Professional Documents

Culture Documents

SWMS2 Confined Space Entry

Uploaded by

Islam SarhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SWMS2 Confined Space Entry

Uploaded by

Islam SarhanCopyright:

Available Formats

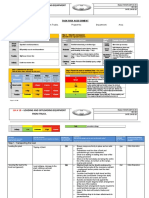

SAFE WORK METHOD STATEMENT

DOC David

DOC ID SWMS2 VERSION 7

OWNER Cowan

CONFINED SPACE ENTRY

ACTIVE DATE 06/03/2018 REVIEW DATE 06/03/2020

INTRODUCTION

This Safe Work Method Statement details how specific risks associated with working in and/or around Confined Spaces are to be managed. It outlines the

common risks and dangers associated with this work and how to best control them based on the Hierarchy of Controls. The control measures listed in this

SWMS must be implemented on site.

If other hazards are identified that are not identified in this SWMS a Risk Assessment for the new hazard must be completed on the WRAP.

CONSULTATION AND REVIEW OF SAFE WORK METHOD STATEMENT (SWMS)

This SWMS has been developed in consultation with Subject Matter Experts. Reviews will be conducted every two years or if an incident occurs or if there is a

change in operational practices or if there is a change in legislation. It will also be reviewed in conjunction with any review of associated procedures and/or

training programs. Effectiveness of control measures will be monitored by on site supervisors

REFERENCE DOCUMENTS - OCCUPATIONS/HIGH RISK WORK

Relevant Work Health & Safety/Environmental Legislation References

QLD Work Health & Safety Act 2011 AS/NZS ISO 31000:2009 – Risk Management

QLD Work Health & Safety Regulations 2011 AS/NZS 2865:2009 Confined Spaces

Confined Spaces Code of Practice 2011 Plant Inspection Checklists - PRO390

How to Manage Work Health and Safety Risks Code of Practice Safe Work Method Statement – Excavation and Trenching

Hazardous Manual Tasks Code of Practice ENERGY Lockout/Tagout Procedure

Environmental Protection Act

ABN: 86 673 835 011

Confidential

SWMS2 1

The following occupations and high risk work tasks are undertaken in this activity:

Occupation Class of High Risk Work

Work Health & Safety Regulations 2011 Work Health & Safety Regulations 2011

N/A N/A

HAZARD ANALYSIS AND CONTROL MEASURES

Task/Activity Hazard/Risk Inherent Control Measures Residual Hierarchy PICOW’s

Risk Risk of Initials

Rating Rating Controls

1. Job 1.Hazard: Inadequate E 1. Ensure that all safety equipment is within test date, has been inspected L Admin

Pre-planning planning immediately prior to commencement of the task and suitable for the

Risk: type of confined space to be entered.

Unsafe work site 2. Ensure team has mobile phones for constant contact with the control Admin

room (where required) available on site.

2 .Preparation 1.Hazard: H 1. Ensure isolation of the following as required: sewage flow, electrical L Isolation

for entry, Heights, adjacent to traffic. and/or mechanical equipment and chemical and/or oxygen injection.

checks from (Refer to Permit to Work for the job)

surface into 2. Set up rescue equipment relevant to the confined space. PPE

confined Risk:

space. Slips, trips, falls, bites, hit by 3. Clear tools, equipment and material from the area around the opening Isolation

car. and visually check the confined space for other hazards e.g. loose drop

pipe, debris, snakes, rats, etc.

4. Ensure that the Standby Person has a mobile phone or two-way radio to PPE

receive any or make any emergency calls.

5. Check the confined space rescue winch cable. ( Wind the cable out Admin

and wind it back in under continuous tension to ensure no bird nesting

has occurred in the cable.

6. Note: Gloves must be worn to protect hands from broken strands.)

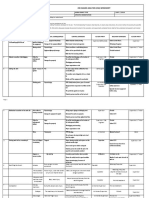

E 1. Gas detection procedures must be conducted before any person enters M Admin

3 .Evaluate 1 Hazard:

any confined space.

atmosphere Poor quality atmosphere,

ABN: 86 673 835 011

Confidential

SWMS2 2

oxygen enriched 2. Securely attach the gas detector to a rope and lower/place into the Admin

atmosphere. confined space. Test the atmosphere at multiple levels and ensure the

Risk: detector goes to the farthest point of the confined space.

Fire or explosion,

NOTE:

suffocation due to oxygen

Ensure that gas detection occurs at all pipe openings down the drop

deficiency, poisoning (e.g.

pipe. Ensure that you break the crust of stagnant water before

by hydrogen sulphide

monitoring commences.

and/or carbon monoxide).

3. Use mechanical ventilation unless the Competent Person has Engineering

determined by risk assessment that natural ventilation will provide a safe

atmosphere in the confined space.

4. Place the gas detector back into the confined space for continuous PPE

monitoring as close as is practicable to the breathing zone of the

worker(s) in the confined space for the duration of the entry.

5. Prior to entry, a gas detector must be attached to the worker within their PPE

breathing zone. This must remain attached for the duration of the entry.

E 1. Clear the Confined Space of any contaminants, where necessary, by M Isolation

4 .Purging and 1.Hazard:

use of a suitable purging agent. (The purging agent or any gas used for

ventilation of Poor quality atmosphere; ventilation purposes shall not be pure oxygen or gas mixtures with

the Confined oxygen enriched oxygen concentration greater than 21%.)

Space atmosphere, heat stress and

fatigue. Purging operations:

Care should be taken in purging a confined space to preclude

Risk: rupture or collapse of the enclosure due to pressure differentials.

Purging operations should be conducted such that the structural

Fire or explosion,

integrity of the confined space is not compromised.

suffocation due to oxygen

Attention should be given to the design pressure, design

deficiency, poisoning (e.g.

temperature, critical exposure temperature and vacuum rating.

by hydrogen sulphide

Where required by risk assessment, barriers and signs should be

and/or carbon monoxide).

erected to indicate exclusion/prohibition areas surrounding

purging vents and openings.

2. Ventilate with fresh air, by natural, forced or mechanical means to

establish and maintain a safe atmosphere and temperature. If the

confined space has sufficient openings then natural ventilation may be

adequate, but in most cases mechanical ventilation will be needed. If

fans are in use, fan controls shall be clearly identified and tagged to

prevent possible interference.

Considerations:

Ventilation techniques must be in line with the Confined Space

ABN: 86 673 835 011

Confidential

SWMS2 3

Ventilation Guidance document (FOR643).

The location where fresh air is drawn from and where the exhaust air

is finally vented to must be considered. This will ensure the fresh air is

not contaminated either by exhaust air or by other pollutants, and

the exhaust air does not cause other risks.

Mechanical ventilation may be either local exhaust ventilation (LEV)

or dilution ventilation.

LEV is located as per risk assessment.(recorded on emergency plan)

Where dilution ventilation is used, air needs to be introduced in a

way that will ensure effective circulation throughout the confined

space, taking account of the configuration of the space, the

position of the openings and the properties of the contaminants.

Check to make sure that fan rotation is correct and air movement is

in the intended direction

Means of testing and monitoring ambient temperatures should be

undertaken to reduce the likelihood of heat stress or temperature

induced fatigue, if identified by risk assessment.

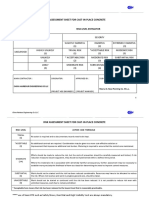

E 1. Check the condition of ladders, step irons etc. visually by using an M Admin

5 .Entering the 1.Hazard:

intrinsically safe torch and/or mirror

confined space Heights,

Single Person Entry: PPE

vermin,

2. Where a fall hazard does exist the person entering a confined space

snakes, must be connected to the winch cable by the safety harness. The

operator remains attached to the cable at all times. A second safety

Risk: rescue rope should be available.

Falling, 3. Ensure that the rescue winch remains in ‘fall arrest mode’ from the time

struck by hook, bites. the worker enters the confined space and for the duration of the

confined space entry and exit. Engineering

Note: Winch only to be used in ‘rescue’ mode when a worker requires

rescue or assistance in evacuating the confined space.

Engineering

Multiple person entry:

4. Employees and other persons on QUU worksites must remain attached to

the rescue winch at all times. Multiple rescue winches will be used if

required. For any job that requires workers to disconnect from the

winch, e.g. traversing the sewer, a specific Risk Assessment must be

created for that job.

CAUTION: Under no circumstances should the person at the bottom of the

confined space disconnect the D-hook from the harness and let it go

until the Standby Person gives instruction to do so, as this may cause

injury to the Standby Person on ground level.

ABN: 86 673 835 011

Confidential

SWMS2 4

6 .Working in 1.Hazard: 1. Monitor the operation of the gas detectors at all times.

the confined Poor quality atmosphere, E (If either gas detector alarm sounds, immediately implement emergency M PPE

space. oxygen enriched procedures. (See below). )

atmosphere, 2. A Standby Person must always remain in the vicinity of the confined Admin

trip hazards. space entry and maintain constant visual or audio contact with the

worker/s inside the confined space and must not perform any other

Risks: work.

Fire or explosion,

suffocation due to oxygen

deficiency, poisoning (e.g.

by hydrogen sulphide

and/or carbon monoxide).

Slips, trips, falls.

E 1. If the item cannot be safely carried in a bucket, it is to be securely tied L Admin

7 .Raising and 1.Hazard:

lowering of to a working line.

Manual handling, falling

tools, objects.

equipment, CAUTION:

buckets of Workers are not to be below any objects being raised or lowered.

material etc. Risk:

Do not use rescue lifelines for this purpose.

Muscular injury, impact.

Admin

E Admin

8 Hot work in 1.Hazard: 2. Complete a Hot Work Permit whenever any of the following activities are M

confined Explosive atmosphere. to be conducted in a Confined Space. cutting, grinding or any other

space. spark or heat producing work (e.g. Electrical equipment) Work is not to

commence unless forced mechanical ventilation is in place.

Risk:

CAUTION: Do not use oxygen as compressed air when working in a

Explosion.

confined space, as this will increase the risk of explosion.

Grinding/Cutting PPE

3. When grinding, ensure person/s working within the confined space is/are

using the correct PPE (including minimum Class P2 disposable respirator).

Engineering

Electrical arc welding

4. Electrical connection to electrodes (including a fully insulated electrode

holder), work return (earth lead) and equipment should be fully insulated

and must be thoroughly checked.

ABN: 86 673 835 011

Confidential

SWMS2 5

Engineering

5. A welding circuit safety switch shall be used and held by the Standby

Person for the duration of the task.

Engineering

6. The Standby Person shall isolate the circuit using the welding circuit

safety switch before and after each welding work and in electrode

change-over.

7. Insulating materials, e.g. rubber mats, shall be used to isolate welder PPE

from wet or metallic surfaces.

Engineering

Oxy-acetylene work

8. Gas cylinders shall be kept outside of confined spaces.

Engineering

9. Torches and pressure hosing connected to the supply shall not be left

inside the working area when not in use. (Very slow leaks of oxygen or

fuel gas can allow an explosive atmosphere to build up rapidly.)

Engineering

9 .Electrical 1.Hazard: E 1. Only air driven or battery operated equipment should be used in M

equipment. confined spaces.

Electricity.

2. Avoid the use of electrical equipment in confined spaces, wherever Isolation

possible but where portable electrical equipment is the only option, the

Risk: equipment is to be connected to an earth free (double insulated), low

Electrocution. voltage supply from an isolating transformer located outside the

confined space or be protected through a residual current device

(RCD) with the device being located outside the confined space.

NOTE:

Where there is risk of a combustible atmosphere only intrinsically safe

electrical equipment can be used (Caution: this risk also applies to

mobile phones that are not intrinsically safe)

E 1. Do not position combustion engine equipment i.e. compressor, L Isolation

10 .Combustion 1.Hazard:

engines. generator, truck, car, where exhaust fumes can be drawn into the

Fumes.

confined space.

CAUTION: Never take Combustion engines, for example generators, pumps,

Risk: etc into a confined space.

Poisoning, asphyxiation.

ABN: 86 673 835 011

Confidential

SWMS2 6

H 1. All air driven equipment and hoses (i.e. air saw, CP Hammer, jack L Engineering

11 .Air driven 1.Hazard:

Equipment. hammer, etc) shall have safety pins fitted to couplings at both

Moving parts.

connection points to the air line to prevent separation.

Risk:

Lacerations, amputations,

breaks.

12 .Completion 1. Hazard: H 1. Ensure tripod winch is in fall arrest mode and no control of cable is L PPE

of work inside required.

Heights,

confined Multiple Persons Admin

space. Damaged equipment

2. When the first person reaches the surface, they disconnect the hook

2, Risks: from their safety harness.

Slips, trips, falls.

struck by

3. The Standby Person lowers the hook to the second person by gripping Admin

the cable with two hands and lowering the hook.

CAUTION:

a) The Standby Person should not let go of the cable until the person at the

bottom of the pit has clearly told him that he has connected the hook to

his safety harness.

b) Confined space must be checked to ensure that all personnel,

equipment and materials have been removed.

Gas Detector PPE

4. Remove the gas detector from the confined space.

Authorised person Admin

5. Completes Confined Space Entry Permit.

6. Contacts the Control Room and their Team Leader to notify them of the Admin

completion of the job.

7. Recheck all equipment to make sure that there has not been any Admin

damage caused during the task.

Emergency Procedures

ABN: 86 673 835 011

Confidential

SWMS2 7

THE EMERGENCY RESCUE PLAN FOR EACH JOB MUST BE DISCUSSED, COMPLETED AND UNDERSTOOD PRIOR TO ENTRY OF THE CONFINED SPACE

NOTE:

If an emergency situation arises, the safety of the persons in the confined space is the highest priority regardless of the task being performed or the

equipment being used.

All workers are to EXIT the confined space immediately, if any of the following situations occur:

• An alarm is indicated by either gas detector.

• Any worker experiences any of the following symptoms:

o Headache. o Nausea. o Burning sensation in the eyes or throat.

o Dizziness or any other symptoms that could indicate the presence of hazardous gases or chemicals in the confined space.

• The water level inside the confined space rises rapidly, e.g. pipe/valve failure.

• The Standby Person must leave their position, e.g. toilet break.

Any other hazard that arises during the entry of a confined space where there may be a risk to the safety of the worker(s) in the Confined Space.

1. In the event of a person collapsing or suffering an injury inside the confined space, the emergency procedures are as follows:

Contact the relevant Supervisor as soon as possible.

a) NO RESCUER SHALL ENTER A CONFINED SPACE TO ATTEMPT A RESCUE, WHERE THERE IS ANY RISK TO THE SAFETY OF THE RESCUER.

b. The Standby Person at the surface alerts other team members at the site of the incident.

c. The Standby Person must ensure that a delegated person has contacted Emergency Services.

Note: When speaking to the Emergency Services, state the Employee’s name, incident location, type of rescue required and address. Instructions

from Emergency Services MUST be followed.

2. Rescuing the injured employee without rescuer entering a confined space:

a. The Standby Person winches the injured employee to the surface using the retrieval winch.

Note: Care should be taken not to unnecessarily further injure the worker during ascent by using excessive force. (the person could get be caught

on an obstacle).

3. Rescuing the injured employee with rescuer entering a confined space.

Examples of this situation include:

Worker injured while detached from winch cable (and no gas detector alarm).

Worker caught on obstacle when being winched to safety (and no gas detector alarm).

The Standby Person must raise the gas detector to the surface and check for any alarm indication.

a) The BA usage board must be filled in by the Standby Person prior to the rescuer entering the confined space.

b) If an alarm is activated only a Rescuer using breathing apparatus should enter the confined space to facilitate the rescue.

ABN: 86 673 835 011

Confidential

SWMS2 8

c) If no alarm is activated, lower the gas detector back into the confined space.

d) The rescuer may descend the ladder and release the injured person from the obstacle or attach the winch cable to the person. The rescuer

will then ascend the ladder and the standby person can proceed to winch the injured person to the surface.

e) When the injured employee is brought to the surface, the employee should be moved away from the access opening and placed in a safe

area clear of the confined space opening. (This is done by firmly grasping their safety harness whilst still attached to the winch cable before

releasing the employee from the harness attachment.)

f) The medical condition of the collapsed or injured employee should be assessed by a qualified person and if necessary, CPR and/or First Aid

should be administered as deemed necessary.

END OF SAFE WORK METHOD STATEMENT

ABN: 86 673 835 011

Confidential

SWMS2 9

You might also like

- Hydro Excavation Safety AnalysisDocument3 pagesHydro Excavation Safety Analysisarnel_ado4412100% (3)

- Risk Assessment FormDocument8 pagesRisk Assessment FormRochdi BahiriNo ratings yet

- Panasonic VP-7721A Audio Analyzer Instruction ManualDocument74 pagesPanasonic VP-7721A Audio Analyzer Instruction ManualLY ChinNo ratings yet

- Job Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdDocument3 pagesJob Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdTeodoro EsquilloNo ratings yet

- Cleaning Risks AssessedDocument6 pagesCleaning Risks Assessedjulius0% (1)

- Sealcoating /crack Repair Parking Lots: Job Safety AnalysisDocument3 pagesSealcoating /crack Repair Parking Lots: Job Safety AnalysisRetselisitsoe0% (1)

- Fall Protection Survey of RIG 40Document3 pagesFall Protection Survey of RIG 40Kevin Josh Bonales100% (1)

- Compressor Risk Assessment v2bDocument4 pagesCompressor Risk Assessment v2bknabpsho100% (1)

- Hot Works Safety Risk AssessmentDocument5 pagesHot Works Safety Risk AssessmentBilal100% (2)

- Basf Jsa SaferadDocument3 pagesBasf Jsa SaferadExsan OthmanNo ratings yet

- BS en 12405-3-2015Document82 pagesBS en 12405-3-2015Doiciel100% (1)

- STE Action Plan 2021-2022Document5 pagesSTE Action Plan 2021-2022Bernadette L. Macadangdang100% (1)

- Visual Search Market Size, Status and Forecast 2019-2025Document8 pagesVisual Search Market Size, Status and Forecast 2019-2025mahi singhNo ratings yet

- Safe Work Method Statement: Excavation, Trenching and Underground ServicesDocument5 pagesSafe Work Method Statement: Excavation, Trenching and Underground ServicesMorhne RufinNo ratings yet

- Hot Works Risk AssessmentDocument4 pagesHot Works Risk AssessmentFaisal RazaNo ratings yet

- Jsa Fueling Equipment On DeckDocument2 pagesJsa Fueling Equipment On DeckIlya BordonosovNo ratings yet

- Work Method Statement: Confined SpaceDocument3 pagesWork Method Statement: Confined SpaceKarthik babu0% (1)

- Job Safety Analysis for Workover OperationsDocument5 pagesJob Safety Analysis for Workover OperationsAshok SureshNo ratings yet

- UQ Confined Space Management Plan GuideDocument27 pagesUQ Confined Space Management Plan GuideYusuf KhanNo ratings yet

- Safe Work Method StatementDocument11 pagesSafe Work Method StatementJNo ratings yet

- Cold weather safetyDocument11 pagesCold weather safetyotak04No ratings yet

- Emergency Response PlanDocument1 pageEmergency Response PlanArslanSaeedNo ratings yet

- NFPA 101 Life Safety Code Compliance R1sDocument2 pagesNFPA 101 Life Safety Code Compliance R1ssimonsecurityNo ratings yet

- Loading-Unloading-Low-Loader Risk AssmntDocument10 pagesLoading-Unloading-Low-Loader Risk AssmntStansilous Tatenda NyagomoNo ratings yet

- Removal of Debris-Filling - Levelling & CompactingDocument8 pagesRemoval of Debris-Filling - Levelling & CompactingAl Mughsar CompanyNo ratings yet

- IDC SOP # XX Laying Down Drill Pipe From DerrickDocument4 pagesIDC SOP # XX Laying Down Drill Pipe From DerrickkareemNo ratings yet

- 42 HSE Risk-Assessment Construction WorksDocument40 pages42 HSE Risk-Assessment Construction WorksSacko MansaNo ratings yet

- Confined Space Rescue PlanDocument50 pagesConfined Space Rescue PlanGhussan ManzoorNo ratings yet

- Group 3 Excavation SafetyDocument72 pagesGroup 3 Excavation SafetyRohadzma N. NajebNo ratings yet

- Pipe Nitrogen Testing in Non Confined SpaceDocument4 pagesPipe Nitrogen Testing in Non Confined SpaceKannan KamalNo ratings yet

- F5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionDocument11 pagesF5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionTaiwo OshinNo ratings yet

- JSA ExcavationDocument6 pagesJSA ExcavationidreisNo ratings yet

- SDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Job Hazard Analysis Template SampleDocument2 pagesJob Hazard Analysis Template SampleJohn KurongNo ratings yet

- RadiographyDocument1 pageRadiographyNature BeautiesNo ratings yet

- Trenching and Excavation SafetyDocument5 pagesTrenching and Excavation SafetyAnge JuanNo ratings yet

- JHA For Radiography TestDocument8 pagesJHA For Radiography TestM8Rskn6wcNo ratings yet

- Plumber - Drainer SWMSDocument12 pagesPlumber - Drainer SWMSallen2912100% (1)

- JSA Scaffolding Erection and Dismentling New 2021Document5 pagesJSA Scaffolding Erection and Dismentling New 2021Captain ChickenNo ratings yet

- Jsa FormDocument3 pagesJsa Formmiaicarba100% (1)

- 01 WI HSE 001 - Risk Assessment GroutingDocument4 pages01 WI HSE 001 - Risk Assessment GroutingMisbah Ul Haq Labeed100% (1)

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- Confined Space Rescue Plan-Fb EngineeringDocument17 pagesConfined Space Rescue Plan-Fb EngineeringPatrick Ruwona100% (1)

- JSA - CABLE TERMINATION SAFETYDocument4 pagesJSA - CABLE TERMINATION SAFETYD FiransyahNo ratings yet

- RHA - Open Cut Piping & Manhole Installation (Page 3)Document6 pagesRHA - Open Cut Piping & Manhole Installation (Page 3)tanaNo ratings yet

- JSA-002 Civil WorksDocument6 pagesJSA-002 Civil WorksMoaatazz NouisriNo ratings yet

- Jha Manual Handling of MaterialDocument5 pagesJha Manual Handling of MaterialAbdul Khairul RiduanNo ratings yet

- Bending MachineDocument52 pagesBending MachineFarrukh AhmedNo ratings yet

- Hand Tool SafetyDocument4 pagesHand Tool SafetyJeffersonDeGuiaNo ratings yet

- cONSTRUCTION WORK JSADocument21 pagescONSTRUCTION WORK JSAMohammed AlshehhiNo ratings yet

- Safety Bulletin # 023: Confined Space Entry (Part 2)Document3 pagesSafety Bulletin # 023: Confined Space Entry (Part 2)Al DubNo ratings yet

- JHA - (Power Brush & Touch-Up Painting Activities 1)Document1 pageJHA - (Power Brush & Touch-Up Painting Activities 1)shaiful annuarNo ratings yet

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- Job Hazard Analysis (Jha) WorksheetDocument4 pagesJob Hazard Analysis (Jha) WorksheetSamer AlsumaryNo ratings yet

- JHA ANALYSIS SCALE REMOVAL VESSELDocument2 pagesJHA ANALYSIS SCALE REMOVAL VESSELRiyadh SalehNo ratings yet

- Fall ProtectionDocument24 pagesFall Protectionmdfahad0047No ratings yet

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 pagesCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaNo ratings yet

- OHS PROC 113 BarricadesDocument9 pagesOHS PROC 113 BarricadesPhillip L100% (1)

- Cast-In Place Concrete - Risk Assessment SheetDocument3 pagesCast-In Place Concrete - Risk Assessment SheetYash SharmaNo ratings yet

- REC162279 KPA Truck Loading and Unloading Operations V4 0Document12 pagesREC162279 KPA Truck Loading and Unloading Operations V4 0Yoga PurwantoNo ratings yet

- JSA For Geotechnical Investigation at OffshoreDocument5 pagesJSA For Geotechnical Investigation at OffshoreHilbrecht De PedroNo ratings yet

- Abdul Rahman Al-Otaishan Group Safety Presentation June 2015Document14 pagesAbdul Rahman Al-Otaishan Group Safety Presentation June 2015jaydeeNo ratings yet

- JSARA - Fire Detection System InstallationDocument13 pagesJSARA - Fire Detection System InstallationUtku Can KılıçNo ratings yet

- CV Software Testing EngineerDocument3 pagesCV Software Testing EngineerRākesh Rakhi100% (1)

- Jdegtaddupdate - Text/ Jdegtaddupdate - Textkeystr: SyntaxDocument5 pagesJdegtaddupdate - Text/ Jdegtaddupdate - Textkeystr: SyntaxRaveRaveNo ratings yet

- Shakirullah Niazi: Professional SummaryDocument4 pagesShakirullah Niazi: Professional SummaryShakir UllahNo ratings yet

- Test 1Document6 pagesTest 1AKASH PALNo ratings yet

- In Southeast Asia Poised For Rapid Growth: AUGUST 2019Document8 pagesIn Southeast Asia Poised For Rapid Growth: AUGUST 2019Nguyễn Vũ HoàngNo ratings yet

- HVAC-Indoor AC-LG-Cassette 4 Way 2x2Document4 pagesHVAC-Indoor AC-LG-Cassette 4 Way 2x2Ashar HassanNo ratings yet

- Quot - Leak Tester BP Ridwan - PTI Cosmetics - 08apr21Document6 pagesQuot - Leak Tester BP Ridwan - PTI Cosmetics - 08apr21mario gultomNo ratings yet

- Teaching and Learning Continuity Amid and Beyond The PandemicDocument5 pagesTeaching and Learning Continuity Amid and Beyond The PandemicAmbbie Porras ManaliliNo ratings yet

- Universal Joint Alignment Proc 111606Document5 pagesUniversal Joint Alignment Proc 111606Slobodan GaricNo ratings yet

- Newmark Beta Method for Solving Structural Dynamics ProblemsDocument4 pagesNewmark Beta Method for Solving Structural Dynamics ProblemsNikhil PotnuruNo ratings yet

- Sunny Brochure 16 Pages 23102018 PDFDocument8 pagesSunny Brochure 16 Pages 23102018 PDFSunilNo ratings yet

- Article Review 1Document24 pagesArticle Review 1limap5No ratings yet

- TLC Online Learning Packs Brochure 2020Document20 pagesTLC Online Learning Packs Brochure 2020trongnvtNo ratings yet

- SALOM LogicResourceDocument162 pagesSALOM LogicResourceAsela SubhasingheNo ratings yet

- SBI Online Registration Form for CINB SaralDocument1 pageSBI Online Registration Form for CINB Saralamitjainis60% (5)

- Daa Mini ProjectDocument18 pagesDaa Mini ProjectSai Rohit PaturiNo ratings yet

- ECO304 - Sampling DistributionDocument39 pagesECO304 - Sampling DistributionNicholas Atuoni GyabaaNo ratings yet

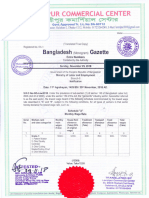

- Gazette On Minimum Wages RMG (Bangladesh) - 2018 - (English)Document11 pagesGazette On Minimum Wages RMG (Bangladesh) - 2018 - (English)Mazharul IslamNo ratings yet

- Capeta 23Document55 pagesCapeta 23janof1No ratings yet

- Mini Project On ''Market Overview On Financial Services'' Nishant Mishra 2008010700143Document40 pagesMini Project On ''Market Overview On Financial Services'' Nishant Mishra 2008010700143Sagar MishraNo ratings yet

- Orbital and Linear Converter With Autotuning: ACT 401-xxx - ManualDocument37 pagesOrbital and Linear Converter With Autotuning: ACT 401-xxx - ManualGeraldo Candido de Azevedo NetoNo ratings yet

- Installation: Indoor UnitDocument10 pagesInstallation: Indoor UnitJohan FloresNo ratings yet

- Practical Application of Refrigerants R600A and R290 in Small Hermetic SystemsDocument20 pagesPractical Application of Refrigerants R600A and R290 in Small Hermetic SystemsTedy Corimanya SoriaNo ratings yet

- BSNL Project MBADocument96 pagesBSNL Project MBAeeshwer85% (26)

- Assessment of Customer Relationship Management On Central Hotel in The Case Hawassa CityDocument41 pagesAssessment of Customer Relationship Management On Central Hotel in The Case Hawassa Cityasu manNo ratings yet

- Las Tendencias Pedagógicas en América Latina. NassifDocument51 pagesLas Tendencias Pedagógicas en América Latina. NassifDora MuñozNo ratings yet