Professional Documents

Culture Documents

PO03020-12-P003B Part 5 Operating Instructions

Uploaded by

hamzehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PO03020-12-P003B Part 5 Operating Instructions

Uploaded by

hamzehCopyright:

Available Formats

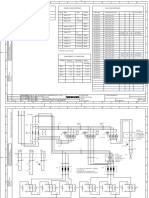

Power Management System - PMA 300 USER MANUAL

SIEMENS Marine Solutions

Automation on Ships

Power Management System

PMA 300

PART 5 – OPERATING INSTRUCTIONS

Project document no: PO03020-12-P003A Part 5 Operating instructions

B 24.02.2010 First project specific data entered KTj

A 17.11.2008 Standard document PMA300 V5.0 Aro Ty

Rev Date Description By Check Accept.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 1 of 31

Power Management System - PMA 300 USER MANUAL

CONTENT Page

5 OPERATING INSTRUCTIONS......................................................................................................4

5.1 PMA 300 Touch panel Screen Pictures: ................................................................................. 4

5.1.1 Main Picture..................................................................................................................... 4

5.1.2 System information picture .............................................................................................. 5

5.1.3 System Navigation picture............................................................................................... 6

5.2 Control of Diesel generator sets .............................................................................................. 8

5.2.1 Functions in 'Local manual' mode (LM) (switchboard/diesel mode)................................ 8

5.2.2 Synchronisation on the bus-bar....................................................................................... 9

5.3 Functions in 'Semi-automatic' mode (SAM) ............................................................................ 9

5.3.1 Manually starting of the set.............................................................................................. 9

5.3.2 Manually starting of the synchronisation ....................................................................... 10

5.3.3 Manually switch on the generator breaker in case of blackout ..................................... 10

5.3.4 Manually switch off the generator breaker .................................................................... 10

5.3.5 Manually stopping of the set.......................................................................................... 10

5.4 Functions in 'Automatic' mode (AM) ...................................................................................... 11

5.4.1 Starting of the diesel generator ..................................................................................... 11

5.4.2 Stopping of the diesel generator.................................................................................... 11

5.5 Blackout start ......................................................................................................................... 12

5.6 Start failure ............................................................................................................................ 12

5.7 Adjustment of the Starting and Stopping times ..................................................................... 12

5.8 Number of start attempts ....................................................................................................... 12

5.9 Diesel shutdown signal.......................................................................................................... 12

5.10 Running with no load before stopping the engine ................................................................. 13

5.11 Switchboard LOCAL/REMOTE switch .................................................................................. 13

5.12 Diesel LOCAL/REMOTE/BLOCKING switch and 'Ready to Start' signal.............................. 13

5.13 Signal 'Motor Running'........................................................................................................... 14

5.14 Input signal 'Alarm' (delayed shut-down input)...................................................................... 14

5.14.1 Delayed shutdown configuration possibilities................................................................ 15

5.15 Alarm blocking ....................................................................................................................... 15

5.16 Suppress alarms from the operator panel ............................................................................. 15

5.17 Reset of Alarms ..................................................................................................................... 15

5.18 Blackout ................................................................................................................................. 16

5.19 Underfrequency/Overfrequency ............................................................................................ 16

5.20 Undervoltage/Overvoltage..................................................................................................... 16

5.21 Load Sharing Supervision ..................................................................................................... 17

5.21.1 Load Sharing Supervision configuration possibilities .................................................... 18

5.22 Generator voltage regulator protection.................................................................................. 18

5.23 Short circuit............................................................................................................................ 18

5.24 Overcurrent............................................................................................................................ 18

5.25 Reverse power....................................................................................................................... 19

5.26 Generator de-excitation trip ................................................................................................... 19

5.26.1 Generator differential protection system ....................................................................... 19

5.26.2 Operation ....................................................................................................................... 19

5.27 Table of Generator protection functions ................................................................................ 20

5.28 Start sequence....................................................................................................................... 20

5.29 Stop sequence....................................................................................................................... 21

5.30 Standby start on bus-bar high load (normal start) ................................................................. 21

5.31 Power dependent automatic stop .......................................................................................... 21

5.32 Blocking of power auto start and power auto stop ................................................................ 22

5.33 Selecting minimum number of sets to run ............................................................................. 22

5.34 Standby start on bus-bar high total current (normal start)..................................................... 22

5.35 Standby start on generator high power (normal start)........................................................... 23

5.36 Standby start on generator high power (alarm start)............................................................. 23

5.37 Standby start on generator high current (normal start) ......................................................... 23

5.38 Standby start by generator high current (alarm start)............................................................ 23

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 2 of 31

Power Management System - PMA 300 USER MANUAL

5.39 Standby start by low frequency (normal start)....................................................................... 23

5.40 Standby start by low frequency (alarm start)......................................................................... 23

5.41 Standby start by low voltage (normal start) ........................................................................... 24

5.42 Standby start by low voltage (alarm start) ............................................................................. 24

5.43 Load and Frequency Control ................................................................................................. 24

5.43.1 Load and Frequency Control with engines in droop mode............................................ 24

5.44 Asymmetric Load Sharing (ASL) / Unbalanced Load Sharing .............................................. 25

5.45 Remote operating (optional) .................................................................................................. 26

5.46 Heavy consumer control........................................................................................................ 26

5.46.1 Blocking of the stop cascade......................................................................................... 26

5.46.2 No Set in Automatic Mode............................................................................................. 27

5.47 Heavy consumer starter interface.......................................................................................... 27

5.48 Heavy consumer configuration .............................................................................................. 27

5.49 Heavy consumer operational considerations ........................................................................ 27

5.50 Bus-tie breakers .................................................................................................................... 28

5.50.1 Breaker control .............................................................................................................. 28

5.50.2 Signal interface .............................................................................................................. 28

5.51 Special requirements for diesel electric propulsion vessels.................................................. 29

5.52 Password protection .............................................................................................................. 29

5.52.1 Changing passwords ..................................................................................................... 29

5.53 Changing system parameters................................................................................................ 30

5.53.1 Editing parameters......................................................................................................... 30

5.53.2 Downloading parameters............................................................................................... 31

5.54 Backup of the complete touch screen panel ......................................................................... 31

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 3 of 31

Power Management System - PMA 300 USER MANUAL

5 Operating instructions

5.1 PMA 300 Touch panel Screen Pictures:

The PMA 300 screen pictures are based on three principles:

• Simplicity

• Functionality

• Easy to read

The different screens, pictures and symbols are more or less self explaining, and after a short time the

user will be familiar with the concept.

5.1.1 Main Picture

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 4 of 31

Power Management System - PMA 300 USER MANUAL

5.1.2 System information picture

This picture gives a Hardware system overview of the actual PMA 300 configured and also the status

for each node.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 5 of 31

Power Management System - PMA 300 USER MANUAL

5.1.3 System Navigation picture

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 6 of 31

Power Management System - PMA 300 USER MANUAL

Operating modes

• Local manual (LM)

• Semi-automatic (SAM)

• Automatic (AM)

The Local Manual mode is enabled when the selector switch in the main switchboard is in LOCAL po-

sition and also the engine control in LOCAL position. In this case only actual values and states will be

displayed, the PMA300 will not execute any functions. Generator and diesel sets will be in a 'transpar-

ent mode'.

With the LOCAL/REMOTE selector switch for switchboard and diesel set is in position REMOTE the

PMA 300 will enter SAM (Semi-automatic mode). In this mode it will be possible to start engines

manually and to manually close generator breakers (with automatic synchronising and load sharing).

From the semi automatic mode (SAM), the PMA300 can be switched to automatic mode (AM). In this

mode the system will be operating fully automatically, for example automatic standby start in case of

power fault or blackout, low load auto stop, heavy consumer blocking or start, and automatic load

shedding.

In automatic mode the generator breaker command buttons will be disabled, but it will be possible to

operate the engine start and stop buttons directly with automatic connection or disconnection of the

generator breaker if this is allowed by the system.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 7 of 31

Power Management System - PMA 300 USER MANUAL

5.2 Control of Diesel generator sets

5.2.1 Functions in 'Local manual' mode (LM) (switchboard/diesel mode)

The 'Local Manual mode' normally is used by maintenance or

service personnel for starting and stopping of the diesel en-

gine from a local place and/or operating the main switchboard

manually.

In this mode the engine is started and stopped with local con-

trols bypassing the PMA300.

This mode is pre-selected for the main switchboard (generator

breaker) by turning the LOCAL-REMOTE switch in the

switchboard in the position LOCAL. For the engine by the

BLOCKED-LOCAL-REMOTE switch in position BLOCKED or

LOCAL.

The engine and the main switchboard (generator breaker) can

individually be selected to local control.

The mode is indicated as “LM' on the screen and 'Not Avail-

able' on generator or diesel engine.

In 'Local Manual mode' no automatic or semi-automatic functions are possible, but the indication

(breaker positions, engine running, voltage and frequency) on the screen are in function.

Speed change or closing of the generator breaker can be made only manually from the switchboard.

Please note that if the engine is started locally, the LOCAL/REMOTE selector switch should not be

switched to remote before the engine is running properly, otherwise the PMA300 will not be able to

pick up that the engine has started.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 8 of 31

Power Management System - PMA 300 USER MANUAL

5.2.2 Synchronisation on the bus-bar

The manual synchronisation of the generator is done with the help of an additional check synchronis-

ing unit.

After starting the generator set manually at the diesel engine the frequency is led to the bus-bar fre-

quency by manually changing the speed of the generator set (at the main switchboard).

By pressing the “BREAKER ON' pushbutton on the main switchboard the generator breaker on com-

mand is given via the check synchronising unit.

In case of a blackout the generator breaker can be switched on directly with the pushbutton

“BREAKER ON' from the main switchboard.

5.3 Functions in 'Semi-automatic' mode (SAM)

Precondition:

The LOCAL/REMOTE switch in the switchboard is selected to REMOTE and/or the 'BLOCKED-

LOCAL-REMOTE' switch for the engine also in REMOTE.

The Semi-automatic mode will be reached automatically. Before the diesel can be started also the

'Ready to start' signal from the diesel control system must be present.

The mode is indicated as SAM on the screen, the indication 'Not Available' and 'Engine Not Ready' will

disappear.

The following functions can be made in Semi Automatic mode (SAM) from the operator panel:

- Starting of the set

- Stopping of the set

- Closing of generator breaker with automatic synchronisation and load sharing

- Opening of generator breaker with automatic offloading

In order to avoid an operation by mistake important commands must be confirmed by pressing the

command twice within 3sec. (START/STOP/CLOSE/OPEN/SAM/AM)

The safety functions for the diesel engine (not part of the PMA300), shutdown in case of over speed,

lubrication oil pressure, cooling water temperature etc. and the generator protection are in function. In

case of a fault the diesel generator will be stopped as in automatic mode. But there is no starting of a

standby set.

5.3.1 Manually starting of the set

By pressing START on the screen and confirm within the 3-second period. If this is not the case, then

the request is withdrawn.

At the same time the state 'Starting' is displayed and the sym-

bol changes to a blue colour with an arrow pointing upwards.

With the digital input signal 'Running' or detection of generator

voltage > 85% (configurable) the start command is taken

back. The start command is given no longer than a certain ad-

justable time ('Starting time').

With the digital input signal 'Engine running' or the signal voltage > 85% the state 'Running' is dis-

played.

If there is no signal 'Engine running' or generator voltage > 85% coming after the predefined time, a

'Start Fault' alarm is initiated. If more than one start attempt has been selected the starting fault alarm

will not be displayed before all attempts have completed.

Running is indicated on engine and generator with a green

symbol colour.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 9 of 31

Power Management System - PMA 300 USER MANUAL

5.3.2 Manually starting of the synchronisation

By pressing CLOSE on the screen and confirm within the 3-second period. If this is not the case, then

the request is withdrawn.

The automatic synchronisation will be started and the generator breaker will be closed automatically.

When the breaker is in the synchronising/closing state the breaker symbol will change to

a blue colour with an arrow pointing towards the breaker-closed position.

If the synchronisation is not completed within the predefined time window an alarm message is dis-

played;

- 'Gen. Breaker Close Fault' (Alarm)

Automatic load sharing will start when the breaker closes. (Controlled by an external load sharing sys-

tem, normally a Woodward load sharing and speed control unit)

5.3.3 Manually switch on the generator breaker in case of blackout

In case of a blackout the generator breaker will be switched on:

- by pressing CLOSE on the screen and confirm

- by changing over to the automatic mode (AM)

NOTE! A true blackout situation is always indicated with a red bus bar in the main picture and alarm.

If there is a fault on a generator breaker feedback signal or tripped control voltage fuse, there will be

no true blackout indication.

5.3.4 Manually switch off the generator breaker

By pressing OPEN on the screen and confirm within the 3-second period. If this is not the case, then

the request is withdrawn.

When the set is in parallel operation with another generator set on the bus bar, a dis-

connection with load reduction will be made. The state 'Opening' is displayed. And the

breaker symbol will change to a blue colour with an arrow pointing away from the

breaker-closed position.

When the load is below a pre-defined power limit, the generator breaker is switched off.

The 'Breaker OFF' command can also be issued from the external load sharing system if this has been

connected. Consult the project drawings.

In the configuration it is possible to decide if it should be possible to open the last generator breaker

and create a blackout. If this is not allowed a symbol 'Open breaker locked' is displayed next

to the generator breaker symbol.

5.3.5 Manually stopping of the set

In the semi-automatic mode the set will not stop as long as the breaker is closed.

Stop the set with generator breaker open, by pressing STOP on the screen and confirm by pressing

the button again within the 3-second period. If this is not the case, then the request is withdrawn.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 10 of 31

Power Management System - PMA 300 USER MANUAL

5.4 Functions in 'Automatic' mode (AM)

The 'Automatic mode' will be reached by pressing the pushbutton AM on the screen and confirm by

pressing the button again within the 3-second period. If this is not the case, then the request is with-

drawn.

In AM nothing is indicated on the main picture.

In Automatic mode the starting (standby start) and

stopping (shutdown, faults, under load) of the diesel

generator takes place automatically.

5.4.1 Starting of the diesel generator

In Automatic Mode a starting procedure is initiated

when this set is 'Standby set' (set selected to AM and

ready to start, no fault displayed on generator and mo-

tor) and a start demand is coming.

Automatic start can be initiated from the blackout detec-

tion, a power request from another set, a power request

from the bus-bar segment, a delayed shutdown alarm

from the alarm system, under voltage 2 or under fre-

quency 2 alarm, generator current or a heavy consumer

start request.

The next available set in the standby sequence

(standby set) is indicated with a small symbol in-

side the engine symbol.

Manually starting can be performed in automatic mode (AM) by pressing START. The set will auto-

matically start, synchronise and connect.

5.4.2 Stopping of the diesel generator

When an un-delayed stop of the diesel engine is made (shut down, short-circuit, reverse power) the

generator breaker is tripped at the same time.

When the generator set is stopped by low bus-bar load a stop with automatic load reduction will be

made.

First the state 'Opening' on the breaker will appear (offloading), then the engine will enter 'Cool down

run' state before 'Stopping' and 'Stopped' is displayed on the engine.

The breaker 'Opening' state has two different output possibilities; 1) a unload command (relay output)

to the engine load sharing unit and 2) also decrease pulses (relay output) in case the external load

sharing unit has no unload input facilities. When the set is unloaded below a configurable limit the

generator breaker is switched off either by 1) a command from the engine load sharing unit or 2) the

power management system.

The engine continues to run without load after opening the generator breaker for a selectable time.

The state “Cool down run' is displayed on the operator panel. After elapsing of the delay time a stop

command is given until the signal 'Engine running' has disappeared and after

a waiting time has expired.

This waiting time has to be adjusted, so that the engine will come to a com-

plete stop during this time.

Giving a STOP command manually the 'Cool down run' can be aborted and

the state changed to 'Stopping' and later 'Stopped'.

Giving a START command manually the 'Cool down run' can be aborted and the state changed to

'Running'.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 11 of 31

Power Management System - PMA 300 USER MANUAL

5.5 Blackout start

The PMA 300 has two different possibilities for the starting signal. The normal start output and the

blackout start output.

In the configuration it is possible to select if only the blackout start output should be active in case a

blackout or if both the normal start and the blackout start output shall be active.

5.6 Start failure

The start procedure with one or several start attempts is carried out in Automatic mode the same way

as in Semi-Automatic mode. If the signal 'Engine running' or generator voltage > 85% is not coming

during the selected number of start attempts, a STOP command is given. Additionally the following

messages are displayed:

- 'Start Fault' (Alarm)

5.7 Adjustment of the Starting and Stopping times

The starting time and the stopping time have to be adjusted according to the requirements of the die-

sel engine. The same times are used for Semi-automatic and for Automatic mode.

Standard settings can be adjusted from the control panel recipe Engine (internal system module MC);

- Start timeout 60s (60 000ms) Alarm delay for running feedback from the engine or

voltage detection above 85% (configurable).

- Stop timeout 20s (20 000ms) Alarm delay after the running feedback has disap-

peared or the voltage drops below the 85% limit.

- Minimum Time In 60s (60 000ms) This is the time the motor controller waits after the run

Stopped State feedback disappears (after stop) and until the motor is

reported ready for start. It is used to allow the engine

to completely come to a halt (zero revolutions) before

it is started again.

5.8 Number of start attempts

The number of start attempts can be changed to any number. Default value and our recommendation

is to use only one.

5.9 Diesel shutdown signal

The PMA300 requires a common shutdown signal from the diesel safety system.

In the local manual mode (LM) no action will be taken on this signal. In case of a diesel shutdown the

generator breaker will trip on reverse power or under voltage. A possibility in some diesel safety sys-

tems is to connect a breaker trip signal directly in case of shutdown.

When the system is in semi-automatic mode (SAM) or automatic mode (AM) a shutdown input from

the diesel safety system will immediately trip the generator breaker.

From automatic mode (AM) the diesel/generator set will also be switched to semi-automatic (SAM).

The following messages will be displayed;

- 'Breaker Trip' (Alarm)

- 'Shutdown' (Alarm)

- 'SAM' (Semi-automatic) (State)

The shutdown alarm input is delayed for 30sec during start up of the set.

Standard setting can be adjusted from the control panel recipe Engine (internal system module MC);

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 12 of 31

Power Management System - PMA 300 USER MANUAL

- Alarm Suppress Delay Dur- 30 s During this time shutdown and delayed shutdown is

ing Start suppressed (inputs not evaluated) immediately after

an engine start.

5.10 Running with no load before stopping the engine

For some diesel engines a 'No load run' before stopping is recommended to cool down the engine. On

the operator panel it can be selected, if a 'No load run' shall be done and how long the time shall be.

If selected, the 'No load run' is active in Automatic Mode.

The following is displayed on the set;

- 'Cool down run' (State)

Standard setting can be adjusted from the control panel recipe Engine (internal system module MC);

- Cool Down Run Time 180s (180 000ms)

If the diesel starter system already has a cool down function we recommend to set this to zero and

use the functionality in the PMA300.

The advantage with control from the PMA300 is that it will be possible to automatically abort the cool

down run time if the set should be required again due to a suddenly increasing load or fault on one of

the other engines.

5.11 Switchboard LOCAL/REMOTE switch

In the main switchboard there is a 'LOCAL-REMOTE' switch for each generator section.

The LOCAL position will give local mode (LM) in the PMA300.

The REMOTE position will automatically switch the PMA300 for this section to semi-automatic (SAM).

In semi-automatic it will be possible to close and open the generator breaker if the diesel engine is

running.

5.12 Diesel LOCAL/REMOTE/BLOCKING switch and 'Ready to Start' signal

At the diesel engines there usually is a “BLOCKED/LOCAL/REMOTE' switch, which will be used when

service work has to be done on the engine.

The “BLOCKED/LOCAL' position will set the diesel control in the PMA300 to local mode (LM) and

block start of the diesel engine from the PMA 300.

The mode will be indicated as “Transparent' and LM on the touch screen operator panel.

With the switch in position REMOTE the diesel control will go to semi-automatic (SAM).

Some engines also have a 'Ready to start' signal available. The PMA300 uses this signal to enable

start, if this signal is not present prior to start the diesel set will be 'Not Available' and 'Engine not

ready'.

NOTE!

In the case where this signal is not available the input cannel should be combined with the REMOTE

signal to indicate when the diesel is ready to start.

The 'Ready to start' signal will only be checked when the engine is in stopped state.

With the signal REMOTE and the 'Ready to start' signal present it will be possible to start and stop the

diesel from the touch screen operator panel.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 13 of 31

Power Management System - PMA 300 USER MANUAL

WARNING

-------------------------------------------------------------------------------------------------------------

In order to prevent certainly a start of the diesel engine, if work has to performed on the

diesel engine, the generator or the switchboard, additionally the voltage for the start sole-

noid or start valve has to be switched off and the starting air has to be turned off by clos-

ing the corresponding valve.

Immediately after the start of the diesel engine dangerous voltages are applied to the

terminals of the generator and the generator breaker.

Not-observance can result in death, severe personal injury or substantial property dam-

age.

Only qualified personnel should work on or around this equipment after becoming thor-

oughly familiar with all warnings, safety notices, and maintenance procedures contained

herein.

The successful and safe operation of this equipment is dependent on proper handling, in-

stallation, operation and maintenance.

5.13 Signal 'Motor Running'

For several functions in the PMA300 a digital input signal 'Motor running' is needed (Running = Con-

tact closed).

The device to generate this signal (for example a speed relay) is not part of the PMA300.

5.14 Input signal 'Alarm' (delayed shut-down input)

This function is used to start a standby set as a precaution, before a value becomes that critical, that a

shutdown of the diesel engine takes place. The signal can come directly from the engine as a pre-

alarm or from the alarm system as a group alarm (for example pre-alarm for low lubrication oil pres-

sure and high cooling water temperature).

We recommend also combining the generator high winding temperature as one of the delayed shut-

down criteria.

When the PMA300 receive an alarm from the diesel set or an alarm system the 'Delayed shutdown'

function will be activated and the delayed shutdown timer (configurable, default 3min) will start to run.

Immediately a standby set will be requested, if a set is available in the standby sequence this will be

started and connected. The diesel speed control and load sharing unit will perform equal load sharing,

After the elapse of the delayed shutdown timer the faulty set will unload, disconnect and stop. If for

some reason a standby set is not available or not able to take over the total load, the faulty set will

continue to run with the 'Delayed shutdown' alarm.

In addition to the external alarm the PMA300 power plant monitoring of voltage and frequency will is-

sue a pre-alarm on abnormal voltage or frequency. To low voltage or to low frequency will also initiate

a delayed shutdown.

In both cases the following message is displayed on the operator panel:

- 'Delayed Shutdown' or (Alarm)

'Under Voltage 2' or

'Under Frequency 2'

- 'Delayed shutdown' (State)

After completing the delayed shutdown;

- 'SAM' (Semi-automatic) (State)

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 14 of 31

Power Management System - PMA 300 USER MANUAL

5.14.1 Delayed shutdown configuration possibilities

Settings for the input signal can be adjusted from the control panel recipe Engine.

• You can select if the delayed shutdown function should disconnect and stop the set with alarm

immediately after a new set is connected to the bus (default setting) or complete the delayed

shutdown time. (Disconnection is blocked if stop blocked due to high power is active).

• The time delay for running with delayed shutdown alarm before completing a changeover or

shutdown can be changed.

• For the delayed shutdown digital input (alarm) you can select this to always trip the generator

breaker without offloading. NOTE: Generator protection alarm (under voltage/frequency 2) will

always trip the breaker without offloading.

• It is possible to enable latching of the delayed shutdown (default setting). If this option is set

the motor controller latches the delayed shutdown state (only for the alarm input, and not for

the internally generated generator protection delayed shutdown conditions). When the option

is not set the motor controller is free to return to running and connected state if the delayed

shutdown condition disappears.

5.15 Alarm blocking

It is possible, to block some alarms, when the engine is not running or during the start-up of the en-

gine. The standard system has a time delay on shut down alarms, voltage and frequency alarms dur-

ing starting and stopping.

5.16 Suppress alarms from the operator panel

The blocking of the alarms for the set is provided for service work and testing. When the SUPP.

pushbutton on the touch screen operator panel is operated, the alarm icons are displayed with an 'X'

on top to indicate this.

Reset of suppression

The colour of the SUPP. pushbutton will have changed to red. Press the button again to switch off the

alarm suppression.

It is possible to disable this function in the configuration recipe: SYSTEM. 'Enable Alarm Suppression

PORT/STBD' = 0 will disable and hide buttons for alarm suppression from the touch screen panel.

5.17 Reset of Alarms

All alarms will appear in a new window on the touch screen panel at the moment they are triggered.

The alarm can be accepted with the pushbutton ACK.

The 'Help' and 'Edit' buttons are default touch screen system buttons, but not used for the PMA300.

To reset the alarm you must select the picture corresponding to the faulty engine or generator and

press the RESET button.

As long as an alarm is on it will be shown in the alarm list and on the corresponding picture. All the

latest alarms will also be stored in the alarm buffer with a time stamp.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 15 of 31

Power Management System - PMA 300 USER MANUAL

5.18 Blackout

From the manufacturer of the switchboard bus-bar monitoring relays are to be included.

a) Signal 'Blackout'

b) Signal 'Control voltage circuit breaker not tripped' (Alarm 'Control Fuse Fault')

The bus-bar monitoring is used for each generator section in the PMA300. The auxiliary contacts of

the relays are lead to the relevant inputs in the PMA300.

In addition to above signals the generator breakers, bus-tie breakers and bus-communication are

monitored before a true blackout is detected.

If blackout is detected, the next available generator set (standby set) is started and switched on with a

short delay when exceeding 85% of the nominal voltage.

Simultaneous closing of the generator breakers of generator sets that have been started the same

time is not possible (simultaneous blocking). Simultaneous blocking is indicated with a key symbol on

the breakers.

Blackout is indicated on the screen with the bus-bar in red colour and alarm. If a signal is missing or a

control fuse has tripped the blackout will not be indicated and no standby start initiated.

5.19 Underfrequency/Overfrequency

The frequency of the ship’s network is transmitted monitored in the SIMATIC S7.

The limiting values of over- and under frequency can be changed from the touch screen panel in the

recipe Data Control.

The following messages are displayed if the actual values fall below or exceed the respective limiting

values:

- Over Frequency 1 (Alarm)

- Over Frequency 2 (Alarm)

- Under Frequency 1 (Alarm)

- Under Frequency 2 (Alarm)

The functions triggered are listed in the table 'Table of generator protection functions'.

The 'Under frequency 2' alarm will also give delayed shutdown and changeover to another set. (see

also chapter 5.14 ).

5.20 Undervoltage/Overvoltage

The voltage of the ship’s network is transmitted via the generator protection and synchronising unit

and monitored in the SIMATIC S7.

The limiting values of over- and under frequency can be changed from the touch screen panel in the

recipe Data Control.

The following messages are given out if the actual values fall below or exceed the respective limiting

values:

- Over Voltage Step 1 (Alarm)

- Over Voltage Step 2 (Alarm)

- Under Voltage Step 1 (Alarm)

- Under Voltage Step 2 (Alarm)

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 16 of 31

Power Management System - PMA 300 USER MANUAL

The functions triggered are listed in the table 'Table of generator protection functions'.

The 'Under voltage 2' alarm will also give delayed shutdown and changeover to another set. (see also

chapter 5.14)

5.21 Load Sharing Supervision

The load sharing supervision use accumulated data for all connected generator sets to evaluate the

quality of the load sharing units and voltage regulators. It is designed to supervise active power and

reactive power. If a sets active power or reactive power deviates too much from the other sets data an

alarm is raised.

There are two modes when detecting load sharing error.

1) If there are two sets running connected and running in loadsharing mode, loadsharing error is

reported if a sets data deviates too much from the two sets average. (Example: Alarm limit

10%. 2 generators running with 50% load > alarm when loadsharing between the sets are

40% & 60% )

2) If there are three or more sets running connected and in loadsharing mode, loadsharing error

is reported if a sets data deviates to much from the data for the other sets in loadsharing

mode. (Example: Alarm limit 10%. 3 generators running with 50% load > alarm if two genera-

tors are taking 55% and one 45%)

The first mode uses hysteresis in calculation, while the latter mode uses a straightforward comparison

of deviation data.

Alarm limits can be adjusted from the control panel recipe LoadShareSupervision.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 17 of 31

Power Management System - PMA 300 USER MANUAL

5.21.1 Load Sharing Supervision configuration possibilities

Depending of configuration and PMA300 options (loadsharing in droop mode) the following functions

can be realized;

• Alarm loadsharing fault on active power will switch all sets to droop mode. If PMA300 version

with loadsharing in droop mode is used the power management system will take over the

loadsharing by giving increase decrease commands to the loadsharing and speed control

unit.

• Alarm loadsharing fault on active power will trip the bus-tie breaker.

Settings can be adjusted from the control panel recipe LoadShareSupervision and SYSTEM.. This

should however not be changed after commissioning without further testing and verification.

5.22 Generator voltage regulator protection

Especially for diesel electric propulsion plants with Siemens generators a protection system is pro-

vided to avoid the effect of a faulty generator voltage regulator. This system monitors the generator

excitation current and the generator voltage. If abnormal values are detected the generator breaker

can be tripped and the engine shut down.

Alarms displayed are;

- Generator under excitation (Alarm)

- Generator over excitation (Alarm)

- Generator excitation measuring fault (Alarm)

This functionality requires a 4-20mA measuring value from the generator excitation circuit.

5.23 Short circuit

The monitoring of the generator currents for short-circuit is carried out in the 'Generator protection unit

and measuring transducer’, Siprotec 7UM62. When a short circuit occurs, the message is sent to the

PMA300 on the bus connection or as a digital input.

The following messages are displayed:

- Short Circuit (Alarm)

- Not Available (State)

- SAM (Semi-automatic) (State)

The OFF command for the generator breaker is coming directly from the generator protection device.

To protect the power plant against several generators connecting on to a short circuit a function 'multi-

ple trip block' has been implemented. With two or more sets running this function will detect the num-

ber of generator breakers tripping within a certain time window. The standard configuration is two

generator breakers tripping within 5 sec. If this is the case all other sets will be switched to semi-

automatic.

5.24 Overcurrent

The monitoring of the generator currents is carried out in the 'Generator protection unit and measuring

transducer’, Siprotec 7UM62. When an overcurrent trip occurs, the message is sent to the PMA300 on

the bus connection or as a digital input.

The PMA300 will issue the following messages:

- Over Current Trip (Alarm)

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 18 of 31

Power Management System - PMA 300 USER MANUAL

- Not Available (State)

The OFF command for the generator breaker is coming directly from the generator protection device.

The three generator currents, I L1, I L2, I L3, are also monitored in the PMA300. If at least one of the cur-

rents exceeds the limiting value, the alarms ‘Over Current 1’ or ‘Over Current 2’ will be displayed when

the delay times elapses.

Exceeding the limits the PMA300 will issue one or several of the following messages:

- Over Current 1 (Alarm)

- Over Current 2 (Alarm)

5.25 Reverse power

The monitoring of the generator power is carried out in the 'Generator protection unit and measuring

transducer' , Siprotec 7UM62. When a reverse power trip occurs, the message is sent to the PMA300

on the bus connection or as a digital input.

The following messages are displayed on the operator panel:

- Reverse Power (Alarm)

- Not Available (State)

- SAM (Semi-automatic) (State)

The off command for the generator breaker is coming directly from the generator protection device.

5.26 Generator de-excitation trip

5.26.1 Generator differential protection system

5.26.2 Operation

In the PMA300 a digital input is provided for connecting the signal 'De-excitation trip', ref above chap-

ter ‘Differential protection system’

The following signals are issued:

- Disconnection of generator breaker (directly from switchboard)

- Generator set stop command

- Blocking of generator set

- Switchover to 'Semi-automatic mode'

The following messages are displayed on the operator panel:

- De-excitation Trip (Alarm)

- Gen. Breaker Trip (Alarm)

- Shutdown (Alarm)

- Not Available (State)

- Start Interlocked (State)

- SAM (Semi-automatic) (State)

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 19 of 31

Power Management System - PMA 300 USER MANUAL

5.27 Table of Generator protection functions

Limit in Actual Delay Stand- Trip of Trip of Trip of Trip of Block Stop Chan- Alarm

% of value time in by start Un- Un- Un- gen. gen. com- ge from

nom. sec. essen- essen- essen- breaker set mand Autom.

value tial tial tial to en- to Semi

con- con- con- gine auto-

default default sumers sumers sumers matic

pri. 1 pri. 2 pri. 3

GENERATOR CURRENT

9999A 0 X(5)

nn nn X (1) X X X

nn nn X (1) X X X

GENERATOR LOAD (kW)

105 0 X X

-10 6 X (1) X X X

BUSBAR TOTAL LOAD (kW)

85 5 X

105 5 X X

110 2 X X X

115 0 X X X X

BUSBAR TOTAL CURRENT (A)

100 5 X

BUSBAR FREQUENCY

-9999 0 X(5)

Hz

105 15 X

102.5 8 X

97.5 8 X

95 15 X (3) X(3) X (4) X

BUSBAR VOLTAGE

-9999 0 X(5)

V

110 15 (2) (2) (2) X

105 8 X

95 8 X

90 15 X(3) X(4) X

(1) Function realised in generator controller (independent of the S7-300 plc).

Current and time settings according to discrimination curves.

(2) Optional de-excitation of generator

(3) Delayed shutdown and connection of standby generator set carried out via blackout if syn-

chronising is not possible during the delayed shutdown time delay (from SW version 3.10).

(4) Only if delayed shutdown has been completed.

(5) Default values will not trigger any standby start.

5.28 Start sequence

By means of the start sequence it can pre-selected which generator set has to start in case of a de-

mand from the PMA300.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 20 of 31

Power Management System - PMA 300 USER MANUAL

The next set in the standby sequence will also be indicated with a small symbol inside the genera-

tor symbol.

Putting a new number in the start order list or directly in the main picture can easily change the se-

quence.

Example: Sequence 1 – 2 – 3 – 4, by touching the no.3 a small keypad will be displayed and you can

e.g. select the value 1 and 'Enter'. The sequence will automatically change to 3 – 2 – 1 – 4. (The new

value and the old value will change place)

The set with the selected lowest value will have the highest priority. No.1 will start first then no.2 and

so on. If in a selected sequence 3>1>2>4 the no. 2 set is not available the next to start will be no.3.

In the configuration it is possible to select the standby sequence to automatically rearrange the run-

ning sets when a new start order is entered. The controller then starts the first set in the order, which

is not running, provided that sets with lower order numbers are connected

5.29 Stop sequence

The stop sequence is vice versa to the start sequence. That means that the set with the selected

highest value will stop first.

5.30 Standby start on bus-bar high load (normal start)

The PMA300 will for each bus-bar configuration calculate total consumed power in % (total active

power plus total reserved power in percent of total connected nominal power). If the calculated total

power exceeds a configured limit for a certain time, a start command is issued to the next standby set.

The limit violation is calculated us-

ing hysteresis in order to avoid re- 100%

peatedly and rapid limit violations.

Bus-bar Total Connnected Load

Available Available

power Power dependent power

start limit Reserved powe

(Heavy consume

The start level is configured in the

recipe MASTER_PORT/STBD pa-

rameter 'Total Power Start Thresh-

old [%]'. There is one recipe for

each bus-bar, but only the settings

from the port side are used when

the bus-tie is closed.

Actual total load

5.31 Power dependent auto-

matic stop

The PMA300 will for each bus-bar

100%

configuration calculate total con-

Available Available

Bus-bar Total Connected Load

sumed power in % (total active power power

power plus total reserved power in Power dependent

percent of total connected nominal stop limit Reserved powe

power). The automatic stop is ac- (Heavy consume

tive if the total loads on the remain-

ing generator sets are below the

power dependent stop limit.

The limit violation is calculated us-

ing hysteresis in order to avoid re-

peatedly and rapid limit violations.

Calculated total load if lowest priority set should stop

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 21 of 31

Power Management System - PMA 300 USER MANUAL

The system will always check if a power dependent stop will be legal. If a disconnection of the given

set would lead to a new start of a standby set due to a power shortage, automatic disconnection of the

set is blocked. A normal stop will always be a stop with load reduction.

The stop level can be configured in the recipe MASTER_PORT/STBD parameter 'Total Power Stop

Block Limit [%]' and 'Total Current Stop Block Limit [%]'.

There is one recipe for each bus-bar, but only the settings from the port side are used when the bus-

tie is closed.

In systems with different sized it is possible to configure the system to disregard the stop order and

stop the smallest generator if the largest could not be stopped.

5.32 Blocking of power auto start and power auto stop

Activating the 'Block power start' function will cause the system to ignore total bus-bar high power de-

pendent start. This can be used to top up the connected sets to maximum load without adding another

one. The function will only block auto start on total bus-bar load, if the individual load on any genera-

tor increases above its limit a standby start will be given.

The 'Block power stop' function will override the bus-bar total low load stop. Typical used during ma-

noeuvring with large changes in load, but when enough power at all times must be available.

The buttons for activating these functions are available for each bus-bar on the main picture. If the

bus-tie is open there will be a set of buttons for each bus-bar section.

Block power auto start button:

Block power auto stop button: Power auto stop selected ON:

5.33 Selecting minimum number of sets to run

In addition to the ‘Blocking of power auto stop’ function it is now possible to select a minimum number

of sets to run. The number entered will continue to run even if the load decreases below the low load

auto stop limit. An increasing load would likewise cause automatic start of additional generator sets.

NOTE! Changing the bus-tie breaker status will always reset the selected minimum number of sets to

run to ‘1’ for each bus-bar section.

5.34 Standby start on bus-bar

high total current (normal

start)

100%

The PMA300 will for each bus-bar Available Available

configuration calculate total con- current Current dependent current

Heavy consu

sumed current in %. If the calculated start limit

with reserv

Bus-bar Total Current

total current exceeds a configured available cu

limit for a certain time, a start com-

mand is issued to the next standby

set.

The limit violation is calculated using

hysteresis in order to avoid repeat-

edly and rapid limit violations.

Calculated total current if lowest priority set should stop

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 22 of 31

Power Management System - PMA 300 USER MANUAL

The start level is configured in the recipe MASTER_PORT/STBD parameter ' Total Current Start

Treshold [%]'. There is one recipe for each bus-bar, but only the settings from the port side are used

when the bus-tie is closed.

5.35 Standby start on generator high power (normal start)

For each generator set a configurable power start limit is available. Exceeding this individual limit will

request a standby set after a configurable time delay.

The start level is configured in the recipe PowerCalculation parameter ' Generator Power Start

Threshold [%]', and time delay ' Set Start Time Delay' valid for generator start on power, current, volt-

age and frequency.

5.36 Standby start on generator high power (alarm start)

For each generator set a configurable power start limit is available. Exceeding this individual limit will

request a standby set after a configurable time delay.

The start level is configured in the recipe DataControl parameter ' Power Alarm Limit [%]', and time de-

lay ' High Power Alarm Delay'.

5.37 Standby start on generator high current (normal start)

For additional safety a generator current standby start can be used.

The generator high current standby start will not cause any alarm.

The start level is configured in the recipe PowerCalculation parameter ' Generator Current Start

Threshold [A]', and time delay ' Set Start Time Delay' valid for generator start on power, current, volt-

age and frequency.

NOTE! This limit must be set below the generator breaker trip limit to serve any purpose.

5.38 Standby start by generator high current (alarm start)

A higher current level will initiate the generator protection and trip the generator breaker. This is con-

figured in the generator protection unit and will issue an alarm and give standby start signal to next

available set.

WARNING!

The limits of the generator protection must be in accordance with the system discrimination analysis

and the generator thermal capabilities. The limits shall not be changed after commissioning without

acceptance from proper authorities.

5.39 Standby start by low frequency (normal start)

A configurable limit for generator low frequency standby start is available. Exceeding the limit beyond

the configurable delay will issue a standby start request.

The generator frequency standby start will not cause any alarm.

The start level is configured in the recipe PowerCalculation parameter ' Generator Frequency Start

Threshold [Hz]', and time delay ' Set Start Time Delay' valid for generator start on power, current, volt-

age and frequency.

NOTE! The limit should be above the other generator underfrequency alarms.

5.40 Standby start by low frequency (alarm start)

The bus-bar frequency is monitored for falling below two different limits.

If the frequency is lower than alarm level 2, the running set will enter the 'Delayed shutdown' mode

and a standby generator set will be requested.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 23 of 31

Power Management System - PMA 300 USER MANUAL

The standby generator set will always attempt to synchronise, if this is not possible due to the fre-

quency difference the changeover to the new started standby generator is carried out via blackout (af-

ter the 'Delayed shutdown' time window has exceeded).

Configuration of frequency alarms is available from the recipe DataControl .

5.41 Standby start by low voltage (normal start)

A configurable limit for generator low voltage standby start is available. Exceeding the limit beyond the

configurable delay will issue a standby start request.

The generator voltage standby start will not cause any alarm.

The start level is configured in the recipe PowerCalculation parameter ' Generator Voltage Start

Threshold [V]', and time delay ' Set Start Time Delay' valid for generator start on power, current, volt-

age and frequency.

NOTE! The limit should be above the other generator undervoltage alarms.

5.42 Standby start by low voltage (alarm start)

The bus-bar voltage is monitored for falling below two different limits.

If the voltage is less than alarm level 2, the running set will enter the 'Delayed shutdown' mode and a

standby generator set will be requested.

The standby generator set will always attempt to synchronise, if this is not possible due to the voltage

difference the changeover to the new started standby generator is carried out via blackout (after the

'Delayed shutdown' time has exceeded).

Configuration of voltage alarms is available from the recipe DataControl .

5.43 Load and Frequency Control

Usually modern diesel engines are delivered with a combined speed controller and loadsharing mod-

ule (typical Woodward 2301D, 721 or 723(PLUS)).

For best possible load sharing the functionality built in to these units are used.

As an option the PMA300 could be delivered with loadsharing and frequency control with engines run-

ning in droop mode.

Loadsharing from the PMA300 is indicated on the engine symbols with the letters DROOP.

5.43.1 Load and Frequency Control with engines in droop mode

When load and frequency control are performed from the PMA300 the operational principle is to give

increase or decrease commands to the engine speed pilot motor or speed controller.

The regulator is configured for a fast response in case of large load and/or frequency deviation and

slower response when the deviation is smaller.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 24 of 31

Power Management System - PMA 300 USER MANUAL

Load Main parameters:

Constant On Band

Constant On limit

Large input Band

Wide ramping deviation limit

Medium input Band

Narrow ramping deviation limit

Small input Band

Constant Off limit

Constant Off Band PWM Zero deviation offset

Constant Off limit

Small input Band

Narrow ramping deviation limit

Medium input Band

Wide ramping deviation limit

Large input Band

Constant On limit

Constant On Band

Time

Configuration is available from the recipe LoadShareControl.

5.44 Asymmetric Load Sharing (ASL) / Unbalanced Load

ad Sharing

After selecting a running generator set to SAM (semi-automatic) and then switched to ASL you can

manually adjust the load set point, either up or down by simply touching the current percentual load

field and enter a new value. The generator set will then run with a fixed load at the desired set point.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 25 of 31

Power Management System - PMA 300 USER MANUAL

If however the load on the other sets increase above or decrease below a configurable level, the

asymmetric load mode will be switched off and the generator return to normal loadsharing.

For sets not available for ASL (not running or not in SAM) the indication 'Disabled' will be shown.

Access to operate the ASL require password for user level 1.

Configuration of is available for each generator set from the recipes AsymmetricLoad.

5.45 Remote operating (optional)

If the PMA 300 is connected with a bus link to an Integrated Automation System (IAS) the following

operation is possible:

- Selecting control station (IAS or PMA300 touch screen panel)

- Selecting SAM (semi-automatic) / AM (automatic) operation

- Starting of the set

- Stopping of the set

- Activating/Deactivating of the start-and stop cascade

- Changing standby sequence

- Closing generator breakers (in SAM)

- Opening generator breakers (in SAM)

- Reset of alarms

In addition the generator active power, current, voltage, frequencies are provided in a data block for

further processing.

For an Integrated Automation System (IAS) to operate the power management system a command

‘TAKE CONTROL’ must be issued.

In remote mode (IAS), the control from the touch screen operation panel is blocked. The display func-

tions operate normally and will give correct information of breaker statuses, load, voltage, frequency

etc.

Pressing the pushbutton 'TAKE CONTROL' takes the control back to the PMA300 touch screen panel.

When control from IAS is used alarms will only be displayed on the local touch screen panel when

LOCAL control has been selected. Otherwise all alarms will appear both on the IAS system and the

PMA300 touch screen panel.

Reset of alarms will only be possible from the selected control location.

5.46 Heavy consumer control

The load demand control calculates the available power and compares it to the power required by the

demand. If there is not enough power a start order to the next standby set is given.

After synchronisation of the new started set the available power is calculated again.

If there is enough power the switch on of the consumer is released.

If there are more consumers selected the demand are stored in their order of arrival. The switch on will

be released according to their demand.

5.46.1 Blocking of the stop cascade

Along with the incoming demand signal a signal to block the stop cascade is given to PMA300. That

way the adding of a large consumer cannot coincide with the stop of a unit due to already existing un-

derload. The stop cascade is enabled again with the switch off of the last consumer.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 26 of 31

Power Management System - PMA 300 USER MANUAL

5.46.2 No Set in Automatic Mode

If there is no further set ready for operation or is set to 'Semi-automatic“, no consumers might be

added when demanded by the load demand control.

5.47 Heavy consumer starter interface

From each heavy consumer the PMA300 requires both a 'Request and running' input from the starter

system. These signals must be a steady signal (closed contact for request/running) as long as a start

is requested.

An output 'Enable start' (closed contact on enable start) will be given when enough power available for

the consumer to start.

For safety reasons the heavy consumer starter should be equipped with a override switch for the pos-

sibility to override the start blocking in case of a fault in the PMA300 system.

5.48 Heavy consumer configuration

Each heavy consumer can be configured individually from the touch screen panel recipes

HeavyConsumer, with the following functions;

• Required power (kW) for start

• Required current (A) for start

• Required number of sets for start

• Reserved power (kW) when consumer is connected (reserved power indicated in main picture)

• Reserved number of sets when consumer is connected

Any combination of above is possible.

5.49 Heavy consumer operational considerations

From the picture 'HEAVY CONSUMERS' it is possible to manually control some of the functions.

Access to operate from this picture require password for user level 1.

• ENABLED/DISABLED. If a heavy consumer is DISABLED the PMA300 will not give a 'start

enable' output response on a 'start request' input, even if power is available.

• OVERRIDE/OVERRIDDEN. If a heavy consumer is OVERRIDDEN the PMA300 will not check

for available power or generator sets and immediately gives a 'start enable' output response

on a 'start request' input.

• CANCLE. During the processing time of a heavy consumer request ('start request' input) it is

possible to abort the request by pressing CANCLE.

• RESET. If for some reason a 'start request' input has failed and the input signal is still present,

an alarm will be initiated and the request must be reset before another attempt can be per-

formed. With the 'start request' input present it will not be possible to reset before the required

number of sets, required current or power is fulfilled.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 27 of 31

Power Management System - PMA 300 USER MANUAL

5.50 Bus-tie breakers

The standard system will only provide buttons (close/open breaker) on the touch screen panel and two

digital outputs, 'synchronise/close breaker' and 'open breaker'.

Automatic synchronising must be arranged in the switchboard.

Access to operate from the bus-tie breaker picture require password for user level 1

5.50.1 Breaker control

The bus-tie breaker is switched ON or OFF manually from the operator panel.

The 'BREAKER ON' command shall start the synchronising device in the switchboard and then cause

the breaker to close.

The 'BREAKER OFF' command from the operator panel will immediately disconnect the breaker, with-

out off loading.

If a bus-tie breaker is installed without operation from the PMA300 the breaker feedback signal must

still be connected. The standard bus-tie breaker picture will also be shown, but no control will be pos-

sible. The bus-tie breaker will be shown in a 'transparent state'.

5.50.2 Signal interface

Signal from the bus-tie breaker position shall be a changeover contact. This will be monitored for cor-

rect feedback. In case of a fault an alarm will be issued ‘Breaker Fault'.

If control (breaker ON/OFF commands) shall be available, also a MANUAL/AUTO (or LO-

CAL/REMOTE) switch must be installed in the switchboard. To allow operation from the PMA 300 the

switch then must give an AUTO or REMOTE feedback signal to the system.

NOTE: In systems with double PLC's and a single bus-tie there must be a breaker position signal to

each PLC.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 28 of 31

Power Management System - PMA 300 USER MANUAL

In systems with double PLC's and double bus-tie breakers the breaker position signal must at least go

from each bus-tie breaker to its dedicated PLC.

5.51 Special requirements for diesel electric propulsion vessels

For diesel electric propulsion powered vessels the class societies have special requirements.

The standard PMA300 offers a 4-20mA analogue output to provide bridge instrumentation (not part of

PMA delivery) with a power plant available power signal.

As an option this could be replaced by one ore several smaller touch screen panels providing informa-

tion of number of connected sets, consumed power and available power. From these panels it will also

be possible to add the next standby sets to the bus-bar.

On vessels with Siemens integrated alarm and control systems the required signals will be provided

trough a Profibus-DP or Profibus-FDL link. Interface to other systems can be provided on request.

At the moment Modbus RTU with RS422/RS485 connection is available trough a Profibus-DP/Modbus

data converter. Also an Ethernet connection can be delivered as an option.

5.52 Password protection

Operation and configuration of the PMA300 system has been restricted by means of password protec-

tion.

For operating the heavy consumers, load shedding, asymmetric loadsharing and bus-tie breaker a

password for user level 1 is required.

For service, configuration, changing of parameters or passwords a password for user level 8 is re-

quired.

As default password login will be valid for 15min after last operation.

Default password for normal operation, user level 1 is: 100

Default password for user level 8 is: pma300

5.52.1 Changing passwords

Access to the system configuration (parameter sets) and the control panel is from the picture named

MAP.

For configuration select CONFIG and for access to the control panel and password management se-

lect SERVICE.

Because parameter and system settings should only be changed by an authorised person, there is a

password protection with user level 8 on these buttons.

To log on enter the password for desired user level in

the login field or simply press the button first and then

enter the password in the pop up window.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 29 of 31

Power Management System - PMA 300 USER MANUAL

With the correct password you will get access to the following picture;

It will now be possible to change the password for both user level 1 and 8 by entering a new value in

the password column and then press the 'enter' button (on the pop up key pad).

The 'Store' function save password settings in a separate file in the MP377 touch screen panel. In

case the touch screen program for some reason has been changed it will then be possible to 'Retrieve'

the stored password settings from this file.

5.53 Changing system parameters

5.53.1 Editing parameters

Select the picture MAP and CONFIG. Type password and log in.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 30 of 31

Power Management System - PMA 300 USER MANUAL

From the drop menu then select the recipe you want to edit.

The “Data Record Name' is the name of a stored set of parameters for the selected recipe.

To collect the actual parameter settings from the CPU press the Upload button.

By pressing the selected value you can change the parameters.

A keypad will appear, write the new value and press

the enter button.

5.53.2 Downloading parameters

For the changes to take affect the new parameter set must be downloaded to the CPU with the

Download button.

Warning!

Do not attempt to download recipes with only zero values as this may damage the configuration. The

zero values will always appear when you select a recipe and be displayed until the actual values are

uploaded or received from a stored data record.

5.54 Backup of the complete touch screen panel

The MP377 panel offers the possibility to backup the complete SW installation and configuration on a

removable compact flash. With this backup you can restore the SW on a new panel if required.

Doc.no: PO03020-12-P003B Part 5 Operating instructions Date:24.02.2010

Copyright © Siemens AS. All Rights reserved. Page 31 of 31

You might also like

- Caterpillar Switchgear Training Manual 3sDocument206 pagesCaterpillar Switchgear Training Manual 3sahmed elsheikh100% (1)

- Fitting & Machining N2 Nodrm-1Document481 pagesFitting & Machining N2 Nodrm-1Junior Khanya ApleniNo ratings yet

- Ford Transmission Installation4 PDFDocument6 pagesFord Transmission Installation4 PDFbelchiorNo ratings yet

- Yp11 21 31 32 41 eDocument20 pagesYp11 21 31 32 41 eIvan MaltsevNo ratings yet

- PE Load Calcs LLC Demo WorkDocument23 pagesPE Load Calcs LLC Demo WorkMaxmore KarumamupiyoNo ratings yet

- CAN and FPGA Communication Engineering: Implementation of a CAN Bus based Measurement System on an FPGA Development KitFrom EverandCAN and FPGA Communication Engineering: Implementation of a CAN Bus based Measurement System on an FPGA Development KitNo ratings yet

- Pareto Agustus 2022Document13 pagesPareto Agustus 2022Ahmad khairudinNo ratings yet

- Deep Sea 5310 Manual PDFDocument65 pagesDeep Sea 5310 Manual PDFMario Emilio Castro TineoNo ratings yet

- 1323408Document70 pages1323408Romulo SmartNo ratings yet

- IPL Saturn 20 PDFDocument56 pagesIPL Saturn 20 PDFJusril HidayatNo ratings yet

- 2nd Generation Henrob Controller: Operation and Maintenance Manual For Henrob Self-Pierce Riveting SystemDocument152 pages2nd Generation Henrob Controller: Operation and Maintenance Manual For Henrob Self-Pierce Riveting SystemAlejandro PuenteNo ratings yet

- Manual BrontoDocument115 pagesManual BrontoDaniel Reinoso Rojo83% (6)

- Projection ManualDocument122 pagesProjection ManualAndrei Gabara100% (1)

- Fresenius-4008s Service - ManualDocument416 pagesFresenius-4008s Service - ManualJana SFNo ratings yet

- Pump Curve 250x350Document1 pagePump Curve 250x350reiNo ratings yet

- Caterpillar Switchgear Training Manual 3 S PDFDocument206 pagesCaterpillar Switchgear Training Manual 3 S PDFKhaleel KhanNo ratings yet

- BOMBA EXTRACORPÓREA Maquet HL 20 - MS PDFDocument254 pagesBOMBA EXTRACORPÓREA Maquet HL 20 - MS PDFAnonymous dGFqrw5vO100% (5)

- Spot Welding Manual PDFDocument50 pagesSpot Welding Manual PDFVanderli AlvesNo ratings yet

- 'On' For Monitored Start (Acknowledge EMERGENCY OFF Cat. 0, Emergency Stop Cat. 1) Ext. Supply (UPS)Document7 pages'On' For Monitored Start (Acknowledge EMERGENCY OFF Cat. 0, Emergency Stop Cat. 1) Ext. Supply (UPS)hamzehNo ratings yet

- M (A) - 28 Piping ErDocument62 pagesM (A) - 28 Piping ErhamzehNo ratings yet

- Handleiding Flexball 3500 Tot 4500 SeriesDocument73 pagesHandleiding Flexball 3500 Tot 4500 SerieshamzehNo ratings yet

- 4008 S Hemodialysis Device Service Manual: Software Version: 11.40 and Higher Edition: 7/01.13 Part No.: M49 985 1Document408 pages4008 S Hemodialysis Device Service Manual: Software Version: 11.40 and Higher Edition: 7/01.13 Part No.: M49 985 1Cherif KhatirNo ratings yet

- GE E9000 Application-Guide DET-291H PDFDocument204 pagesGE E9000 Application-Guide DET-291H PDFRei ArmellaNo ratings yet

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Hettich Rotanta 460 - Repair ManualDocument92 pagesHettich Rotanta 460 - Repair ManualService Medisal100% (1)

- Manual Ps500Document62 pagesManual Ps500O mecanico88% (8)

- enDocument306 pagesenAshok PatelNo ratings yet

- 4008 S Hemodialysis Device Service Manual: Software Version: 11.40 and Higher Edition: 6/06.12 Part No.: M47 959 1Document402 pages4008 S Hemodialysis Device Service Manual: Software Version: 11.40 and Higher Edition: 6/06.12 Part No.: M47 959 1Oscar AvilaNo ratings yet

- PMC Maintenance - 3xi & 0id v2Document256 pagesPMC Maintenance - 3xi & 0id v2Jesus Alberto RIVERA /CALVEK AUTOMATION100% (2)

- Guentner GMM EC Manual Version3.0 ENDocument129 pagesGuentner GMM EC Manual Version3.0 ENRodrigo GonçalvesNo ratings yet

- Datasheet ICE3BR0665J V2!3!19nov2012Document31 pagesDatasheet ICE3BR0665J V2!3!19nov2012Andres AlegriaNo ratings yet

- PASOLINKV3Document56 pagesPASOLINKV3Didier SepulvedaNo ratings yet

- Im01e20f12-01e 001 Profibus Pa Axfa14Document76 pagesIm01e20f12-01e 001 Profibus Pa Axfa14j2pabloNo ratings yet

- P N M T: PNMT (Java Version) Operation ManualDocument56 pagesP N M T: PNMT (Java Version) Operation ManualsvktcNo ratings yet

- P N M T: PNMT (Java Version) Operation ManualDocument85 pagesP N M T: PNMT (Java Version) Operation ManualRaja solaimalaiNo ratings yet