Professional Documents

Culture Documents

Ficha Técnica TD600

Uploaded by

Marcos Mezahuaman LaimeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ficha Técnica TD600

Uploaded by

Marcos Mezahuaman LaimeCopyright:

Available Formats

STEAM TRAPS

Steam Traps TD600

Thermodynamic Steam Trap Thermodynamic

Model TD600, TD600L

Sizes 3/8”, 1/2”, 3/4”, 1”

Connections NPT

Body Material Stainless Steel 420F

Options Insulation Cap

PMO Max. Operating Pressure 600 PSIG

TMO Max. Operating Temperature 800ºF

PMA Max. Allowable Pressure 600 PSIG up to 800ºF

TMA Max. Allowable Temperature 800ºF @ 600 PSIG

Typical Applications Sample Specification

DRIP, TRACING: TD600 model steam traps are most commonly The steam trap shall be a thermodynamic disc type with all

used in drip applications, such as draining condensate from stainless steel construction. Integral seat design and disc to be

steam mains and steam supply lines. They can also be used for hardened for long service life. Unit shall be capable of installation

steam tracing applications. These traps are suitable for outdoor in any orientation and self-draining when mounted vertically.

applications that are subject to freezing as well as superheated

steam conditions. They are compact and rugged with only a Installation and Maintenance

single moving part. If a trap with an integral strainer is desired, The TD600 can be installed in any orientation; however, horizontal

the TD600S is recommended. If a fully in-line repairable design with cap facing upward is preferred for longest service life. The

is required, the TD700S or the UTD450 with Universal Quick- one piece body-seat design is extremely simple and economical;

Change connector is recommended. however, this configuration is generally considered not fully

repairable since the seat cannot be repaired if damaged or worn.

How It Works Welding of trap body directly into pipeline is not recommended

The disc is the only moving part inside a thermodynamic trap. since excessive heat may cause distortion of the seat area. The

When steam enters the trap, it creates an internal pressure above TD600 does not contain an integral strainer and separate strainer

the disc that instantly forces the disc to close tightly on the seat, should therefore be installed to protect from dirt and pipe scale. If

preventing the steam from escaping. The internal steam pressure a fully in-line repairable design or a trap that can be welded into

(holding the disc and seat shut) eventually drops, and the trap pipeline is desired, the TD700S, TD900S or the UTD450 with

re-opens. When condensate enters the trap, it pushes the disc Universal Quick-Change connector is recommended.

upwards, allowing the condensate to freely discharge. If steam

is present, the trap instantly shuts. Helpful Selection Information

The TD600L has reduced size discharge orifice holes which

Features are preferable in terms of performance, longevity, and efficiency;

particularly on pressures over 150 psi. For most drip applications

• High pressure applications up to 600 PSIG the 1/2” TD600L should have sufficient capacity. For higher load

• Hardened stainless steel seat and disc for extended service drip applications or if a 3/4” pipe connection is required, use

life even at high pressure 3/4” TD600L for best results. Choosing a model with a condensate

• Single trap will operate over the entire pressure range of handling capacity in the range of the specific application will

3.5-600 PSIG (recommended above 30 PSIG) prolong trap life.

• Suitable for superheated steam L = Reduced Size Discharge Orifice holes which are preferable in

terms of performance, longevity, and efficiency; particularly on

• Freeze-proof when trap is piped in a vertical orientation pressures over 150 psi.

for complete drainage of condensate

• Three-hole balanced discharge extends life of the seat area Options

• Trap will function in any orientation (horizontal preferred) An insulation cap is available to reduce cycle rates and steam

loss in rain, snow, or cold environments.

38 www.watsonmcdaniel.com •• Pottstown PA • USA • Tel: 610-495-5131

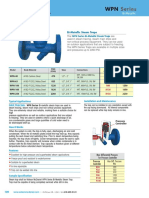

Steam Traps TD600

STEAM TRAPS

Thermodynamic Steam Trap Thermodynamic

Optional

Insulation

Cap

B

FLOW

Cover

C A

Disc

DIMENSIONS & WEIGHTS – inches Seat

Size Model Code Connection A B C Weight (lbs)

3/8” TD600-11-N NPT 1.37 1.69 2.00 0.75 3-Hole

Balanced

1/2” TD600-12-N NPT 1.50 2.00 2.69 1.25 Discharge

3/4” TD600-13-N NPT 1.75 2.38 2.81 2.00

1” TD600-14-N NPT 2.12 2.81 3.81 3.00

1/2” TD600L-12-N NPT 1.50 1.81 2.71 1.00

3/4” TD600L-13-N NPT 1.50 2.25 2.75 1.75

How to Size / Order M AT E R I A L S

Select working pressure; follow column down to correct capacity Body Stainless Steel, AISI 420F

(lbs/hr) block. Example: Disc Stainless Steel, AISI 420

Application: 500 lbs/hr at 100 PSIG working inlet pressure Cover Stainless Steel, AISI 416

Insulation Cap Stainless Steel, AISI 304

Size/Model: 3/4” TD600L-13-N

C A PA C I T I E S – Condensate (lbs/hr)

Steam Inlet Pressure (PSIG)

Size Model Code 3.5 5 10 15 20 25 30 40 50 75 100 150 200 250 300 350 400 450 500 550 600

1/2” TD600L-12-N 180 185 190 195 200 215 220 230 250 310 375 500 620 710 800 825 900 1070 1120 1185 1290

3/4” TD600L-13-N 300 315 350 380 415 440 470 515 580 710 825 1020 1165 1300 1440 1565 1670 1775 1880 1960 2060

3/8” TD600-11-N 180 185 190 195 200 215 220 230 250 310 375 500 620 710 800 825 900 1070 1120 1185 1290

1/2” TD600-12-N 300 315 350 380 415 440 470 515 580 710 825 1020 1165 1300 1440 1565 1670 1775 1880 1960 2060

3/4” TD600-13-N 415 430 475 520 565 610 650 720 825 1020 1185 1480 1710 1950 2110 2265 2490 2625 2780 2985 3140

1” TD600-14-N 650 680 740 815 885 940 1000 1080 1225 1500 1800 2215 2625 2935 3300 3600 3875 4120 4350 4560 4840

Notes: 1) Maximum back pressure not to exceed 80% of inlet pressure (measured in absolute pressure) or trap may not close.

2) For optimum performance, recommended for operating pressure above 30 PSIG.

Tel: 610-495-5131 • Pottstown PA • USA •• www.watsonmcdaniel.com 39

You might also like

- Forum Fluid End Pump PartsDocument18 pagesForum Fluid End Pump PartsriskvisionNo ratings yet

- Sanskrit Subhashit CollectionDocument110 pagesSanskrit Subhashit Collectionavinash312590% (72)

- TD700S TDF700S SteamTrapDocument4 pagesTD700S TDF700S SteamTrapauxiliar.termicaNo ratings yet

- Watson 3Document3 pagesWatson 3Jair Alvarez ApaleNo ratings yet

- WT4000 SteamTrapDocument2 pagesWT4000 SteamTrapdanielaNo ratings yet

- SteamTraps WD700SDocument2 pagesSteamTraps WD700SfranzumarragaNo ratings yet

- Spirax Sarco TD62Document2 pagesSpirax Sarco TD62JUANITOPYTNo ratings yet

- Trampas de Vapor FFTDocument5 pagesTrampas de Vapor FFTAndrés ChuquillaNo ratings yet

- Thermodynamic Steam TrapsDocument12 pagesThermodynamic Steam TrapsbuddhansamratNo ratings yet

- Catalogo Watson McdanielDocument12 pagesCatalogo Watson McdanielCarlos LopezNo ratings yet

- FTT FTTS SteamTrapDocument3 pagesFTT FTTS SteamTrapauxiliar.termicaNo ratings yet

- IB SERIES Inverted Bucket Steam TrapDocument6 pagesIB SERIES Inverted Bucket Steam TrapThanh ThuNo ratings yet

- Nicholson Thermostatic Steam TrapsDocument18 pagesNicholson Thermostatic Steam TrapsAli Fanani100% (1)

- EspeyDocument20 pagesEspeyGuillermo Esteban Diaz QuezadaNo ratings yet

- Purgadores de VaporDocument6 pagesPurgadores de VaporPaulo CostaNo ratings yet

- Steam Trapping OverviewDocument22 pagesSteam Trapping OverviewSekson JunsukplukNo ratings yet

- T330AH / T330AA - 250 PSI EPDM Steam Hose: WarningDocument1 pageT330AH / T330AA - 250 PSI EPDM Steam Hose: Warningsergio jose morales perazaNo ratings yet

- Valvula Presion y Vacio3100Document5 pagesValvula Presion y Vacio3100Anonymous hEqjR5gNo ratings yet

- Valvula Presion y Vacio3100 - CompressedDocument5 pagesValvula Presion y Vacio3100 - CompressedAnonymous hEqjR5gNo ratings yet

- Valvula Presion y Vacio3100-ComprimidoDocument5 pagesValvula Presion y Vacio3100-ComprimidoAnonymous hEqjR5gNo ratings yet

- (Repairable) : Clean Steam Thermostatic Steam TrapDocument1 page(Repairable) : Clean Steam Thermostatic Steam TrapPaulo CostaNo ratings yet

- Valvula Presion y Vacio3100-Comprimido - CompressedDocument5 pagesValvula Presion y Vacio3100-Comprimido - CompressedAnonymous hEqjR5gNo ratings yet

- SHOT SleeveDocument2 pagesSHOT Sleeve박상길No ratings yet

- Tubeskin Thermocouples PDFDocument6 pagesTubeskin Thermocouples PDFAyman Hassanien AzaziNo ratings yet

- Fte S F & T S T: Eries Loat Hermostatic Team RapsDocument4 pagesFte S F & T S T: Eries Loat Hermostatic Team RapsAlvaro Yaciel Rodríguez LagunesNo ratings yet

- Description Materials: Cast Iron For Horizontal InstallationDocument2 pagesDescription Materials: Cast Iron For Horizontal InstallationParth GosaiNo ratings yet

- Ul Listed Fire Damper Afdi-Gs/SsDocument20 pagesUl Listed Fire Damper Afdi-Gs/SsZubair KhanNo ratings yet

- Steam Trapping OverviewDocument22 pagesSteam Trapping OverviewHayder HusseinNo ratings yet

- AB Thermal Catalog All Silicone Rubber Fusing Tape SectionDocument50 pagesAB Thermal Catalog All Silicone Rubber Fusing Tape SectionDouglas LimaNo ratings yet

- SZR IV D Technical InformationDocument2 pagesSZR IV D Technical InformationdiogosaborNo ratings yet

- Nicholson NTD600 Series Thermodynamic SteamTrapDocument2 pagesNicholson NTD600 Series Thermodynamic SteamTrapmarlon19762009No ratings yet

- Steam TrapDocument2 pagesSteam TrapJozsef MagyariNo ratings yet

- Steam TrapsDocument2 pagesSteam Trapslaxmans20No ratings yet

- Conservation Vent (Pressure & Vacuum)Document8 pagesConservation Vent (Pressure & Vacuum)SudhirNo ratings yet

- L&J 94020-2BDocument8 pagesL&J 94020-2BBureau VeritasNo ratings yet

- Motor Protection: A. Motor Cooling MethodsDocument5 pagesMotor Protection: A. Motor Cooling MethodsamrezzatNo ratings yet

- Spirax Trap Review GST - 33 PDFDocument22 pagesSpirax Trap Review GST - 33 PDFFrank UrsNo ratings yet

- 19.UNIDIRECTIONAL Square Guillotine DamperDocument11 pages19.UNIDIRECTIONAL Square Guillotine DamperRohit BirajdarNo ratings yet

- Steam TrapDocument10 pagesSteam TrapvictorvikramNo ratings yet

- Steam Trap OverviewDocument15 pagesSteam Trap OverviewJodin Alido MahinayNo ratings yet

- SERIES 40/40D AND C250/260: Yarway Process Thermodynamic Steam TrapsDocument8 pagesSERIES 40/40D AND C250/260: Yarway Process Thermodynamic Steam TrapsEngr Mohammad FarhanNo ratings yet

- Parflex Fluid Conveyance: Temperature, Flexibility, Abrasion and Length ChangeDocument2 pagesParflex Fluid Conveyance: Temperature, Flexibility, Abrasion and Length ChangeYazad DoctorrNo ratings yet

- SMD GoedhartVRScustomized 2016-06 ENDocument2 pagesSMD GoedhartVRScustomized 2016-06 ENselvaortonNo ratings yet

- TPI WL 80-54 E - 0806 - FAG Heating Devices PowerThermDocument32 pagesTPI WL 80-54 E - 0806 - FAG Heating Devices PowerThermNuM NaNo ratings yet

- Breather Valve 94020-3HDocument8 pagesBreather Valve 94020-3Hbuzz cmkyNo ratings yet

- TD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Document2 pagesTD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Rupesh DesaiNo ratings yet

- 6 Heavy Duty Cooler - Ultra Temp Brochure Rev - 4 FinalDocument13 pages6 Heavy Duty Cooler - Ultra Temp Brochure Rev - 4 FinalSantoshNo ratings yet

- Eurodist System: Laboratory Distillation Plants Astm D 2892 and D 5236Document24 pagesEurodist System: Laboratory Distillation Plants Astm D 2892 and D 5236AlexanderNo ratings yet

- FMTD64Document2 pagesFMTD64Ilaya SundaramNo ratings yet

- Ficha Tecnica Amstrong.1Document2 pagesFicha Tecnica Amstrong.1ANo ratings yet

- Valquatight Gasket: Valqua No. 6590 Product Name BLACKTIGHT (Basic Design)Document5 pagesValquatight Gasket: Valqua No. 6590 Product Name BLACKTIGHT (Basic Design)성수길No ratings yet

- Conservation Vent (Pressure & Vacuum)Document8 pagesConservation Vent (Pressure & Vacuum)Bureau VeritasNo ratings yet

- Duet W10255469B PDFDocument1 pageDuet W10255469B PDFJuan MedinaNo ratings yet

- SG Interspiro Spiromatic 90u DatasheetDocument2 pagesSG Interspiro Spiromatic 90u DatasheetSorin - Viorel MaresNo ratings yet

- Air 0423Document34 pagesAir 0423AdilsonNo ratings yet

- TERMODINAMICASDocument12 pagesTERMODINAMICASLuis LugoNo ratings yet

- Customized Air Coolers Cooling & Freezing (Fezn)Document2 pagesCustomized Air Coolers Cooling & Freezing (Fezn)gemagdyNo ratings yet

- Float & Thermostatic Steam Traps: For Efficient Condensate Drainage of Industrial Process and HVAC EquipmentDocument12 pagesFloat & Thermostatic Steam Traps: For Efficient Condensate Drainage of Industrial Process and HVAC Equipmentmember1000No ratings yet

- Garlock: Compression Packing Technical ManualDocument28 pagesGarlock: Compression Packing Technical ManualjbertralNo ratings yet

- Sink CSMDocument2 pagesSink CSMZulfiqar AhmedNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Mindman MUSDocument1 pageMindman MUSMarcos Mezahuaman LaimeNo ratings yet

- Low Pressure Second Stage Regulators LV5503B Series: Materials ApplicationDocument1 pageLow Pressure Second Stage Regulators LV5503B Series: Materials ApplicationMarcos Mezahuaman LaimeNo ratings yet

- Trampa Tipo Flotador FTEDocument4 pagesTrampa Tipo Flotador FTEMarcos Mezahuaman LaimeNo ratings yet

- IB SERIES Inverted Bucket Steam TrapDocument6 pagesIB SERIES Inverted Bucket Steam TrapThanh ThuNo ratings yet

- FT Series: Float & Thermostatic Steam TrapDocument2 pagesFT Series: Float & Thermostatic Steam TrapMarcos Mezahuaman LaimeNo ratings yet

- V4055A, B, D, E On-Off Fluid Power Gas Valve Actuator: ApplicationDocument8 pagesV4055A, B, D, E On-Off Fluid Power Gas Valve Actuator: ApplicationMarcos Mezahuaman LaimeNo ratings yet

- Guia de Autoevaluacion AmbientalDocument6 pagesGuia de Autoevaluacion AmbientalSergio LorenzoNo ratings yet

- Instruction Manual: RatingsDocument24 pagesInstruction Manual: RatingsMarcos Mezahuaman LaimeNo ratings yet

- Guia de Autoevaluacion AmbientalDocument6 pagesGuia de Autoevaluacion AmbientalSergio LorenzoNo ratings yet

- Catalogo General de Valvulas KUNKLEDocument16 pagesCatalogo General de Valvulas KUNKLEMarcos Mezahuaman LaimeNo ratings yet

- 1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Document2 pages1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Mario FloresNo ratings yet

- Nescom Test For AM (Electrical) ImpDocument5 pagesNescom Test For AM (Electrical) Impشاہد یونسNo ratings yet

- Cambridge IGCSE: CHEMISTRY 0620/42Document12 pagesCambridge IGCSE: CHEMISTRY 0620/42Khairun nissaNo ratings yet

- RSC Article Template-Mss - DaltonDocument15 pagesRSC Article Template-Mss - DaltonIon BadeaNo ratings yet

- (Isaac Asimov) How Did We Find Out About AntarcticDocument24 pages(Isaac Asimov) How Did We Find Out About AntarcticDrBabu PSNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNo ratings yet

- Cpar Characteristics and Functions Week 3Document128 pagesCpar Characteristics and Functions Week 3christianwood0117No ratings yet

- Group 2 ITI Consensus Report: Prosthodontics and Implant DentistryDocument9 pagesGroup 2 ITI Consensus Report: Prosthodontics and Implant DentistryEsme ValenciaNo ratings yet

- Strategic Marketing: The University of Lahore (Islamabad Campus)Document3 pagesStrategic Marketing: The University of Lahore (Islamabad Campus)Sumaira IrshadNo ratings yet

- Accounting Students' Perceptions On Employment OpportunitiesDocument7 pagesAccounting Students' Perceptions On Employment OpportunitiesAquila Kate ReyesNo ratings yet

- Power System TransientsDocument11 pagesPower System TransientsKhairul AshrafNo ratings yet

- LEMBAR JAWABAN CH.10 (Capital Budgeting Techniques)Document4 pagesLEMBAR JAWABAN CH.10 (Capital Budgeting Techniques)Cindy PNo ratings yet

- Research Group 3 11abmb1Document32 pagesResearch Group 3 11abmb1arianeNo ratings yet

- Refutation EssayDocument6 pagesRefutation Essayapi-314826327No ratings yet

- Homeopatija I KancerDocument1 pageHomeopatija I KancermafkoNo ratings yet

- Sainik School Balachadi: Name-Class - Roll No - Subject - House - Assigned byDocument10 pagesSainik School Balachadi: Name-Class - Roll No - Subject - House - Assigned byPagalNo ratings yet

- Microwave EngineeringDocument2 pagesMicrowave Engineeringசுந்தர் சின்னையா0% (9)

- Omnitron CatalogDocument180 pagesOmnitron Catalogjamal AlawsuNo ratings yet

- Masoneilan - 78 Series Air Filter Regulators IOMDocument8 pagesMasoneilan - 78 Series Air Filter Regulators IOMNithyANo ratings yet

- Lab Manual Switchgear and Protection SapDocument46 pagesLab Manual Switchgear and Protection SapYash MaheshwariNo ratings yet

- Body Systems Portfolio - Tommy JDocument8 pagesBody Systems Portfolio - Tommy Japi-554072790No ratings yet

- 35 Electrical Safety SamanDocument32 pages35 Electrical Safety SamanSaman Sri Ananda RajapaksaNo ratings yet

- KCG-2001I Service ManualDocument5 pagesKCG-2001I Service ManualPatrick BouffardNo ratings yet

- Plain English Part 2Document18 pagesPlain English Part 2ابو ريمNo ratings yet

- STS Module 11Document64 pagesSTS Module 11Desiree GalletoNo ratings yet

- Computer System Servicing 1 NC-II MODULE 8A (Second Semester: Week 6 - 7)Document19 pagesComputer System Servicing 1 NC-II MODULE 8A (Second Semester: Week 6 - 7)Carl John GomezNo ratings yet

- Xtype Power Train DTC SummariesDocument53 pagesXtype Power Train DTC Summariescardude45750No ratings yet

- Drager Narkomed 6400 Field Service Procedure Software Version 4.02 EnhancementDocument24 pagesDrager Narkomed 6400 Field Service Procedure Software Version 4.02 EnhancementAmirNo ratings yet

- 160kW SOFT STARTER - TAP HOLE 1Document20 pages160kW SOFT STARTER - TAP HOLE 1Ankit Uttam0% (1)