Professional Documents

Culture Documents

Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work Activity

Uploaded by

Jayendra PatelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work Activity

Uploaded by

Jayendra PatelCopyright:

Available Formats

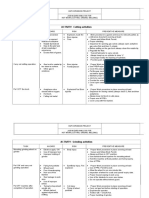

JOB SAFETY ANALYSIS (JSA)

Title of Activity / Work: Hot work activity

Name of Project Site and Date of JSA preparation 25.06.2019

Location

Name of Contractor: Activity/ Work location Name : JSA No.:

Sl. No. Subactivity / Steps Hazard Effect Control Measures Responsibility Remarks

STANDARD JSA

1 Ensure the Hot Work Permit for Welding Gas cutting and Grinding Works. Job Supervisor

2 Provide Barricading around the hot work area.

3 Ensure the usage of the Cutting Goggles, Face shield, Leather Hand gloves, etc.

4 Use only gas cylinder trolleys with properly secured by using the chains.

6 Flash back arrestor must be fitted at the both ends of the hoses and check the valve near

the cutting torch.

7 Gas cylinder valves fitting should be kept free from grease/oil.

8 Gas hoses and gauges must be inspected prior to use and free from defect.

Fire hazard, Explosion of gas 9 Cylinders must be secured in upright position.

cylinders, Bustring of hose pipes, 10 Provide fire watch man with vest equipped with fire extinguisher and (water spray if

Back fire from cutting torch, Fall Burn injury due to fire and required)

1 Gas Cutting Works of gas cylinders at same levlel, at explosion, bodyli injury due to

different level, Heat exposure, fall of cylinders 11 Ensure sufficient fire blanket are provided around the hot works area.

Spreading of sparks and hot

melton metals, Triping hazard 12 Firewatcher should accomplish a daily hot work inspection checklist signed by

FM/Supervisor.

13 Remove all combustible materials around the hot work area. Maintain hosuekeeping,

hose should be laid down safely.

14 Test the joints by using water or soap solution for leakages.

15 Experienced and trained gas cutters for doing the gas cutting works.

16.Adequate dual gauge must be provided in gas cutting set.

17.Only standard eye protection shall be worn by the gas cutter.

18. Valve protection cap must be ensured in gas cylinders.

1 Ensure that Shield barriers are provided for grinding area by using the Non-combustible Job Supervisor

materials like Fire blankets or Galvanised Iron Sheets.

2 Ensure the Face Shield, Hand gloves, Apron, Sleeves.

1 Ensure that all rotating parts provided with guard

2 Don’t allow to use the loose clothing.

3 Ensure that the grinding wheel design speed is more than the grinding machine speed.

Cut injury due to unguarded

Fire hazard, Spreading of sparks, wheel, burn injury , 4 Ensure that grinding wheel diameter and tied is adequate for the Metal to be cuttted.

2 Grinding Electrical hazard, weheel rupture, Electrocution, Injury to

unguarded wheel, Triping hazard persons due to trip hazard and 5 Provide good quality grinding wheels and from approved vendor.

spreading of spark

1 of 2

Cut injury due to unguarded

Fire hazard, Spreading of sparks, wheel, burn injury ,

2 Grinding Electrical hazard, weheel rupture, Electrocution, Injury to

Sl. No. Subactivity / Steps Hazard

unguarded wheel, Triping hazard persons due Effect

to trip hazard and Control Measures Responsibility Remarks

spreading of spark

6 Experienced grinders only allowed doing the grinding

1 All electrical power tools should be thoroughly inspected prior to use and replace

damaged one.

2 Use only 110v for all electrical power tools and ensure extension outlet is protected &

ensure that supply is given via 30 mA ELCB/RCCB.

3. Grinding machine safety checklist must be prepared prior to operate the grinding

machine.

1 It shall be ensured that hot work permit is obtained from the concerned personnel. Job Supervisor

2 Trained workers shall be used for welding.

34 Fire

The blankets to be used

fire extinguisher shalltobe

confine

made welding

availablearea

at site before start of work. Workers must be

aware about use of fire extinguisher in case of fire emergency.

Fire hazard, Explosion of gas

cylinders, Bustring of hose pipes, Burn injury due to fire and 5 Fire Watchman shall be deployed.

3 Welding Work Electrical hazard, Heat exposure, explosion, bodyli injury due to 6 Proper earth grounding and approved machines shall be ensured

Spreading of sparks and hot fall of cylinders, Electrocution,

melton metals, Triping hazard 7 Daily inspection checklist for all work shall be maintained & made available at site.

8 Ensure gas hoses(DA, Oxygen) & welding/power cables are not being laid together.

9 Painting & hot work shall not be carried out in one location.

10 Job specific training for all concerns related to work shall be conducted before start of

work. Ensure use of adequate PPE's by crew members.

1 Ensure that scaffolds provided with proper access to the working platform, mid, top hand Job Supervisor

rails, working platform with hand rails, etc. & inspected by scaffold supervisor providing

green tag.

2 Provide and ensure the usage of full body harness with double lanyard.

3 Train all personnel’s regarding work at height hazards and controls.

Fall of person Injury to persons, material 4 100 % anchoring off by wearing full body harness shall be ensured.

4 Work at Height Fall of Material damage

Collapse of scaffold 5 Tie the hand tools one end with permanent structure and other end with tools.

6 Don’t allow any person under the work area. Area barrication to be ensured.

7 Observed Safe Manual Handling techniques, Train all concerns in manual materials

handling techniques.

8. Ensure adequate work platform with hand rail, mid rail, toe guard, access /egress, life

line, safety net for working at height.

9. Physical test must be carried out for the persons who working at height.

Note : If any incident happened during the work, then work will be stopped and JSA will be reviewed. Work will be restarted after implementing safety measures mentioned in revised JSA."

Space for additional Remarks/Instruction/comments /safety mesures to be taken as per site situation and nature of job.

Prepared by: Approved by:

Name Reviewed by: Name and

and sign. Name and sign. sign.

2 of 2

You might also like

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- JSA for Drain Line ReplacementDocument5 pagesJSA for Drain Line ReplacementMadhan KannanNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- JSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Document7 pagesJSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Marvin BerrensteinNo ratings yet

- Risk Assessment for Shuttering/FormworkDocument1 pageRisk Assessment for Shuttering/FormworkHSE fahadNo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSDocument4 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSfaizan khanNo ratings yet

- JHA Fabrication WorkDocument4 pagesJHA Fabrication WorkRavi thokalNo ratings yet

- Jsa forOperatingAForkliftDocument2 pagesJsa forOperatingAForkliftsupahing supahingNo ratings yet

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- Job Hazard Analysis - Granite Surface PlateDocument2 pagesJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNo ratings yet

- JSA For Work at HeightDocument3 pagesJSA For Work at Heightbagas prakoso100% (1)

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,No ratings yet

- 3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseDocument5 pages3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar Gondal100% (1)

- Nuclear power welding safetyDocument8 pagesNuclear power welding safetyPiyush SinghNo ratings yet

- 5.confined Space EntryDocument6 pages5.confined Space EntryMohammad Fazal KhanNo ratings yet

- JSA ScaffoldingDocument2 pagesJSA ScaffoldingHrishikesh UnnikrishnanNo ratings yet

- Exavation Works PipercksDocument4 pagesExavation Works PipercksHRTYR100% (1)

- Jsa PaintDocument2 pagesJsa PaintKhalid NaseemNo ratings yet

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNo ratings yet

- Jsa Installing BracketDocument3 pagesJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- Excavation SafetyDocument11 pagesExcavation SafetyDenease CrummieNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- JSA Excavation PDFDocument6 pagesJSA Excavation PDFmohamedamine.zemouriNo ratings yet

- Job Safety AnalysisDocument2 pagesJob Safety AnalysiscitraNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1Sanjeet SinghNo ratings yet

- Composite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Document2 pagesComposite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Bhargav BbvsNo ratings yet

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDocument4 pagesPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834No ratings yet

- Sinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Document3 pagesSinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Nora Afzam Abd WahabNo ratings yet

- JSA For Flue Gas Duct Height WorkDocument4 pagesJSA For Flue Gas Duct Height Worksubhadipmanna8No ratings yet

- NPCIL JHA for Work at HeightsDocument13 pagesNPCIL JHA for Work at HeightsBurhan KhanNo ratings yet

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- JSA Scaffolding Erection and Dismentling New 2021Document5 pagesJSA Scaffolding Erection and Dismentling New 2021Captain ChickenNo ratings yet

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- JSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentDocument4 pagesJSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentMohammed Minhaj100% (1)

- JSa For Operation of Jack HammeringDocument3 pagesJSa For Operation of Jack Hammeringyc safety0% (1)

- JHA Hot WorkDocument1 pageJHA Hot WorkNilamSanjeev Kumar SinghNo ratings yet

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- Operating A Telescoping Aerial Boom LiftDocument1 pageOperating A Telescoping Aerial Boom LiftTFattahNo ratings yet

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- JSA For Screeding With MeshDocument4 pagesJSA For Screeding With MeshMohammed Minhaj100% (1)

- Jsa For Dismantel of StructureDocument2 pagesJsa For Dismantel of StructureBaiju SinghNo ratings yet

- JHA Formation Preparation or Leveling.Document2 pagesJHA Formation Preparation or Leveling.Mark Buendia100% (1)

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Document3 pagesJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21No ratings yet

- Shifting of Material & Equipment.: Job Safety Analysis JobDocument6 pagesShifting of Material & Equipment.: Job Safety Analysis JobPrabir PujariNo ratings yet

- JHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEDocument8 pagesJHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEaloysius akpanNo ratings yet

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Jsa For Hvac Equipment InstallDocument4 pagesJsa For Hvac Equipment Installpowergroup engineersNo ratings yet

- Hot Works: Risk Assesment Form For Rolling ShutterDocument1 pageHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30No ratings yet

- JOB SAFETY ANALYSISDocument21 pagesJOB SAFETY ANALYSISThái Đạo Phạm Lê100% (1)

- Confine Space at Water TankDocument7 pagesConfine Space at Water TanknaraNo ratings yet

- Job Safety Analysis (JSA) : Description Hazard ControlDocument3 pagesJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrNo ratings yet

- JSA - CABLE TERMINATION TITLEDocument4 pagesJSA - CABLE TERMINATION TITLESyed Yousuf Ali100% (1)

- Tie in Hot Work JHADocument4 pagesTie in Hot Work JHAmalik jahan100% (2)

- Jsa Bearing Replacement-OverhaulingDocument2 pagesJsa Bearing Replacement-Overhaulingashish engineeringNo ratings yet

- INSTALLATION SAFETY ANALYSISDocument22 pagesINSTALLATION SAFETY ANALYSISSyed Yousuf Ali100% (1)

- Jsa Civil Work (00000002)Document6 pagesJsa Civil Work (00000002)Ali AlahmaNo ratings yet

- JSA New Line Installation 2012Document2 pagesJSA New Line Installation 2012Deshbandhu Aman PandeyNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNo ratings yet

- 02concreting & Block Bricks Work JSADocument3 pages02concreting & Block Bricks Work JSAJayendra Patel100% (1)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingJayendra Patel89% (9)

- Compressed Gas SafetyDocument28 pagesCompressed Gas SafetyDiaa Gab-AllahNo ratings yet

- Inspection Check List - UTCLDocument25 pagesInspection Check List - UTCLAltafNo ratings yet

- JJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Document9 pagesJJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Ah Tiang100% (1)

- Reviewer in Smaw NC IDocument2 pagesReviewer in Smaw NC IMaricar CarandangNo ratings yet

- Module 1 Week 4-6, TVE SMAW 10Document25 pagesModule 1 Week 4-6, TVE SMAW 10Daryl TesoroNo ratings yet

- LEEA Correspondence Courses: Assignment 1.10Document6 pagesLEEA Correspondence Courses: Assignment 1.10ikponmwonsaNo ratings yet

- GAS WeldingDocument6 pagesGAS WeldingsrijaNo ratings yet

- DJJ10022 REPORT (Machining)Document6 pagesDJJ10022 REPORT (Machining)Muhd Imran Kasyidi OmarNo ratings yet

- Procedures For Approval of Service Suppliers - v01!05!13Document43 pagesProcedures For Approval of Service Suppliers - v01!05!13_LuisErnesto_No ratings yet

- Effect of Thermal Cutting Methods On The Fatigue Life of High Strength Structural Steel S690QDocument9 pagesEffect of Thermal Cutting Methods On The Fatigue Life of High Strength Structural Steel S690QVane LopezNo ratings yet

- Most Important Questions For Basic Manufacturing Processes (BME) 1Document2 pagesMost Important Questions For Basic Manufacturing Processes (BME) 1fgfdgdfgdfvvb100% (2)

- Welding Lecture and OrientationDocument57 pagesWelding Lecture and OrientationHenry SyNo ratings yet

- Manufacturing and Testing of Propellant TankDocument38 pagesManufacturing and Testing of Propellant TankSai RamNo ratings yet

- Piping QC PocketBook Navaneethan SundaramDocument25 pagesPiping QC PocketBook Navaneethan SundaramShanmuga NavaneethanNo ratings yet

- Document WPS OfficeDocument5 pagesDocument WPS Officecollins chinsungweNo ratings yet

- Project Report FinalDocument18 pagesProject Report Finalsdfa100% (2)

- GP Posters 8-14Document7 pagesGP Posters 8-14Tom AlexNo ratings yet

- Code of Practice 6: The Safe Distribution of Acetylene in The Pressure Range 0 - 1.5 BAR Revision 3: 2015Document51 pagesCode of Practice 6: The Safe Distribution of Acetylene in The Pressure Range 0 - 1.5 BAR Revision 3: 2015Justin ChongNo ratings yet

- Production TechnologyDocument60 pagesProduction Technology2mohan7100% (2)

- Cutting Torch SafetyDocument1 pageCutting Torch Safetyyasser awadallhNo ratings yet

- WTDocument299 pagesWTrsarunprasathNo ratings yet

- Super EgoDocument40 pagesSuper Egolong_kongoNo ratings yet

- Welded ConnectionsDocument144 pagesWelded ConnectionsshivaniNo ratings yet

- HSE FRM-20 HSE Assessment ReportDocument4 pagesHSE FRM-20 HSE Assessment Reportmazen fakhfakhNo ratings yet

- Daily Safety Compliance Report For InterviewDocument7 pagesDaily Safety Compliance Report For InterviewLemuel PetronioNo ratings yet

- Oxy-Acetylene Safety RulesDocument5 pagesOxy-Acetylene Safety RuleschrisNo ratings yet

- WELDER (Dual Mode) : Under Dual Training SystemDocument33 pagesWELDER (Dual Mode) : Under Dual Training SystemUmang SoniNo ratings yet

- Oxy-Acetylene Welding and CuttingDocument96 pagesOxy-Acetylene Welding and CuttingGutenberg.orgNo ratings yet

- En 16129Document142 pagesEn 16129hasan noah0% (1)

- Welding & Hotwork Safety-JackieDocument43 pagesWelding & Hotwork Safety-JackieNinia GannabanNo ratings yet