Professional Documents

Culture Documents

Case Spring Garden Tool

Case Spring Garden Tool

Uploaded by

SOUVIK ROY MBA 2021-23 (Delhi)Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Spring Garden Tool

Case Spring Garden Tool

Uploaded by

SOUVIK ROY MBA 2021-23 (Delhi)Copyright:

Available Formats

E1C14.

qxd 8/2/10 2:40 PM Page 674

674 Part 2 • Supply Chain Management

CASE PROBLEM S14.3

Spring Garden Tools The reasons the company has prospered are its ability

The Spring family has owned and operated a garden tool to meet customer demand on time and its high quality. As

and implements manufacturing company since 1952. The a result, the Spring Company will produce on an overtime

company sells garden tools to distributors and also directly basis in order to meet its sales requirements, and it also

to hardware stores and home improvement discount chains. has a longstanding arrangement with a local tool and die

The Spring Company’s four most popular small garden company to manufacture its tool heads. The Spring Com-

tools are a trowel, a hoe, a rake, and a shovel. Each of these pany feels comfortable subcontracting the first-stage op-

tools is made from durable steel and has a wooden handle. erations, since it is easier to detect defects prior to

The Spring family prides itself on its high-quality tools. assembly and finishing. For the same reason, the com-

The manufacturing process encompasses two stages. pany will not subcontract for the entire tool, since defects

The first stage includes two operations—stamping out the would be particularly hard to detect after the tool is fin-

metal tool heads and drilling screw holes in them. The ished and packaged. However, the company does have

completed tool heads then flow to the second stage. The 100 hours of overtime available each month for each op-

second stage includes an assembly operation, in which eration in both stages. The regular production and over-

the handles are attached to the tool heads, a finishing time costs per tool for both stages are provided in the

step, and finally packaging. The processing times per tool following table:

for each operation are provided in the following table:

Stage 1 Stage 2

Total Hours

Regular Overtime Regular Overtime

Tool (Hours/Unit) Available

Cost ($) Cost ($) Cost ($) Cost ($)

Operation Trowel Hoe Rake Shovel Per Month

Trowel 6.00 6.20 3.00 3.10

Stamping 0.04 0.17 0.06 0.12 500

Hoe 10.00 10.70 5.00 5.40

Drilling 0.05 0.14 — 0.14 400

Rake 8.00 8.50 4.00 4.30

Assembly 0.06 0.13 0.05 0.10 600

Shovel 10.00 10.70 5.00 5.40

Finishing 0.05 0.21 0.02 0.10 550

Packaging 0.03 0.15 0.04 0.15 500

The cost of subcontracting in stage 1 adds 20% to the

The steel the company uses is ordered from an iron regular production cost.

and steel works in Japan. The company has 10,000 square The Spring Company wants to establish a production

feet of sheet steel available each month. The metal re- schedule for regular and overtime production in each

quired for each tool and the monthly contracted produc- stage and for the number of tool heads subcontracted, at

tion volume per tool are provided in the following table: the minimum cost. Formulate a linear programming

model for this problem and solve the model using Excel.

Sheet Monthly Which resources appear to be most critical in the produc-

Metal (FT2) Contracted Sales tion process?

Trowel 1.2 1800

Hoe 1.6 1400

Rake 2.1 1600

Shovel 2.4 1800

CASE PROBLEM 14.4

Walsh’s Juice Company

Walsh’s Juice Company produces three products from vineyards near the Great Lakes. The climate in this area

unprocessed grape juice—bottled juice, frozen juice con- is good for growing the concord grapes necessary to pro-

centrate, and jelly. It purchases grape juice from three duce grape juice products. The grapes are harvested at

You might also like

- Astm A108-18Document7 pagesAstm A108-18Ryan Zhang75% (4)

- Comscore Case StudyDocument3 pagesComscore Case StudySanyee DiehNo ratings yet

- Lumière: Supporting A Virtual Workspace On The Cloud Case AnalysisDocument2 pagesLumière: Supporting A Virtual Workspace On The Cloud Case AnalysisMohamad BachoNo ratings yet

- Activity Map AirbnbDocument1 pageActivity Map Airbnbsajjad147No ratings yet

- THE EFFECT OF RISK MANAGEMENT ON FINANCIAL PERFORMANCE OF INSURANCE COMPANIES IN KENYA Chapter 1Document20 pagesTHE EFFECT OF RISK MANAGEMENT ON FINANCIAL PERFORMANCE OF INSURANCE COMPANIES IN KENYA Chapter 1Dennis NziokiNo ratings yet

- This Study Resource Was: Individial Case Analysis of AraucoDocument6 pagesThis Study Resource Was: Individial Case Analysis of AraucofereNo ratings yet

- Quality Management: Ikea Case StudyDocument5 pagesQuality Management: Ikea Case StudyXuân HươngNo ratings yet

- CA Technologies - Bringing The Cloud To Earth PDFDocument7 pagesCA Technologies - Bringing The Cloud To Earth PDFRuchir Jain100% (1)

- Case 4.1 - Group 3Document10 pagesCase 4.1 - Group 3Trần Nguyễn Thanh ThoaNo ratings yet

- Choosing A Cloud ProviderDocument9 pagesChoosing A Cloud ProviderGabriel GiraldoNo ratings yet

- Financial Management of Phoenix Petroleum Philippines Inc. BodyDocument29 pagesFinancial Management of Phoenix Petroleum Philippines Inc. BodyAl Therese R. CedeñoNo ratings yet

- American Hospital Supply Corporation Case Study-ParthaDocument7 pagesAmerican Hospital Supply Corporation Case Study-Parthasurojitsaha15094No ratings yet

- Dawlance Private LimitedDocument10 pagesDawlance Private Limitedalhumdulilah100% (2)

- Shell Ems - EditedDocument14 pagesShell Ems - EditedGeovanie LauraNo ratings yet

- STRAMADocument6 pagesSTRAMAClaude PeñaNo ratings yet

- MashaweerDocument5 pagesMashaweerebruklcnNo ratings yet

- 5 PorterDocument10 pages5 PorterkulsoomalamNo ratings yet

- Auto Credit System DocumentationDocument47 pagesAuto Credit System Documentationcity cyberNo ratings yet

- Chapter 8 Long Lived Assets - SolutionsDocument102 pagesChapter 8 Long Lived Assets - SolutionsKate SandersNo ratings yet

- HR Practices IntelDocument19 pagesHR Practices IntelKomal Mehta100% (1)

- Information Systems For Managers: FINTECH: Choosing A Cloud Services ProviderDocument11 pagesInformation Systems For Managers: FINTECH: Choosing A Cloud Services ProviderAkshay BNo ratings yet

- Case StudyDocument4 pagesCase StudyArifNo ratings yet

- NUCORDocument12 pagesNUCORKurniawan Che-uNo ratings yet

- ME15 - Unit 3Document59 pagesME15 - Unit 3Bharathi RajuNo ratings yet

- LDFL Case SolutionDocument6 pagesLDFL Case Solutionaashish gupthaNo ratings yet

- Agfa Case - James SurovecDocument6 pagesAgfa Case - James SurovecWaqas RafiqueNo ratings yet

- Time Warner and ORC Case StudyDocument12 pagesTime Warner and ORC Case StudyisomiddinovNo ratings yet

- MashaweerDocument3 pagesMashaweerCleo VanNo ratings yet

- Product, Service and Branding Strategy: Consumer GoodsDocument1 pageProduct, Service and Branding Strategy: Consumer Goodsnr syaakirahNo ratings yet

- Case Study - HCL TechnologiesDocument1 pageCase Study - HCL TechnologiesAshraf Uz ZamanNo ratings yet

- Company Customers Competitors Collaborators ContextDocument3 pagesCompany Customers Competitors Collaborators ContextSanjay SankhalaNo ratings yet

- DWDG Case 1 - MewDocument3 pagesDWDG Case 1 - MewJAY BHAVIN SHETH (B14EE014)No ratings yet

- ISM Case Analysis (Cisco Systems) : Group 13 Section - ADocument6 pagesISM Case Analysis (Cisco Systems) : Group 13 Section - AManish Kumar BansalNo ratings yet

- Ashwani Gupta 2019SMF6652 Newell Case StudyDocument3 pagesAshwani Gupta 2019SMF6652 Newell Case Studypooja guptaNo ratings yet

- NetflixDocument10 pagesNetflixHenry WaribuhNo ratings yet

- Aboitiz Power CorporationDocument10 pagesAboitiz Power CorporationrobertNo ratings yet

- ERP (Group Week 1)Document14 pagesERP (Group Week 1)Nguyên Nguyễn KhôiNo ratings yet

- PTCLDocument19 pagesPTCLShahzad AliNo ratings yet

- TargetDocument11 pagesTargetAbbie Sajonia DollenoNo ratings yet

- WWF PDFDocument9 pagesWWF PDFRiya Dutta100% (1)

- Week 3 Case - Group 6Document4 pagesWeek 3 Case - Group 6Kshitiz NeupaneNo ratings yet

- STRAMADocument7 pagesSTRAMACheryl Arcega PangdaNo ratings yet

- GEP Gameplan 2022 BschoolDocument16 pagesGEP Gameplan 2022 BschoolDiva SharmaNo ratings yet

- IS110 Case FacilitationDocument37 pagesIS110 Case FacilitationSean WoonNo ratings yet

- Case Memo #3Document3 pagesCase Memo #3Iris WangNo ratings yet

- Symphony TheatreDocument8 pagesSymphony TheatreSanyam RahejaNo ratings yet

- Dell 5 Forces AnalysisDocument1 pageDell 5 Forces Analysisstromss100% (4)

- CH 12Document49 pagesCH 12Natasya SherllyanaNo ratings yet

- Greenville PPT Group 1Document22 pagesGreenville PPT Group 1Anushree GawadNo ratings yet

- Caesars - A Casino On The BrinkDocument36 pagesCaesars - A Casino On The BrinkIMTRUTH_2013No ratings yet

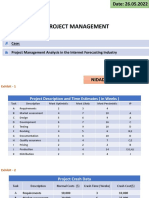

- Project Management Analysis in The Internet Forecasting IndustryDocument14 pagesProject Management Analysis in The Internet Forecasting IndustryNiranjan NidadavoluNo ratings yet

- Voltas GrowthDocument30 pagesVoltas Growthachaluec100% (1)

- 2003 Edition: This Bibliography Contains Abstracts of The 100 Best-Selling Cases During 2002Document30 pages2003 Edition: This Bibliography Contains Abstracts of The 100 Best-Selling Cases During 2002Raghib AliNo ratings yet

- Asirius Philippines Inc.Document96 pagesAsirius Philippines Inc.Lee SuarezNo ratings yet

- Business Strategy Case Study - DoCoMoDocument18 pagesBusiness Strategy Case Study - DoCoMoRobinHood TiwariNo ratings yet

- "Tata Motors: Can The Turnaround Plan Improve Performance?" NameDocument16 pages"Tata Motors: Can The Turnaround Plan Improve Performance?" NameMehdi BelabyadNo ratings yet

- Corporate Financial Analysis with Microsoft ExcelFrom EverandCorporate Financial Analysis with Microsoft ExcelRating: 5 out of 5 stars5/5 (1)

- Optimization TechniquesDocument8 pagesOptimization TechniquesMuhammad Asim Muhammad ArshadNo ratings yet

- Learn Assignment 1 Draw-And-Determine A VSM Swim Lane - and - OEE 22-23 QS 1-And-2Document9 pagesLearn Assignment 1 Draw-And-Determine A VSM Swim Lane - and - OEE 22-23 QS 1-And-2Adam KučeraNo ratings yet

- In India, Horlicks Has Always Been Marketed As The Great Family Nourisher' and Is Mainly Consumed at HomeDocument6 pagesIn India, Horlicks Has Always Been Marketed As The Great Family Nourisher' and Is Mainly Consumed at HomeTanu GuptaNo ratings yet

- Brand Anthropomorphism 2Document8 pagesBrand Anthropomorphism 2Tanu GuptaNo ratings yet

- Break Free From The Product Life CycleDocument13 pagesBreak Free From The Product Life CycleTanu GuptaNo ratings yet

- BRM 6Document48 pagesBRM 6Tanu GuptaNo ratings yet

- Greenlam 2021 DP CompressedDocument143 pagesGreenlam 2021 DP CompressedTanu GuptaNo ratings yet

- Course OutlineDocument5 pagesCourse OutlineTanu GuptaNo ratings yet

- MergedDocument299 pagesMergedTanu GuptaNo ratings yet

- R1-The 4 Phases of Marketing Communication During Covid-19Document5 pagesR1-The 4 Phases of Marketing Communication During Covid-19Tanu GuptaNo ratings yet

- Case-1 - Questions-Heromotocorp Taking A Forward LeapDocument4 pagesCase-1 - Questions-Heromotocorp Taking A Forward LeapTanu GuptaNo ratings yet

- Course OutlineDocument7 pagesCourse OutlineTanu GuptaNo ratings yet

- IFM 09 Trade FinanceDocument27 pagesIFM 09 Trade FinanceTanu GuptaNo ratings yet

- Case-1 - Heromotocorp Taking A Forward LeapDocument3 pagesCase-1 - Heromotocorp Taking A Forward LeapTanu GuptaNo ratings yet

- Tax Havens - Implications For Developed and Developing World and Capital FlightDocument8 pagesTax Havens - Implications For Developed and Developing World and Capital FlightTanu GuptaNo ratings yet

- IFM 08 Transfer PriceDocument27 pagesIFM 08 Transfer PriceTanu GuptaNo ratings yet

- IFM 05 ExposuresDocument58 pagesIFM 05 ExposuresTanu GuptaNo ratings yet

- International Financial Management: Course Coordinator: V. Raveendra Saradhi Course Credit: 3Document4 pagesInternational Financial Management: Course Coordinator: V. Raveendra Saradhi Course Credit: 3Tanu GuptaNo ratings yet

- IFM 03 FE MarketsDocument22 pagesIFM 03 FE MarketsTanu GuptaNo ratings yet

- IFM 01 Monetary SystemsDocument49 pagesIFM 01 Monetary SystemsTanu GuptaNo ratings yet

- IFM 06 Intl Cap BudtgDocument39 pagesIFM 06 Intl Cap BudtgTanu GuptaNo ratings yet

- IFM 04 Parity RelationshipsDocument24 pagesIFM 04 Parity RelationshipsTanu GuptaNo ratings yet

- 9 Service-Delivery Modeling and OptimizationDocument18 pages9 Service-Delivery Modeling and OptimizationTanu GuptaNo ratings yet

- IFM 02 Exchange Rate SystemsDocument53 pagesIFM 02 Exchange Rate SystemsTanu GuptaNo ratings yet

- Case Queuing QuandaryDocument2 pagesCase Queuing QuandaryTanu Gupta0% (1)

- Group 4C - IFMDocument7 pagesGroup 4C - IFMTanu GuptaNo ratings yet

- Case Hotel SimulationDocument1 pageCase Hotel SimulationTanu GuptaNo ratings yet

- David OR BookDocument30 pagesDavid OR BookTanu GuptaNo ratings yet

- Kendall Remington ResumeDocument1 pageKendall Remington ResumeKendall RemingtonNo ratings yet

- Material HandlingDocument15 pagesMaterial HandlingusamaNo ratings yet

- C. The New Marketing RealitiesDocument2 pagesC. The New Marketing RealitiesSean Chris ConsonNo ratings yet

- Selektivno Lasersko SinteriranjeDocument20 pagesSelektivno Lasersko Sinteriranjesuler sulerNo ratings yet

- My PRJCTDocument85 pagesMy PRJCTpawan_aujlaNo ratings yet

- CORP.: Structural Transformation Through E-BusinessDocument15 pagesCORP.: Structural Transformation Through E-Businessnguyenhongmay86No ratings yet

- BBF Assignment Within 500 WordsDocument3 pagesBBF Assignment Within 500 WordsMuhammad RubelNo ratings yet

- Autonomy Annual Report 2010 PDFDocument92 pagesAutonomy Annual Report 2010 PDFVaggos MalbaNo ratings yet

- Limits Fits and Tolerances (Dfc-Jo7237-03l's Conflicted Copy 2018-03-01)Document56 pagesLimits Fits and Tolerances (Dfc-Jo7237-03l's Conflicted Copy 2018-03-01)Itemogeng Bernatt BabeNo ratings yet

- 010 Quality, Change and Emerging Business ModelsDocument13 pages010 Quality, Change and Emerging Business ModelsgagahejuniorNo ratings yet

- An Investigation Into Marketing ChannelsDocument6 pagesAn Investigation Into Marketing ChannelsZaki ChNo ratings yet

- Event TPM JipmDocument29 pagesEvent TPM JipmImamRN100% (3)

- Functions of The Marketing DepartmentDocument4 pagesFunctions of The Marketing DepartmentYeshwanth Netha100% (1)

- Stephen Galvin Biotech Process Validation Master PlanDocument14 pagesStephen Galvin Biotech Process Validation Master PlanTanChantreaNo ratings yet

- My Business Plan: A Clothing Store Named "Royal Boutique"Document22 pagesMy Business Plan: A Clothing Store Named "Royal Boutique"032 Md Shahroz HussainNo ratings yet

- Consumer BehaviourDocument109 pagesConsumer BehaviourPrem KnowlesNo ratings yet

- DocxDocument5 pagesDocxNevan NovaNo ratings yet

- (A Govt. of India Society, Ministry of MSME) ISO 9001:2000 & ISO 14001:2004 ORGANISATIONDocument36 pages(A Govt. of India Society, Ministry of MSME) ISO 9001:2000 & ISO 14001:2004 ORGANISATIONSomnath RangrejNo ratings yet

- Rancati2 PaperDocument18 pagesRancati2 PaperEzeddinLibyaNo ratings yet

- SIPOCDocument3 pagesSIPOCsophia787No ratings yet

- QualityWise - PL IATF 16949 Workbook Lesson 2Document15 pagesQualityWise - PL IATF 16949 Workbook Lesson 2R.BALASUBRAMANINo ratings yet

- Case Study On Different Types of StrategiesDocument5 pagesCase Study On Different Types of StrategiesSasi VisvaNo ratings yet

- New Venture DevelopmentDocument13 pagesNew Venture DevelopmentMwirigi MareteNo ratings yet

- Azmera Final ResearchDocument40 pagesAzmera Final ResearchÄbřîśh Łìj MęŘãNo ratings yet

- Course Plan - New EditedDocument10 pagesCourse Plan - New EditedBala ThebossNo ratings yet

- Creative Merchandising Concepts Deck: HermesDocument5 pagesCreative Merchandising Concepts Deck: HermesWritting HubNo ratings yet

- 5.E&M Unit-5 (Entrepreneurship)Document25 pages5.E&M Unit-5 (Entrepreneurship)A - STARNo ratings yet

- Unit I EntrepreneurshipDocument67 pagesUnit I EntrepreneurshipRica ArtajoNo ratings yet

- Ipp Tag FormatDocument1 pageIpp Tag FormatSKAI AUTO100% (1)