Professional Documents

Culture Documents

Transport, Handling and Storage Guidelines: General Information

Uploaded by

ZzzdddOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transport, Handling and Storage Guidelines: General Information

Uploaded by

ZzzdddCopyright:

Available Formats

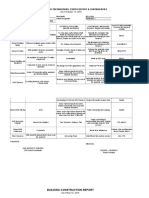

GENERAL INFORMATION

Transport, handling and storage guidelines

Always use

appropriate safety.

Do not attempt to lift drums of cable without inserting the fork lift tynes This cable has been

fully under both flanges as the tynes can damage the cable, making it un- rendered unserviceable

serviceable. Do not attempt to lift drums by the flange or to lift drums into through fork lift tyne

the upright (correct) position by lifting the top flanges as it may break the damage and may ne-

flange from the drum barrel. The drum will then be undeliverable. Use a cessitate the scrapping

length of steel pipe through the centre of the drum to provide leverage of the whole drum.

and control.

Do not use the fork lift tynes to push cable drums sideways on a truck tray or the ground as damage to

the flanges can result in the drum being unacceptable to customers.

WWW.PRYSMIANCABLE.COM.AU ∣ 1300 300 304

GENERAL INFORMATION

Prior to lifting any drums, ensure Avoid impact force loadings. Never

the site has suitably rated mechani- drop drums.

cal handling equipment to handle

the drum.

Lower drums gently onto the ground

or transport.

Always protect cable from rubbing Never let drum flanges contact cable

or damage. Adjust load or consider on adjacent drums.

using separators such as carpet, ply

or corflute between products for

protection.

Heavy drums should be chained ap- Never lay drums on their side, even

propriately for transit, with protection on top of pallets, as protruding bolts

from the chain rubbers or carpet for damage spools and cable.

the spindle hole in the centre of the

drum. Under no circumstances are

drums to be transported on their side.

Always protect product, especially Never use rope directly over shrink-

spools, against load restraint dam- wrapped cable.

age during tying down of load. Con-

sider using angles or carpet under

straps, chains and rope.

Ensure drums are restrained to re- When securing drums for transit,

strict movement during sudden do not place ropes or chains over

stop/starts. cable as damage can occur to the

outer insulation rendering the ca-

ble unserviceable.

Ensure cable sealing is intact so Avoid use of additional nails on

moisture cannot seep into cable. drums or cable. Flange thicknesses

Report damage. vary and some customers prohibit

their use.

When placing drums on an uneven Never climb or walk over products

surface be prepared to chock drums loaded on the truck. If you must get

to prevent rolling if required. onto the tray, do not go higher than

the deck height.

Do not roll cable drums from the

back of a delivery truck to the

ground as the resulting flange dam-

age will be unacceptable to the cus-

tomer as the cable will not be able to

be rolled off the drum and the drum

will need to be returned.

WWW.PRYSMIANCABLE.COM.AU ∣ 1300 300 304

GENERAL INFORMATION

Before lifting or rolling any product, When rewinding cables, drums shall be of suitable construc-

first confirm there isn’t any mechani- tion and in good condition. All drums shall be held firmly in

cal aids to do the task. If there isn’t, al- appropriate pay-off stands to prevent vibration and ensure

ways assess its weight and size to en-

smooth, even rotation to minimise inner end cable grow-out

sure it is safe to manually handle. If

you believe there is a risk of injury DO and tangling. Cables shall be wound evenly and uniformly,

NOT attempt. Report to supervisor. then secured.

Unloading – safety exclusion zones

At all sites, you should determine if the area is safe to under- If it isn’t, contact your manager for further advice so alterna-

take the loading and unloading task, that you can establish a tive arrangements can be made.

safety exclusion zone with cooperation of site representa- Use this guide to set up your safety exclusion zone.

tives, and that appropriate lifting equipment is available.

GREEN ZONES

Safety exclusion zone when mobile equipment

is operating in red zone. Ensure visual contact

is maintained with mobile plant operator.

AMBER ZONES

Management approved handling task only –

you must not enter unless company records

confirm you are registered as competent to

perform this task.

Minimum 10 m Minimum 2 m

RED ZONES

People are not allowed in this zone whilst mo-

bile plant is operating. Ensure its engine is off

before entering.

WWW.PRYSMIANCABLE.COM.AU ∣ 1300 300 304

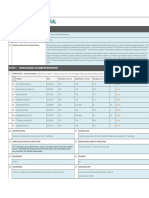

GENERAL INFORMATION

Storage recommendations

When storing cable drums for long periods, please take the

following guidelines into consideration:

✓ Select a site for storage that is level and dry, preferably in- ✓ The bolts should be tightened at regular intervals.

✓

✓

doors with a concrete surface, with no risk of falling ob-

✓ During storage, the drums should be rolled to an angle of 90°

jects, chemical spills (oil, grease, etc.) open flames and

✓

every three months (see fig. 3).

excessive heat (see fig. 1).

✓ When only a portion of the cable is used, the open end of

✓ If concrete hard storage is not available, select a well-drai-

✓

the cable remaining on the drum should immediately be

✓

ned surface that will prevent the reel flanges sinking into

re-sealed to prevent the entrance of moisture. Once it has

it (see fig. 1).

been re-sealed, the cut end should be fixed to the inside

✓ The drums must always be stored with their flanges ver- edge of the drum flange to prevent the end from exten-

✓

tical. ding beyond the flanges during drum movement.

✓ Leave enough space between stored drums for air circula- ✓ When it is required to rewind the cable on to another drum,

✓

✓

tion (see fig. 2). always consider that the diameter of the new drum barrel

should be at least the same size of the original drum barrel

✓ If drums are stored in a high traffic area (fork lifts frequ-

diameter (see fig. 4).

✓

ent transit) suitable barriers should be erected to prevent

damage from moving equipment (see fig. 2).

Fig. 2

Fig. 3

Fig. 1

Drums barrel

diameter

Smaller drum

Original drum

Fig. 4

WWW.PRYSMIANCABLE.COM.AU ∣ 1300 300 304

You might also like

- The Effective Change Manager's Handbook - Essential Guidance To The Change Management Body of Knowledge PDFDocument633 pagesThe Effective Change Manager's Handbook - Essential Guidance To The Change Management Body of Knowledge PDFrwn data81% (31)

- BS 7346-8 2013 Components For Smoke Control SystemsDocument56 pagesBS 7346-8 2013 Components For Smoke Control SystemsMeric100% (8)

- Strategic Thinking A Nine Step Approach To Strategy and Leadership For Managers and MarketersDocument159 pagesStrategic Thinking A Nine Step Approach To Strategy and Leadership For Managers and MarketersBhadriLaNo ratings yet

- Class Opening Preparations Status ReportDocument3 pagesClass Opening Preparations Status ReportMaria Theresa Buscato86% (7)

- Request For Proposal Construction & Phase 1 OperationDocument116 pagesRequest For Proposal Construction & Phase 1 Operationsobhi100% (2)

- Cradle Operations ManualDocument33 pagesCradle Operations ManualArul Alvin InfantNo ratings yet

- Anatomy of A BMU SKYRIDERDocument4 pagesAnatomy of A BMU SKYRIDERSamson Rajan Babu0% (1)

- 07 Overhead Cables (Aac Aaac Acsr ABC)Document34 pages07 Overhead Cables (Aac Aaac Acsr ABC)mlutfimaNo ratings yet

- BS 5839 6 Guide 2020 Update Jan 2021Document19 pagesBS 5839 6 Guide 2020 Update Jan 2021ZzzdddNo ratings yet

- BS 5306-0-2020 - TC - (2021-02-02 - 08-57-23 PM)Document198 pagesBS 5306-0-2020 - TC - (2021-02-02 - 08-57-23 PM)daniela fabiola Cisternas0% (1)

- BSI Standards PublicationDocument48 pagesBSI Standards Publicationandres100% (5)

- Why Islam Is The True Religion in Light of The Quran and SunnahDocument7 pagesWhy Islam Is The True Religion in Light of The Quran and SunnahAsmau DaboNo ratings yet

- NSX 100-630 User ManualDocument152 pagesNSX 100-630 User Manualagra04100% (1)

- Icelandic Spells and SigilsDocument16 pagesIcelandic Spells and SigilsSimonida Mona Vulić83% (6)

- Drum Handlingstorage Installation GuidelineDocument12 pagesDrum Handlingstorage Installation GuidelineShubham Baderiya100% (1)

- Drum Handling Procedure Eland CablesDocument3 pagesDrum Handling Procedure Eland CablesEddie TweNo ratings yet

- Cable Drum Handling ManualDocument40 pagesCable Drum Handling Manualjeb13No ratings yet

- Power AscenderDocument6 pagesPower AscenderApriliando KurniawanNo ratings yet

- Safe Use of Eyeblts Dlhonline PDFDocument2 pagesSafe Use of Eyeblts Dlhonline PDFMoetaz MohamedNo ratings yet

- Lifting Support Risk AssessmentDocument10 pagesLifting Support Risk AssessmentcitraNo ratings yet

- Rigging Saftey Program Docx e RDocument48 pagesRigging Saftey Program Docx e RTawfik Mohamed Abu ZaidNo ratings yet

- Crane Jib Check ListDocument1 pageCrane Jib Check ListsawkariqbalNo ratings yet

- Sling Saver: 69 All Rights ReservedDocument12 pagesSling Saver: 69 All Rights ReservedPradhipta W NurrobbiNo ratings yet

- Australian/New Zealand Standard™: Scaffolding Part 1: General RequirementsDocument75 pagesAustralian/New Zealand Standard™: Scaffolding Part 1: General RequirementsArdamitNo ratings yet

- 0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Document2 pages0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Achmad ChusnadiNo ratings yet

- TPG Acsr 435 PDFDocument2 pagesTPG Acsr 435 PDFNurlita Dewi UtamiNo ratings yet

- Underground Cable Technical SpecificationsDocument5 pagesUnderground Cable Technical SpecificationsCangkang SainsNo ratings yet

- Wire Rope Slings: Recommended Guideline For Proof Test Procedures ForDocument22 pagesWire Rope Slings: Recommended Guideline For Proof Test Procedures Fordonnyars1979No ratings yet

- Company Profile Apave GulfDocument36 pagesCompany Profile Apave GulfamitNo ratings yet

- Chapter01 ShacklesDocument38 pagesChapter01 ShacklesHamzahrudin SunandarNo ratings yet

- Overhead Crane Pre Shift InspectionDocument1 pageOverhead Crane Pre Shift InspectionRafflesia GroupNo ratings yet

- Webbing SlingDocument3 pagesWebbing Slingmoha19841No ratings yet

- Kimanis Power Project: Job Safety AnalysisDocument8 pagesKimanis Power Project: Job Safety AnalysisHSSE IP WAYAMENo ratings yet

- Learner Guide - RBDocument61 pagesLearner Guide - RBEducation 2.0No ratings yet

- PDF Gi 0002721 2016 Arc Flash CompressDocument23 pagesPDF Gi 0002721 2016 Arc Flash CompressMark DingalNo ratings yet

- Chain Slings SI 1.3Document2 pagesChain Slings SI 1.3reda mesbahNo ratings yet

- OTC Guide PDFDocument34 pagesOTC Guide PDFswordleee swordNo ratings yet

- Safety Net CatalogueDocument1 pageSafety Net CatalogueFireNo ratings yet

- Steel CstructionDocument18 pagesSteel CstructionChen QingNo ratings yet

- EM 385-1-1 2014 Section 22Document44 pagesEM 385-1-1 2014 Section 22TinasheNo ratings yet

- Plywood Material Safety Data Sheet For MR Plywood PDFDocument4 pagesPlywood Material Safety Data Sheet For MR Plywood PDFNirvana NircisNo ratings yet

- SFPSG-Reducing Unintended Movement of PlantDocument60 pagesSFPSG-Reducing Unintended Movement of PlantLyle KorytarNo ratings yet

- Stringing T&P Reqd For A606 765 KV Dc-ZebraDocument3 pagesStringing T&P Reqd For A606 765 KV Dc-Zebraprithvirajd20No ratings yet

- Isolation and Lockout - IEDocument25 pagesIsolation and Lockout - IEyuwantoniNo ratings yet

- Onshore Combined Mto Updated 9-04-20Document97 pagesOnshore Combined Mto Updated 9-04-20Ahmed Al-MenshadNo ratings yet

- Alimak Hek 65 - 32Document5 pagesAlimak Hek 65 - 32Zhoro Boyssan LestaluhuNo ratings yet

- Wire Rope Slings Guide for Lifting ApplicationsDocument22 pagesWire Rope Slings Guide for Lifting ApplicationsMahmoud Al-SherbinyNo ratings yet

- 012 Piling WorkDocument17 pages012 Piling WorkSarah HaiderNo ratings yet

- Accii LR2Document4 pagesAccii LR2pnsanatNo ratings yet

- ER-MO - 02 Preparing and Installing Components1Document17 pagesER-MO - 02 Preparing and Installing Components1Alex IgnatNo ratings yet

- As 4722-2009 Passenger Ropeways and Passenger ConveyorsDocument8 pagesAs 4722-2009 Passenger Ropeways and Passenger ConveyorsSAI Global - APACNo ratings yet

- As 4143.1-1993 Methods of Test For Fibre Ropes Dimensions Linear Density Breaking Force and ElongationDocument2 pagesAs 4143.1-1993 Methods of Test For Fibre Ropes Dimensions Linear Density Breaking Force and ElongationSAI Global - APAC0% (1)

- Fall Protection Gear CatalogDocument9 pagesFall Protection Gear CatalogPraful E. PawarNo ratings yet

- Conveyor Guarding Case Study Protects Workers from Nip and Shear PointsDocument18 pagesConveyor Guarding Case Study Protects Workers from Nip and Shear PointsDSG100% (1)

- Brosur Nyaf 1 X 4 mm2 Biru 100 Meterrol JemboDocument1 pageBrosur Nyaf 1 X 4 mm2 Biru 100 Meterrol Jembom4l4ik4tny4w4No ratings yet

- Skyway ED 3 WebDocument84 pagesSkyway ED 3 Webtroyel99100% (1)

- Chain&AccessoriesDocument57 pagesChain&AccessoriesAnonymous YggO6T6GzNo ratings yet

- MWR 135Document20 pagesMWR 135Philip Bautista TotanesNo ratings yet

- Operation and maintenance manual for high mastsDocument7 pagesOperation and maintenance manual for high mastsmaninderpreetNo ratings yet

- Nym Sni IecDocument4 pagesNym Sni IecDimas BlNo ratings yet

- Drum Handling, Storing and Installation GuideDocument20 pagesDrum Handling, Storing and Installation Guideajaipeter100% (3)

- Rigging Safety TipsDocument2 pagesRigging Safety Tipspruncu.alianmNo ratings yet

- 3 (1) Leea Advice On Eyebolts PDFDocument2 pages3 (1) Leea Advice On Eyebolts PDFReda MashalNo ratings yet

- Rigging Equipment Inspection FormDocument4 pagesRigging Equipment Inspection FormWaqar AhmedNo ratings yet

- Method Statement - PullingDocument9 pagesMethod Statement - PullingjahanzaibNo ratings yet

- Instructions For The Safe Use Of: Jacks: AlwaysDocument1 pageInstructions For The Safe Use Of: Jacks: Alwaysreda mesbahNo ratings yet

- Wire Rope Slings Si 2 - 2 EmmDocument2 pagesWire Rope Slings Si 2 - 2 EmmheppyfaebanffNo ratings yet

- EIGER 500 AGR DW - How To Use - PopUpProductsDocument4 pagesEIGER 500 AGR DW - How To Use - PopUpProductsГеоргий ПрокофьевNo ratings yet

- Draft MOS For Cable LayingDocument8 pagesDraft MOS For Cable LayingHtun SoeNo ratings yet

- Product: Cables: (Handling, Storage & Installation)Document22 pagesProduct: Cables: (Handling, Storage & Installation)Pritam Singha RoyNo ratings yet

- Handling Installation Rev 22 PDFDocument24 pagesHandling Installation Rev 22 PDFtwo travellerNo ratings yet

- Flat Rate Service - Quantity Take-Off by RoomDocument1 pageFlat Rate Service - Quantity Take-Off by RoomZzzdddNo ratings yet

- Flat Rate Service - Take-Off DetailDocument2 pagesFlat Rate Service - Take-Off DetailZzzdddNo ratings yet

- Material Report for Hot Tub, Landscape ProjectDocument8 pagesMaterial Report for Hot Tub, Landscape ProjectZzzdddNo ratings yet

- Getting Paid For Your Work Jonathan ParkerDocument38 pagesGetting Paid For Your Work Jonathan ParkerZzzdddNo ratings yet

- Flat Rate Service - Quantity Take-Off by RoomDocument1 pageFlat Rate Service - Quantity Take-Off by RoomZzzdddNo ratings yet

- Material Report for Hot Tub, Landscape ProjectDocument8 pagesMaterial Report for Hot Tub, Landscape ProjectZzzdddNo ratings yet

- Flat Rate Service - Flat Rate DetailDocument2 pagesFlat Rate Service - Flat Rate DetailZzzdddNo ratings yet

- Flat Rate Service - Flat Rate DetailDocument2 pagesFlat Rate Service - Flat Rate DetailZzzdddNo ratings yet

- Flat Rate Service - Take-Off DetailDocument2 pagesFlat Rate Service - Take-Off DetailZzzdddNo ratings yet

- Conditional Sentences, If-Clauses Type I, Ii, IiiDocument3 pagesConditional Sentences, If-Clauses Type I, Ii, IiiDaniel SanchezNo ratings yet

- Cost Estimating PHD PDFDocument28 pagesCost Estimating PHD PDFGeethaNo ratings yet

- 22 Hull WWTW Sludge Treatment Facility (STF) Commissioning Plan - High LevelDocument72 pages22 Hull WWTW Sludge Treatment Facility (STF) Commissioning Plan - High LevelZzzdddNo ratings yet

- Contract Award Approval: Section H Project InformationDocument3 pagesContract Award Approval: Section H Project InformationZzzdddNo ratings yet

- Conditional Sentences, If-Clauses Type I, Ii, IiiDocument3 pagesConditional Sentences, If-Clauses Type I, Ii, IiiDaniel SanchezNo ratings yet

- 22 Hull WWTW Sludge Treatment Facility (STF) Commissioning Plan - High LevelDocument72 pages22 Hull WWTW Sludge Treatment Facility (STF) Commissioning Plan - High LevelZzzdddNo ratings yet

- Commissioning Team Role Responsibilities 1Document9 pagesCommissioning Team Role Responsibilities 1ZzzdddNo ratings yet

- Commissioning Team Roles & ResponsibilitiesDocument8 pagesCommissioning Team Roles & ResponsibilitiesGabrielNo ratings yet

- BS 5306 0 2020Document198 pagesBS 5306 0 2020ZzzdddNo ratings yet

- Blueprint For Electrical Contracting Firm Business Development (2014)Document38 pagesBlueprint For Electrical Contracting Firm Business Development (2014)ZzzdddNo ratings yet

- A Guide To Project Finance - 2013 PDFDocument92 pagesA Guide To Project Finance - 2013 PDFPuneet MittalNo ratings yet

- UK FacilitiesMgr Spec Book A4 Web Feb 17Document19 pagesUK FacilitiesMgr Spec Book A4 Web Feb 17ZzzdddNo ratings yet

- BS 5839 6 2019 FIA Update Will LloydDocument28 pagesBS 5839 6 2019 FIA Update Will LloydZzzdddNo ratings yet

- SE10908 WD Catalogue WebDocument312 pagesSE10908 WD Catalogue WebZzzdddNo ratings yet

- SEB Cable Pulling and Laying Equipment CatalogueDocument24 pagesSEB Cable Pulling and Laying Equipment CatalogueZzzdddNo ratings yet

- Corporate Governance in SMEsDocument18 pagesCorporate Governance in SMEsSana DjaanineNo ratings yet

- Load Frequency Control of Hydro and Nuclear Power System by PI & GA ControllerDocument6 pagesLoad Frequency Control of Hydro and Nuclear Power System by PI & GA Controllerijsret100% (1)

- Emilio Aguinaldo CollegeDocument1 pageEmilio Aguinaldo CollegeRakeshKumar1987No ratings yet

- Inspection and Acceptance Report: Stock No. Unit Description QuantityDocument6 pagesInspection and Acceptance Report: Stock No. Unit Description QuantityAnj LeeNo ratings yet

- Multivariate Analysis Homework QuestionsDocument2 pagesMultivariate Analysis Homework Questions歐怡君No ratings yet

- Integrating Therapeutic Play Into Nursing and Allied Health PracticeDocument214 pagesIntegrating Therapeutic Play Into Nursing and Allied Health PracticeIbrahim SabraNo ratings yet

- L Williams ResumeDocument2 pagesL Williams Resumeapi-555629186No ratings yet

- AIOUDocument2 pagesAIOUHoorabwaseemNo ratings yet

- XXCCCDocument17 pagesXXCCCwendra adi pradanaNo ratings yet

- Ketchikan Shipyard Improvements Plan CompleteDocument230 pagesKetchikan Shipyard Improvements Plan CompleteOpó Ishak Bawias Adare100% (1)

- LogDocument119 pagesLogcild MonintjaNo ratings yet

- Managing Post COVID SyndromeDocument4 pagesManaging Post COVID SyndromeReddy VaniNo ratings yet

- Getting the Most from Cattle Manure: Proper Application Rates and PracticesDocument4 pagesGetting the Most from Cattle Manure: Proper Application Rates and PracticesRamNocturnalNo ratings yet

- BCRW Course - Answer-Booklet PDFDocument18 pagesBCRW Course - Answer-Booklet PDFSarah ChaudharyNo ratings yet

- SS1c MIDTERMS LearningModuleDocument82 pagesSS1c MIDTERMS LearningModuleBryce VentenillaNo ratings yet

- Organizational Behaviour Group Assignment-2Document4 pagesOrganizational Behaviour Group Assignment-2Prateek KurupNo ratings yet

- Project Report On Evaporative CoolerDocument12 pagesProject Report On Evaporative Coolersourabh singh tomerNo ratings yet

- Best Home Oxygen Concentrators-Lowest Prices & Fast Shipping (Oxygen Machines) - 2021 - YuwellDocument1 pageBest Home Oxygen Concentrators-Lowest Prices & Fast Shipping (Oxygen Machines) - 2021 - YuwellPelayanan ResusitasiNo ratings yet

- Barelwiyah, Barelvi Chapter 1 (Part 2 of 5)Document31 pagesBarelwiyah, Barelvi Chapter 1 (Part 2 of 5)Dawah ChannelNo ratings yet

- 2 5 Marking ScheduleDocument6 pages2 5 Marking Scheduleapi-218511741No ratings yet

- InteliLite AMF20-25Document2 pagesInteliLite AMF20-25albertooliveira100% (2)

- Kltdensito2 PDFDocument6 pagesKltdensito2 PDFPutuWijayaKusumaNo ratings yet

- Serendipity - A Sociological NoteDocument2 pagesSerendipity - A Sociological NoteAmlan BaruahNo ratings yet

- DCAD OverviewDocument9 pagesDCAD OverviewSue KimNo ratings yet

- Classroom Observation Form 1Document4 pagesClassroom Observation Form 1api-252809250No ratings yet