Professional Documents

Culture Documents

Design Class Detail Utilities Cooling Systems / Cooling Water Systems Project Date

Uploaded by

Ignatios StaboulisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Class Detail Utilities Cooling Systems / Cooling Water Systems Project Date

Uploaded by

Ignatios StaboulisCopyright:

Available Formats

ECCN EAR 99

Design Class Detail

Utilities Cooling Systems / Cooling Water

Systems PROJECT Date

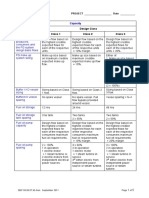

Capacity

Design Design Class

Item

Class 1 Class 2 Class 3

Line Sizing Cooling water (CW) CW system piping shall be CW system piping shall be

system piping shall be designed with a 5% designed with a 10%

designed without a circulation allowance. circulation allowance.

circulation allowance.

Tower Sizing No recirculation allowance shall be added to ambient 1 to 2F shall be added to

wet bulb temperature. ambient wet bulb

temperature, selected per

21EG-1, to allow for hot air

recirculation.

Expandability

Design Design Class

Item

Class 1 Class 2 Class 3

Plot Space No plot space shall be Consideration shall be Plot space shall be

provided for extra given to providing plot provided for expansion of

cooling water tower space for one additional the CWT (via new cells) to

(CWT) cells or CW CWT cell and space in the accommodate a specified

pumps pump pit for one additional future expansion case.

CW pump if minimal cost Blinded connections shall

is involved. be provided in the main

supply and return piping to

tie-in piping from new CW

pumps and to new cells.

The basin shall have

blinded connections for tie-

in to a new basin.

Line Sizing CW system piping shall Sizes of main supply and All CW lines shall be

be designed for high main lateral CW lines shall designed for a specified

velocity with no room for be “rounded up” future expansion case.

expansion

DEP 00.00.07.91-Gen. September 2011 Page 1 of 3

ECCN EAR 99

Design Class Detail

Utilities Cooling Systems / Cooling Water

Systems PROJECT Date

Capacity Utilization

Design Design Class

Item

Class 1 Class 2 Class 3

Electrical Supply A single electrical supply Electrical supply for fans Electrical supply for fans

for the CWT fans and and pumps shall have and pumps shall have

the CW supply pumps minimum level of highest level of

shall be provided, unless redundancy. redundancy.

safety is a concern. Consideration shall be

given to using combination

of electric motor and

steam turbine drivers for

pumps.

Number of Cells Single cell design shall Designs with two cells may Designs shall use a

be used where be used. No spare cells minimum of three cells.

permitted. No spare shall be provided. No spare cells shall be

cells shall be provided. provided.

Spare Pumps CW system may have CW system shall have two CW system shall have a

one supply pump unless auto-start pumps, each minimum of three auto-

safety is a concern. capable of meeting 100% start pumps, each capable

of system requirements of meeting 100/(N-1) % of

(unless Class 3 provides a system requirements

lower installed cost) (where N is the total

number of pumps).

Operability and Maintainability

Design Design Class

Item

Class 1 Class 2 Class 3

Backflush No backflush Backflush connections on Backflush connections on

Connections connections on CW selected CW exchangers all process CW

exchangers shall be shall be provided. exchangers shall be

provided. provided. Chemical

cleaning connections shall

be provided where

required.

Basin Simple basin and pump Simple basin and pump pit Pump pit shall be

pit with minimum basin with 3 minute residence designed in accordance

capacity shall be time in basin shall be with Hydraulic Institute

provided. provided. standards with 5 minute

residence time in basin.

DEP 00.00.07.91-Gen. September 2011 Page 2 of 3

ECCN EAR 99

Design Class Detail

Utilities Cooling Systems / Cooling Water

Systems PROJECT Date

Operability and Maintainability (cont'd)

Design Design Class

Item

Class 1 Class 2 Class 3

Instrumentation No flow instrumentation Local flow instrumentation Local flow instrumentation

in the CW distribution for total CW circulation, for total CW circulation,

system shall be blowdown and make-up flows to critical

provided. shall be provided. exchangers, blowdown

and make-up shall be

provided.

Type of Tower Film fill shall be used in Film or splash fill shall be selected basis careful analysis

CWT unless quality of of makeup water quality an its variations and

makeup water is consequences of a leak of process fluids into the CW.

prohibitively poor.

Packaged CWTs with Long life low maintenance CWT built in accordance with

integral basins shall be 21 GS-1 shall be used.

used as dictated by

costs.

Valving for Flow No flow balancing valves Flow balancing valves in main CW laterals shall be

Balancing in main CW laterals shall provided. Contractor shall perform a hydraulic network

be provided. analysis of the CW distribution system.

Water Chemistry Manual monitoring and Automated monitoring and adjustment of CW chemistry.

Control adjustment of all CW

chemistry except pH.

DEP 00.00.07.91-Gen. September 2011 Page 3 of 3

You might also like

- App A - Baseline STDDocument3 pagesApp A - Baseline STDsehyong0419No ratings yet

- Shunt Reactor ConfigurationDocument11 pagesShunt Reactor ConfigurationAnindya Bikash DeNo ratings yet

- Special Transformers ABB PDFDocument8 pagesSpecial Transformers ABB PDFRicardo Rivas ZuñigaNo ratings yet

- ECO Conductors Low Loss Conductor SolutionDocument2 pagesECO Conductors Low Loss Conductor SolutionBalaji_Rajaman_2280No ratings yet

- CVT and CC - North American BrochureDocument8 pagesCVT and CC - North American Brochurejose dupimNo ratings yet

- Battery SizingDocument5 pagesBattery SizingMuneer MPNo ratings yet

- Shunt Reactors White Paper GEA31994 PDFDocument8 pagesShunt Reactors White Paper GEA31994 PDFAndré LuizNo ratings yet

- TCVT and TCC - International BrochureDocument8 pagesTCVT and TCC - International BrochureRupan mukherjeeNo ratings yet

- 02 - Thermal Rating Implications of The Co-Location of HV Cable Circuits in TunnelsDocument5 pages02 - Thermal Rating Implications of The Co-Location of HV Cable Circuits in Tunnelssaghaee.rezaNo ratings yet

- Is 1554Document14 pagesIs 1554Pardeep KhosaNo ratings yet

- Class E-A New Single-Ended Class of High-Efficiency Tuned Switching Power AmplifiersDocument9 pagesClass E-A New Single-Ended Class of High-Efficiency Tuned Switching Power AmplifiersVanshika JindalNo ratings yet

- Class E-A New Class of High-Efficiency Tuned Single-Ended Switching Power AmplifiersDocument9 pagesClass E-A New Class of High-Efficiency Tuned Single-Ended Switching Power AmplifiersBendera Hitam Dari TimurNo ratings yet

- ETAP Application of Variable Frequency Drive On The ConDocument12 pagesETAP Application of Variable Frequency Drive On The ConNicodemus Ervino MandalaNo ratings yet

- Air-Core Neutral Grounding ReactorsDocument2 pagesAir-Core Neutral Grounding ReactorsharpreetNo ratings yet

- HVSR Brochure Letter AmericanVersionDocument8 pagesHVSR Brochure Letter AmericanVersionJaveed A. KhanNo ratings yet

- Article 220 - Branch-Circuit, Feeder, and Service CalculationsDocument1 pageArticle 220 - Branch-Circuit, Feeder, and Service CalculationsaharchtopiaNo ratings yet

- Application of Variable Frequency Drive On The Condensate Pump Motors of APR1400 Nuclear Power Plants For Energy SavingsDocument12 pagesApplication of Variable Frequency Drive On The Condensate Pump Motors of APR1400 Nuclear Power Plants For Energy Savings陆华林No ratings yet

- Pad Mounted TransformersDocument8 pagesPad Mounted Transformersمدهش الاديبNo ratings yet

- Electric Distribution LinesDocument7 pagesElectric Distribution LinesluisepasNo ratings yet

- Armstrong Applications CalculationDocument27 pagesArmstrong Applications CalculationAryû BelleNo ratings yet

- Of Steam Turbine-Generators: I Method For Predicting The PerformanceDocument40 pagesOf Steam Turbine-Generators: I Method For Predicting The PerformancenckpourlasNo ratings yet

- Dry-Type, Air-Core Shunt Reactors: ProvenDocument8 pagesDry-Type, Air-Core Shunt Reactors: ProvenWardencasianAlanisNo ratings yet

- Article Supercritical Control en 37630Document4 pagesArticle Supercritical Control en 37630etong saturninaNo ratings yet

- Options For Ground Fault Clearance in HVDC Offshore NetworksDocument8 pagesOptions For Ground Fault Clearance in HVDC Offshore NetworksFelix GamarraNo ratings yet

- Application of Variable Frequency Drive On The Condensate Pump Motors of APR1400 Nuclear Power Plants For Energy SavingsDocument12 pagesApplication of Variable Frequency Drive On The Condensate Pump Motors of APR1400 Nuclear Power Plants For Energy Savings陆华林No ratings yet

- Design Class Detail Piping Project Date: DEP 00.00.07.85-Gen. Page 1 of 3Document5 pagesDesign Class Detail Piping Project Date: DEP 00.00.07.85-Gen. Page 1 of 3Ignatios StaboulisNo ratings yet

- Section 6 Battery SizingDocument54 pagesSection 6 Battery SizingAca ChchNo ratings yet

- Bill of Quantities Sewage Treatment PlanDocument11 pagesBill of Quantities Sewage Treatment PlanMiguel ChanNo ratings yet

- ANSI MV TechTopics55 EN PDFDocument2 pagesANSI MV TechTopics55 EN PDFJason SonidoNo ratings yet

- System DesignDocument25 pagesSystem DesignJon LopezNo ratings yet

- Wind Power Plant Collector System Design - SCRDocument7 pagesWind Power Plant Collector System Design - SCRLuis FebresNo ratings yet

- Part-B Volume - Ii Chapter - Ii-E11 BatteryDocument10 pagesPart-B Volume - Ii Chapter - Ii-E11 BatteryJayashree GaneshNo ratings yet

- Section 6 Battery SizingDocument54 pagesSection 6 Battery SizingWilly Mauricio Garcia PorcelNo ratings yet

- Fire Fighting - Technical Specifications - G04 - MEPSSPL CommentsDocument74 pagesFire Fighting - Technical Specifications - G04 - MEPSSPL CommentsamolNo ratings yet

- A Clustering Based Wind Farm Collector System Cable Layout DesignDocument6 pagesA Clustering Based Wind Farm Collector System Cable Layout DesignGcNo ratings yet

- Comments Sheet ENC BLD ACIDSDocument4 pagesComments Sheet ENC BLD ACIDSajay booraNo ratings yet

- 21-26 EngDocument6 pages21-26 EngVaibhav SanNo ratings yet

- Wind Power Plant Testing and CommissioningDocument4 pagesWind Power Plant Testing and CommissioningaNo ratings yet

- Comments On Existing PFRDocument1 pageComments On Existing PFRDeepak SharmaNo ratings yet

- BusBar LiteratureDocument4 pagesBusBar LiteratureschaktenNo ratings yet

- For HT PVC Cable PDFDocument12 pagesFor HT PVC Cable PDFAnonymous Gg6z0u9IBzNo ratings yet

- Bus Ele PP 10397 QSCP Solar ApplicationsDocument1 pageBus Ele PP 10397 QSCP Solar ApplicationsVictor Manuel Flores ZuñigaNo ratings yet

- Problem List: Nuclear Power Plant Systems and Operation Problem SetDocument8 pagesProblem List: Nuclear Power Plant Systems and Operation Problem Setda_tru_nigga8122No ratings yet

- Water Turbines - Power Systems Questions and Answers - SanfoundryDocument1 pageWater Turbines - Power Systems Questions and Answers - SanfoundryFikre shameboNo ratings yet

- 3 Ace Steam Generation Package HCL Synthesis MersenDocument2 pages3 Ace Steam Generation Package HCL Synthesis MersenUmair NasimNo ratings yet

- Brown University Revised 2/1/2006 Facilities Design & Construction RequirementsDocument6 pagesBrown University Revised 2/1/2006 Facilities Design & Construction RequirementsVahid BehjatNo ratings yet

- A 0.4 V, Sub-Nw, 8-Bit 1 Ks/s SAR ADC in 65 NM CMOS For Wireless Sensor ApplicationsDocument5 pagesA 0.4 V, Sub-Nw, 8-Bit 1 Ks/s SAR ADC in 65 NM CMOS For Wireless Sensor ApplicationsSilpa VelagaletiNo ratings yet

- Whitepaper Switching of Filter Circuits With Vacuum SwitchesDocument8 pagesWhitepaper Switching of Filter Circuits With Vacuum Switchesvijayeee82No ratings yet

- APFC Panel DesigningDocument16 pagesAPFC Panel Designingyrmn200% (1)

- ANPC-5L Technology Applied To Medium Voltage Variable Speed Drives ApplicationsDocument8 pagesANPC-5L Technology Applied To Medium Voltage Variable Speed Drives ApplicationsRen Hong GiangNo ratings yet

- Mitigating Carrier Holes in Power Line Carrier: Tony BellDocument3 pagesMitigating Carrier Holes in Power Line Carrier: Tony Bellschaefer1015719No ratings yet

- Central Battery BroDocument24 pagesCentral Battery BromdaslamabidNo ratings yet

- 02 TT - 01 Methods of Maintenance PDFDocument3 pages02 TT - 01 Methods of Maintenance PDFMohammad NasarNo ratings yet

- DAB Fire PumpsDocument16 pagesDAB Fire PumpsAhamed KyanaNo ratings yet

- Experiences With The Center-Tapped Wye-Delta Transformer Test CaseDocument5 pagesExperiences With The Center-Tapped Wye-Delta Transformer Test CaseFandi PrayogaNo ratings yet

- Bahrain Projects Important PointsDocument6 pagesBahrain Projects Important PointsDawoodNo ratings yet

- Technique of A Feasibility Study For The Use of A Variable Frequency Drive in Pumping UnitsDocument7 pagesTechnique of A Feasibility Study For The Use of A Variable Frequency Drive in Pumping UnitsMakhsum BozorovNo ratings yet

- Product Data: Airstream™ 42BHC, BVC System Fan CoilsDocument40 pagesProduct Data: Airstream™ 42BHC, BVC System Fan CoilsMaxmore KarumamupiyoNo ratings yet

- CliP University of CataniaDocument6 pagesCliP University of CataniaUsman MohsinNo ratings yet

- Design Class Detail Piping Project Date: DEP 00.00.07.85-Gen. Page 1 of 3Document5 pagesDesign Class Detail Piping Project Date: DEP 00.00.07.85-Gen. Page 1 of 3Ignatios StaboulisNo ratings yet

- Design Item Design Class Class 1 Class 2 Class 3Document4 pagesDesign Item Design Class Class 1 Class 2 Class 3Ignatios StaboulisNo ratings yet

- Expandability: Design Class Detail Plant Layout Project DateDocument2 pagesExpandability: Design Class Detail Plant Layout Project DateIgnatios StaboulisNo ratings yet

- Design Item Design Class Class 1 Class 2 Class 3: Once Through Cooling Water System Design Cooling DutyDocument3 pagesDesign Item Design Class Class 1 Class 2 Class 3: Once Through Cooling Water System Design Cooling DutyIgnatios StaboulisNo ratings yet

- Design Class Detail Pressure Vessels Project DateDocument4 pagesDesign Class Detail Pressure Vessels Project DateIgnatios StaboulisNo ratings yet

- Design Item Design Class Class 1 Class 2 Class 3Document5 pagesDesign Item Design Class Class 1 Class 2 Class 3Ignatios StaboulisNo ratings yet

- Shell - Process Flow SchemesDocument17 pagesShell - Process Flow SchemesIgnatios Staboulis100% (1)

- Shell - Process Safeguarding Flow SchemesDocument37 pagesShell - Process Safeguarding Flow SchemesIgnatios Staboulis100% (1)

- IEC 60079-16 (Ed. 1990) - Explosive Atmospheres, Artificial Ventilation For Protection of AnalyzersDocument24 pagesIEC 60079-16 (Ed. 1990) - Explosive Atmospheres, Artificial Ventilation For Protection of AnalyzersIgnatios StaboulisNo ratings yet

- IS 9570 (Ed. 1980) - Classification of Flammable Gases or VapoursDocument18 pagesIS 9570 (Ed. 1980) - Classification of Flammable Gases or VapoursIgnatios StaboulisNo ratings yet

- Is 5572 (Ed. 2009) - Classification of Hazardous Areas, Flammable Gases & Vapours For Electrical InstallationDocument46 pagesIs 5572 (Ed. 2009) - Classification of Hazardous Areas, Flammable Gases & Vapours For Electrical InstallationIgnatios StaboulisNo ratings yet

- API 650 - SCAST Committee Response On Inquiries (APR 2019)Document28 pagesAPI 650 - SCAST Committee Response On Inquiries (APR 2019)Ignatios Staboulis0% (1)

- Cortem - Junction BoxesDocument340 pagesCortem - Junction BoxesIgnatios StaboulisNo ratings yet

- Dynamic Compaction of SoilDocument6 pagesDynamic Compaction of SoilAhmed ibraheemNo ratings yet

- DP Monitor 14061 DriversDocument1,087 pagesDP Monitor 14061 Driversberto_716No ratings yet

- Trampa Termodinamica Modelo NTD600Document2 pagesTrampa Termodinamica Modelo NTD600Willy Lecca VenauteNo ratings yet

- Eamm-A enDocument80 pagesEamm-A enIqtidar GulNo ratings yet

- General Mechanical Questionnaire Without AnswersDocument7 pagesGeneral Mechanical Questionnaire Without AnswersDaniel Jimenez MerayoNo ratings yet

- Automatic Voltage Regulator: C A Pa C I T Y: 1 0 0 0 Va - 5 0 0 0 VaDocument12 pagesAutomatic Voltage Regulator: C A Pa C I T Y: 1 0 0 0 Va - 5 0 0 0 VaNihar RoyNo ratings yet

- PMP Comprehensive Notes - ChowdaryDocument27 pagesPMP Comprehensive Notes - ChowdarySachith Seneviratna100% (3)

- Comparacion Norma TIA-F Y TIA-GDocument30 pagesComparacion Norma TIA-F Y TIA-GAlioska Aguirre MendozaNo ratings yet

- SEMPDocument29 pagesSEMPMustafa ArifNo ratings yet

- RAME2016 ScheduleDocument6 pagesRAME2016 ScheduleVerma AbhiNo ratings yet

- MGMT201 Application 3 (Case Only) - 2021Document4 pagesMGMT201 Application 3 (Case Only) - 2021hieu maiNo ratings yet

- Certificado SofarDocument3 pagesCertificado SofarJeff DanceNo ratings yet

- Hello, From Sotja Interiors Bali - 27 NOV 2017Document174 pagesHello, From Sotja Interiors Bali - 27 NOV 2017Ibrahim Amir HasanNo ratings yet

- Rock Cutting: 12.4 Design and Construction of Hill RoadsDocument13 pagesRock Cutting: 12.4 Design and Construction of Hill RoadsAnkan RakshitNo ratings yet

- Powder MetallurgyDocument43 pagesPowder MetallurgythirumalaikumaranNo ratings yet

- Lampiran 4Document24 pagesLampiran 4csecNo ratings yet

- Service Tools: 3.2. Inverter Checker RSUK09-17Document15 pagesService Tools: 3.2. Inverter Checker RSUK09-17markiimreNo ratings yet

- Non - Halogen Flame RetardantsDocument8 pagesNon - Halogen Flame RetardantsJimmy WongNo ratings yet

- HPHT Cementing GuidelinesDocument15 pagesHPHT Cementing Guidelineshamora33100% (4)

- HIC 412C - Data Sheet (CT Vacuum Pump & Evaporator) PDFDocument3 pagesHIC 412C - Data Sheet (CT Vacuum Pump & Evaporator) PDFsuyono4131No ratings yet

- GATE-2007 Physics Question PaperDocument22 pagesGATE-2007 Physics Question PaperDavid HudsonNo ratings yet

- Deckwatchkeeping 1 - Collision RegulationDocument13 pagesDeckwatchkeeping 1 - Collision RegulationLalyn Navora BalansagNo ratings yet

- Suspension Trasera 97-98Document6 pagesSuspension Trasera 97-98kilofome05No ratings yet

- SM T210 Tshoo 7Document30 pagesSM T210 Tshoo 7Alexander MolinaNo ratings yet

- BibliographyDocument5 pagesBibliographyMonal ParekhNo ratings yet

- Object Oriented ProgrammingDocument2 pagesObject Oriented Programmingprince_kc2002No ratings yet

- Steel DOS 1Document107 pagesSteel DOS 1MazharYasinNo ratings yet

- Eco 100 +Document66 pagesEco 100 +Leidy Viviana Ramírez SánchezNo ratings yet

- Control Theory IntroductionDocument53 pagesControl Theory IntroductionSushmita KujurNo ratings yet

- Từ Điển Thuật Ngữ p3Document10 pagesTừ Điển Thuật Ngữ p3Minh Thien TranNo ratings yet