- Transacciones SAP PSDocument67 pagesTransacciones SAP PSpablopfv0% (1)