Professional Documents

Culture Documents

JSA Welding & Grinding

Uploaded by

taufikCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA Welding & Grinding

Uploaded by

taufikCopyright:

Available Formats

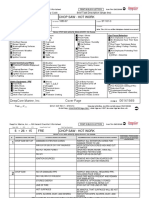

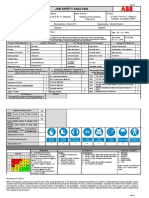

Job Safety Analysis - Risk Identification

Location: JSA Number:

Prepared By: Crews Reviewed By: Supervisor's

Date: Date:

No Form : L2-CI-CF-HSE-8-3

Complete page 1 & 2 prior to performing all work

1. DESCRIPTION OF WORK:

Complete page

1 for ship

2. HAZARD IDENTIFICATION Note: Yellow = Golden Rules

Exposure to ✓ Exposure to ✓ Exposure to or ✓ General Notes:

Energy: Substance: requirement for

Situations:

Electrical Acids/Alkalis Permit To Work 1) Inform Team Leader of work being conducted.

Mechanical Gases Energy Isolation 2) All work being done will follow and reference the relevant

Hydraulic Vapours Ground Disturbance Procedures.

Pneumatic Fumes Confined Space Entry 3) All Lifting operations must be managed in coordination with the

Steam Dangerous Goods Working At Heights Supervisor

4) All personnel involved in the operation must be part of the JSA

Pressure systems Hazardous Substances Lifting Operations

Heat Fibres Driving Safety Crew/ Personnel;

Noise Microbiological Management of Change Name Signature

Vibration Open Pits/floor plates

High Temperature Suspended Loads

Low Temperature Slippery Surfaces

Flames Workplace Lighting

Commissioning Of Plant

Emissions

3. PRECAUTIONS NOTE: Safety Helmet,

Engineering Controls Personal Protection

Permits Required Administrative Controls Emergency Management

✓ Required And In ✓ ✓ (PPE) Required and ✓ ✓

and in place: Required and In Place: Required and In Place:

Place: Available:

LOTO Fire Extinguishers Notify SLC Safety Helmet Personal Exposure Detectors

Cold Work Barricades Notify Team Leader Eye Protection Warning Devices

Confined Space Guarding Complete Site Induction Safety Footwear Man Down Alarm

Hot Work Housekeeping Observer/Buddy required Protective Gloves Process Control

Work at Heights System Purging Limited Duration Hearing protection Maintenance

Work over Water Mechanical Ventilation Work Instructions Respirator Inspection

Lifting Lighting Quality Control Coveralls Liquid Containment

Bunkering Scaffolding Assembly Points Impervious suit Air Emissions Control

Energy Isolations Alarms Harness Waste Minimisation

Safety Showers High Visibility Vest Emergency Access adequate

Breathing Apparatus Life Jacket Emergency escape route

Communications Chin Strap

Radiation Detector

Stiffy Sticks

Fall Arrestors

Page 1 Version 2.0 - July 2022

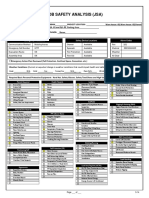

JSA - Risk Identification Eliminate Substitute Control Mitigate

Item No: STEPS HAZARDS POTENTIAL CONSEQUENCES CONTROLS

(Energy Sources) (Injury, illness, damage) (Consequence/ likelihood)

1 Persiapan alat Alat las tidak aman, short - Terbakar - Pre-Used Check welding machine

- Pre-Used Check grinding machine

- Ledakan - Welder terlatih

- Helper terlatih

- People Injury - PTW

2 Pengelasan Api terbuka - Terbakar - Sertifikasi welder

- Menggunakan Kap Las yang layak

Electrical - Tersengat listrik - Flash back arrester terpasang untuk tabung acetylene

dan oksigen

Sinar UV - Burnt Eye - Pastikan tidak ada bahan mudah terbakar di area

penngelasan

Incompetent Welder - Struktur Las buruk, kekuatan tidak maksimal - Batasi/Barikade area pengeleasan

- Siapkan alat pemadam api ringan, fire blanket

- People Injury

3 Penggerindaan Grinder Movement (Mechanical Energy) - People Injury - Personnel terlatih

- Gerinda dilengkapi safety guard

Percikan api - Terbakar - Pakai Faceshield

- Pastikan tidak ada bahan mudah terbakar di area

Api terbuka penngelasan

- Batasi/Barikade area pengeleasan

- Siapkan alat pemadam api ringan, fire blanket

4 Finishing dan Houskeeping Sumber panas - Bekas pengelasan dan gerinda terbakar - Fire Watch, keep monitor no open flame for 1 hour after

welding/grinding

Slip & Trip - Tersandung bahan dan alat kerja - Kembalikan alat pada tempatnya

- Bersihkan kembali area kerja

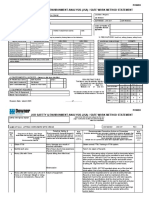

AAR; Action & Responsible Person of Every Step

RECOMMENDATION ACTION BY DUE DATE

Item Job Step

What Who When

1 Persiapan alat - Persiapan PTW

- Pre-Used Check welding machine

- Pre-Used Check grinding machine

2 Pengelasan - Menggunakan Kap Las yang layak

- Flash back arrester terpasang untuk tabung acetylene dan oksigen

- Pastikan tidak ada bahan mudah terbakar di area penngelasan

- Batasi/Barikade area pengeleasan

- Siapkan alat pemadam api ringan, fire blanket

3 Penggerindaan - Pakai Faceshield

- Pastikan tidak ada bahan mudah terbakar di area penngelasan

- Batasi/Barikade area pengeleasan

- Siapkan alat pemadam api ringan, fire blanket

4 Finishing & Housekeeping - Fire Watch, keep monitor no open flame for 1 hour after welding/grinding

- Kembalikan alat pada tempatnya

- Bersihkan kembali area kerja

Page 2 Version 2.0 - July 2022

You might also like

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisAndhy DhannyNo ratings yet

- Physical Hazard Control: Preventing Injuries in the WorkplaceFrom EverandPhysical Hazard Control: Preventing Injuries in the WorkplaceNo ratings yet

- Chop Saw PDFDocument3 pagesChop Saw PDFAnonymous YrCsoYgNo ratings yet

- JSA Analysis of Rudder Shaft Seal Tightening (less than 40 charsDocument2 pagesJSA Analysis of Rudder Shaft Seal Tightening (less than 40 charsIlya BordonosovNo ratings yet

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- HIRAforCOVID 19Document4 pagesHIRAforCOVID 19marvinNo ratings yet

- JSA Safety AnalysisDocument3 pagesJSA Safety AnalysisLusy Gusti EfendiNo ratings yet

- Job Safety AnalysisDocument13 pagesJob Safety AnalysisnagarjunaNo ratings yet

- Job Safety Analysis for Fabrication WorkDocument4 pagesJob Safety Analysis for Fabrication WorkAbhi SandiNo ratings yet

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- JSA G20 Scaffolding Erection DismantlingDocument4 pagesJSA G20 Scaffolding Erection DismantlingemmyNo ratings yet

- Crane Safety TipsDocument4 pagesCrane Safety Tipssetiawanaji407100% (1)

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With Cranesetiawanaji407No ratings yet

- STARRT CardDocument2 pagesSTARRT Cardsanny100% (1)

- Workplace Hazard Assessment Form: Task Hazard(s) PPE Required Notes DepartmentDocument2 pagesWorkplace Hazard Assessment Form: Task Hazard(s) PPE Required Notes DepartmentMashur Al JunaibiNo ratings yet

- JSA Installation-Fire-Alarm-SystemDocument12 pagesJSA Installation-Fire-Alarm-Systemuz9143895No ratings yet

- Job Safety Analysis for Instrument Sample Point InstallationDocument3 pagesJob Safety Analysis for Instrument Sample Point InstallationNasrullah JanNo ratings yet

- 1.0 Acts Hse Form 0001 Jsa 20120405 Rev 1 Company Job Safety Analysis FormDocument3 pages1.0 Acts Hse Form 0001 Jsa 20120405 Rev 1 Company Job Safety Analysis FormPaul BeephanNo ratings yet

- 2 - JSA Hot WorkDocument9 pages2 - JSA Hot WorkAijaz AhmedNo ratings yet

- Job Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisDocument25 pagesJob Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisFaraz KhalidNo ratings yet

- ERECTION, MODIFICATION & DISMANTLING OF SCAFFOLDING WORKS - Risk assessment - REV01Document10 pagesERECTION, MODIFICATION & DISMANTLING OF SCAFFOLDING WORKS - Risk assessment - REV01SolimanNo ratings yet

- JOB SAFETY ANALYSIS FOR WELDINGDocument2 pagesJOB SAFETY ANALYSIS FOR WELDINGSravan Dasari100% (3)

- Ewrc SHP Gen Hse Jsa 00040Document12 pagesEwrc SHP Gen Hse Jsa 00040Rickz CabaloNo ratings yet

- Site OrientationDocument2 pagesSite OrientationHitesh VaghasiyaNo ratings yet

- HSE Plan Ocon CommentsDocument4 pagesHSE Plan Ocon CommentsqaqqaqqNo ratings yet

- Lifting and Removing Using Unloading, Loading and Placing 0F Cable ReelsDocument3 pagesLifting and Removing Using Unloading, Loading and Placing 0F Cable ReelsAMINNo ratings yet

- JHA (Rev) - Install New Genset On SPLMDocument4 pagesJHA (Rev) - Install New Genset On SPLMAditya Permana PutraNo ratings yet

- TRA Strainer Cleaning 01Document7 pagesTRA Strainer Cleaning 01Ijaz Hussain0% (1)

- JSA - Drilling ActivitiesDocument4 pagesJSA - Drilling ActivitiesAMIN100% (1)

- Jsa - Hot TappingDocument15 pagesJsa - Hot TappingAmadeo Sabanal0% (1)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyanNo ratings yet

- JSA Loading & UnloadingDocument2 pagesJSA Loading & UnloadingSodikinNo ratings yet

- Jsa - Duck Bank InstallationDocument10 pagesJsa - Duck Bank InstallationAmadeo Sabanal100% (1)

- Jsa MV Cable Pulling, Termination and TestingDocument11 pagesJsa MV Cable Pulling, Termination and TestingMohammad AqilNo ratings yet

- iFUEL CON Risk AssessmentDocument3 pagesiFUEL CON Risk AssessmentHoang Quoc DungNo ratings yet

- JHA General Maintenance Activity PDFDocument5 pagesJHA General Maintenance Activity PDFdede SinbadNo ratings yet

- JRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaDocument8 pagesJRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaAijaz AhmedNo ratings yet

- Risk Assess JSA Derrick Flare Structure Installation Erection 018Document11 pagesRisk Assess JSA Derrick Flare Structure Installation Erection 018Abdeldjalil Ferhati100% (3)

- Employee safety risk analysisDocument6 pagesEmployee safety risk analysisVictor Thembinkosi MakhubeleNo ratings yet

- Megger Test ENDocument2 pagesMegger Test ENTilalNo ratings yet

- Packing Pumps New - FO-GL-HAL-HSE-0103FDocument4 pagesPacking Pumps New - FO-GL-HAL-HSE-0103FMohamed El-SawahNo ratings yet

- 11.pneumatic Pressure Testing.Document7 pages11.pneumatic Pressure Testing.Mohammad Fazal KhanNo ratings yet

- Backhoe WORK PLAN JsaDocument1 pageBackhoe WORK PLAN JsaMax McguireNo ratings yet

- Job Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisDocument7 pagesJob Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisSKH CultureNo ratings yet

- JSA Pipe Installation 2012Document2 pagesJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- Weekly site inspection summaryDocument2 pagesWeekly site inspection summaryDark FantasyNo ratings yet

- SWMS Crane 1711211774Document13 pagesSWMS Crane 1711211774Sarmad AbbasiNo ratings yet

- SWMS2 Confined Space EntryDocument9 pagesSWMS2 Confined Space EntryIslam Sarhan100% (1)

- JSEA Job Safety and Environmental Analysis Format SWMS 2 Oct 2020Document6 pagesJSEA Job Safety and Environmental Analysis Format SWMS 2 Oct 2020sarge18No ratings yet

- Workplace Hazard Identification & Assessment SheetDocument3 pagesWorkplace Hazard Identification & Assessment SheetTawsif Ahmed100% (1)

- TRA - Amine System Degreasing - October 14, 2018Document9 pagesTRA - Amine System Degreasing - October 14, 2018Ijaz HussainNo ratings yet

- CERI-JSA-2023-02 - JSA Hot WorksDocument12 pagesCERI-JSA-2023-02 - JSA Hot Worksdiaf bilalNo ratings yet

- Appendix A SPA FormDocument2 pagesAppendix A SPA FormMohamed HadjkacemNo ratings yet

- Heights Safe Working atDocument7 pagesHeights Safe Working atHendrias Ari SujarwoNo ratings yet

- Job Safety Analysis: Pembuatan Dinding PenahanDocument7 pagesJob Safety Analysis: Pembuatan Dinding PenahanAnnisa AgustinaNo ratings yet

- 1 - JSA Erectoin and Dismantling of ScaffoldingDocument5 pages1 - JSA Erectoin and Dismantling of ScaffoldingAijaz AhmedNo ratings yet

- Job Safety Analysis WitcoDocument2 pagesJob Safety Analysis WitcoOmega Chang'eNo ratings yet

- ACFrOgC0KOv5NUQ5bYAMTANTxFAWZz38Y05GJOPPKNqz0LbbUWq7pCgsvYcmv1COOGSSVaxbAoXEABf4zTZ N-TsX6Nrxp8x8U-b425aIwqxtBMUVNMS MTHXJQC U5Aocn IaX8O3qoEWGiv2DnDocument4 pagesACFrOgC0KOv5NUQ5bYAMTANTxFAWZz38Y05GJOPPKNqz0LbbUWq7pCgsvYcmv1COOGSSVaxbAoXEABf4zTZ N-TsX6Nrxp8x8U-b425aIwqxtBMUVNMS MTHXJQC U5Aocn IaX8O3qoEWGiv2DntaufikNo ratings yet

- TB-QA-201700002 - ISE CERTWEB LaunchDocument6 pagesTB-QA-201700002 - ISE CERTWEB LaunchtaufikNo ratings yet

- 11 HandtoolDocument66 pages11 Handtooliqbal syauqiNo ratings yet

- Elmar Product Catalogue PDFDocument258 pagesElmar Product Catalogue PDFbattakopapanteco100% (2)

- Wellheads Xmas Trees ValvesDocument29 pagesWellheads Xmas Trees ValvesAbdul Hameed OmarNo ratings yet

- Plusco400 Wireline Products Wireline Spray Wireline Corrosion InhibitorDocument1 pagePlusco400 Wireline Products Wireline Spray Wireline Corrosion InhibitortaufikNo ratings yet

- Daily Usage of Fuel Tank: Base: DateDocument4 pagesDaily Usage of Fuel Tank: Base: DatetaufikNo ratings yet

- Wellhead Adapter ListDocument6 pagesWellhead Adapter ListtaufikNo ratings yet

- Phuel Oil Tools PCE CatalogueDocument66 pagesPhuel Oil Tools PCE CataloguetaufikNo ratings yet

- SOP 1155 L.O.T.O. Machine Lockout ProceduresDocument11 pagesSOP 1155 L.O.T.O. Machine Lockout ProcedurestaufikNo ratings yet

- SOP 1155 L.O.T.O. Machine Lockout ProceduresDocument11 pagesSOP 1155 L.O.T.O. Machine Lockout ProcedurestaufikNo ratings yet

- Maintenance of Hand and Power Tools Procedure (VET)Document6 pagesMaintenance of Hand and Power Tools Procedure (VET)taufikNo ratings yet

- 1Document5 pages1qweqweNo ratings yet

- Manual Mta TemperaturaDocument2 pagesManual Mta TemperaturaChristian JacoboNo ratings yet

- 2narrative Essay - My Favorite TeacherDocument9 pages2narrative Essay - My Favorite TeacherHerbertKoh100% (1)

- Marketing Strategies Audit On Hewlett Packard (HP)Document19 pagesMarketing Strategies Audit On Hewlett Packard (HP)auraNo ratings yet

- Way Back To The BibleDocument19 pagesWay Back To The BiblePearlCladelLapidezNo ratings yet

- Rapid Web Development With Python/Django: Julian HillDocument37 pagesRapid Web Development With Python/Django: Julian Hilljppn33No ratings yet

- Review Relative Clauses, Articles, and ConditionalsDocument10 pagesReview Relative Clauses, Articles, and ConditionalsNgoc AnhNo ratings yet

- Excerpts From The Way of The Samurai (Shīdo) : Primary Source Document With Questions (DBQS)Document2 pagesExcerpts From The Way of The Samurai (Shīdo) : Primary Source Document With Questions (DBQS)Valeria MontalvaNo ratings yet

- MS6711 Data Mining Homework 1: 1.1 Implement K-Means Manually (8 PTS)Document6 pagesMS6711 Data Mining Homework 1: 1.1 Implement K-Means Manually (8 PTS)Yihan WangNo ratings yet

- G25M R TransmissionDocument29 pagesG25M R TransmissionMaksym VovkNo ratings yet

- Earned Value Analysis 8 StepsDocument8 pagesEarned Value Analysis 8 StepsHira RazzaqNo ratings yet

- Weekly TestDocument12 pagesWeekly Testrossana rondaNo ratings yet

- Brfo193 Radiotherapy Dose Fractionation Third-Edition PDFDocument137 pagesBrfo193 Radiotherapy Dose Fractionation Third-Edition PDFMed MedNo ratings yet

- Faktor OrganisasiDocument9 pagesFaktor OrganisasiNur Fatin NabilahNo ratings yet

- Resume-Mariam Abdul AzizDocument2 pagesResume-Mariam Abdul Azizmaryam cookNo ratings yet

- Letter of Request For Brgy. ProfileDocument2 pagesLetter of Request For Brgy. ProfileRhea Mae MacabodbodNo ratings yet

- LPI PH PDFDocument4 pagesLPI PH PDFHumberto Tapias CutivaNo ratings yet

- 14 Ways To Acquire KnowledgeDocument4 pages14 Ways To Acquire KnowledgeRenato MiguelNo ratings yet

- Outline of The Gospel of John: Book of Signs: Jesus Reveals His Glory To The World (Israel) (1:19-12:50)Document4 pagesOutline of The Gospel of John: Book of Signs: Jesus Reveals His Glory To The World (Israel) (1:19-12:50)Aamer JavedNo ratings yet

- Social Engineering For Pentester PenTest - 02 - 2013Document81 pagesSocial Engineering For Pentester PenTest - 02 - 2013Black RainNo ratings yet

- HZVDocument6 pagesHZVnurrozaqNo ratings yet

- Mil STD 882eDocument104 pagesMil STD 882ecihan dağNo ratings yet

- Regina Downtown Community Support Team ReportDocument28 pagesRegina Downtown Community Support Team ReportJeremy SimesNo ratings yet

- Biotensegrity and Myofascial Chains A Global Approach To An Integrated Kinetic ChainDocument8 pagesBiotensegrity and Myofascial Chains A Global Approach To An Integrated Kinetic ChainMohamed ElMeligieNo ratings yet

- An Engineer's Guide To Designing With Precision Amplifiers: E-BookDocument60 pagesAn Engineer's Guide To Designing With Precision Amplifiers: E-BookIan ChegeNo ratings yet

- Installation, Operation and Maintenance Instructions For 9957W Automatic Balancing ValveDocument2 pagesInstallation, Operation and Maintenance Instructions For 9957W Automatic Balancing ValveManuel Molina CamposNo ratings yet

- RAF Bomber Command March 1943Document4 pagesRAF Bomber Command March 1943catracho84No ratings yet

- Romeo and Julliet - Close Read AnalysisDocument5 pagesRomeo and Julliet - Close Read Analysisapi-514407929No ratings yet

- Strength and Serviceability of Hanger ConnectionsDocument12 pagesStrength and Serviceability of Hanger ConnectionsVitor OlivettiNo ratings yet