Professional Documents

Culture Documents

JSA Safety Analysis

Uploaded by

Lusy Gusti EfendiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA Safety Analysis

Uploaded by

Lusy Gusti EfendiCopyright:

Available Formats

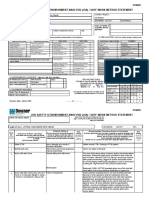

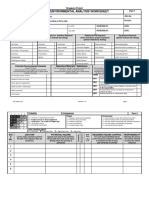

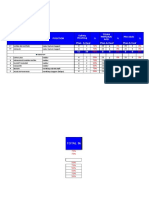

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA)

ACTIVITY OR TASK: Location / Project:

JSA Preparation & Job Number:

task work team: JSA Number: JSA Revision:

Competence = Relevant Training/Qualifications + Experience

Competence/ Qualific’n

Codes of Practice &

req’d to complete work

Legislation that are

safely

applicable:

JSA approved by Name: Position / Competence/ License: Date:

person responsible i.e.

Team Leader / Tradesman

2. HAZARD IDENTIFICATION Identify hazards that may be present by checking items on the list below. 3. PRECAUTIONS: hard hat, safety glasses, safety boots compulsory

WORK LOCATION HAZARDOUS AREA HIGH RISK HIGH RISK ADDITIONAL PRECAUTIONS PERMITS

Difficult Entry/Exit Hazardous Substances Falling Objects Suspended loads Gloves: typ0e: Hot Work

Oxygen Deficiency - attach MSDS to JSA Poor Lighting Poor Visibility Goggles Excavation

Oxygen Excess Working at Heights Slippery Surfaces Inhalable Dusts/Fibres Full Face Shield Confined Space

Engulfment (trench collapse) Remote Area Multiple Electrical Feeds High Noise Levels High Visibility Vest Hazardous Work Clearance

Poisonous Gas Present Motor Room Hazards Trip Hazards Use of Chemicals Harness Access to Area

Temperature Extremes Toxic Substances Electrical Hazards - LV Elevated Work Platform Fire Extinguishers High Voltage Access

Defined Confined Space Potential for Difficult Rescue Electrical Hazards - HV Difficulty to Communicate Barricades Scaffolding

Explosive Gas Present amongst workers Ventilation Other?

Manual Handling Moving Machinery Lighting

PERMIT NUMBER

HAZARDOUS SUBSTANCES in work area / to be used -attach MSDS Sharp Materials Tools & Equipment Erect Scaffolding to access

Ladders used in the task Heat/ Sunlight/ Radiation Respirator or Dust mask

Working at Heights Traffic Movement Erect Warning signs

Working near Crane & Working near Operation Personal Locks or Tag system

Crane Runways Processing Lines Group isolation

Rail Movement Live Rails Welding screen

Pressurised Fluids Pneumatics Fall Arrest systems

Flamm. Materials Present Welding Face Shield

4. ENVIRONMENTAL HAZARDS – (IMPACTS) check those identified Consequences: how severe an injury?

Likelihood:

Air Pollution (dust, fumes) Spills to ground Other: RISK RATING TABLE How likely is it to Death Serious Medical 1st Aid

This table is used to calculate whether be that bad? Injuries Treatment req’d

Noise (plant & equipment) Soil Erosion Req’d

the hazard you have identified is

Spills to drains/waterways Hazard to Flora /Fauna Extreme: 9-10 High: 7-8, Almost Certain - 10 9 8 7

Expected to Occur

Medium: 5-6 or Low: 3-4

Likely – could 9 8 7 6

5. EQUIPMENT REQUIRED: happen sometime

Static Plant & Equipment The objective of rating the risk is to lower the risk Moderate – could 8 7 6 5

by initiating risk control measures. The score is happen but not likely

Mobile Plant & Equipment noted in the JSA risk score column on the next Unlikely – could

page – both before & after risk control measures 7 6 5 4

Safety / Emergency Equip’t happen but very rare

have been nominated. Rare - could happen 6 5 4 3

but probably never will

Revision Date: January 2013 ………. of …………..

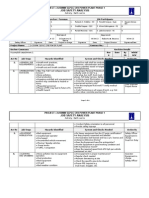

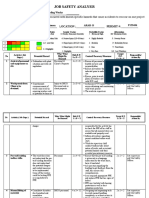

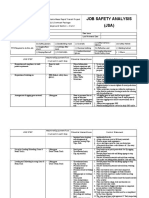

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA)

NAME OF TASK: JSA Number: Rev:

Potential Safety & Risk Recommended Corrective Action or Procedure Risk

Step Sequence of Basic Job Steps Environmental Hazards/Impacts Rating Determine what actions are necessary to eliminate or minimise all hazards that Rating

No. Break down Job into steps. Each step should Identify the hazards (health and safety or Use table on could lead to an accident, injury, illness or environmental incident. The risk must Of the risk

Logical accomplish a major task and be logical. environmental) associated with each step, the previous be reduced or controlled to a level that is acceptable before work commences. following

sequence

Environmental Aspects examine each to find all possible risk factors page to Indicate who is to perform the action where applicable against each action corrective

score risk action

Revision Date: January 2013 ………. of …………..

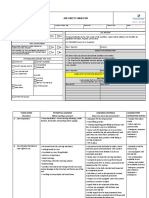

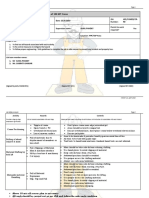

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA)

CONSULTATION & SIGN-OFF RECORD

I confirm by my signature below, that I have attended a briefing on the requirements of the attached Job Safety &

Environment Analysis and agree to perform the work in the manner detailed on it.

I confirm that copies of the relevant Permits, MSDS's, Isolation Plans etc. have been reviewed.

Rev:

JSA NAME JSA No:

NAME (Please print) SIGNATURE DATE

THIS SAFE WORK BRIEFING / TRAINING WAS CARRIED OUT BY (responsible person at that location) :

Name: Signature: Date:

Client sign off (where applicable)

Site / Project Manager sign off (document reviewed)

Revision Date: January 2013

You might also like

- JSA G20 Scaffolding Erection DismantlingDocument4 pagesJSA G20 Scaffolding Erection DismantlingemmyNo ratings yet

- Crane Safety TipsDocument4 pagesCrane Safety Tipssetiawanaji407100% (1)

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- 2014 Energized Electrical Work Permit - ByU-IdahoDocument2 pages2014 Energized Electrical Work Permit - ByU-Idahocarrot123456No ratings yet

- JSA PRE-TEST UploadDocument2 pagesJSA PRE-TEST UploadDenny Kurniawan PrawiraNo ratings yet

- Job Safety Analysis FormDocument4 pagesJob Safety Analysis FormMohammed NayeemuddinNo ratings yet

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 pagesJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNo ratings yet

- JSA For New EmployeesDocument20 pagesJSA For New EmployeesNilayNo ratings yet

- JSA ProjectDocument4 pagesJSA ProjectbrantasNo ratings yet

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikNo ratings yet

- Job Safety Analysis: How To Use This FormDocument4 pagesJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- Jsa For TIE INS in Accommodation BlockDocument4 pagesJsa For TIE INS in Accommodation BlockAliNo ratings yet

- Jsa FormDocument3 pagesJsa Formmiaicarba100% (1)

- JHA For Installation 2 Inch Nozzle..Document6 pagesJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel FactorNo ratings yet

- JSA FormDocument4 pagesJSA Formpharhuntrun100% (2)

- 2x150MW Power Plant JSA for Excavation WorkDocument4 pages2x150MW Power Plant JSA for Excavation WorkRen SalazarNo ratings yet

- FINAL Shivani Confined Space PermitDocument1 pageFINAL Shivani Confined Space PermitVimal SinghNo ratings yet

- Pre-Job Safety Assessment ChecklistDocument2 pagesPre-Job Safety Assessment Checklistgueettaf faresNo ratings yet

- Permit To Work EOH-SP-FORM 531.01Document2 pagesPermit To Work EOH-SP-FORM 531.01Brad EubankNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNo ratings yet

- 07 - Tata Power Scaffold Safety ProcedureDocument24 pages07 - Tata Power Scaffold Safety Procedurehse bsjNo ratings yet

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- Catalyst Filling & SeggregationDocument3 pagesCatalyst Filling & SeggregationMohammed MinhajNo ratings yet

- JSA Gasket & StudboltsDocument1 pageJSA Gasket & StudboltsKarl WilliamsNo ratings yet

- Jsa Bearing Replacement-OverhaulingDocument2 pagesJsa Bearing Replacement-Overhaulingashish engineeringNo ratings yet

- JHA For Steam PipingDocument17 pagesJHA For Steam PipingM8Rskn6wcNo ratings yet

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,No ratings yet

- 972 99 100 (Mobile) : Job Safety AnalysisDocument8 pages972 99 100 (Mobile) : Job Safety AnalysisSreeraj Reghunathan Nair VanmazhyNo ratings yet

- Petrochina International Jabung LTD.: Job Safety AnalysisDocument4 pagesPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNo ratings yet

- EHS-GF-02 A Safety InductionDocument1 pageEHS-GF-02 A Safety Inductionshamshad ahamedNo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- Job Safety Analysis for Right-of-Way ClearingDocument5 pagesJob Safety Analysis for Right-of-Way ClearingMoaatazz Nouisri100% (1)

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Blank Form (Jsea)Document4 pagesBlank Form (Jsea)MinMin100% (2)

- JSA Steel Structure FabricationDocument8 pagesJSA Steel Structure FabricationArib RahmanNo ratings yet

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiNo ratings yet

- Job Safety Analysis for High Pressure TestingDocument5 pagesJob Safety Analysis for High Pressure TestingSaiyad RiyazaliNo ratings yet

- Using Hand Drill (WS)Document2 pagesUsing Hand Drill (WS)John KalvinNo ratings yet

- Lifting Support Risk AssessmentDocument10 pagesLifting Support Risk AssessmentcitraNo ratings yet

- JHA for Hill Cutting Activities at Port of SalalahDocument8 pagesJHA for Hill Cutting Activities at Port of SalalahSreekumarNo ratings yet

- Excavation Permit FormDocument2 pagesExcavation Permit FormKarim KachourNo ratings yet

- Technical Drilling SafetyDocument4 pagesTechnical Drilling SafetyjihadspiritNo ratings yet

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- Mig Welding JSADocument2 pagesMig Welding JSANoval Febri100% (1)

- JSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentDocument4 pagesJSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentMohammed Minhaj100% (1)

- Pipe Lowering JHADocument6 pagesPipe Lowering JHASalam AlkataluniNo ratings yet

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 pagesCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaNo ratings yet

- JSA Lifting With Equipment+Load ChartDocument13 pagesJSA Lifting With Equipment+Load ChartBoas BoetarzNo ratings yet

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- HIRA-22 Logistic & Commissioning Activity OKDocument8 pagesHIRA-22 Logistic & Commissioning Activity OKadityajailani19No ratings yet

- AL AIN MALL WORK PERMITDocument1 pageAL AIN MALL WORK PERMITVeterano 1968No ratings yet

- Pre Commissioning Electrical EquipmentDocument4 pagesPre Commissioning Electrical Equipmentmohammed a hseNo ratings yet

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With Cranesetiawanaji407No ratings yet

- JSA - Scissor - Lift 2023Document4 pagesJSA - Scissor - Lift 2023syed khaja misbhuddinNo ratings yet

- Job Safety Analysis for Instrument Sample Point InstallationDocument3 pagesJob Safety Analysis for Instrument Sample Point InstallationNasrullah JanNo ratings yet

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- JSA For Lift Personnel in Scissor LiftDocument6 pagesJSA For Lift Personnel in Scissor Liftnawalmaftah23No ratings yet

- Book 1Document2 pagesBook 1Lusy Gusti EfendiNo ratings yet

- Resolution Mepc.196Document8 pagesResolution Mepc.196captaksahNo ratings yet

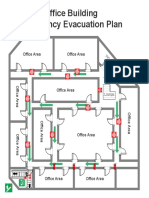

- Emergency Evacuation PlanDocument1 pageEmergency Evacuation PlanAnonymous zwSP5gvNo ratings yet

- Form Rev.0 Tabel Pengukuran GasDocument3 pagesForm Rev.0 Tabel Pengukuran GasLusy Gusti EfendiNo ratings yet

- AbsenDocument15 pagesAbsenLusy Gusti EfendiNo ratings yet

- JKKKKKDocument1 pageJKKKKKLusy Gusti EfendiNo ratings yet

- IndoxxiDocument1 pageIndoxxiLusy Gusti EfendiNo ratings yet

- JKKKKKDocument1 pageJKKKKKLusy Gusti EfendiNo ratings yet

- IndoxxiDocument1 pageIndoxxiLusy Gusti EfendiNo ratings yet

- Template Contoh HSE PlanDocument31 pagesTemplate Contoh HSE PlanAndi MuliadiNo ratings yet

- Kaluga Me STBDDocument8 pagesKaluga Me STBDLusy Gusti EfendiNo ratings yet

- Operator's Manual: iERP: 129535 D6558/0 (English) © BW Technologies 2010. All Rights ReservedDocument22 pagesOperator's Manual: iERP: 129535 D6558/0 (English) © BW Technologies 2010. All Rights ReservedLusy Gusti EfendiNo ratings yet

- Template Contoh HSE PlanDocument31 pagesTemplate Contoh HSE PlanAndi MuliadiNo ratings yet

- Template Contoh HSE PlanDocument9 pagesTemplate Contoh HSE PlanLusy Gusti EfendiNo ratings yet

- Candidate Declaration: Pump Damage Based On Calculation of Head Pump and Water Hammer in LPG Plant TambunDocument1 pageCandidate Declaration: Pump Damage Based On Calculation of Head Pump and Water Hammer in LPG Plant TambunLusy Gusti EfendiNo ratings yet

- Approval IV - VDocument2 pagesApproval IV - VLusy Gusti EfendiNo ratings yet

- Approval IV - VDocument2 pagesApproval IV - VLusy Gusti EfendiNo ratings yet

- Hydraulic Pump PDFDocument20 pagesHydraulic Pump PDFLusy Gusti EfendiNo ratings yet

- Intro Under Balanced DrillDocument50 pagesIntro Under Balanced DrillLusy Gusti EfendiNo ratings yet

- 2024 CVS1 K12 Hipertensi Essensial 2Document46 pages2024 CVS1 K12 Hipertensi Essensial 2Ken HutaurukNo ratings yet

- End of Life CareDocument80 pagesEnd of Life CareRakesh MohanNo ratings yet

- THERA DWI K. (202010230311349/G) : Read The Text Carefully and Answer The QuestionsDocument2 pagesTHERA DWI K. (202010230311349/G) : Read The Text Carefully and Answer The Questionsthera dwiNo ratings yet

- Laboratory Health and Safety HandbookDocument88 pagesLaboratory Health and Safety HandbookEugenNo ratings yet

- Nursing Theories Goal AttainmentDocument9 pagesNursing Theories Goal AttainmentAmbili AneeshaNo ratings yet

- Concept Map PedsDocument6 pagesConcept Map Pedsapi-546398486No ratings yet

- Appendix 1 Nursing DiagnosisDocument5 pagesAppendix 1 Nursing Diagnosisscribd2No ratings yet

- Social WorkDocument843 pagesSocial WorkAnanta Chalise100% (1)

- NSTP Silm 21 22Document120 pagesNSTP Silm 21 22Tip TapNo ratings yet

- NZ Mini-ACE Administration and Scoring Guide 2020Document6 pagesNZ Mini-ACE Administration and Scoring Guide 2020madalinaNo ratings yet

- C. Mobilization of Essential Items (Ie. PPE, Alcohol, Disinfectant, Etc.) (5%)Document8 pagesC. Mobilization of Essential Items (Ie. PPE, Alcohol, Disinfectant, Etc.) (5%)Rolando ValdezNo ratings yet

- Food, Nutrition and Occupational Health: Postgraduate Study 2022Document40 pagesFood, Nutrition and Occupational Health: Postgraduate Study 2022issac jettoNo ratings yet

- Unit Test 4A ExtendedDocument2 pagesUnit Test 4A ExtendedМарія МалерикNo ratings yet

- ERAS & TTSH Experience - Indonesia 2019 JakartaDocument79 pagesERAS & TTSH Experience - Indonesia 2019 JakartaFransisca Dewi KumalaNo ratings yet

- Hyasol PF MsdsDocument8 pagesHyasol PF MsdsBrayan MerchanNo ratings yet

- Outpatient High-Dose-Rate Brachytherapy For Cervical Cancer in The Radiation DepartmentDocument6 pagesOutpatient High-Dose-Rate Brachytherapy For Cervical Cancer in The Radiation DepartmentasclepiuspdfsNo ratings yet

- Final Pico Question InformaticsDocument5 pagesFinal Pico Question Informaticsapi-310396820No ratings yet

- Ppe and First AidDocument5 pagesPpe and First Aidjela rose camilonNo ratings yet

- The Nadi Vigyan by DR - Sharda Mishra MD (Proff. in Jabalpur Ayurved College)Document5 pagesThe Nadi Vigyan by DR - Sharda Mishra MD (Proff. in Jabalpur Ayurved College)Vivek PandeyNo ratings yet

- Physical DisabilitiesDocument11 pagesPhysical DisabilitiesBobo Wong100% (2)

- Flash Cards Vocab For Exam 1. Jarvis CH 1-3, 8, 9, 12, 13http - P.quizlet - Com - Settitle Health Assessment Vocab For Exam 1Document22 pagesFlash Cards Vocab For Exam 1. Jarvis CH 1-3, 8, 9, 12, 13http - P.quizlet - Com - Settitle Health Assessment Vocab For Exam 1tipredd100% (1)

- Mental Health Access For ChildrenDocument29 pagesMental Health Access For ChildrenEmily EresumaNo ratings yet

- CSR CADILA HEALTHCARE LTDDocument7 pagesCSR CADILA HEALTHCARE LTDsaurabhNo ratings yet

- Ted CubeDocument6 pagesTed Cubeinfo7615No ratings yet

- Saving Lives Averting CostsDocument79 pagesSaving Lives Averting CostsMedCR1987No ratings yet

- 4TH P. T. Mapeh 2016Document5 pages4TH P. T. Mapeh 2016Felita Daya0% (1)

- Midyear Training CADCA MYTI14 - Program - FinalDocument48 pagesMidyear Training CADCA MYTI14 - Program - FinalRuss BelvilleNo ratings yet

- 3911515Document1 page3911515Gemmelle CangcoNo ratings yet

- Jawaban Tutorial Blok 22 IkmDocument8 pagesJawaban Tutorial Blok 22 IkmAryaMaulanaNo ratings yet

- The Future of HR Is RH...Document16 pagesThe Future of HR Is RH...Pedro ResendeNo ratings yet