Professional Documents

Culture Documents

Masterflex 611: Gun Grade, Hydroswelling Waterbar

Uploaded by

Andri AjaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Masterflex 611: Gun Grade, Hydroswelling Waterbar

Uploaded by

Andri AjaCopyright:

Available Formats

MASTERFLEX® 611

Gun grade, hydroswelling waterbar

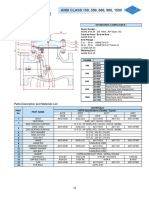

DESCRIPTION Swelling: Typical swelling behaviour of MASTERFLEX

611 in distilled water is illustrated below. The swelling

Masterflex 611 is a single component, urethane action depends on the solution to which it is exposed.

modified, gun grade, hydroswelling waterbar for

120

application in situations where pre-formed waterbars 20x10x50mm

cannot be used. 100

Swelling rate in volume

FIELDS OF APPLICATION 80

(%)

MASTERFLEX 611 is recommended for sealing all 60

narrow joints, cavities or gaps exposed to hydrostatic 40

pressure. Applications include :

20

• insitu casting of ‘gaskets’ for sealing joints in

piping and between precast elements. 0

• sealing of construction joints. 0 2 4 7 10 14 21 28 35

Immersion duration (days)

• use as a smoothing and adhesive paste over

uneven joint surfaces before laying MASTERFLEX

610. PROPERTIES

• repair works and sealing of gaps.

Note : If MASTERFLEX 611 is used on exposed Appearance : Paste

surfaces, the swelling effect from continuous rain may

cause the unprotected part of the waterbar to bulge Specific Gravity (JIS A 1439) : 1.29 +/-0.05

slightly.

Extrusion (JIS A 1439) : max 5 sec

FEATURES AND BENEFITS

Slump (JIS A 1439) : max 5 mm

Swells in contact with Seals gaps effectively.

water by over 90%

Tack-free time (JIS A 1439) : within 5 hr

Water molecules held No wicking effect that

by molecular could cause leaks.

attraction APPLICATION

Excellent adhesion No leakage through bond Surface Preparation

interface. Correct preparation is critical for optimum

Highly elastic Prevents damage from performance. Surfaces should be structurally sound,

swelling and shrinking clean, and free from loose particles and sharp

cycles caused by wetting protrusion, oil, grease, or any other contaminant.

and drying. Repair any honeycombs and such other defects with a

Controlled swelling Minimise the risk of suitable repair mortar (consult BASF Construction

damage to substrate. Chemicals). Clear any standing water from the

surface.

Bonds to moist Benefit in humid areas.

Insert the cartridge filled with MASTERFLEX 611 into

surfaces

the frame of a standard sealant gun. Cut off the nozzle

at a suitable distance from the end in diagonal to

TYPICAL PERFORMANCE obtain an opening that best matches the width of the

gap to be sealed or of the waterbar (MASTERFLEX

Tensile strength (JIS A 6251) : min 3.9 N/mm2 610) to be laid.

Elongation (JIS K 6251) : min 1000 %

Placing

Tear strength (JIS K 6252) : min12 N/mm With the nozzle just above the substrate surface,

Swelling ratio (JIS K 6258) : min 85% gently and repeatedly squeeze the trigger depositing a

o continuous bead of MASTERFLEX 611 into the gap or

Distilled water at 23 C

where the waterbar is to be laid. Avoid entrapment of

BASF Construction Chemicals offices in ASEAN

Singapore Malaysia Indonesia Thailand Vietnam Philippines

Tel :+65-6861-6766 Tel :+60-3-5628-3888 Tel :+62-21-526-2481 Tel :+66-2204-9427 Tel :+84-650-3743-100 Tel : +63-2-889-4321

Fax :+65-6861-3186 Fax :+60-3-5628-3776 Fax :+62-21-526-2541 Fax :+66-2664-9267 Fax :+84-650-3743-200 Fax : +63-2-889-4361

MASTERFLEX® 611

air in the gunned material by matching the rate of PACKAGING

advance of the gun nozzle with the rate of deposition.

If using as a smoothing or adhesive paste for Masterflex 611 is packaged in 320 ml (400 g)

MASTERFLEX 610 (pre-formed waterbar), place the cartridges. 24 cartridges are packed per carton.

waterbar over the adhesive paste while it is still tacky

and gently press to ensure bonding. SHELF LIFE

Masterflex 611 can be stored in a well enclosed dry

CURING place for 6 months in unopened original packing away

from heat and direct sunlight.

MASTERFLEX 611 is self curing. It achieves tack-free

state within 5 hr. at 25°C.

PRECAUTIONS

Note : It is important to protect the waterbar from

exposure to water until it is fully cured. Health : Some people may be sensitive to certain

resin systems. Wear impervious gloves and use hand

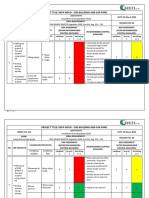

ESTIMATING DATA barrier cream while handling the product. Prevent eye

contact. Ventilate application area. Wash thoroughly

The coverage in running metres of a 320 ml cartridge after handling. Persons who are sensitive to the

for common widths and thicknesses of application is vapours must wear approved respirators.

given below.

Should skin contact occur, wash immediately with

Application Application width in mm soap and water, or an effective hand cleaner.

Depth in mm In case of accidental eye contact wash with copious

5 10 20 25 30

quantities of water and seek medical help immediately.

5 3.2 2.6 2.1 If ingested, do not induce vomiting. Consult doctor

10 6.4 3.2 1.6 1.3 1.1 immediately.

If the inhalation of vapours is causing discomfort,

20 3.2 1.6 0.8 0.6 0.5

remove to fresh air.

25 2.6 1.3 0.6 0.5 0.4 Fire : Product is flammable. Avoid exposure to naked

flame or other ignition sources. Do not smoke while

handling the product.

Flash point : 44°C

For Health, Safety and Environmental

recommendations, please consult and follow all

instructions on the product Material Safety Data Sheet.

AN/MFlex611/v2/050609

The technical information and application advice given in this BASF Construction Chemicals publication are

STATEMENT OF based on the present state of our best scientific and practical knowledge. As the information herein is of a

general nature, no assumption can be made as to a product's suitability for a particular use or application and

RESPONSIBILITY no warranty as to its accuracy, reliability or completeness either expressed or implied is given other than

those required by law. The user is responsible for checking the suitability of products for their intended use.

NOTE Field service where provided does not constitute supervisory responsibility. Suggestions made by BASF

Construction Chemicals either orally or in writing may be followed, modified or rejected by the owner,

engineer or contractor since they, and not BASF Construction Chemicals, are responsible for carrying out

procedures appropriate to a specific application.

You might also like

- Good Year Industrial Hose Catalog 2010Document332 pagesGood Year Industrial Hose Catalog 2010Andri AjaNo ratings yet

- Easyarc 7018Document2 pagesEasyarc 7018Andri AjaNo ratings yet

- KS Product Specification 2015Document32 pagesKS Product Specification 2015Andri AjaNo ratings yet

- Masterflow 870: Dual Shrinkage Compensated, Precision GroutDocument3 pagesMasterflow 870: Dual Shrinkage Compensated, Precision GroutAndri AjaNo ratings yet

- NDD010 MCS Type B Foam ChambersDocument6 pagesNDD010 MCS Type B Foam ChambersAndri AjaNo ratings yet

- Masterflow 648CP PLUS - PDS - ASEAN - 161209Document2 pagesMasterflow 648CP PLUS - PDS - ASEAN - 161209Andri AjaNo ratings yet

- How To Order Alfa Forged Gate, Globe, and Check ValvesDocument1 pageHow To Order Alfa Forged Gate, Globe, and Check ValvesAndri AjaNo ratings yet

- Masterflow 626: Heavy Duty, Epoxy Resin Based GroutDocument2 pagesMasterflow 626: Heavy Duty, Epoxy Resin Based GroutAndri AjaNo ratings yet

- Ansi Class 150 and 300: FL AngesDocument4 pagesAnsi Class 150 and 300: FL AngesAndri AjaNo ratings yet

- Breather Valve 2046Document3 pagesBreather Valve 2046Andri AjaNo ratings yet

- Masterflow 622: Heavy Duty Epoxy Resin Chocking GroutDocument2 pagesMasterflow 622: Heavy Duty Epoxy Resin Chocking GroutAndri AjaNo ratings yet

- Ground WireDocument3 pagesGround WireAndri AjaNo ratings yet

- 03b Check Valves Preesure SealDocument2 pages03b Check Valves Preesure SealAndri AjaNo ratings yet

- 07 Forged Cryogenic Gate GlobeDocument2 pages07 Forged Cryogenic Gate GlobeAndri AjaNo ratings yet

- Masterflex 801 Asean 0509Document2 pagesMasterflex 801 Asean 0509Andri AjaNo ratings yet

- Sonolastic Ultra Asean 0509Document2 pagesSonolastic Ultra Asean 0509Andri AjaNo ratings yet

- 01 Basic Design Structure FeaturesDocument8 pages01 Basic Design Structure FeaturesAndri AjaNo ratings yet

- Primocon - Anti FaulingDocument2 pagesPrimocon - Anti FaulingAndri AjaNo ratings yet

- Forged Steel Needle Globe Valve: ANSI Class 800, 1500 ANSI Class 800, 1500Document1 pageForged Steel Needle Globe Valve: ANSI Class 800, 1500 ANSI Class 800, 1500Andri AjaNo ratings yet

- Interseal 670HS: Surface Tolerant EpoxyDocument2 pagesInterseal 670HS: Surface Tolerant EpoxyAndri AjaNo ratings yet

- 00 Valve Design and ConstructionDocument3 pages00 Valve Design and ConstructionAndri AjaNo ratings yet

- Cast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Document5 pagesCast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Andri AjaNo ratings yet

- Cast Steel Swing Check Valve: ANSI CLASS 150, 300, 600, 900, 1500Document3 pagesCast Steel Swing Check Valve: ANSI CLASS 150, 300, 600, 900, 1500Andri AjaNo ratings yet

- Interprime 198Document4 pagesInterprime 198Andri AjaNo ratings yet

- Interthane 990: Long Term Recoatability With AestheticsDocument2 pagesInterthane 990: Long Term Recoatability With AestheticsAndri AjaNo ratings yet

- PBH Power Line FilterDocument2 pagesPBH Power Line FilterAndri AjaNo ratings yet

- PBH Power Line FilterDocument2 pagesPBH Power Line FilterAndri AjaNo ratings yet

- Interprime 198: Product DescriptionDocument4 pagesInterprime 198: Product DescriptionAndri AjaNo ratings yet

- Junction Boxes and Wall-Mount EnclosuresDocument1 pageJunction Boxes and Wall-Mount EnclosuresAndri AjaNo ratings yet

- Intergard 345: Fast Drying Direct To Metal EpoxyDocument2 pagesIntergard 345: Fast Drying Direct To Metal EpoxyAndri AjaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 51 Ijmrp 3 (6) 263-65Document3 pages51 Ijmrp 3 (6) 263-65ahmed samirNo ratings yet

- CHOLElithiasisDocument93 pagesCHOLElithiasisfranciscomaricris13No ratings yet

- 013 HIRARC Installation of Hoisting BeamDocument8 pages013 HIRARC Installation of Hoisting Beambdiey100% (1)

- Sleeping Pattern Among Students ReportDocument15 pagesSleeping Pattern Among Students ReportHazwani RahmanNo ratings yet

- Acute Neurotherapeutics and Neuromonitoring FellowshipDocument7 pagesAcute Neurotherapeutics and Neuromonitoring FellowshippuspoNo ratings yet

- Forthcoming Grand Chamber Case Vavricka and Others v. Czech RepublicDocument3 pagesForthcoming Grand Chamber Case Vavricka and Others v. Czech RepublicZiarul de GardăNo ratings yet

- Literature Review On OgiDocument7 pagesLiterature Review On Ogiafdtaeczo100% (1)

- Vaccine Guide - Randall NeustaedterDocument6 pagesVaccine Guide - Randall NeustaedterttreksNo ratings yet

- Positive Psychology: For More, SeeDocument5 pagesPositive Psychology: For More, SeeAbby NavarroNo ratings yet

- Brick Work JSA HSE ProfessionalsDocument1 pageBrick Work JSA HSE ProfessionalsStansilous Tatenda NyagomoNo ratings yet

- Correcta Posicion Del TornilloDocument5 pagesCorrecta Posicion Del TornilloSilvia PluisNo ratings yet

- 240809-Data Penelitian Dan Publikasi IPDS Di IndonesiaDocument22 pages240809-Data Penelitian Dan Publikasi IPDS Di IndonesiaHasbiallah YusufNo ratings yet

- Case:: Biddy's Bakery (BB)Document3 pagesCase:: Biddy's Bakery (BB)tehreem chohanNo ratings yet

- Aseptic TechniqueDocument34 pagesAseptic TechniqueJessa Adenig100% (1)

- Journals IndexDocument203 pagesJournals Indexrajupetalokesh100% (1)

- 1.neuro Intro-1 UMTDocument51 pages1.neuro Intro-1 UMTLOVELY WALEEDNo ratings yet

- Fneur 13 871187Document7 pagesFneur 13 871187Yery AparicioNo ratings yet

- Sample - RSO Manual Hospital CathlabDocument39 pagesSample - RSO Manual Hospital CathlabPaul Ivan JulianNo ratings yet

- Afmp FMRDocument173 pagesAfmp FMRRonel Dimaya CañaNo ratings yet

- Naranjo AlgorithmDocument3 pagesNaranjo AlgorithmmilkymilkyNo ratings yet

- Case Study Hyperbilirubinemia FinalDocument21 pagesCase Study Hyperbilirubinemia FinalPrecious Ophelia Nana Adjoa100% (2)

- Vessel Due FDocument2 pagesVessel Due Fianecunar88% (8)

- Defination of FireDocument21 pagesDefination of FireVikas YamagarNo ratings yet

- 5 PDFDocument8 pages5 PDFoskar ORTIZNo ratings yet

- Design and Characterization of Flucytosine Loaded Bioadhesive in Situ Ophthalmic Gel For Improved BioavailabilityDocument4 pagesDesign and Characterization of Flucytosine Loaded Bioadhesive in Situ Ophthalmic Gel For Improved BioavailabilityRam SahuNo ratings yet

- NCP Shoulder DystociaDocument4 pagesNCP Shoulder DystociaTrishia CaroNo ratings yet

- Turkish Exhibitors: 8-11 MARCH 2013Document9 pagesTurkish Exhibitors: 8-11 MARCH 2013qday1No ratings yet

- Jurnal Kebidanan KomunitasDocument5 pagesJurnal Kebidanan KomunitasdeffiNo ratings yet

- Effectiveness of Orange Peelings As Insect Repellent: Mark Anthony Paul Borabo Jonard Estrallado Raff QuillosDocument4 pagesEffectiveness of Orange Peelings As Insect Repellent: Mark Anthony Paul Borabo Jonard Estrallado Raff QuillosAoki kazeNo ratings yet

- Counseling For Behavior Change: F. Daniel Duffy, MD, MACP Michael G. Goldstein, MDDocument28 pagesCounseling For Behavior Change: F. Daniel Duffy, MD, MACP Michael G. Goldstein, MDKodhandaiah Nesanuru NNo ratings yet