Professional Documents

Culture Documents

Cse-I-Elements of Mechanical Engg. l1

Uploaded by

Hemanth Kumar ReddyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cse-I-Elements of Mechanical Engg. l1

Uploaded by

Hemanth Kumar ReddyCopyright:

Available Formats

Elements of Mechanical Engineering 15EME14

Elements of Mechanical Engineering

Subject Code: 15EME14/15 EME 24 IA Marks: 20

Hours/Week: 04 Exams. Hours: 03

Total Hours: 50 Exams. Marks: 80

Course Objectives:

Students belonging to all branches of Engineering are made to learn certain fundamental topics

related to mechanical engineering so that they will have a minimum understanding of mechanical

systems, equipment and process.

Module - 1

Energy Resources: Non-renewable and renewable energy resources, Petroleum based solid,

liquid and gaseous fuels, Calorific values of fuels, Combustion and combustion products of fuels,

Solar Power: Solar Radiation, Solar constant (definition only), Solar Thermal energy harvesting,

ex: liquid flat plate collectors, solar ponds (principle of operation only), Solar photovoltaic

principle. Wind Power: principle of operation of a typical windmill. Hydro Power: Principles

of electric power generation from hydro power plants, Nuclear Power: Principles of Nuclear

power plants, Bio Fuels: introduction to bio fuels, examples of various biofuels used in

engineering applications, Comparison of biofuels with petroleum fuels in terms of calorific value

and emission.

Steam Formation and Properties: Classification of boilers, Lancashire boiler, Babcock and

Wilcox boiler, boiler mountings and accessories (No sketches for mountings and accessories),

wet steam, saturated and superheated steam, specific volume, enthalpy and internal energy. (No

numerical problems in this module) 10 Hours

Module- 2

Turbines and IC Engines and Pumps

SteamMturbines – Classification, Principle of operation of Impulse and reaction turbines,

Delaval’s turbine, Parson’s turbine. (No compounding of turbines).

Gas turbines: Classification, Working principles and Operations of Open cycle and closed cycle

gas turbines.

Water turbines- Classification, Principles and operations of Pelton wheel, Francis turbine and

Kaplan turbine

Department of Mechanical Engineering, SJBIT Page 1

Elements of Mechanical Engineering 15EME14

Internal Combustion Engines

Classification, I.C. Engines parts, 2 Stroke and 4 stroke Petrol engines, 4 stroke diesel engines.

P-V diagrams of Otto and Diesel cycles. Problems on indicated power, brake power, indicated

thermal efficiency, brake thermal efficiency, mechanical efficiency, and specific fuel

consumption

[Numerical on IC Engines] 10 Hours

Module -3

Machine Tools and Automation

Machine Tools Operations:

Turning, facing, knurling, Thread cutting, Taper Turning by swivelling the compound rest,

Drilling, Boring, Reaming, Tapping, Counter Sinking, Counter Boring, -Plane milling, End

milling, Slot milling. (No sketches of Machine tools, sketches to be used only for explaining

operations. Students to be shown the available machine tools in the Machine Shop of the college

before explaining the operations)

Robotics and Automation:

Robotics: Introduction, classification based on robots configuration; Polar, cylindrical, Cartesian

Coordinate and spherical. Application, Advantages, and disadvantages

Automation: Definition, types –Fixed, Programmable & Flexible automation, NC/ CNC

machines:

Basic elements with simple block diagrams, advantages and disadvantages. 10 Hours

Module - 4

Engineering materials and joining processes:

Engineering Materials: Types and applications of Ferrous & Nonferrous metals and alloys,

Composites: Introduction: Definition, Classification and applications (Air craft and

Automobiles)

Soldering, Brazing and Welding:

Definitions, classification and method of soldering, Brazing and welding. Differences between

soldering, Brazing and Welding. Description of Electric Arc Welding and Oxy-Acetylene

Welding. 10 Hours

Department of Mechanical Engineering, SJBIT Page 2

Elements of Mechanical Engineering 15EME14

Module – 5

Refrigeration, Air-Conditioning

Refrigerants: properties of refrigerants, list of commonly used refrigerants. Refrigeration –

Definitions – Refrigerating effect, Ton of Refrigeration, Ice making capacity, COP, Relative

COP, unit of Refrigeration. Principle and working of vapor compression refrigeration and vapour

absorption refrigeration: Principles and applications of air conditioners, Room air conditioner.

10 hours

Course outcomes:

Students shall demonstrate the Knowledge associated with,

1. Various Energy sources, Boilers, Prime movers such as turbines and IC engines, Refrigeration

and air-conditioning systems

2. Metal removal process using Lathe, drilling, Milling Robotics and Automation.

3. Fair understanding of application and usage of various engineering materials.

Scheme of examination:

• Two full questions (with a maximum of four sub questions) of twenty marks each to be set

from each module. Each question should cover all the contents of the respective module.

• Students have to answer five full questions choosing one full question from each module

Text Books:

1. V.K.Manglik, “Elements of Mechanical Engineering”, PHI Publications, 2013. (Module-1, 2,

4, 5)

2. Mikell P.Groover, “Automation, Production Systems & CIM”, 3rd Edition, PHI (Module -3)

3. K.R.Gopalkrishna, “A text Book of Elements of Mechanical Engineering”-Subhash

Publishers, Bangalore. (Module -1, 2, 3, 4, 5)

Reference Books:

1. S.TrymbakaMurthy, “A Text Book of Elements of Mechanical Engineering”, 4th Edition

2006, Universities Press (India) Pvt Ltd, Hyderabad.

2. K.P.Roy, S.K.Hajra Choudhury, Nirjhar Roy, “Elements of Mechanical Engineering”, Media

Promoters & Publishers Pvt Ltd,Mumbai,7th Edition,2012

3. Pravin Kumar, “Basic Mechanical Engineering”, 2013 Edition, Pearson.

Department of Mechanical Engineering, SJBIT Page 3

Elements of Mechanical Engineering 15EME14

CONTENTS

Module 1 Energy Resources 5-12

Module 2 Turbines and IC Engines and Pumps 13-25

Module 3 Machine Tools and Automation 26-45

Module 4 Engineering materials and joining processes 46-58

Module 5 Refrigeration, Air-Conditioning 58-66

Department of Mechanical Engineering, SJBIT Page 4

Elements of Mechanical Engineering 15EME14

Module - 1

Energy Resources

There are nine major areas of energy resources. They fall into two categories:

nonrenewable and renewable. Nonrenewable energy resources, like coal, nuclear, oil, and natural

gas, are available in limited supplies. This is usually due to the long time it takes for them to be

replenished. Renewable resources are replenished naturally and over relatively short periods of

time. The five major renewable energy resources are solar, wind, water (hydro), biomass, and

geothermal.

Since the dawn of humanity people have used renewable sources of energy to survive

wood for cooking and heating, wind and water for milling grain, and solar for lighting fires. A

little more than 150 years ago people created the technology to extract energy from the ancient

fossilized remains of plants and animals. These super-rich but limited sources of energy (coal,

oil, and natural gas) quickly replaced wood, wind, solar, and water as the main sources of fuel.

Fossil fuels make up a large portion of today’s energy market, although promising new

renewable technologies are emerging. Careers in both the renewable and nonrenewable energy

Department of Mechanical Engineering, SJBIT Page 5

Elements of Mechanical Engineering 15EME14

industries are growing; however, there are differences between the two sectors. They each have

benefits and challenges, and relate to unique technologies that play a role in our current energy

system. For a range of reasons, from the limited amount of fossil fuels available to their effects

on the environment, there is increased interest in using renewable forms of energy and

developing technologies to increase their efficiency. This growing industry calls for a new

workforce.

Renewable Energy sources: Defined as the energy resources which are produced continuously in

nature and are essentially inexhaustible at least in the time frame of human societies.

1. Ex: Direct solar energy

2. Wind energy

3. Tidal energy

4. Hydel energy

5. Ocean thermal energy

Non-Renewable Energy sources: defined as the energy resources which have been accumulated

over the ages and not quickly replenish able when they are exhausted.

1. Ex: Fossil fuels

2. Nuclear fuels

NUCLEAR FUELS

Alternative source of energy.

Uranium is the main element required to run a nuclear reactor.

Nuclear fission or fusion will produce tremendous amount of heat energy.

Nuclear fusion: Fusion energy is a form of nuclear energy released by the fusion (combustion)

of two light nuclei (i.e. nuclei of low mass) to produce heavier mass.

Nuclear fission:

Nuclear fission is the process, where a heavy nucleus splits into two fragments of more or

less of equal mass.

Department of Mechanical Engineering, SJBIT Page 6

Elements of Mechanical Engineering 15EME14

Neutron + Heavy nucleus → Fission fragments + Neutrons ( 2 to 3 ) + energy

The energy released by fission of I gram of U-235 is equal to that due to combustion of

50 million tons of coal ; it is about 8.5 x 1010 J.

Figure 1: Nuclear fission

NUCLEAR REACTOR

A nuclear reactor is a device which controls the nuclear fission chain reaction to

hardness nuclear energy for peaceful purposes.

A nuclear reactor which is used t generate electricity, is called a nuclear power plant.

Fuel in the form of pellets is enclosed in several tubular claddings of steel or aluminum.

This is called fuel assembly. Enriched U-235 or Pu-239 is the fuel material.

A coolant is circulated through the reactor to remove the heat generated. Ordinary water

is most commonly used coolant.

Rods made of boron or cadmium which are neutron absorbers are used as control rods.

The neutrons available for fission are controlled by moving the control rods in and out of

the nuclear core. The rods can be used to shut down the reactor.

Department of Mechanical Engineering, SJBIT Page 7

Elements of Mechanical Engineering 15EME14

Figure 2: Nuclear reactor

Heat produced during fission process is absorbed by the coolant and is used to convert

water in to steam in the heat exchanger. The steam is used to rotate the steam turbine.

The steam turbine is connected to a generator which generates electricity.

The entire reactor is enclosed in a concrete building with lead sheets covered inside to

prevent radioactive radiations being released in to the environment.

Steam Formation and Properties:

Steam Boilers:

Steam boiler is a closed vessel, which is used to convert water into steam at required temperature

and pressure by the application of heat.

Classification of Boilers:

1) Horizontal, vertical or inclined

2) Fire tube boiler & water tube boiler

3) Internally fired & externally fired boiler

4) Forced circulation & natural circulation

5) High pressure boiler & low pressure boiler

6) Single tube & multi tube boiler

7) Stationary & portable (locomotive) boiler

Department of Mechanical Engineering, SJBIT Page 8

Elements of Mechanical Engineering 15EME14

Lancashire Boiler:

Figure :Lancashire Boiler

Babcock & Wilcox Boiler:

Department of Mechanical Engineering, SJBIT Page 9

Elements of Mechanical Engineering 15EME14

Figure :Babcock & Wilcox Boiler

Boiler mountings:

The boiler mountings are necessary for the proper function & safety of a boiler.

Safety valve

Water level indicator

Pressure gauge

Blow off valve

Steam stop valve

Feed check valve

Boiler accessories:

Boiler accessories are auxiliary parts used in steam boilers for their proper functioning and to

improve the efficiency of the power plant.

Super heater

Economizer

Air pre-heater

Department of Mechanical Engineering, SJBIT Page 10

Elements of Mechanical Engineering 15EME14

Steam separator

Steam trap

Department of Mechanical Engineering, SJBIT Page 11

You might also like

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyFrom EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyRating: 5 out of 5 stars5/5 (1)

- Department of Mechanical Engineering, SJBITDocument65 pagesDepartment of Mechanical Engineering, SJBITMahavir DamakaleNo ratings yet

- Cse Eme NotesDocument65 pagesCse Eme NotesVedNo ratings yet

- Elements of Mechanical Engineering 15me14Document65 pagesElements of Mechanical Engineering 15me14Panchami RNo ratings yet

- EME (18ME15) - Notes-JSA & BMD PDFDocument93 pagesEME (18ME15) - Notes-JSA & BMD PDFDhaminiNo ratings yet

- 18ME25 Module-1 (WWW - Vtuloop.com)Document10 pages18ME25 Module-1 (WWW - Vtuloop.com)Robin BinoyNo ratings yet

- Elements of Mechanical Engg Syllabus (VTU)Document4 pagesElements of Mechanical Engg Syllabus (VTU)Prabhu SwamyNo ratings yet

- Engineering Colleges: Department of Mechanical EngineeringDocument126 pagesEngineering Colleges: Department of Mechanical EngineeringchandramouliNo ratings yet

- MTech EnergyDocument28 pagesMTech EnergyPrashant100% (1)

- NEW AND RENEWABLE ENERGY SYSTEMS INTRODUCTIONDocument32 pagesNEW AND RENEWABLE ENERGY SYSTEMS INTRODUCTIONdondbNo ratings yet

- Energy Engineering SyllabusDocument5 pagesEnergy Engineering SyllabusNikNo ratings yet

- Course File PPE OriginalDocument16 pagesCourse File PPE OriginalMadan Mohan ReddyNo ratings yet

- Energy Engg 18ME81 Introduction Syllabus MR Girish BDocument22 pagesEnergy Engg 18ME81 Introduction Syllabus MR Girish BGirish DNo ratings yet

- NoteDocument130 pagesNoterkNo ratings yet

- Power Plant Engineering Course OverviewDocument7 pagesPower Plant Engineering Course OverviewsumikannuNo ratings yet

- B. Tech. 8 Semester Mechanical Engineering: Theory Sessional TotalDocument10 pagesB. Tech. 8 Semester Mechanical Engineering: Theory Sessional TotalAbhishek MeNo ratings yet

- Institute of Engineering & Technology, Devi Ahilya University, Indore, (M.P.), India. (Scheme Effective From July 2015)Document2 pagesInstitute of Engineering & Technology, Devi Ahilya University, Indore, (M.P.), India. (Scheme Effective From July 2015)NARESH KUMARNo ratings yet

- 8th Sem SyllabusDocument10 pages8th Sem SyllabusSAUMYAJIT SABUINo ratings yet

- Mech PDFDocument2 pagesMech PDFKartik NadigerNo ratings yet

- 15eme14 PDFDocument5 pages15eme14 PDFRavichandran GNo ratings yet

- ME1052 - Steam Power Cycle - 19batchDocument4 pagesME1052 - Steam Power Cycle - 19batchOvini De SilvaNo ratings yet

- Fuel Cell Lectures Lecture 01Document106 pagesFuel Cell Lectures Lecture 01JaggaJatt100% (4)

- M.tech SyllabusDocument41 pagesM.tech SyllabusRushikeshKatkarNo ratings yet

- Lecture-1 NotesDocument24 pagesLecture-1 NotesmithiNo ratings yet

- ES II - Introduction and OverviewDocument23 pagesES II - Introduction and OverviewHPNo ratings yet

- Subject PlanDocument4 pagesSubject PlanAya HassanNo ratings yet

- Thermal Engineering SyllabusDocument144 pagesThermal Engineering SyllabusVpr NaturalsNo ratings yet

- Power Plant Engineering SyllabusDocument2 pagesPower Plant Engineering SyllabusPardeep8056No ratings yet

- ENERGY ENGINEERING SUBJECT CODE 10ME53Document2 pagesENERGY ENGINEERING SUBJECT CODE 10ME53Prashanth JagadeeshNo ratings yet

- Powerplant SyllabusDocument2 pagesPowerplant SyllabusATHARV BANSALNo ratings yet

- ME 6701 Power Plant Engineering EEE 5 Sem A & BDocument16 pagesME 6701 Power Plant Engineering EEE 5 Sem A & BprabuparthibanNo ratings yet

- Eme Sem 1 SyllabusDocument1 pageEme Sem 1 Syllabusapi-379010665No ratings yet

- Beme805T: Energy Conversion - Iii (Theory)Document2 pagesBeme805T: Energy Conversion - Iii (Theory)Saifuddin AhmedNo ratings yet

- ME8792 PPE by WWW - Learnengineering.inDocument136 pagesME8792 PPE by WWW - Learnengineering.inKarthi BENo ratings yet

- Basic Thermodynamics (BTME-305-18)Document14 pagesBasic Thermodynamics (BTME-305-18)Surjit Kumar GandhiNo ratings yet

- Mechanical Engineering Power Plant CourseDocument3 pagesMechanical Engineering Power Plant CourseVasudevan KunjithapathamNo ratings yet

- ERT SyllabusDocument2 pagesERT Syllabusnavneetkpatil8409No ratings yet

- Renewable Energy Sources and Engery Conservation PDFDocument6 pagesRenewable Energy Sources and Engery Conservation PDFYugalNo ratings yet

- Me8792 - Power Plant EngineeringDocument48 pagesMe8792 - Power Plant EngineeringPalanivel Rajan A RNo ratings yet

- Vidyavardhaka College of Engineering, Mysore Department of Mechanical Engineering Lesson PlanDocument2 pagesVidyavardhaka College of Engineering, Mysore Department of Mechanical Engineering Lesson PlanAmruth RaoNo ratings yet

- 3rd Sem Syllabus EnergyDocument4 pages3rd Sem Syllabus EnergyManoj PepiNo ratings yet

- Power Plant Engineering Study MaterialsDocument136 pagesPower Plant Engineering Study MaterialsKarthikeyan GovindarajNo ratings yet

- ME6701 - PPE - SyllabusDocument2 pagesME6701 - PPE - Syllabusommech2020No ratings yet

- Me 6701 Power Plant Engineering - Department of Mechanical Engineering Question BankDocument13 pagesMe 6701 Power Plant Engineering - Department of Mechanical Engineering Question BankEstelito PerezNo ratings yet

- Electric StructureDocument40 pagesElectric StructureBeni LanuzaNo ratings yet

- New SME Lab ManualDocument64 pagesNew SME Lab ManualSahil GupteNo ratings yet

- Lect 2 To StundentDocument39 pagesLect 2 To Stundentahmedimam508No ratings yet

- Lesson Plan Me 100 Basics of Mechanical Engineering 2-1-0-3 Course ObjectivesDocument4 pagesLesson Plan Me 100 Basics of Mechanical Engineering 2-1-0-3 Course ObjectivesAjeshSomanPulladNo ratings yet

- Assignment - I Unit - I Level - I: Me6701 Power Plant Engineering L T P C 3 0 0 3Document6 pagesAssignment - I Unit - I Level - I: Me6701 Power Plant Engineering L T P C 3 0 0 3Niyas AhamedNo ratings yet

- SyllabusDocument2 pagesSyllabusTarun GuptaNo ratings yet

- Subject: Elements of Mechanical Engineering: Mid Sem Exam Syllabus Be Sem - IDocument1 pageSubject: Elements of Mechanical Engineering: Mid Sem Exam Syllabus Be Sem - ImkkhuntiNo ratings yet

- Electrical Power GenerationDocument20 pagesElectrical Power GenerationTabassum SavanurNo ratings yet

- Elements of Mechanical EngineeringDocument2 pagesElements of Mechanical EngineeringMayur CharanNo ratings yet

- SyllabusDocument4 pagesSyllabusArjun SainiNo ratings yet

- 15 Scheme 7th SEM Lesson Plans Compressed PDFDocument25 pages15 Scheme 7th SEM Lesson Plans Compressed PDFSmithaNo ratings yet

- Gujarat Technological UniversityDocument4 pagesGujarat Technological UniversityAbhishek BisoyiNo ratings yet

- Power Generation: Dr. Tahir Mahmood Lecture No. 1 Sections: / / Days: DatedDocument48 pagesPower Generation: Dr. Tahir Mahmood Lecture No. 1 Sections: / / Days: Datedosama_tahir_3No ratings yet

- VR 19 PPE - Class PPT For UNIT-1 Reference PurposeDocument116 pagesVR 19 PPE - Class PPT For UNIT-1 Reference Purposecherry tejaNo ratings yet

- Lecture Plan For NCESDocument1 pageLecture Plan For NCESJoseph George KonnullyNo ratings yet

- Elect3 2Document2 pagesElect3 2pranav10dulkarNo ratings yet

- Cambridge IGCSE: PHYSICS 0625/41Document20 pagesCambridge IGCSE: PHYSICS 0625/41ProBro Rock 2No ratings yet

- GHG Protocolo Florestas e SAFs 01Document32 pagesGHG Protocolo Florestas e SAFs 01CPSSTNo ratings yet

- Presentation of Ceramic TestingDocument2 pagesPresentation of Ceramic TestingNyeem BasharNo ratings yet

- No Load and Load Test - Electrical MachinesDocument22 pagesNo Load and Load Test - Electrical MachinesMadhumita KaruppusamyNo ratings yet

- DG Synch Control Relay PanelDocument11 pagesDG Synch Control Relay PanelGanesh DeyNo ratings yet

- Electrical Transient Interactions Between Transformers and Power SystemsDocument8 pagesElectrical Transient Interactions Between Transformers and Power SystemsKiran BurriNo ratings yet

- On-Load Tap-Changer OILTAP® G: Technical Data TD 48Document34 pagesOn-Load Tap-Changer OILTAP® G: Technical Data TD 48Ravindra AngalNo ratings yet

- Remote Visual InspectionDocument209 pagesRemote Visual InspectionMassimo FumarolaNo ratings yet

- OMSC Bachelor of Science in Electrical Engineering Program DetailsDocument4 pagesOMSC Bachelor of Science in Electrical Engineering Program DetailsJade Danielle Enmoceno FortezaNo ratings yet

- Electrically Operated Units: Fire Suppression SystemsDocument2 pagesElectrically Operated Units: Fire Suppression SystemsImad QsnNo ratings yet

- G4 Mors Smitt MTBF DataDocument5 pagesG4 Mors Smitt MTBF DataBan Juan OoiNo ratings yet

- Liebherr R9400Document22 pagesLiebherr R9400Rohman FashihinNo ratings yet

- QUICLOCDocument24 pagesQUICLOCTamilSelvanNo ratings yet

- I-19 Instruction For Replac of ICU Fuel Valve AssemblyDocument15 pagesI-19 Instruction For Replac of ICU Fuel Valve Assemblyposeidon100% (3)

- Part 4 B 2022Document23 pagesPart 4 B 2022Abu Hasnat Md. ShaedNo ratings yet

- Sa227 Series: Maintenance ManualDocument20 pagesSa227 Series: Maintenance ManualRicardo zafra0% (1)

- Astm D323-15a PVRDocument11 pagesAstm D323-15a PVRAngel MurilloNo ratings yet

- Motor Zongshen ZS156FMI-2ADocument191 pagesMotor Zongshen ZS156FMI-2Aserg perNo ratings yet

- Installation & Maintenance Manual: Simplifi Ed Wired Controller Model: CIS01Document20 pagesInstallation & Maintenance Manual: Simplifi Ed Wired Controller Model: CIS01Victor ValenciaNo ratings yet

- HSD Bio Diesel and SoapDocument35 pagesHSD Bio Diesel and SoapkdkrkdkrkdkrNo ratings yet

- BBC - HomepageDocument13 pagesBBC - HomepageITCHADOUKPENo ratings yet

- Service Letter SL2018-665/MET: SO Scrubber Retrofit On Two-Stroke Engines in ServiceDocument3 pagesService Letter SL2018-665/MET: SO Scrubber Retrofit On Two-Stroke Engines in ServiceWing On WongNo ratings yet

- En & S AssignmentDocument5 pagesEn & S AssignmentCollege ITNo ratings yet

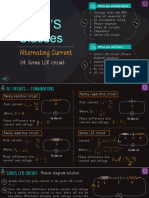

- Series LCR CircuitDocument24 pagesSeries LCR Circuitspidy warriorsNo ratings yet

- BreatheDocument9 pagesBreatheMohammad Arshad KamarNo ratings yet

- MCCB Thermal Magnetic - DPX 160 - Icu 36 Ka 400 V - 3P - 40 ADocument1 pageMCCB Thermal Magnetic - DPX 160 - Icu 36 Ka 400 V - 3P - 40 AHenry Roger Sanchez AguilarNo ratings yet

- Unit5 Dgset UpsDocument9 pagesUnit5 Dgset UpsPatel NeelNo ratings yet

- JSW EnergyDocument525 pagesJSW EnergyReTHINK INDIANo ratings yet

- Arka Series WSMD-380-400 Wel-E&pd-380-400-144-Mp-Hc-07-19.09.2020Document2 pagesArka Series WSMD-380-400 Wel-E&pd-380-400-144-Mp-Hc-07-19.09.2020Anand PuntambekarNo ratings yet

- Submit TalDocument1,204 pagesSubmit TalcanchaneNo ratings yet