Professional Documents

Culture Documents

3118 TP Tipper Truck

3118 TP Tipper Truck

Uploaded by

Venkat Cmrl0 ratings0% found this document useful (0 votes)

14 views2 pagestruck

Original Title

3118 Tp Tipper Truck

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttruck

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views2 pages3118 TP Tipper Truck

3118 TP Tipper Truck

Uploaded by

Venkat Cmrltruck

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Passion, innovation and customer satisfaction. These are the core values that drive AMW Motors Ltd.

From heavy trucks to special application vehicles, AMW builds products that increase profits and

productivity for customers. One such product is Tipper 3118 from the AMW stable; specifically built for

the mining industry to transport coal across any terrain. AMW Tipper 3118 delivers the best of all worlds-

dependability, low operating costs, great visibility, high driver comfort and easy maintenance.

AMW Motors Ltd.

AMW Motors Ltd. AMW 3118 TP

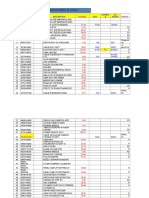

CHASSIS NOMINAL DIMENSIONS - ENGINE SUSPENSION

Unladen (mm) Model: CUMMINS – B 5.9 180 31 - BS III Front : 2 Semi elliptical leaf springs.

Type: Compression ignition Turbocharged & Span : 1650mm at first front axle and 1600mm

A Wheel Base : 5535 Intercooler, Water Cooled, DI - Diesel Engine at second front axle Shock absorber

A1 Wheel Base : 4660 No. of Cylinders: 6nos Inline only on first front axle.

Bore x Stroke: 102 x 120 mm Rear : Fully articulated inverted Semi elliptical

B Front Overhang : 1350 Displacement: 5883 CC leaf Springs on Tandem Bogie

C Rear Overhang : 670 Max Power: 132 KW (178 BHP) @ 2500 rpm Trunnion & with Torque rods.

Max Torque: 675 Nm @ 1500 rpm Span : 1350mm

C1 Rear Overhang : 1243 Compression Ratio: 18:01

Oil Sump Capacity: 15.4 Ltrs STEERING

D Overall Length : 8230

Air Filter: Dry type Remote Mounted Twin Steerable Front axle. Integral Power

E Overall Height (Cab) : 2700 Oil Filter: Full Flow Paper Type Steering with UJ, ZF 8046. Gear Ratio 26.2:1

Fuel Filter: Single filter with water separator Adjustable steering wheel

F Overall Width (Cab) : 2475 Fuel Injection Pump: Rotary FIP Steering Wheel Dia: 470 mm

G Overall Width (Rear Tyres) : 2494 Fuel Tank: 240 Ltrs Optional: Hubei Forni, Gear Ratio 26.7:1

H Wheel Track - Front : 2020 CLUTCH WHEELS & TYRES

J Wheel Track - Rear : 1856 Single dry plate Coil spring type 380mm Dia Rims: B7.5 x 20 – 10 Bolts, Spigotted

clutch, Hydro pneumatically operated. Tyres: Front: 10.00 – 20, 16 PR - 4 No's (Rib)

K Front Axle to Back of Cabin : 760 Rear: 10.00 – 20, 16 PR – 8 No's (Lug)

L Approach Angle : 30° GEAR BOX Spare: 10.00 – 20, 16 PR - 1 No (Rib)

Model: 9S FS-6209X GB– Synchromesh

M Departure Angle : 64° Speed Ratios BRAKES

N Min Ground Clearance - Front: 280 Crawler – 12.64, I – 8.81, II – 6.55, III – 4.77, IV – Service Brakes: Pneumatic, Foot operated,

3.55, V – 2.48, VI – 1.85, VII – 1.34, VIII – 1, Dual line on all wheels with Automatic slack

O Min Ground Clearance - Rear : 270 Reverse – 13.21 adjuster. Parking Brake: Hand operated spring

actuated on both Rear Axles Engine Exhaust

P Frame Width : 864

PROPELLER SHAFT Brake: Butterfly type, provided.

Q Distance between front axles : 1750 No of shafts: 3 (1 Center Bearing Shaft, Drive

Shaft and Inter axle shaft between two rear axles) ELECTRICAL SYSTEM

R Distance between Rear axles : 1350 XS Flange -GB to rear Axle,1710 series propeller System : 24 Volt (Negative Earth)

S Distance between : 1000 shaft Dia Spl.90 series inter axle shaft. Alternator: 75 A

front axles to rear of Battery: 2 x 12V x 100 Amp hr (20 hr rating)

REAR AXLE A/C. Wiper Motor – Electrically operated with

air intake bracket Fully floating Tandem Rear Axles – Both Driven 3 Blade wiping system

U Distance between Center of : 102 Hypoid Bevel Gears with Inter axle diff. lock – air

rear axles to reference line of operated. Ratio: 6.17 CABIN

Fully furnished, Hydraulic Tiltable Sleeper semi

Rear overhang

AMW/2013/11/3118TP/REV01

FRONT AXLE suspended Cab with A/C

Forged I Section – Reverse Elliot type – 2 Nos Seating capacity: 2 in all

FRAME PERFORMANCE (@ 25000Kgs)

WEIGHTS (Kgs) HSLA Steel, Ladder Type Bolted Cross members. Max Speed - geared (KMPH) : 78

Frame Side Member: 270 x 82 x 7mm Channel Max. Gradeability (%) @ 31T : 28.32%

Unladen Laden

and Fully reinforced with 7mm thk flitch Max. Gradeability (deg) @ 31T : 12.74°

chassis* (CMVR) No. of Cross members: 6 Min.Turning Circle Diameter (mm) : 20000

Front Axle : 6090 12000

Disclaimer:

BODY & TIPPING SYSTEM Any modification related to chassis to be done with

Rear Axle : 6470 19000 All steel welded body construction with prior approval from R&D, AMW.

Automatic Tail gate. Capacity – 20/18/16 Cu. m

Total : 12560 31000 Do not weld or drill chassis.

Box body 4 Stage Single Ram, Front end Tipping Technical Specifications are subject to change without notice.

*With 20 cu. m. Box Body - Max tipping angle 51° Accessories shown are not part of the standard fitment.

AMW Motors Ltd.

7th Floor, Tower-1, Equinox Business Park, Peninsula Techno Park,

Off. Bandra Kurla Road, L.B.S. Marg, Kurla (West), Mumbai - 400 070, India.

Tel.: + (91-22) 3382 6000 • Fax: + (91-22) 3382 6123.

• www.amwmotors.com AMW Motors Ltd. AMWMotorsLtd

TOLL FREE HELPLINE : 1800-209-2447

You might also like

- 4018 TRDocument2 pages4018 TRBALANo ratings yet

- NewHolland Fiat 640 2WD Tractor - NH Fiat 640 Tractor - New Holland Tractors - FIAT Tractors - NewHolland Fiat Exporters in PakistanDocument2 pagesNewHolland Fiat 640 2WD Tractor - NH Fiat 640 Tractor - New Holland Tractors - FIAT Tractors - NewHolland Fiat Exporters in PakistanLAli100% (1)

- ZZ1167M4617C Chassis 270hpDocument1 pageZZ1167M4617C Chassis 270hpAndy WangNo ratings yet

- Daf FTT 95Document2 pagesDaf FTT 95Bartek GrzybowskiNo ratings yet

- Maz 643008Document3 pagesMaz 643008Gerson SuarezNo ratings yet

- ZZ4257N3241D1 380hpDocument1 pageZZ4257N3241D1 380hpAndy WangNo ratings yet

- Ficha Tecnica HFC4253-6X4 TRACTOR H EAD (CUM420) 按设计方案Document1 pageFicha Tecnica HFC4253-6X4 TRACTOR H EAD (CUM420) 按设计方案rogermantilla08No ratings yet

- Zz3257m2947a 290HPDocument1 pageZz3257m2947a 290HPAndy WangNo ratings yet

- ZZ4257N3241VDocument1 pageZZ4257N3241VAndy WangNo ratings yet

- Astra - HD9 - Spec SheetDocument2 pagesAstra - HD9 - Spec SheetRanyeri Moreira de SousaNo ratings yet

- IVECO TRAKKER TRACTOR HEAD 4X2 and 6X4 (05-18-2016) PDFDocument2 pagesIVECO TRAKKER TRACTOR HEAD 4X2 and 6X4 (05-18-2016) PDFJohn YangNo ratings yet

- Specifications Of: Tata LPT 1918Document1 pageSpecifications Of: Tata LPT 1918indramaniNo ratings yet

- ZZ3167M4611 266HPDocument1 pageZZ3167M4611 266HPcherryNo ratings yet

- NPR71HDocument2 pagesNPR71Hmed.achrxfNo ratings yet

- Premier: MotorcorporationDocument23 pagesPremier: MotorcorporationEugy AlexNo ratings yet

- SuspensionDocument2 pagesSuspensionSandeep MeenaNo ratings yet

- 2.1. Specs. Howo Dumper Truck. 8X4. 371HP_E2Document1 page2.1. Specs. Howo Dumper Truck. 8X4. 371HP_E2Seprudin 82No ratings yet

- FM 400 8X4 Tipper With 29 Cu.M Coal BodyDocument4 pagesFM 400 8X4 Tipper With 29 Cu.M Coal BodymaiquelernNo ratings yet

- Scania r580 PDFDocument2 pagesScania r580 PDFrendi predianto0% (1)

- Datasheet Camion-Polybene 2017-11Document1 pageDatasheet Camion-Polybene 2017-11johnNo ratings yet

- Brosur Scania P250LA-6x2Document2 pagesBrosur Scania P250LA-6x2Bayu Adie SeptiantoNo ratings yet

- 01 FVZ34SU-PD-2E Spec SheetDocument4 pages01 FVZ34SU-PD-2E Spec Sheetferdinand hutapeaNo ratings yet

- Howo Tipper Truck 6x4 371HP PDFDocument2 pagesHowo Tipper Truck 6x4 371HP PDFIbrahim Fadhl KalajengkingNo ratings yet

- FM400 8x4 With 18cum Rock Body - 06 PDFDocument4 pagesFM400 8x4 With 18cum Rock Body - 06 PDFsanvae123No ratings yet

- Dimensions: Technical Specifications 2523 (6x4)Document2 pagesDimensions: Technical Specifications 2523 (6x4)Venkat CmrlNo ratings yet

- Weichai Sdac HybridDocument1 pageWeichai Sdac HybridJOSE EDUARDO VASQUEZ TAVAREZNo ratings yet

- 25C Series CatalogueDocument3 pages25C Series CatalogueAgro PópuloNo ratings yet

- Zz3251n3241a 336HPDocument1 pageZz3251n3241a 336HPAndy WangNo ratings yet

- ZZ3253M3641 336HPDocument1 pageZZ3253M3641 336HPAndy WangNo ratings yet

- Canter 4.5tDocument2 pagesCanter 4.5tJ Eduardo Garcia Moreno50% (2)

- Scania 380-6x6Document2 pagesScania 380-6x6Bayu Adie SeptiantoNo ratings yet

- Box Truck Without Tail LiftDocument3 pagesBox Truck Without Tail LiftAliNo ratings yet

- AT 440S43 T/FP LT Low Tractor 4x2: Plated / Design Weights (KG.) G.V.W. G.C.W. 1st Axle 2nd AxleDocument2 pagesAT 440S43 T/FP LT Low Tractor 4x2: Plated / Design Weights (KG.) G.V.W. G.C.W. 1st Axle 2nd AxleDaniel SemereNo ratings yet

- ZZ4257S3231V 371hpDocument1 pageZZ4257S3231V 371hpAndy WangNo ratings yet

- Dokumen - Tips 1615 Tipperpdf5 P e C F C A T o N 5 Tata LPK 1615 TC Tipper Cummins 6bt s9 WaterDocument2 pagesDokumen - Tips 1615 Tipperpdf5 P e C F C A T o N 5 Tata LPK 1615 TC Tipper Cummins 6bt s9 WaterKhush DhakaNo ratings yet

- MP4500 6x4 Cursor 13Document4 pagesMP4500 6x4 Cursor 13brayandparavicinoNo ratings yet

- 2 1 Fg8jglt Eep Final (PM)Document1 page2 1 Fg8jglt Eep Final (PM)hyde2520015754No ratings yet

- 1 1 Fg8jklb Eep Final Rigid Fg8j 4x2Document1 page1 1 Fg8jklb Eep Final Rigid Fg8j 4x2Shahzad ShaikhNo ratings yet

- Fuso FJ - 2523Document2 pagesFuso FJ - 2523Lucky Intiland100% (2)

- MP180E25W: Technical DescriptionsDocument13 pagesMP180E25W: Technical DescriptionsBroCactusNo ratings yet

- Workshop Manual 850 Le MansDocument53 pagesWorkshop Manual 850 Le MansLos Ángeles Customs GarageNo ratings yet

- International 7600 Specification SheetDocument4 pagesInternational 7600 Specification SheetJuan Pablo Maque CastilloNo ratings yet

- Eurorider 270Document1 pageEurorider 270fatalgamersNo ratings yet

- Tippers PDFDocument2 pagesTippers PDFmanoj262400/2No ratings yet

- MD - Granite TractorDocument2 pagesMD - Granite TractorSebastian RentschNo ratings yet

- Eurocargo ML225E28PDocument2 pagesEurocargo ML225E28PAl FbaNo ratings yet

- G1 Fab CGB45Document31 pagesG1 Fab CGB45anggieNo ratings yet

- Isuzu FVR/FVD1000Document2 pagesIsuzu FVR/FVD1000Hugo RodriguezNo ratings yet

- MPDFDocument2 pagesMPDFEmerson LealNo ratings yet

- Hino 238 2017 Technical SpecificationsDocument2 pagesHino 238 2017 Technical SpecificationsSlamat AgungNo ratings yet

- FJ Tipper/Mixer 6×4 SPECIFICATIONS: FJ2528C - Lea EtDocument2 pagesFJ Tipper/Mixer 6×4 SPECIFICATIONS: FJ2528C - Lea EtLucky IntilandNo ratings yet

- HimkDocument1 pageHimkarifNo ratings yet

- SINOTRUK 64.290 6x4 12m3 TipperDocument2 pagesSINOTRUK 64.290 6x4 12m3 TipperIT AccountNo ratings yet

- Tata LPT 909 SpecificationsDocument4 pagesTata LPT 909 SpecificationsAbhi Shek0% (1)

- FVL1350 1400Document2 pagesFVL1350 1400Hisham HamdiNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- MXT 840 BS4 - NEW CAB FILTER-12.06.2023 Vysakh and Navin - MEILDocument1 pageMXT 840 BS4 - NEW CAB FILTER-12.06.2023 Vysakh and Navin - MEILYernena NareshNo ratings yet

- JCB 430 ZXDocument1 pageJCB 430 ZXYernena NareshNo ratings yet

- LPT 2518 Tcic BS Iii Cat PDFDocument317 pagesLPT 2518 Tcic BS Iii Cat PDFYernena Naresh100% (1)

- HYDRA-12 STD CATALOGUE Rev-01, 25-01-17 PDFDocument425 pagesHYDRA-12 STD CATALOGUE Rev-01, 25-01-17 PDFYernena Naresh100% (2)

- HYDRA-12 STD CATALOGUE Rev-01, 25-01-17 PDFDocument425 pagesHYDRA-12 STD CATALOGUE Rev-01, 25-01-17 PDFYernena Naresh100% (2)

- FIRESTONE Tire Catalog PDFDocument27 pagesFIRESTONE Tire Catalog PDFWill SudNo ratings yet

- Xtool X 100 Pad2 Mileage Adjustment Model List PDFDocument17 pagesXtool X 100 Pad2 Mileage Adjustment Model List PDFSelva Prem KumarNo ratings yet

- Diagramas Electricos Mazda CX 7 Awd 2.3l Turbo 2008 FreeDocument2 pagesDiagramas Electricos Mazda CX 7 Awd 2.3l Turbo 2008 FreeJonathan YagualNo ratings yet

- Combination Meter: D1 (A), D2 (B)Document10 pagesCombination Meter: D1 (A), D2 (B)PeterNo ratings yet

- Manual Del Usuario Chevrolet Colorado 2005 enDocument416 pagesManual Del Usuario Chevrolet Colorado 2005 enTazzitinNo ratings yet

- Almera n16 Europa Idx-K9kDocument6 pagesAlmera n16 Europa Idx-K9kMARK llNo ratings yet

- Programa TU 19 Junio T3Document1 pagePrograma TU 19 Junio T3cumbiambero lopezNo ratings yet

- Sistema Eléctrico Ford FiestaDocument4 pagesSistema Eléctrico Ford FiestaMisael100% (1)

- Isuzu Engine-6UZ1X CatalogDocument4 pagesIsuzu Engine-6UZ1X Catalogmadhi vijayNo ratings yet

- Vehicle Diag ManualDocument102 pagesVehicle Diag ManualThalia Haro50% (2)

- EPH Drawings CHNR 201838Document30 pagesEPH Drawings CHNR 201838Ruben OscarNo ratings yet

- Balotario de PreguntasDocument8 pagesBalotario de PreguntasGlenn DiazNo ratings yet

- FW02 14101152Document17 pagesFW02 14101152Joe ShowNo ratings yet

- Vehicle History: Registration Number: GJ12EE0886 No - of Visits Requested:13Document8 pagesVehicle History: Registration Number: GJ12EE0886 No - of Visits Requested:13kamran.shahNo ratings yet

- CANTIDDocument5 pagesCANTIDAldoMendozaNo ratings yet

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument5 pagesEngine Controls (Powertrain Management) - ALLDATA RepairRonald FerminNo ratings yet

- ABBAUT VSH200 PANEL 1mrk514002-Ben - en - Relay - and - Control - Cubicles - VSH - 200Document4 pagesABBAUT VSH200 PANEL 1mrk514002-Ben - en - Relay - and - Control - Cubicles - VSH - 200João LamelaNo ratings yet

- Abo 3503Document2 pagesAbo 3503Edmore MukozhoNo ratings yet

- 2016-04 PP Semi Low Loaders STZ enDocument48 pages2016-04 PP Semi Low Loaders STZ enLuis SousaNo ratings yet

- Ont Axle Hub Drum - 2018 - 04 - 25 - 183747 PDFDocument6 pagesOnt Axle Hub Drum - 2018 - 04 - 25 - 183747 PDFJuanSantillanNo ratings yet

- 2015 Volvo XC70 Brochure PDFDocument4 pages2015 Volvo XC70 Brochure PDFAmadeuszNo ratings yet

- A B D e F G H I J K L M N P oDocument2 pagesA B D e F G H I J K L M N P oLuis BarriosNo ratings yet

- Abs 8.2 & 9.0 CodingDocument3 pagesAbs 8.2 & 9.0 CodingCristian100% (1)

- Associations Related To Manufacturing IndustriesDocument25 pagesAssociations Related To Manufacturing Industriesnagabhupal433No ratings yet

- VW Golf mk5 - Fuse Box Fuse Box in Passenger CompartmentDocument4 pagesVW Golf mk5 - Fuse Box Fuse Box in Passenger CompartmentKãdí100% (1)

- Electrical Systems Integration Guide 2021 HX Jan and Newer 3Document582 pagesElectrical Systems Integration Guide 2021 HX Jan and Newer 3Cesar Palacios ToctoNo ratings yet

- 2014 Sportsman 570 Service ManualDocument456 pages2014 Sportsman 570 Service ManualBrianCook100% (2)

- BMW R 1200 GS (+ Adventure) - Review, History, SpecsDocument16 pagesBMW R 1200 GS (+ Adventure) - Review, History, Specspedroserus100% (2)

- Repair Manuals LB75, LB85, LB90, LB95, LB110, LB115AWSDocument12 pagesRepair Manuals LB75, LB85, LB90, LB95, LB110, LB115AWSpouya kazemi50% (6)

- GE Plastics AutomotiveDocument2 pagesGE Plastics AutomotiveBhavesh AgrawalNo ratings yet