Professional Documents

Culture Documents

Aac Block Adhesive: Product Description

Uploaded by

maznahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aac Block Adhesive: Product Description

Uploaded by

maznahCopyright:

Available Formats

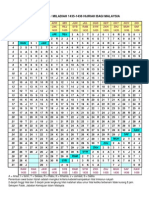

AAC BLOCK ADHESIVE The following is the coverage table for wall area in Square feet

that can be constructed using AAC Blocks of size 600mm X

Product Description: 200mm X 100mm

AAC Block Adhesive is a factory prepared blend of carefully

selected raw materials, Portland cement and graded

aggregates and polymers. Designed for use with water to

produce high strength thixotropic mortar, for laying Aerated Thickness Coverage for 50 Coverage for 20

Light weight concrete, Fly ash bricks, cement hollow blocks, Kg bag Kg Bag

Cellular concrete blocks or smoothing over the block work 2 mm 300 Sft 120 Sft

surface in layers of up to 12mm thickness, that meet and

3 mm 200 Sft 80 Sft

exceed the requirements of National and International

Standards. 4 mm 150 Sft 60 Sft

5 mm 120 Sft 48 Sft

Application: 6 mm 100 Sft 40 Sft

For interior and exterior use for preparing thin bed adhesive

for AAC, ALC and cellular concrete blocks. NOTE: Coverage depends on the substrate evenness and the

thickness at which the AAC Block adhesive is applied.

Advantages:

High Strength Shelf Life:

Factory sealed bags of this product are guaranteed to be of first

No curing required after block work is done.

quality for one (1) year* if stored off the ground in a dry area, at

Flexible, shock & impact resistant

21C and 50% RH.

Improved adhesion between two blocks

improved bond strength, compressive & tensile strength *High humidity will reduce the shelf life of bagged product

Thin jointing with high adhesion to contribute to load

bearing capacity of masonry Limitations:

easy to use Adhesives/mastics, mortars and grouts for ceramic tile, pavers,

Long working time brick and stone are not replacements for waterproof membranes.

Fast & economical When a waterproof membrane is required, use a LATICRETE

Waterproof Membrane

Suitable Substrates:

Concrete Blocks Cautions:

Cement Mortar Blocks/Bricks During cold weather, protect finished work from use until fully

Concrete hollow blocks cured.

Aerated Light weight blocks Contains Portland cement and silica sand. May irritate eyes and

Cellular concrete blocks skin. Avoid contact with eyes or prolonged contact with skin. In

Fly Ash Bricks case of contact, flush thoroughly with water.

Do not take internally. Silica sand may cause cancer or serious

Packaging : 20 Kg & 50 kg bag lung problems. Avoid breathing dust. Wear a respirator in dusty

areas.

Colour: Grey Keep out of reach of children

Coverage:

Coverage is based on smoothness and evenness of the TECHNICAL DATA

substrate, size of blocks used and the thickness of mortar

used. A general guide line for coverage of mortar is given Applicable Standard:

when used with 30% Water is added to powder Conforms to ANSI A118.1 & ANSI A118.4-1999

Performance Properties:

AAC BLOCK ADHESIVE mixed with water

Test Results

Compressive strength >5 MPa

Flexural Strength >3 MPa

Tensile Adhesion >1MPa

strength

MYKL-TDS-AAC – REV 00; 10/17

Working Properties: 3) As Adhesive to install tiles:

AAC BLOCK ADHESIVE mixed with water (70F (21C)) AAC Block Adhesive can be used as a thin-set adhesive to install

Pot Life 1 Hour tiles/stones on AAC Block/Fly ash brick walls. Use a suitable

Open Time 30 Minutes notch trowel to achieve desired thickness of adhesive for

Time to Plaster 24 hours installation of tiles /stones on the wall

Time to full dry hard 14 Days

Wet Density 1750 kg/m 3 Plaster:

Specifications are subject to change without notification. Plumb, square and true concrete block wall can be finished with

Results shown are typical but reflect test procedures used. the applications of Special polymer plaster from MYK Laticrete.

Actual field performance will depend on installation methods

and site conditions Plasters made with site mix may slump and powder due to water

absorption of the block work.

INSTALLATION

Cleaning:

Surface Preparation: Clean tools and containers with water while mortar is fresh.

All surfaces should be between 40 F (4C) and 90F (32C)

and structurally sound, clean and free of all dirt, oil, grease,

AVAILABILITY AND PRICE

concrete sealers or curing compounds. Rough or uneven

concrete surfaces should be made smooth with MYK

LATICRETE Latex Portland Cement underlayment to Availability:

provide a wood float (or better) finish. Installation may be LATICRETE and LATAPOXY ® materials are available

made on a damp surface. worldwide.

All slabs must be plumb and true to within ¼” (6mm) in 10 ft For distributor information:

(3m). Telephone: +91-40-30413100

Follow ANSI Specification AN-3.8 “Requirements for FAX: +91-40-23378784

Expansion Joints” or TCA Detail EJ171 “Expansion Joints”. e-mail: contact@myklaticrete.com

Do not cover expansion joints with mortar.

Price:

Mixing : Contact a MYK LATICRETE representative / Authorized dealer in

your area.

Use approx. 50kg of AAC Block Adhesive thin bed mortar

MAINTENANCE

with Approx. 15 ltrs of potable water. Take water in the

container and slowly add the powder into the water while LATICRETE and LATAPOXY grouts require routine cleaning with

mixing by hand or slow speed mixing machine. Mix for 3 to 5 a neutral pH soap and water. All other LATICRETE and

minutes till a smooth thixotropic mix without lumps is LATAPOXY materials require no maintenance but installation

obtained. Performance and durability may depend on properly maintaining

products supplied by other manufacturers.

Application

WARRANTY

1) Thin bed mortar for laying blocks: MYK LATICRETE India Pvt Ltd warrants that AAC BLOCK

Before placing mortar, ensure the block work to be dry and ADHESIVE, Thin bed mortar is free from manufacturing defects

surfaces cleaned properly. Place the mixed mortar on the and will not break down, deteriorate or disintegrate under normal

block work in thin layers of 2 to 3 mm (or as required by usage for a period of one (1) year from date of manufacture,

engineers at site) using trowel and place the next layer of subject to the terms and conditions stated in MYK LATICRETE

blocks on the mortar. Keep joints between the blocks as Product Warranty

required by the site engineers and fill the joints with the

TECHNICAL SERVICES

mixed mortar, using a trowel. Check the plumb of the wall

while laying the blocks to keep the walls perfectly vertical to Technical assistance

the plumb. Information is available by calling the LATICRETE Technical

Service at:

Telephone: +91-40-30413100

2) Smoothing over the block work: FAX: +91-40-23378784

Before placing mixed mortar, apply a bonding layer of 1 to e-mail: technicalservices@myklaticrete.com

2mm thick AAC Block Adhesive mortar using a trowel

MYK Laticrete India Pvt Ltd.

pressing down on the block work. Then apply AAC Block

8-2-703/A, Fourth Floor, Leela Gopal Towers

Adhesive at a thickness of 8 to 10mm and smoothen using a

Road No-12, Banjara Hills,

sponge or rubber / wooden float.

Hyderabad – 500034 (A.P)

Tel: +91-40--30413100

Fax: +91-40-23378784

e-mail: contact@myklaticrete.com

Website: www.myklaticrete.com

MYKL-TDS-AAC – REV 00; 10/17

You might also like

- AAC Block Adhesive TDS NEWDocument2 pagesAAC Block Adhesive TDS NEWAakriti VermaNo ratings yet

- Specification GlassFiberDocument6 pagesSpecification GlassFiberMukesh MaharjanNo ratings yet

- Sikaflex®-11 FCDocument4 pagesSikaflex®-11 FCAbdulghani AsalaiNo ratings yet

- PDS Sikacrete 113 PPDocument4 pagesPDS Sikacrete 113 PPKoh HanNo ratings yet

- Dm-dsi-SPEC09 - Corrosion PR & Odor CNTRLDocument13 pagesDm-dsi-SPEC09 - Corrosion PR & Odor CNTRLhardikNo ratings yet

- The Manuf. of Paver BlockDocument4 pagesThe Manuf. of Paver BlockMirtunjay KumarNo ratings yet

- Skim Coat & Plaster Cementitious WaterproofingDocument2 pagesSkim Coat & Plaster Cementitious WaterproofingginasuhandiniNo ratings yet

- Decoding Multi-Purpose Waterproofing, Crack Isolation, Sound Reduction and Uncoupling MembranesDocument6 pagesDecoding Multi-Purpose Waterproofing, Crack Isolation, Sound Reduction and Uncoupling MembranesibrahimNo ratings yet

- Anti-Crak: Solutions For Concrete ReinforcementDocument8 pagesAnti-Crak: Solutions For Concrete ReinforcementCopyingCatNo ratings yet

- POLYCELL PU 510WB 22sDocument2 pagesPOLYCELL PU 510WB 22snorlailiNo ratings yet

- TECH (2018) CRAFTSTONE VENEER TECHNICAL MANUALDocument13 pagesTECH (2018) CRAFTSTONE VENEER TECHNICAL MANUALvikon.rabbitNo ratings yet

- Fosroc Conbextra BB80: Constructive SolutionsDocument4 pagesFosroc Conbextra BB80: Constructive SolutionsVincent JavateNo ratings yet

- High Strength Non-Shrink Micro Concrete GroutDocument4 pagesHigh Strength Non-Shrink Micro Concrete GroutilhamNo ratings yet

- 148 DR Fixit RoofsealDocument3 pages148 DR Fixit RoofsealSasi KumarNo ratings yet

- Sika Damp Proofing Slurry Pds CeDocument4 pagesSika Damp Proofing Slurry Pds Cejuli_radNo ratings yet

- High Strength Non-Shrink Micro Concrete GroutDocument4 pagesHigh Strength Non-Shrink Micro Concrete GroutJoshua EkoNo ratings yet

- Boscoseal Torch OnDocument3 pagesBoscoseal Torch OnjbonvierNo ratings yet

- Sikaflex - 11 FCDocument4 pagesSikaflex - 11 FCSahanNo ratings yet

- Ds Sikalastic-1k-Pds v2Document5 pagesDs Sikalastic-1k-Pds v2stilpgNo ratings yet

- Flo-Grout 2WWA Non-Shrink Cement GroutDocument2 pagesFlo-Grout 2WWA Non-Shrink Cement Groutosama mohNo ratings yet

- L 9237 WaterproofDocument4 pagesL 9237 WaterproofAbdul Raheem SyedNo ratings yet

- X-Tile CTADocument2 pagesX-Tile CTABernardo GarciaNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPm.elsanee.cubicNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPMuhammad ShoaibNo ratings yet

- Type N Mortar MixDocument2 pagesType N Mortar MixAnatoliy StepchinNo ratings yet

- LDS6330 - LATAPOXY 300 AdhesiveDocument4 pagesLDS6330 - LATAPOXY 300 AdhesiveanamikakahlatihaiNo ratings yet

- Duracrete FichaDocument2 pagesDuracrete FichavankarpNo ratings yet

- Cemcoat PuttyDocument2 pagesCemcoat Puttyosama mohNo ratings yet

- Monoseal: DescriptionDocument2 pagesMonoseal: Descriptionosama mohNo ratings yet

- Foam Concrete SalinasDocument4 pagesFoam Concrete SalinasDyego Clemente FerrerNo ratings yet

- VersaBond DS 5 - 08Document3 pagesVersaBond DS 5 - 08cdubos1No ratings yet

- Sika Davco k10 Plus Data SheetDocument4 pagesSika Davco k10 Plus Data SheetJiang TerenceNo ratings yet

- Sika - Sikagrout 215Document9 pagesSika - Sikagrout 215afnan hamimiNo ratings yet

- Catalog enDocument14 pagesCatalog envishalNo ratings yet

- Sikalastic - 1 KmyDocument4 pagesSikalastic - 1 KmyEric LewNo ratings yet

- IKOTE CM 50X TDS (02-APRIL-2024) V1.3Document2 pagesIKOTE CM 50X TDS (02-APRIL-2024) V1.3nguyen hoang AnhNo ratings yet

- Fosroc - UG Water Tank SpecsDocument1 pageFosroc - UG Water Tank SpecsShakil AkhterNo ratings yet

- Polydek: Elastomeric, Single Component Water-Based Waterproofing MembraneDocument4 pagesPolydek: Elastomeric, Single Component Water-Based Waterproofing MembraneprasadNo ratings yet

- Sikatop 107 SealDocument3 pagesSikatop 107 SealDede SantanuNo ratings yet

- Bendable Concrete PDFDocument14 pagesBendable Concrete PDFKunal Bathija100% (24)

- SikaTop Seal-107 PDFDocument4 pagesSikaTop Seal-107 PDFDan BermasNo ratings yet

- Anupam - Roff Tile Fixing Solutions 2018Document62 pagesAnupam - Roff Tile Fixing Solutions 2018seemeshwariNo ratings yet

- Monoseal TDSDocument2 pagesMonoseal TDSVikas AttigeriNo ratings yet

- Squash Court Finish PDFDocument5 pagesSquash Court Finish PDFFrancis T. TolibasNo ratings yet

- Sikafloor-ColourSeal W 0307Document4 pagesSikafloor-ColourSeal W 0307Chris AdaminovicNo ratings yet

- Laticrete 252 TDS 2 PDFDocument5 pagesLaticrete 252 TDS 2 PDFvikash singh tomarNo ratings yet

- Non-shrink cement grout for foundation platesDocument4 pagesNon-shrink cement grout for foundation platesLftea AdiNo ratings yet

- UltraTech Master BrochureDocument17 pagesUltraTech Master BrochureHimanshu Kumar100% (1)

- IKOTE CM 31 TDS (11-Oct-2023)Document2 pagesIKOTE CM 31 TDS (11-Oct-2023)nguyen hoang AnhNo ratings yet

- Preventing Water Penetration in Below-Grade Concrete Masonry WallsDocument4 pagesPreventing Water Penetration in Below-Grade Concrete Masonry WallsDenver AbanoNo ratings yet

- Method of AAC BlockworkDocument11 pagesMethod of AAC BlockworkShamim Ahsan ZuberyNo ratings yet

- MU-380 ThinBedMax PDFDocument1 pageMU-380 ThinBedMax PDFAlfredNo ratings yet

- LD Method StatementDocument17 pagesLD Method Statementالاوربيه للبلاستكNo ratings yet

- Sika® Tite WPU: Product Data SheetDocument3 pagesSika® Tite WPU: Product Data SheetZèlia FláviaNo ratings yet

- Presentation On Self Healing Bendable ConcreteDocument32 pagesPresentation On Self Healing Bendable ConcreteAJEET SINGHNo ratings yet

- Water Proofing - W02 - Work Method StatementDocument3 pagesWater Proofing - W02 - Work Method StatementJohn Rhey Lofranco TagalogNo ratings yet

- L 310TDS 1Document4 pagesL 310TDS 1Chetan MahajanNo ratings yet

- Conbextra BB80Document4 pagesConbextra BB80m.elsanee.cubicNo ratings yet

- 4.07 Fast Roof Pu 570Document4 pages4.07 Fast Roof Pu 570Nadeem Ahmed MirzaNo ratings yet

- Beacons Equipment Sdn. BHD.: QuotationDocument2 pagesBeacons Equipment Sdn. BHD.: QuotationmaznahNo ratings yet

- KUALA LUMPUR MONSOON ACTIVITY CENTRE WEATHER REPORTDocument6 pagesKUALA LUMPUR MONSOON ACTIVITY CENTRE WEATHER REPORTmaznahNo ratings yet

- ACO K9 en - Kap03Document22 pagesACO K9 en - Kap03Jizelle JumaquioNo ratings yet

- Air Handler Air Filter Sell SheetDocument1 pageAir Handler Air Filter Sell SheetmaznahNo ratings yet

- Dura MHC600 - : Manhole CoverDocument2 pagesDura MHC600 - : Manhole CovermaznahNo ratings yet

- Bizchannel@Cimb Application Form: Please Complete The Following Checklist Before Submitting Your ApplicationDocument3 pagesBizchannel@Cimb Application Form: Please Complete The Following Checklist Before Submitting Your Applicationmaznah50% (2)

- Mechanical Leak Detector Installation - FE Petro STP MLD ManualDocument8 pagesMechanical Leak Detector Installation - FE Petro STP MLD ManualSarge ChisangaNo ratings yet

- Enviro M-3Document2 pagesEnviro M-3maznahNo ratings yet

- The Leading Supplier of Quality Waterstops and Waterproof MaterialsDocument18 pagesThe Leading Supplier of Quality Waterstops and Waterproof MaterialsmaznahNo ratings yet

- MetalformmaxspanpurlinsgirtsdesignmanualDocument41 pagesMetalformmaxspanpurlinsgirtsdesignmanualmaznahNo ratings yet

- Hospital Energy Efficiency Best Practices GuideDocument55 pagesHospital Energy Efficiency Best Practices Guidebala10me007No ratings yet

- PAPER 3 BKT Antarabangsa Failure 02Document5 pagesPAPER 3 BKT Antarabangsa Failure 02Steven ChongNo ratings yet

- Webemobile Howto HotspotDocument1 pageWebemobile Howto HotspotmaznahNo ratings yet

- Green Terramesh System: Method StatementDocument2 pagesGreen Terramesh System: Method StatementmaznahNo ratings yet

- 2012 42 Spring Wiring Matters Filling StationsDocument5 pages2012 42 Spring Wiring Matters Filling StationsmaznahNo ratings yet

- Instal Geotex PDFDocument1 pageInstal Geotex PDFmaznahNo ratings yet

- Precast Concrete Traffic Barriers: Purpose, Specifications & TypesDocument27 pagesPrecast Concrete Traffic Barriers: Purpose, Specifications & Typesjunaid112No ratings yet

- Gu Fang Bu Zi Shang Volume 02Document280 pagesGu Fang Bu Zi Shang Volume 02maznah100% (1)

- FRP Underground TankDocument4 pagesFRP Underground TankMaznah MakhtarNo ratings yet

- Takwim 2014 / Miladiah 1435-1436 Hijriah Bagi MalaysiaDocument1 pageTakwim 2014 / Miladiah 1435-1436 Hijriah Bagi MalaysiaAbdul Rahman HilmiNo ratings yet

- Report-Soil & GunitingDocument4 pagesReport-Soil & GunitingmaznahNo ratings yet

- Failure of Soil Nail WallsDocument13 pagesFailure of Soil Nail WallsAndy AcousticNo ratings yet

- List of Accredited Testing Labs-MalaysiaDocument3 pagesList of Accredited Testing Labs-MalaysiamaznahNo ratings yet

- SI Spects Cidb 2Document33 pagesSI Spects Cidb 2rowatersNo ratings yet

- Gu Fang Bu Zi Shang Volume 01Document184 pagesGu Fang Bu Zi Shang Volume 01lol100% (10)

- ASM 12cDocument304 pagesASM 12cFrank Hack100% (1)

- A Cero - Modular HouseDocument1 pageA Cero - Modular HouseBil AndersenNo ratings yet

- Symbology of The TempleDocument2 pagesSymbology of The TempleCheGanJiNo ratings yet

- Fundamentals of FirefightingDocument168 pagesFundamentals of FirefightingibaanNo ratings yet

- Camella Silang Project PresentationDocument20 pagesCamella Silang Project PresentationJr RobNo ratings yet

- 02 ABB Users Group Anchorage HarmonyDocument67 pages02 ABB Users Group Anchorage HarmonyKarim MagdyNo ratings yet

- Civil Engineering MCQ'sDocument1 pageCivil Engineering MCQ'sNISHIKANTA MONDALNo ratings yet

- Upload A Document For Free Download Access.: Select Files From Your Computer or Choose Other Ways To Upload BelowDocument5 pagesUpload A Document For Free Download Access.: Select Files From Your Computer or Choose Other Ways To Upload BelowAndrew AtkinsonNo ratings yet

- Monash UniversityDocument96 pagesMonash UniversityNurul Ilmi SalsabilaNo ratings yet

- DPWH Spa2007 03Document132 pagesDPWH Spa2007 03Edelyn Lindero Ambos100% (1)

- Museum of Modern Literature, GermanyDocument14 pagesMuseum of Modern Literature, GermanyAntonio CampoverdeNo ratings yet

- Winelib GuideDocument25 pagesWinelib GuideCedric NiamkéNo ratings yet

- The House of PastroviciDocument16 pagesThe House of PastroviciLejla BLNo ratings yet

- Qcs 2010 Part 5.06 Property Requirements PDFDocument30 pagesQcs 2010 Part 5.06 Property Requirements PDFRotsapNayrbNo ratings yet

- Catalogue Multiplate Mp200Document50 pagesCatalogue Multiplate Mp200Barbulescu CiprianNo ratings yet

- WS Services Pipes & Its Reference PDFDocument1 pageWS Services Pipes & Its Reference PDFbilal almelegyNo ratings yet

- MS 1314-5 2004Document19 pagesMS 1314-5 2004Anonymous 6vZfB9pfza100% (1)

- OV SCCB Specs PDFDocument24 pagesOV SCCB Specs PDFanuahlNo ratings yet

- ZTE LTE FDD VoLTE Feature GuideDocument216 pagesZTE LTE FDD VoLTE Feature GuideOrlando Medina100% (1)

- Air Conditioning and Refrigeration C H R O N O L O G YDocument19 pagesAir Conditioning and Refrigeration C H R O N O L O G YLuís Fernando Ferreira SilvaNo ratings yet

- AAM Integrated Windows Authentication/ Basic NTLM: How To Deploy A10 Networks AAM NTLM Feature Within Thunder ADCDocument8 pagesAAM Integrated Windows Authentication/ Basic NTLM: How To Deploy A10 Networks AAM NTLM Feature Within Thunder ADCPham Van NamNo ratings yet

- fm12 Odbc JDBC Guide en PDFDocument64 pagesfm12 Odbc JDBC Guide en PDFJose Luis Beltran HernandezNo ratings yet

- GC Lost Blocks DiagnosticsDocument8 pagesGC Lost Blocks Diagnosticssuad8082No ratings yet

- Mirror LinkDocument3 pagesMirror LinkjedverdejoNo ratings yet

- Greedy Perimeter Stateless Routing PDFDocument2 pagesGreedy Perimeter Stateless Routing PDFAmjad AfridiNo ratings yet

- 64162b Giles Fsh-2 Spec Sheet-Uv.06.08Document2 pages64162b Giles Fsh-2 Spec Sheet-Uv.06.08rajNo ratings yet

- 8086 Bios and Dos Interrupts (IBM PC)Document20 pages8086 Bios and Dos Interrupts (IBM PC)tonynascNo ratings yet

- DX DiagDocument29 pagesDX DiagFahlevi DzulfikarNo ratings yet

- 2.method Statement Plastering WorkDocument8 pages2.method Statement Plastering WorksochealaoNo ratings yet

- Motivation Letter FCTDocument2 pagesMotivation Letter FCTStanley Lima100% (2)