Professional Documents

Culture Documents

JSA G20 Scaffolding Erection Dismantling

Uploaded by

emmyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA G20 Scaffolding Erection Dismantling

Uploaded by

emmyCopyright:

Available Formats

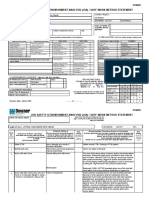

POWER

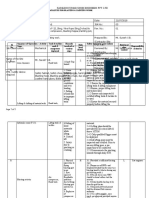

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

Location / Project:

ACTIVITY OR TASK: Scaffolding (Erection and Dismantling)

JSA Preparation & Job Number:

task work team: JSA Number: G20 JSA Revision:

Competence = Relevant Training/Qualifications + Experience

Competence/ Qualific’n

Codes of Practice &

req’d to complete work

Legislation that are

safely

applicable:

JSA approved by person Name: Position / Competence/ License: Date:

responsible i.e. Team

Leader / Tradesman

2. HAZARD IDENTIFICATION Identify hazards that may be present by ticking items on the list below. 3. PRECAUTIONS: hard hat, safety glasses, safety boots compulsory

WORK LOCATION HAZARDOUS AREA HIGH RISK HIGH RISK ADDITIONAL PRECAUTIONS PERMITS

Difficult Entry/Exit Hazardous Substances Falling Objects Suspended loads Gloves: type …………………. Hot Work

Oxygen Deficiency - attach MSDS to JSA Poor Lighting Poor Visibility Goggles Excavation

Oxygen Excess Working at Heights Slippery Surfaces Inhalable Dusts/Fibres Full Face Shield Confined Space

Engulfment (trench collapse) Remote Area Multiple Electrical Feeds High Noise Levels High Visibility Vest Hazardous Work Clearance

Poisonous Gas Present Motor Room Hazards Trip Hazards Use of Chemicals Harness Access to Area

Temperature Extremes Toxic Substances Electrical Hazards - LV Elevated Work Platform Fire Extinguishers High Voltage Access

Defined Confined Space Potential for Difficult Rescue Electrical Hazards - HV Difficulty to Communicate Barricades Scaffolding

Explosive Gas Present amongst workers Ventilation Other?

Manual Handling Moving Machinery Lighting

Permit Number

HAZARDOUS SUBSTANCES in work area / to be used -attach MSDS Sharp Materials Tools & Equipment Erect Scaffolding to access

Ladders used in the task Heat/ Sunlight/ Radiation Respirator or Dust mask

Working at Heights Traffic Movement Erect Warning signs

Working near Crane & Working near Operation Personal Locks or Tag system

Crane Runways Processing Lines Group isolation

Rail Movement Live Rails Welding screen

Pressurised Fluids Pneumatics Fall Arrest systems

Flamm. Materials Present Welding Face Shield

4. ENVIRONMENTAL HAZARDS – (IMPACTS) tick those identified

Likelihood: Consequences: how severe an

Air Pollution (dust, fumes) Spills to ground Other: RISK RATING TABLE injury?

How likely is it to

This table is used to calculate whether

Noise (plant & equipment) Soil Erosion be that bad? Death Serious Medical 1st Aid

the hazard you have identified is Injuries Treatment req’d

Spills to drains/waterways Hazard to Flora /Fauna Extreme: 9-10 High: 7-8, Req’d

Medium: 5-6 or Low: 3-4 Almost Certain - 10 9 8 7

Expected to Occur

5. EQUIPMENT REQUIRED:

Likely – could

The objective of rating the risk is to lower the risk 9 8 7 6

Static Plant & Equipment happen sometime

by initiating risk control measures. The score is

Mobile Plant & Equipment Moderate – could

noted in the JSA risk score column on the next 8 7 6 5

happen but not likely

page – both before & after risk control measures

Safety / Emergency Equip’t Unlikely – could

have been nominated. 7 6 5 4

happen but very rare

Rare - could 6 5 4 3

happen but probably

never will

Revision Date: March 2005 ………. of ………….. OHS-03-F01

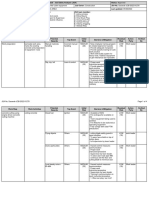

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

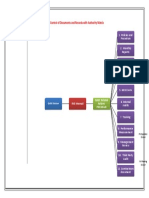

NAME OF TASK: Scaffolding (Erection and Dismantling) JSA Number: G20 Rev:

Potential Safety & Risk Recommended Corrective Action or Procedure Risk

Step Sequence of Basic Job Steps Environmental Hazards/Impacts Rating Determine what actions are necessary to eliminate or minimise all hazards that Rating

No. Break down Job into steps. Each step should Identify the hazards (health and safety or Use table on could lead to an accident, injury, illness or environmental

Of the risk

Logical accomplish a major task and environmental) associated with each step, the previous incident. The risk must be reduced or controlled to a level following

sequence

be logical. examine each to find all possible risk factors page to that is acceptable before work commences. corrective

score risk Indicate who is to perform the action where applicable against each action action

Environmental Aspects

1 Site Inspection Injury as a result of exposure to Be aware of and plan escape routes. Be aware of wind.

substances released due to

equipment failure

Slips, Trips and Falls due to Due care and attention.

slippery surfaces, obstructions,

restricted access.

Injury due to equipment failure, Liaise with permit authority / operations to minimize exposure to

moving equipment, activity and creation of hazards.

2 Raise Permit Stress and frustration due to Ensure all information supplied is as accurate and

incorrect information misdirecting understandable as possible.

efforts

3 Transport scaffold equipment to site Injury/damage related to vehicle Use correct vehicle and handling procedures

operation and equipment handling

Injury / damage due to collision / Plan route to avoid other personnel and equipment

impact with other workgroups /

equipment

Injury / damage as a result of Use appropriate barricades and bunting to protect personnel and

dropping tools and scaffold equipment

components

4 Erect scaffolding Hot and cold burns as a result of Adequate PPE with correct instruction and use.

contact with pipework

Injury due to limited egress in Ensure scaffold has adequate egress for any situation.

emergency

Injury / damage as a result of Use appropriate barricades and bunting to protect personnel and

dropping tools and scaffold equipment

components

Injury / damage due to scaffold Erect and dismantle all scaffold to comply with all legal and site

collapse requirements.

Injury / damage due to damaged All components to be checked prior to installation

components causing equipment

failure

Revision Date: March 2005 ………. of ………….. OHS-03-F01

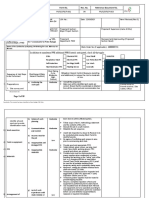

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

Injury / damage caused by scaffold Check specified limits of scaffold before utilization

collapse due to excessive load on

scaffold

Injury / damage due to scaffolding Scaffold must only be erected by trained personnel

erected by unauthorized personnel

Injury / damage caused by Licenced scaffolder to supervise apprentices at all times

scaffolding erected by persons with

limited competency

Injury / damage caused by Use appropriate barricades and bunting to protect personnel and

personnel falling from scaffolding equipment. Use IFAS harness.

Injury / damage caused by persons Use independent fall arrest system. 1.8m fall limit and standby

falling whilst working outside person precautions

scaffolding

5 Handover of scaffold Injury as a result of incomplete Check scaffold properly before attaching scafftag. Tag must be

scaffold, loose boards, kickplates, signed by qualified person. Use scaffold checklist.

etc causing slips,trips and falls

6 Dismantle scaffold Excess scaffold components cause Stack scaffold gear in stillage and remove from site. Keep site

clutter. Injury results. clean

Injury results from untidy worksite Keep worksite clean and tidy at all times to reduce hazards to a

minimum

Injury / damage caused by falling Inspect scaffold to ensure it is clear of debris before turning

objects boards and dismantling

Injury / damage caused by incorrect Correct procedure for dismantling of scaffold is adhered to.

sequence of dismantling

Revision Date: March 2005 ………. of ………….. OHS-03-F01

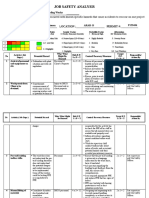

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA)

CONSULTATION & SIGN-OFF RECORD

I confirm by my signature below, that I have attended a briefing on the requirements of the attached Job Safety &

Environment Analysis and agree to perform the work in the manner detailed on it.

I confirm that copies of the relevant Permits, MSDS's, Isolation Plans etc. have been reviewed.

Rev:

JSA NAME JSA No:

NAME (Please print) SIGNATURE DATE

THIS SAFE WORK BRIEFING / TRAINING WAS CARRIED OUT BY (responsible person at that location) :

Name: Signature: Date:

Client sign off (where applicable)

Site / Project Manager sign off (document reviewed)

Revision Date: March 2005 OHS-03-F01

You might also like

- Job Safety & Environment Analysis (Jsa) : Activity or TaskDocument3 pagesJob Safety & Environment Analysis (Jsa) : Activity or TaskLusy Gusti EfendiNo ratings yet

- JSA G17 Lift Container With Crane PDFDocument4 pagesJSA G17 Lift Container With Crane PDFsetiawanaji407100% (1)

- JSA - Blasting & PaintingDocument11 pagesJSA - Blasting & PaintingRajuNo ratings yet

- JSA Hand ToolsDocument1 pageJSA Hand ToolsInoy dy hesusNo ratings yet

- Risk Assessment-Instllation & Fabrication of Steel Structural WorkDocument3 pagesRisk Assessment-Instllation & Fabrication of Steel Structural WorkKono Nor AtanNo ratings yet

- Rock BreakingDocument1 pageRock BreakingGyanendra Narayan NayakNo ratings yet

- JHA Formation Preparation or Leveling.Document2 pagesJHA Formation Preparation or Leveling.Mark Buendia100% (1)

- TEIPL-JSA-021 Working at Height, Scaffolding R1Document5 pagesTEIPL-JSA-021 Working at Height, Scaffolding R1ba ratnaparkheNo ratings yet

- Shifting of Materials by Double HydraDocument1 pageShifting of Materials by Double HydraShahid RazaNo ratings yet

- JS A Excavation Work For Electrical CableDocument3 pagesJS A Excavation Work For Electrical CableMohammed MinhajNo ratings yet

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikNo ratings yet

- Job Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Document5 pagesJob Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Madhan KannanNo ratings yet

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDocument13 pagesJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezNo ratings yet

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- Job Hazard Analysis For Cementitious GroutingDocument8 pagesJob Hazard Analysis For Cementitious Groutingaloysius akpanNo ratings yet

- WBS & Pre-Job Risk Assessment: (Low/Medium/ High)Document8 pagesWBS & Pre-Job Risk Assessment: (Low/Medium/ High)Ahmed KhalifaNo ratings yet

- Job Safety Assessment (Jsa)Document19 pagesJob Safety Assessment (Jsa)Saravanan Sara0% (1)

- AHA-009, Construction & Removing FormsDocument4 pagesAHA-009, Construction & Removing FormsBuddhikaNo ratings yet

- Jsa Loading and Unloading of Pile PipesDocument4 pagesJsa Loading and Unloading of Pile PipesOsiobe Ewomazino100% (1)

- Petrochina International Jabung LTD.: Job Safety AnalysisDocument4 pagesPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNo ratings yet

- File - 20200905 - 105458 - Jsa Wind PowerDocument10 pagesFile - 20200905 - 105458 - Jsa Wind PowerMon Trang NguyễnNo ratings yet

- Concrete Cutting JsaDocument4 pagesConcrete Cutting JsaMohammad Irfan Kiki IsmailNo ratings yet

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- JHA (Excavation of IPS Rev. B)Document4 pagesJHA (Excavation of IPS Rev. B)Armando AballeNo ratings yet

- JSA Topographic SurveyDocument3 pagesJSA Topographic Surveyhermawan tjipto saputroNo ratings yet

- Job Safety Analysis (JSA) : Description Hazard ControlDocument3 pagesJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrNo ratings yet

- Job Safety Analysis: Manual ExcavationDocument2 pagesJob Safety Analysis: Manual Excavationfdfddf dfsdfNo ratings yet

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,No ratings yet

- Job Hazard Analysis - Granite Surface PlateDocument2 pagesJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNo ratings yet

- JSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Document15 pagesJSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Habib ur rahmanNo ratings yet

- JSA For Erection & Dismantling of ScaffoldingDocument4 pagesJSA For Erection & Dismantling of ScaffoldingNoe AranelNo ratings yet

- Working at Height - JHA-1Document13 pagesWorking at Height - JHA-1Burhan KhanNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNo ratings yet

- Hira RCC Cement MillDocument2 pagesHira RCC Cement MillRajuNo ratings yet

- JSA Pipe Installation 2012Document2 pagesJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- Lifting Permit PermitDocument1 pageLifting Permit PermitHSE Health Safety EnvironmentNo ratings yet

- Confined Space Entry For Painting Inside PontoonDocument4 pagesConfined Space Entry For Painting Inside PontoonAchalere Shekhar KashinathNo ratings yet

- Job Hazard Analysis (Jha) Worksheet: Body Injury 2 2 4 1 1 1 AcceptableDocument2 pagesJob Hazard Analysis (Jha) Worksheet: Body Injury 2 2 4 1 1 1 Acceptableganeshkanth0% (1)

- JSA - Dismantling CM ShedDocument4 pagesJSA - Dismantling CM ShedvivekaramanaNo ratings yet

- Jsa PaintDocument2 pagesJsa PaintKhalid NaseemNo ratings yet

- 23 JSA For Block WorkDocument2 pages23 JSA For Block WorkWakil AhmadNo ratings yet

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Excavation, Trenching & Pot HolingDocument1 pageExcavation, Trenching & Pot HolingHafiz SabriNo ratings yet

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1Sanjeet SinghNo ratings yet

- Project JHA For Grading Compacting WorksDocument27 pagesProject JHA For Grading Compacting WorksBasker Balu100% (1)

- (SWMS - 04) Carpentry Work Temporary & PermanentDocument6 pages(SWMS - 04) Carpentry Work Temporary & PermanentPRATEEK SINGHNo ratings yet

- Ra FormDocument5 pagesRa FormEngrHazrat MaazNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- 0019 JSA Crane LiftingDocument4 pages0019 JSA Crane LiftingViron Baxhia100% (1)

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- JSA Lifting With Equipment+Load ChartDocument13 pagesJSA Lifting With Equipment+Load ChartBoas BoetarzNo ratings yet

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With Cranesetiawanaji407No ratings yet

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- JSA - Scissor - Lift 2023Document4 pagesJSA - Scissor - Lift 2023syed khaja misbhuddinNo ratings yet

- FMD Control of Documents and Records With Authority Matrix: Facilities Maintenance Department FilesDocument1 pageFMD Control of Documents and Records With Authority Matrix: Facilities Maintenance Department FilesemmyNo ratings yet

- Health Assessment Statistics-As of 31 March-2018Document1 pageHealth Assessment Statistics-As of 31 March-2018emmyNo ratings yet

- Safety Violation Report and Corrective Action: Location: Description of DeficiencyDocument1 pageSafety Violation Report and Corrective Action: Location: Description of DeficiencyemmyNo ratings yet

- Lusail Stadium Steel Structure Works Preliminary Schedule: Mobilization DemobilizationDocument4 pagesLusail Stadium Steel Structure Works Preliminary Schedule: Mobilization DemobilizationemmyNo ratings yet

- HSE Weekly Report-On 5 April-2018Document4 pagesHSE Weekly Report-On 5 April-2018emmy100% (1)

- READ ME (Unison MIDI Chord Pack Setup Instructions)Document1 pageREAD ME (Unison MIDI Chord Pack Setup Instructions)emmyNo ratings yet

- Generic Risk Assessment For Use Of: Tower Scaffolds: Estates FacilitiesDocument8 pagesGeneric Risk Assessment For Use Of: Tower Scaffolds: Estates FacilitiesemmyNo ratings yet

- 5 IRCA Code of ConductDocument1 page5 IRCA Code of ConductemmyNo ratings yet

- 4 Course AgendaDocument2 pages4 Course AgendaemmyNo ratings yet

- SOP For Preventive Maintenance (Electric) PDFDocument3 pagesSOP For Preventive Maintenance (Electric) PDFemmy100% (2)

- Scaffold MobileDocument15 pagesScaffold MobileemmyNo ratings yet

- Ra-27 Covid-19 01 PDFDocument4 pagesRa-27 Covid-19 01 PDFemmyNo ratings yet

- Nov 2019 Daily Report Form DXBDocument15 pagesNov 2019 Daily Report Form DXBemmyNo ratings yet

- 16.7 Scaffolding Rev 4Document6 pages16.7 Scaffolding Rev 4emmyNo ratings yet

- Sample Examination Questions 2015 - 0 PDFDocument21 pagesSample Examination Questions 2015 - 0 PDFemmyNo ratings yet

- CFR 1926.450 - SUBPART L ScaffoldsDocument21 pagesCFR 1926.450 - SUBPART L ScaffoldsemmyNo ratings yet

- Risk Assessment Guide Ref No. 69 Assessment For: LEAD BURNING/PLUMBING WORK - Lead Burning (Welding) of Lead Sheet or Pipe Significant RisksDocument6 pagesRisk Assessment Guide Ref No. 69 Assessment For: LEAD BURNING/PLUMBING WORK - Lead Burning (Welding) of Lead Sheet or Pipe Significant RisksemmyNo ratings yet

- ScaffoldDocument1 pageScaffoldemmyNo ratings yet

- Business Ethics PDFDocument16 pagesBusiness Ethics PDFRitika DiwakarNo ratings yet

- Sapient Paper On 11Th April, 2008Document12 pagesSapient Paper On 11Th April, 2008rayorizNo ratings yet

- Multiplexers DemultiplexersDocument17 pagesMultiplexers Demultiplexerslvsaru100% (1)

- Coneplot (20170407)Document30 pagesConeplot (20170407)LinggaNo ratings yet

- Acer V193 Service ManualDocument46 pagesAcer V193 Service Manualagun92No ratings yet

- 02 Samss 009Document13 pages02 Samss 009barouniamineNo ratings yet

- 10D Unit-Coral Reefs PDFDocument14 pages10D Unit-Coral Reefs PDFIWAN KUNCORONo ratings yet

- Probability DistributionsDocument167 pagesProbability DistributionslihaiyangNo ratings yet

- K230F Equipment ManualsDocument166 pagesK230F Equipment ManualsHui ChenNo ratings yet

- 5 Ijcms-V3i2-2012-02Document6 pages5 Ijcms-V3i2-2012-02saiNo ratings yet

- DS-KH6320-TE1 Video Intercom Network Indoor Station: Key FeatureDocument3 pagesDS-KH6320-TE1 Video Intercom Network Indoor Station: Key FeatureDaniellMargaritNo ratings yet

- 5 Dysfunctions of A TeamDocument5 pages5 Dysfunctions of A TeamSreejit Menon100% (2)

- H-330 Field Installation Manual IndexDocument11 pagesH-330 Field Installation Manual IndexRamon JimenezNo ratings yet

- How To "Revert-Back" To "Previous-Version"???: Build 1 Testing DeploymentDocument19 pagesHow To "Revert-Back" To "Previous-Version"???: Build 1 Testing DeploymentClaudiu Stefan HaiduNo ratings yet

- Cover Modul 4 TMJ 2012Document7 pagesCover Modul 4 TMJ 2012Haura Nadya AmaliaNo ratings yet

- PW160-7K S 0411Document890 pagesPW160-7K S 0411ado_22100% (3)

- Canon Ir8070 Error Codes List PDFDocument18 pagesCanon Ir8070 Error Codes List PDFGirish KumarNo ratings yet

- En 4j2 4fDocument71 pagesEn 4j2 4fRafael HernandezNo ratings yet

- Sex Quiz ResultsDocument1 pageSex Quiz Resultsapi-285789748No ratings yet

- Nasution 2019 J. Phys. Conf. Ser. 1235 012115Document8 pagesNasution 2019 J. Phys. Conf. Ser. 1235 012115RiswanHariantoNo ratings yet

- Project Profile AdamaDocument4 pagesProject Profile AdamaYohannes AlemayehuNo ratings yet

- 4UIE - AB - Nov 23Document2 pages4UIE - AB - Nov 23aaaNo ratings yet

- How Summer Students Perceive The Closed Summer Program: in The Case of Jimma UniversityDocument17 pagesHow Summer Students Perceive The Closed Summer Program: in The Case of Jimma UniversityКонстантин НечетNo ratings yet

- Gold Experience B1 WorkbookDocument14 pagesGold Experience B1 WorkbookOli Sisti100% (2)

- GP125 - 200s Maintenance Manual-A520180913Document170 pagesGP125 - 200s Maintenance Manual-A520180913paulatclayxNo ratings yet

- NF EN 10028-3-EnglishDocument17 pagesNF EN 10028-3-Englishhakan gecerNo ratings yet

- Parrot: by Alan BrownjohnDocument2 pagesParrot: by Alan BrownjohnPADUMI SASIKALA50% (2)

- LP40W LED Driver 2017Document4 pagesLP40W LED Driver 2017Daniel MéndezNo ratings yet

- Lesson Plan in Mathematics Grade9Document6 pagesLesson Plan in Mathematics Grade9Abegail VillanuevaNo ratings yet

- AWS Certified Developer - AssociateDocument2 pagesAWS Certified Developer - AssociateKS ReddyNo ratings yet