Professional Documents

Culture Documents

Allagr Fishing Ve

Allagr Fishing Ve

Uploaded by

Jerry Sumok WalterCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Allagr Fishing Ve

Allagr Fishing Ve

Uploaded by

Jerry Sumok WalterCopyright:

Available Formats

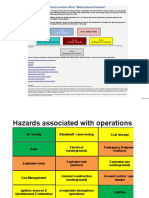

Department of Occupational Safety and Health

Ministry of Human Resources

HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK

CONTROL IN AGRICULTURE SECTOR

PALM OIL PLANTATION

1 2 3 4

Chemical Preparation Transport Fertilizer and Spraying Manuring

Chemicals

Slip and fall Chemical spillage Slip and fall

Safe working procedure Excessive load Chemical management Safe working procedure

Apply buddy system

Chemical spillage Slip and fall Chemical spillage

Personnel protective Manual handling Safe working procedure Personnel protective equipment

equipment Safe working procedure

Heat stress Heat stress

Chemicals Bending work Allocation of drinking waters Allocation of drinking waters

Chemical management Uneven ground nearby nearby

Slip and fall Personnel protective

Training equipment Snakes, hornet and bees

Destroy or remove the nest

Chemical spillage Snake, hornet and bees

Personnel protective Destroy or remove the nest

equipment

5 6 7

Harvesting Trunk Injection Change Tractor Tyre

Slip and fall Very toxic chemicals Excessive pressure in tyre

Falling fronds and debris Chemical spillage Unstable tractor position

Training on correct positioning of pole Personnel protective equipment Heavy load

length Scheduled health surveillance Safe working procedure

Good hygiene practice

Sharp sickle Bending work

Safe working procedure Slip and fall Training

Sharp object

Sharp thorn Safe working procedure

Personnel protective equipment

Snake, hornet and bees

Destroy or remove the nest

Hazard Control

In Collaboration with Sime Darby and Ladang Salak, Negeri Sembilan

11 (1st Floor), Jalan SS26/8, Taman Mayang Jaya, 47301 Petaling Jaya, Selangor

Outreach Poster under Occupational of Safety and Health Master Plan (OSH-MP15), Strategy 3, Program 2,

Department of Occupational Safety and Health Malaysia (Ministry of Human Resources)

Plantation

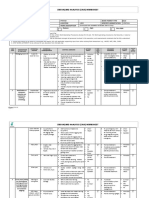

Department of Occupational Safety and Health

Ministry of Human Resources

HAZARD IDENTIFICATION, RISK ASSESSMENT AND

RISK CONTROL IN THE FISHING INDUSTRY: AQUACULTURE

1 2 3 4

Pintu Tong

Pond Border

Feeding the fish Mowing lawns around the pond Removing fish eggs from the fish’s Inspecting the condition of the fish

mouth in the storage bins

Open edges around the pond Lawn mower

Ensure body position is not too close to Flying objects Violent reaction from fish Heavy storage covers

the border of the pond to avoid falling Noise Provide training to employees on the Provide hinges on storage covers

into it Venomous animals proper techniques of removing fish Provide Safe Work Procedures related

Place boundary markers showing the Wear appropriate personal protective eggs from the fish’s mouth to manual handling

limit of where an employee is allowed equipments (safety shoes, apron, eye Wear appropriate personal protective Provide training on safe inspection

to feed the fish protection) equipments (goggles and gloves) techniques to employees

Install water level depth markers

Hot conditions Muddy pond Slippery floor

Place warning signs of places with

holes and soft ground Provide drinking water dispensers to Provide Safe Working Procedures Use rubber shoes to avoid falling and

employees Adopt a 'buddy' system slipping

Exposure to chemicals Provide training to employees on basic

Open edges around the pond Bending works

Provide information to employees about swimming techniques

the hazards of chemicals (i.e. fish food) Place warning signs of places with Provide training and Safe Working

holes and soft ground Wear safety jackets

used (refer to MSDS) Procedures on ergonomics

Good personal hygiene Install water level depth markers

Ensure body position is not too close to Uncovered storage bins

the border of the pond to avoid falling Adopt a 'buddy' system

into it Provide warning lights to indicate work

Place boundary markers showing the is being carried out

limit of where an employee is allowed

to mow the lawn

5 6 7 8

Slippery Floor

Ladder

Slippery Floor

Monitoring the fish in the storage Treating diseased fish Selecting fish using strainer Inserting oxygen into plastic bags

bins before fish are sold

Exposure to chemicals Slippery floor

Unstable ladders Provide information to employees about Use suitable rubber shoes to avoid Bending works

Use a stable working platform the health hazards of chemicals falling and slipping Use a table suitable with the worker’s

(i.e. drugs) used (refer to MSDS) Provide warning signs on a slippery height in order to conveniently insert

Slippery floor Use appropriate personal protective working environment oxygen into the plastic bag

Install warning signs on a slippery equipment (goggles, gloves and safety Maintain the floor at all times Provide training to employees on the

working environment shoes) proper methods to insert oxygen into

Maintain the floor at all times Messy wiring the plastic bags

Slippery floor Ensure tidiness of electrical wires used

Use proper shoes to avoid falling and

slipping Use proper shoes to avoid falling and Pressurized oxygen tanks

Ensure wiring is in accordance with the

slipping standards set Provide Safe Working Procedures

Provide warning signs on slippery Replace old or damaged electrical

working environment Leaked oxygen tanks

wiring

Maintain the floor at all times Place warning signs in the work area,

Place warning signs in the area of

for example "CAUTION, FLAMMABLE"

slippery floors

Place warning signs in the area of Fallen oxygen tanks

electrical wires

Provide fencing around the oxygen tank

to ensure tank stays up right

Provide a stable base to place the

oxygen tank

Hazard Control

Outreach Poster under Occupational Safety and Health Master Plan (OSH-MP15), Strategy 3 Program 2,

Department of Occupational Safety and Health (Ministry of Human Resources)

You might also like

- IBC - Process Discovery Basics - SolutionsDocument49 pagesIBC - Process Discovery Basics - SolutionsPurushotam Sharma75% (4)

- CMAA Time Management GuidelinesDocument74 pagesCMAA Time Management Guidelinescyrus dresselhaus100% (1)

- Jsa - Duck Bank InstallationDocument10 pagesJsa - Duck Bank InstallationAmadeo Sabanal100% (1)

- Hiradc-12 LabDocument5 pagesHiradc-12 LabizzahNo ratings yet

- Training Needs AssessmentDocument5 pagesTraining Needs AssessmentahmadNo ratings yet

- BGPI-HSSE-008 Minimum HSSE Training RequirementDocument4 pagesBGPI-HSSE-008 Minimum HSSE Training RequirementEngr Najam U SaqibNo ratings yet

- HSE PlanDocument71 pagesHSE PlanAli HadiNo ratings yet

- Jsa - Hot TappingDocument15 pagesJsa - Hot TappingAmadeo Sabanal0% (1)

- 09052019K6EKJ42CRiskAssessment UploadDocument26 pages09052019K6EKJ42CRiskAssessment UploadAhmed IbrahimNo ratings yet

- HSE Plan For Old ContractDocument72 pagesHSE Plan For Old ContractDURGAPRASAD JANYAVULANo ratings yet

- LiquidDocument4 pagesLiquidMohamed SelimNo ratings yet

- Hse Plan: W S Power SectorDocument130 pagesHse Plan: W S Power Sectorsurender bNo ratings yet

- 4 Tools For Safety Excellence RK SinghDocument27 pages4 Tools For Safety Excellence RK SinghPT. SAMUDRA INTIM JAYA SHIPPINGNo ratings yet

- Risk Assessment For Installation of Water Supply SystemDocument2 pagesRisk Assessment For Installation of Water Supply Systemمقاول تكييف كهرباء وصحيNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisAndhy DhannyNo ratings yet

- PUBH6002 Work Health and Safety AssessmentDocument8 pagesPUBH6002 Work Health and Safety AssessmentAna MariaNo ratings yet

- Power Sector: A N Health, Safety and Environment PlanDocument81 pagesPower Sector: A N Health, Safety and Environment PlanJithin M Krishna EzhuthachanNo ratings yet

- Hazard DatabaseDocument1,193 pagesHazard Database1009 AMILINENI SUDHEER CHANDRANo ratings yet

- Sample Induction Training PresentationDocument22 pagesSample Induction Training Presentationsarath SNo ratings yet

- A. 3 HirarcDocument29 pagesA. 3 HirarcJeny MulyaNo ratings yet

- Risk Assessment For VA MenlynDocument6 pagesRisk Assessment For VA MenlynVictor Thembinkosi MakhubeleNo ratings yet

- HIRAforCOVID 19Document4 pagesHIRAforCOVID 19marvinNo ratings yet

- Jsa Scrubbing of CranesDocument2 pagesJsa Scrubbing of CranesIlya BordonosovNo ratings yet

- JSA Welding & GrindingDocument2 pagesJSA Welding & GrindingtaufikNo ratings yet

- EXAMPLE RISK ASSESMENT For RTDocument6 pagesEXAMPLE RISK ASSESMENT For RTaredjoe100% (1)

- Risk Assessment For Anti-TermiteDocument6 pagesRisk Assessment For Anti-TermiteDan SarmientoNo ratings yet

- Job Hazard Analysis: Step Hazard Cause/Threat Preventive MeasureDocument1 pageJob Hazard Analysis: Step Hazard Cause/Threat Preventive MeasureJin DelaCruzNo ratings yet

- Hse Oil and Gas Ebook 2018Document7 pagesHse Oil and Gas Ebook 2018MohammedNo ratings yet

- Audit Checklist Process ApproachDocument131 pagesAudit Checklist Process ApproachEvaan KhanNo ratings yet

- Apds-Ra-011 Filtration Operation of Apds Filtration System Rev BDocument4 pagesApds-Ra-011 Filtration Operation of Apds Filtration System Rev BHua Tien DungNo ratings yet

- Behavior-Based Safety Observation Checklist - SafetyCultureDocument5 pagesBehavior-Based Safety Observation Checklist - SafetyCultureconstantinop.gonzalezNo ratings yet

- JSA-054 Crossing WorksDocument6 pagesJSA-054 Crossing WorksMajdiSahnounNo ratings yet

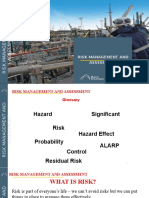

- Risk Management and AssessmentDocument50 pagesRisk Management and Assessmentfaik395No ratings yet

- PSJV Duqm Refinery Project Hsse Observations Tracking RegisterDocument3 pagesPSJV Duqm Refinery Project Hsse Observations Tracking RegisterbalasubramaniamNo ratings yet

- Risk Assessment Form: ChemicalsDocument2 pagesRisk Assessment Form: Chemicalsabubakre100% (1)

- Safety InductionDocument35 pagesSafety Inductionsumit solankiNo ratings yet

- E2 HIRARC FORM-1Document5 pagesE2 HIRARC FORM-1Hanzzel CharlesNo ratings yet

- Risk Assessment For PVC ConduitsDocument2 pagesRisk Assessment For PVC Conduitsمقاول تكييف كهرباء وصحي100% (1)

- WORKSHOP 4 - INTEGRATING ACTIVITY HIRACDocument16 pagesWORKSHOP 4 - INTEGRATING ACTIVITY HIRACrissarivera1495No ratings yet

- Risk Assessment - PlantingDocument5 pagesRisk Assessment - PlantingJunaid Mir100% (1)

- Risk Assessment Form: Workin GIN Confine D Space (Excavati On& Trenching)Document3 pagesRisk Assessment Form: Workin GIN Confine D Space (Excavati On& Trenching)Jhundel Factor0% (1)

- Idoc - Pub - Task Risk Assessment For RadiographyDocument5 pagesIdoc - Pub - Task Risk Assessment For RadiographySasi YNo ratings yet

- Jsa Waste Water Drain CleaningDocument4 pagesJsa Waste Water Drain CleaningASLAM MULANINo ratings yet

- Rse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerDocument2 pagesRse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerOws Anish100% (1)

- Hirarc - Firzan-Setting JobDocument3 pagesHirarc - Firzan-Setting JobKok Wen KaiNo ratings yet

- Loading & Unloading of Fire Fighting Foam 2V-7261 PDFDocument8 pagesLoading & Unloading of Fire Fighting Foam 2V-7261 PDFSanil ThomasNo ratings yet

- IOSH - Project Risk AssessmentDocument2 pagesIOSH - Project Risk Assessmenttawan ismatNo ratings yet

- Supply Chain Risk Management Template IDocument9 pagesSupply Chain Risk Management Template IMax WanNo ratings yet

- Incident Details: Construction - Event ReportDocument2 pagesIncident Details: Construction - Event Reportdeepak bhagatNo ratings yet

- 2022 Latest AcronymDocument3 pages2022 Latest AcronymSaqib JavedNo ratings yet

- TRA Strainer Cleaning 01Document7 pagesTRA Strainer Cleaning 01Ijaz Hussain50% (2)

- JHA Construction of Drain and SumpDocument6 pagesJHA Construction of Drain and SumpSamsiah TolaNo ratings yet

- Hazard Identification, Risk Assessment & ControlDocument4 pagesHazard Identification, Risk Assessment & ControlEdgar ManubagNo ratings yet

- Al1 - Result and DiscussionDocument8 pagesAl1 - Result and Discussionhari6622No ratings yet

- Job Hazard Analysis ExampleDocument1 pageJob Hazard Analysis ExampleAnimeMysteryNo ratings yet

- Activity Date Risk Assessment Ref: Rev. 00Document2 pagesActivity Date Risk Assessment Ref: Rev. 00Ordu Henry OnyebuchukwuNo ratings yet

- Risk Assessment; working at heightDocument3 pagesRisk Assessment; working at heightpeace.mudauNo ratings yet

- PDF DocumentDocument1 pagePDF Documentn.nuhanashNo ratings yet

- Enabling Ministry (Security and Safety)Document2 pagesEnabling Ministry (Security and Safety)Arman GubatNo ratings yet

- Physical Hazard Control: Preventing Injuries in the WorkplaceFrom EverandPhysical Hazard Control: Preventing Injuries in the WorkplaceNo ratings yet

- A Practical Approach to Hazard Identification for Operations and Maintenance WorkersFrom EverandA Practical Approach to Hazard Identification for Operations and Maintenance WorkersNo ratings yet

- Usaha Ternak Ayam Kampung KUBDocument11 pagesUsaha Ternak Ayam Kampung KUBahmadNo ratings yet

- Training Needs AssessmentDocument5 pagesTraining Needs AssessmentahmadNo ratings yet

- Chemic Fertilis 2020Document4 pagesChemic Fertilis 2020ahmadNo ratings yet

- LIGALITYDocument121 pagesLIGALITYahmadNo ratings yet

- Effect of Water Quality On The Performance of Boiler in Nigerian Petroleum IndustryDocument19 pagesEffect of Water Quality On The Performance of Boiler in Nigerian Petroleum IndustryahmadNo ratings yet

- (Draft) MYNI 2019 of The RSPO Principles and Criteria 2018-EnglishDocument34 pages(Draft) MYNI 2019 of The RSPO Principles and Criteria 2018-EnglishahmadNo ratings yet

- Web 5Document5 pagesWeb 5ahmadNo ratings yet

- MSDS NalcoDocument10 pagesMSDS Nalcoahmad0% (1)

- Quantifying The Cost Benefits Risks of Due Diligence For RBCDocument65 pagesQuantifying The Cost Benefits Risks of Due Diligence For RBCahmadNo ratings yet

- Tia Terms of Reference For Due Diligence: 1. Background InformationDocument10 pagesTia Terms of Reference For Due Diligence: 1. Background InformationahmadNo ratings yet

- Presentation On 17065Document40 pagesPresentation On 17065ahmadNo ratings yet

- Contractor Safety Handbook HroDocument86 pagesContractor Safety Handbook HroahmadNo ratings yet

- Conformity Assessment 17065Document16 pagesConformity Assessment 17065ahmadNo ratings yet

- SOP Pelayanan LitbangDocument3 pagesSOP Pelayanan LitbangahmadNo ratings yet

- BisnisDocument1 pageBisnisahmadNo ratings yet

- TUV Rheinland of North America, Inc.: 12 Commerce Road, Newton, CT 06470, USADocument1 pageTUV Rheinland of North America, Inc.: 12 Commerce Road, Newton, CT 06470, USAahmadNo ratings yet

- Final ISO IEC FDIS 17065 2012 E Conformity AssDocument77 pagesFinal ISO IEC FDIS 17065 2012 E Conformity AssahmadNo ratings yet

- Palm Oil MalaysiaDocument90 pagesPalm Oil MalaysiaahmadNo ratings yet

- Infinite Series and Differential Equations: Nguyen Thieu HuyDocument26 pagesInfinite Series and Differential Equations: Nguyen Thieu HuyTùng NguyễnNo ratings yet

- COS-MATH-241-Linear Algebra Spring 2020 - Midterm Exam 2 (20%)Document2 pagesCOS-MATH-241-Linear Algebra Spring 2020 - Midterm Exam 2 (20%)Zulqarnain KhanNo ratings yet

- Escaner Electromagnético de Faja Transportadora-Steel SPECTDocument85 pagesEscaner Electromagnético de Faja Transportadora-Steel SPECTEdwin Alfredo Eche QuirozNo ratings yet

- Shravana CharacterDocument5 pagesShravana CharacterSuresh SharmaNo ratings yet

- Valtra S Series Brochure 2013Document32 pagesValtra S Series Brochure 2013Luka BornaNo ratings yet

- BT90 - User ManualDocument1 pageBT90 - User ManualskgmonicaNo ratings yet

- TP-Link WiFi 6E AXE5400 PCIe WiFi Card - Installation ManualDocument2 pagesTP-Link WiFi 6E AXE5400 PCIe WiFi Card - Installation ManualhelpfulNo ratings yet

- IpcsyllabusDocument2 pagesIpcsyllabusapi-294874588No ratings yet

- Tale of Squirrel NutkinDocument23 pagesTale of Squirrel NutkinNgoc Tram NguyenNo ratings yet

- Ma034 RPDocument9 pagesMa034 RPkamal kannanNo ratings yet

- C1116-C1116M - 10aDocument7 pagesC1116-C1116M - 10aElder SantosNo ratings yet

- ModCon 75 Instruction Manual - enDocument79 pagesModCon 75 Instruction Manual - enRahul DevaNo ratings yet

- Bangalore Property Owners Attitude Towards The Property Tax Under Self-Assessment Scheme: A Kruskal Wallis Test AnalysisDocument6 pagesBangalore Property Owners Attitude Towards The Property Tax Under Self-Assessment Scheme: A Kruskal Wallis Test AnalysisIJAR JOURNALNo ratings yet

- Esws at 8edDocument7 pagesEsws at 8edAddy The humanNo ratings yet

- COMP 3620: Artificial Intelligence Jochen Renz: Knowledge Representation and Reasoning, Part 2: First-Order LogicDocument26 pagesCOMP 3620: Artificial Intelligence Jochen Renz: Knowledge Representation and Reasoning, Part 2: First-Order LogicMaleeha MobeenNo ratings yet

- A Jungian View of AstrologyDocument6 pagesA Jungian View of Astrologystilbone100% (3)

- NG Gan Zee v. Asian Crusader Life AssuranceDocument5 pagesNG Gan Zee v. Asian Crusader Life AssuranceJose Antonio BarrosoNo ratings yet

- V5 Digital Health Experience-ICT Award Presentation SlideDocument16 pagesV5 Digital Health Experience-ICT Award Presentation SlideJhon KevinNo ratings yet

- Maths Project Work For FA-4Document14 pagesMaths Project Work For FA-4Siddharth GautamNo ratings yet

- New 5. Sfe-Dst-Pip-1402-4105 DST For Needle ValveDocument3 pagesNew 5. Sfe-Dst-Pip-1402-4105 DST For Needle ValveSandeepNBabuNo ratings yet

- Lesson Plan CO3Document12 pagesLesson Plan CO3Giovanni QuevedoNo ratings yet

- Address of All HospitalsDocument31 pagesAddress of All HospitalsFUTURE IT100% (1)

- Madison County ScoresDocument2 pagesMadison County Scoresm100% (1)

- Img 20230215 0005Document1 pageImg 20230215 0005Hashir FaheemNo ratings yet

- Siemens Water Treatment GuideDocument8 pagesSiemens Water Treatment GuideKarthick VelayuthamNo ratings yet

- SAP Security Concepts Segregation of DutDocument36 pagesSAP Security Concepts Segregation of Duttardio pozoNo ratings yet

- Carel EVD +030220205Document10 pagesCarel EVD +030220205elshan_asgarovNo ratings yet

- DatasheetDocument9 pagesDatasheetjim campbellNo ratings yet