Professional Documents

Culture Documents

(Nonmandatory Information) X1. Friability Ratings

Uploaded by

le hoang vietOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Nonmandatory Information) X1. Friability Ratings

Uploaded by

le hoang vietCopyright:

Available Formats

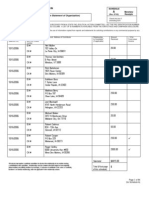

A 701

shall be agreed upon between the purchaser and the manufac- 9. Rejection

turer. Such elements in trace quantities shall be reported as less

9.1 Any claim or rejection shall be made to the seller within

than “<” the limit of analytical equipment. This shall be

45 days from receipt of material by the purchaser.

mutually agreed uon between the purchaser and the manufac-

turer.

7.3 For purposes of determining conformance with this 10. Packaging and Package Marking

specification, the reported analysis shall be rounded to the 10.1 The material shall be packed in containers suitably

nearest unit in the last right-hand place of figures used in designed to withstand shipping handling or shipped in bulk so

expressing the limiting value, in accordance with the rounding that no material is lost or contaminated in transit.

method of Practice E 29.

11. Keywords

8. Inspection

8.1 The manufacturer shall afford the inspector representing 11.1 ferromanganese-silicon

the purchaser all reasonable facilities, without charge, to satisfy

him that the material is being furnished in accordance with this

specification.

APPENDIX

(Nonmandatory Information)

X1. FRIABILITY RATINGS

Code No. Definition

1 Very tough materials which are susceptible to little, if any, breakage during shipment or handling.

(Example: low-carbon ferrochrome)

2 Some breakage of large pieces probable in shipping and handling. No appreciable fines produced from either

lump or crushed sizes.

(Example: chrome metal)

3 Appreciable reduction in size of large pieces possible in shipping and handling. No appreciable production

of fines in handling of crushed sizes.

(Example: ferrovanadium)

4 Appreciable reduction in size of large pieces upon repeated handling. Some fines produced upon repeated

handling of crushed sizes.

(Example: Standard ferromanganese)

5 Appreciable reduction in size in repeated handling of large pieces. Appreciable fines may be produced in the

handling of crushed sizes.

(Example: 50 percent ferrosilicon)

6 This category represents the most friable alloys.

(Example: calcium-silicon)

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above address or at

610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website (www.astm.org).

You might also like

- Doskvol: Scores: Skullduggery CivilianDocument2 pagesDoskvol: Scores: Skullduggery CivilianJulian DardenneNo ratings yet

- The Starting Point of All Achievement Is DESIREDocument61 pagesThe Starting Point of All Achievement Is DESIREMayirp Remo100% (2)

- Confessio RC Fraternitatis by Dr. H. Spencer Lewis (English)Document100 pagesConfessio RC Fraternitatis by Dr. H. Spencer Lewis (English)Lagduf100% (2)

- Registration Standing Order TNDocument520 pagesRegistration Standing Order TNRavishankar75% (4)

- Astm F 1110Document4 pagesAstm F 1110eliasNo ratings yet

- Banking Law DoctrinesDocument3 pagesBanking Law DoctrinesJun JunNo ratings yet

- D227 PDFDocument2 pagesD227 PDFArnold RojasNo ratings yet

- Sample Employment ContractDocument5 pagesSample Employment ContractWorkMonkNo ratings yet

- Aboitiz Shipping Corp. vs. CADocument2 pagesAboitiz Shipping Corp. vs. CABay Nald LaraNo ratings yet

- Astm D 3310 - 00Document2 pagesAstm D 3310 - 00phaindika100% (1)

- Astm C1264-19Document3 pagesAstm C1264-19Stefano CamillucciNo ratings yet

- C22-C22M - 00 (Reapproved 2010)Document2 pagesC22-C22M - 00 (Reapproved 2010)Black Goku0% (1)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionFrom EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionNo ratings yet

- Astm D-1752Document2 pagesAstm D-1752Franchute83No ratings yet

- Group Dynamics 1Document12 pagesGroup Dynamics 1Varun Lalwani100% (2)

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- Case Digest - Corpus Vs CuadernoDocument2 pagesCase Digest - Corpus Vs CuadernoMeriam Wong100% (4)

- Index of Organizational ReactionsDocument6 pagesIndex of Organizational ReactionsLeana Polston-Murdoch100% (1)

- Composite MaterialsFrom EverandComposite MaterialsA.T. Di BenedettoRating: 1 out of 5 stars1/5 (1)

- Transactional Analysis HandoutDocument5 pagesTransactional Analysis HandoutJai Prakash YadavNo ratings yet

- Resistance of Organic Coatings To The Effects of Rapid Deformation (Impact)Document3 pagesResistance of Organic Coatings To The Effects of Rapid Deformation (Impact)hernando gelvesNo ratings yet

- Astm B843 1993 PDFDocument2 pagesAstm B843 1993 PDFAriq FauzanNo ratings yet

- Ferromanganese-Silicon: Standard Specification ForDocument2 pagesFerromanganese-Silicon: Standard Specification ForGustavo SuarezNo ratings yet

- B237Document2 pagesB237Ashkan Nourizadeh DehkordiNo ratings yet

- Coal-Tar-Saturated Organic Felt Used in Roofing and WaterproofingDocument3 pagesCoal-Tar-Saturated Organic Felt Used in Roofing and WaterproofingRufo CascoNo ratings yet

- B364 96Document3 pagesB364 96Srinivasan KrishnamoorthyNo ratings yet

- Latex Agents For Bonding Fresh To Hardened ConcreteDocument2 pagesLatex Agents For Bonding Fresh To Hardened ConcreteEvert RiveraNo ratings yet

- C 1059 - 99 QzewntkDocument2 pagesC 1059 - 99 QzewntkEnrique Alejandro OvandoNo ratings yet

- C59C59M Gypsum Casting Plaster and Gypsum Molding PlasterDocument2 pagesC59C59M Gypsum Casting Plaster and Gypsum Molding PlasterEder DávilaNo ratings yet

- Latex Agents For Bonding Fresh To Hardened ConcreteDocument2 pagesLatex Agents For Bonding Fresh To Hardened ConcreteJesús Luis Arce GuillermoNo ratings yet

- Carbon Black-Sieve Residue: Standard Test Method ForDocument3 pagesCarbon Black-Sieve Residue: Standard Test Method Forc458qvws28No ratings yet

- D43 PDFDocument2 pagesD43 PDFArnold RojasNo ratings yet

- Limestone For Animal Feed UseDocument2 pagesLimestone For Animal Feed Usekoushik15No ratings yet

- Astm C933-11Document2 pagesAstm C933-11Luis Galarreta LedesmaNo ratings yet

- Asphalt Used in Canal, Ditch, and Pond Lining: Standard Specification ForDocument2 pagesAsphalt Used in Canal, Ditch, and Pond Lining: Standard Specification FordaovandongpktNo ratings yet

- C 317 - C 317M - 00 Qzmxny9dmze3tqDocument2 pagesC 317 - C 317M - 00 Qzmxny9dmze3tqHumberto GutierrezNo ratings yet

- Astm A845Document2 pagesAstm A845Jesus VelizNo ratings yet

- Inorganic Underlayment For Use With Steep Slope Roofing ProductsDocument2 pagesInorganic Underlayment For Use With Steep Slope Roofing ProductsMohammad YaseenNo ratings yet

- Sizes of Ferroalloys and Alloy Additives: Standard Specification ForDocument2 pagesSizes of Ferroalloys and Alloy Additives: Standard Specification ForGustavo SuarezNo ratings yet

- D6909 10 (2016)Document2 pagesD6909 10 (2016)tuyjvbnvNo ratings yet

- Sandwich Corrosion Test: Standard Test Method ForDocument4 pagesSandwich Corrosion Test: Standard Test Method ForJuanNo ratings yet

- D 1863 - 03 Rde4njmDocument2 pagesD 1863 - 03 Rde4njmdaovandongpktNo ratings yet

- C22 PDFDocument2 pagesC22 PDFLW85100% (1)

- Water-Or Solvent-Soluble Liquid Adhesives For Automatic Machine Sealing of Top Flaps of Fiberboard Shipping CasesDocument2 pagesWater-Or Solvent-Soluble Liquid Adhesives For Automatic Machine Sealing of Top Flaps of Fiberboard Shipping CasesAlevj DbNo ratings yet

- 02-Cert-Norm Astm D-4479Document2 pages02-Cert-Norm Astm D-4479Nicole BrigmannNo ratings yet

- ASTM D2794.tzep1589Document3 pagesASTM D2794.tzep1589Kevin XuNo ratings yet

- Sampling, Inspection, Rejection, Certification, Packaging, Marking, Shipping, Handling, and Storage of Gypsum Panel ProductsDocument2 pagesSampling, Inspection, Rejection, Certification, Packaging, Marking, Shipping, Handling, and Storage of Gypsum Panel ProductsJerome PalicteNo ratings yet

- Silver-Tungsten Electrical Contact Materials: Standard Specification ForDocument4 pagesSilver-Tungsten Electrical Contact Materials: Standard Specification ForsamehNo ratings yet

- B39-79 (2013) Standard Specification For NickelDocument3 pagesB39-79 (2013) Standard Specification For NickeldcardonasterNo ratings yet

- ASTM C 121 Standard Test Method For Water Absorption of SlateDocument3 pagesASTM C 121 Standard Test Method For Water Absorption of SlateRyan LasacaNo ratings yet

- D 2091 - 96 - RdiwotetotyDocument3 pagesD 2091 - 96 - RdiwotetotymorchedtounsiNo ratings yet

- Sampling and Testing Ferroalloys For Determination of Size: Standard Test Methods ForDocument2 pagesSampling and Testing Ferroalloys For Determination of Size: Standard Test Methods ForGustavo SuarezNo ratings yet

- Astm A 610 PDFDocument2 pagesAstm A 610 PDFMohamed Ahmed MaherNo ratings yet

- 11.01 Astm-D2794-Impact-ResistanceDocument4 pages11.01 Astm-D2794-Impact-ResistancehoanvuNo ratings yet

- Astm C 22C 22MDocument2 pagesAstm C 22C 22MProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNo ratings yet

- Ferrochromium: Standard Specification ForDocument3 pagesFerrochromium: Standard Specification ForleonciomavarezNo ratings yet

- PDFsam - B 413 - 97a (2012)Document3 pagesPDFsam - B 413 - 97a (2012)mike.jensen0581No ratings yet

- C847Document2 pagesC847reefreefNo ratings yet

- D 5643 - 94 R00 Rdu2ndmDocument2 pagesD 5643 - 94 R00 Rdu2ndmmang juhaiNo ratings yet

- Bonding Compounds For Interior Gypsum PlasteringDocument5 pagesBonding Compounds For Interior Gypsum PlasteringSgjsevenpNo ratings yet

- Astm A 101Document3 pagesAstm A 101RECEP ÇETİNKAYANo ratings yet

- Astm C932Document5 pagesAstm C932adolfo camayoNo ratings yet

- Astm A 323 - 93 R00Document3 pagesAstm A 323 - 93 R00Er WidodoNo ratings yet

- D 1874 - 62 R04 Rde4nzqDocument2 pagesD 1874 - 62 R04 Rde4nzqMarceloNo ratings yet

- C1788-14 Standard Specification For Non Metallic Plaster Bases (Lath) Used With Portland Cement Based Plaster in Vertical Wall ApplicationsDocument2 pagesC1788-14 Standard Specification For Non Metallic Plaster Bases (Lath) Used With Portland Cement Based Plaster in Vertical Wall ApplicationsmithileshNo ratings yet

- Latex Agents For Bonding Fresh To Hardened ConcreteDocument2 pagesLatex Agents For Bonding Fresh To Hardened ConcretemickyfelixNo ratings yet

- 1P-60910-2 Detail of Manway For Urea Reactor R06101 R2Document1 page1P-60910-2 Detail of Manway For Urea Reactor R06101 R2le hoang vietNo ratings yet

- 1P-60910 General Assembly For Carbamate Separator R06101 R2Document1 page1P-60910 General Assembly For Carbamate Separator R06101 R2le hoang vietNo ratings yet

- 1P-60910-4 Liner Detail For Urea Reactor R06101 R2Document1 page1P-60910-4 Liner Detail For Urea Reactor R06101 R2le hoang vietNo ratings yet

- 1P-60910-1 Detail of Nozzles For Urea Reactor R06101 R3Document1 page1P-60910-1 Detail of Nozzles For Urea Reactor R06101 R3le hoang vietNo ratings yet

- 1P-60910 General Assembly For Carbamate Separator R06101 R2Document1 page1P-60910 General Assembly For Carbamate Separator R06101 R2le hoang vietNo ratings yet

- A 709/A 709M - 01b: N 1 - Where ". - ." Appears in This Table, There Is No RequirementDocument1 pageA 709/A 709M - 01b: N 1 - Where ". - ." Appears in This Table, There Is No Requirementle hoang vietNo ratings yet

- TABLE 1 Materials For Line Posts and Assemblies: A B A BDocument1 pageTABLE 1 Materials For Line Posts and Assemblies: A B A Ble hoang vietNo ratings yet

- Low-Alloy Steel Deformed and Plain Bars For Concrete ReinforcementDocument5 pagesLow-Alloy Steel Deformed and Plain Bars For Concrete Reinforcementle hoang vietNo ratings yet

- A 709/A 709M - 01b: TABLE S1.1 Impact Testing Temperature ZonesDocument2 pagesA 709/A 709M - 01b: TABLE S1.1 Impact Testing Temperature Zonesle hoang vietNo ratings yet

- D2992-12 Standard Practice For Obtaining Hydrostatic or Pressure Design Basis For "FiberglDocument11 pagesD2992-12 Standard Practice For Obtaining Hydrostatic or Pressure Design Basis For "Fiberglle hoang vietNo ratings yet

- A New Mission For StarbucksDocument16 pagesA New Mission For StarbucksmuuayliiNo ratings yet

- Heart Paws EAPPDocument2 pagesHeart Paws EAPPIlog Mark Lawrence E.No ratings yet

- Remedies in Tort LawDocument22 pagesRemedies in Tort LawDiana RamlanNo ratings yet

- Callado Case DigestDocument1 pageCallado Case DigestYawa HeheNo ratings yet

- HSC Commerce 2015 March OcDocument2 pagesHSC Commerce 2015 March OcManish SharmaNo ratings yet

- Arrest Log July 17, 2016-July 23, 2016Document10 pagesArrest Log July 17, 2016-July 23, 2016MansfieldMAPoliceNo ratings yet

- Socrates - The Man and His MissionDocument394 pagesSocrates - The Man and His MissionMimilikys100% (1)

- Alternatives To IncarcerationDocument3 pagesAlternatives To IncarcerationghurapNo ratings yet

- Why Its Cool To Be Kind British English TeacherDocument14 pagesWhy Its Cool To Be Kind British English TeacherMaria Dolores RodriguezNo ratings yet

- Ethics in LifeDocument32 pagesEthics in Lifeprateek buddyNo ratings yet

- Danger of Smoking in The MorningDocument6 pagesDanger of Smoking in The MorningindriNo ratings yet

- Presentation (Four Pillars)Document13 pagesPresentation (Four Pillars)Nor HazimahNo ratings yet

- Culver Chet - 5083 - A - ContributionsDocument85 pagesCulver Chet - 5083 - A - ContributionsZach EdwardsNo ratings yet

- Listening Be4 - Mergers and Acquisitions: Task 5.1Document4 pagesListening Be4 - Mergers and Acquisitions: Task 5.1Trần ThuânNo ratings yet

- Biomedical ResearchDocument4 pagesBiomedical ResearchLiliana RogozeaNo ratings yet

- IFJ Pacific Media Freedom ReportDocument60 pagesIFJ Pacific Media Freedom ReportRicardo MorrisNo ratings yet

- Course Syllabus Template - 2017Document3 pagesCourse Syllabus Template - 2017Anonymous BBs1xxk96VNo ratings yet

- Angry QuoteDocument5 pagesAngry QuoteAnggraeni EnnieNo ratings yet

- How To Make Your Wife HappyDocument4 pagesHow To Make Your Wife HappyShahid KhanNo ratings yet