Professional Documents

Culture Documents

Pressure Booster An 17

Uploaded by

jack macOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Booster An 17

Uploaded by

jack macCopyright:

Available Formats

Application Note:

Pressure Booster Accessory

The Problem The Solution

High-pressure air is frequently required to operate external Uson can supply a custom-matched pressure booster operated

clamping devices used to seal the product under test. In other by normal house air. An air input of 80 psig can be boosted to

situations, high pressure air is used to inflate the product itself. pressures up to 500 psig.

To supply these high test pressures (typically from 150 to 500 A Uson pressure booster has these advantages over motor-

psig), some firms bring in bottles of compressed gas, or install driven compressors and gas bottles:

high-pressure motor-driven air compressors.

Quiet: No loud motors and pistons

Motor-driven compressors have a large energy demand, are

Safe: No risk in overheating or explosion.

noisy, can be fire hazards, and require maintenance to keep them

Clean: No oil to contaminate air.

clean and working.

Small: No need for large production space.

Gas cylinders are expensive to rent and can be dangerous to

store in production settings. Besides these advantages, a Uson pressure booster costs much

less than renting gas bottles or buying a clean, high-pressure,

motor-driven compressor.

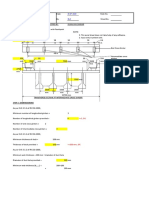

How It Works

The pressure booster works like this:

• Clean and dry house air is supplied to the valve (V)

(Figure 1)

• The valve allows the A-side of the piston to fill with house

air pressure through the check valve (CV1)

• The main valve then directs house air to the B-side of the

booster piston. The booster then compresses the air in the

A-side to a higher pressure. The exact pressure increase

depends on the booster bore, stages, and type selected.

• The boosted air then moves to the accumulator through

check valve CV2. The system is ready for the next cycle.

• The cycle operation is controlled by a small time, which

causes the booster to function as long as the tester is in

operation.

Figure 1

Air-to-Air Booster Pneumatic Diagram

AN-17 Dec2009

United States | United Kingdom | China

Application Note:

Pressure Booster Accessory

Booster Theory Boosters Built by Uson

The packaging of multiple states (pistons) exerting force on Uson can design a pressure booster specifically for your

a common shaft produces an air output with a potential much requirements.

greater than the air input. Think of it as an air multiplier: with The booster is contained in a metal enclosure and there is no risk

each stroke of the piston, the same multiplied air is created. of moving parts or electrical exposure to the operator. All the

customer needs to do is supply clean, dry air; generally the same

Of course, the piston must activate a number of times to create air delivered to the tester.

the required volume of air; the higher the output pressure, the

By selecting the proper combination of bore size, stroke, power

more times the piston must activate.

factor and regulating input pressure, the exact output pressure

Output force is a function of the cylinder multiplied by the total and required volume can be achieved and maintained.

effective piston area (one piston times the number of stages). For testing small parts or operating small clamping devices, a

The output force is therefore two, three, or four times that of a small pressure accumulator is adequate. For larger products and

conventional single-piston cylinder. clamping devices, a larger pressure accumulator can be used.

Applications Benefits

Consider using a pressure booster when an air pressure above • Less expensive than bottled gas

normal house air is needed to operate clamping devices or for high

test pressures. • Less expensive than motor-driven compressors

A pressure booster can be applied to manual or automated • Can be located right at the test site

operations.

• All components are in one small enclosure

Uson supplies a complete ready-to-operate system. The customer

• No danger of explosion.

need only supply AC power and clean, dry house air.

• Uses existing house air

Please contact Uson for assistance in selecting the optimum air-to-

air booster for your application. • Pressure can be matched to the application

• Very few moving parts

• Very low maintenance

Uson L.P.

8640 N. Eldridge Parkway

Houston, Texas 77041

USA

Phone: +1-281-671-2000

Fax: +1-281-671-2001

info@uson.com

www.uson.com

United States | United Kingdom | China

You might also like

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Linked PDFDocument422 pagesLinked PDFBander ShtatNo ratings yet

- Manual Skidders John DeereDocument16 pagesManual Skidders John Deererossini_daniel50% (2)

- BDA30603 Tutorial 4Document7 pagesBDA30603 Tutorial 4Firdaus JannahNo ratings yet

- AGMA 925 Effect of Lubrification On Gear SurfaceDocument58 pagesAGMA 925 Effect of Lubrification On Gear SurfaceEry FreireNo ratings yet

- Pressure TestingDocument27 pagesPressure Testingsaie_1No ratings yet

- Compressor, Main Parts, Types and Working Principle: PV NRT P TDocument6 pagesCompressor, Main Parts, Types and Working Principle: PV NRT P TMuhammad Arslan AfzalNo ratings yet

- Application Note:: Autocouple DevicesDocument2 pagesApplication Note:: Autocouple Devicesjack macNo ratings yet

- 6 Design of Air Booster PDFDocument7 pages6 Design of Air Booster PDFSalih AnwarNo ratings yet

- Aircraft Pneumatic and Environmental Control SystemsDocument8 pagesAircraft Pneumatic and Environmental Control SystemsKishorkumar Chandrasen UkirdeNo ratings yet

- PV211 ManualDocument2 pagesPV211 Manualسمية صلاحNo ratings yet

- Amit-Training Report On Pneumaticsat FestoDocument27 pagesAmit-Training Report On Pneumaticsat Festoamit100% (2)

- Chapter 1 - FullDocument60 pagesChapter 1 - FullMohamad Zulamirulfaha100% (1)

- FLMC Whitepaper Dust Collector March2021Document6 pagesFLMC Whitepaper Dust Collector March2021Alicos MathewNo ratings yet

- HTTP WWW Red Bag Com Engineering Guides 582 BN Eg k4 Standard Method For Safety Relief Valve Calculations HTMLDocument9 pagesHTTP WWW Red Bag Com Engineering Guides 582 BN Eg k4 Standard Method For Safety Relief Valve Calculations HTMLmashudi_fikriNo ratings yet

- Drill JigDocument36 pagesDrill JigVijay GanapathyNo ratings yet

- Manual Book Booster 25hpDocument32 pagesManual Book Booster 25hpBernad OrlandoNo ratings yet

- Programmable Regulator: Application NoteDocument2 pagesProgrammable Regulator: Application Notejack macNo ratings yet

- DJJ5123 Introduction of PneumaticDocument35 pagesDJJ5123 Introduction of PneumaticMigug SalamNo ratings yet

- Haskel GasBoostersDocument36 pagesHaskel GasBoosterskammoNo ratings yet

- Control Valve SourcebookDocument5 pagesControl Valve Sourcebookpneuma110No ratings yet

- Chapter15 Pneumatic Hoist 2Document8 pagesChapter15 Pneumatic Hoist 2YAKUBU A. AROGENo ratings yet

- Tescom Technical Training - Pressure Regulators Explained - Ver1.1Document19 pagesTescom Technical Training - Pressure Regulators Explained - Ver1.1Amod DeshpandeNo ratings yet

- Fabrication Pneumatic JackDocument43 pagesFabrication Pneumatic JackElakkiya Karthic50% (2)

- Design and Fabrication Automatic Pneumatic Inbuilt Jack System by Using Fifth Wheel Parking SystemDocument2 pagesDesign and Fabrication Automatic Pneumatic Inbuilt Jack System by Using Fifth Wheel Parking Systemsubramanian.vNo ratings yet

- Section 30 - Relief ValvesDocument17 pagesSection 30 - Relief ValveshammamiNo ratings yet

- Hydraulic Starting System Installation Operating ManualDocument6 pagesHydraulic Starting System Installation Operating ManualCali MelendezNo ratings yet

- Compressor PDFDocument57 pagesCompressor PDFAhmad Wildan ZakawaliNo ratings yet

- Oxygen Safety PracticesDocument6 pagesOxygen Safety Practicestoxa0707No ratings yet

- Group # 03 (Eve) Gas Compression SystemDocument25 pagesGroup # 03 (Eve) Gas Compression SystemMALIK ZARYABBABARNo ratings yet

- EjectorsDocument4 pagesEjectorsTirathBaxiNo ratings yet

- Fs Curtis - Sat45-355+en - 副本Document8 pagesFs Curtis - Sat45-355+en - 副本Heri BatanghariNo ratings yet

- Safety Valve LaserDocument15 pagesSafety Valve Lasersajjad_naghdi241No ratings yet

- Static Pressure in HVAC Systems BOACDocument32 pagesStatic Pressure in HVAC Systems BOACKesava DhoniNo ratings yet

- Chapter - 1 1.1 PunchingDocument53 pagesChapter - 1 1.1 PunchingKkkkNo ratings yet

- Agk Lecture 3Document40 pagesAgk Lecture 3Emaan Sattar KhanNo ratings yet

- INTRODUCTIONDocument13 pagesINTRODUCTIONPrabhav KulkarniNo ratings yet

- Mel 215 - Operation of Single Acting Cylinde-1Document8 pagesMel 215 - Operation of Single Acting Cylinde-1Aliyu omeiza YusufNo ratings yet

- Haskel Catalogo Dei Gas BoostersDocument36 pagesHaskel Catalogo Dei Gas BoosterslorytechNo ratings yet

- Pneumatic Hacksaw MachineDocument41 pagesPneumatic Hacksaw MachineMahesh KumarNo ratings yet

- Mechanical Engineering Trainee: Mohd - AqifDocument10 pagesMechanical Engineering Trainee: Mohd - AqifMohd AqifNo ratings yet

- Trouble Shooting in Vacuum PumpDocument12 pagesTrouble Shooting in Vacuum Pumpj172No ratings yet

- Anti Surge Control ValveDocument7 pagesAnti Surge Control ValveMuhammadAsimNo ratings yet

- Understanding BlowersDocument11 pagesUnderstanding BlowersJam BabNo ratings yet

- HTTP WWW - Spiraxsarco.com Resources Steam-Engineering-tutorials Control-Applications Pressure-Contr NewDocument15 pagesHTTP WWW - Spiraxsarco.com Resources Steam-Engineering-tutorials Control-Applications Pressure-Contr NewPalash KayathwalNo ratings yet

- Air Amplifiers SystemsDocument12 pagesAir Amplifiers Systemsfake7083No ratings yet

- BlowerDocument32 pagesBlowerajaysharma_1009No ratings yet

- CompressorDocument10 pagesCompressorVina SulistyaNo ratings yet

- Automatic Pneumatic Vice and JackDocument33 pagesAutomatic Pneumatic Vice and JackTechnico Technocrats100% (2)

- Introduction To Pneumatic ControlDocument10 pagesIntroduction To Pneumatic ControlRavikant TendulkarNo ratings yet

- Jet Ejector ProcessDocument6 pagesJet Ejector Processfais verianNo ratings yet

- Compressed Air Production Using Vehicle SuspensorDocument28 pagesCompressed Air Production Using Vehicle SuspensorJyotishk MalviyaNo ratings yet

- Twin Lobe CompressorDocument14 pagesTwin Lobe Compressorpbs9890271109100% (1)

- BOOTSDocument9 pagesBOOTSDamon LeongNo ratings yet

- Gas BoostersDocument36 pagesGas BoostersRadhakrishnan Sreerekha100% (1)

- Flare Gas Recovery & Zero Flare SolutionsDocument16 pagesFlare Gas Recovery & Zero Flare SolutionsEddie TaiNo ratings yet

- Arel Guna PneumaticDocument8 pagesArel Guna PneumaticKhairul SyahreelNo ratings yet

- Q151 WML 204Document9 pagesQ151 WML 204Luis AlfonsoNo ratings yet

- Turbocharger and SuperchargerDocument65 pagesTurbocharger and Superchargerzia malikNo ratings yet

- Air CompressorsDocument44 pagesAir CompressorsZYJA DLANE MALITNo ratings yet

- Ass. 2Document18 pagesAss. 2Ramez RaymonNo ratings yet

- JJ512 Pneumatic & HydraulicDocument35 pagesJJ512 Pneumatic & HydraulicHafiz UdinNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- LDF Twosteppet e 1120 Reva - Web 1Document4 pagesLDF Twosteppet e 1120 Reva - Web 1jack macNo ratings yet

- 070 EN Leak Detection11Document36 pages070 EN Leak Detection11jack macNo ratings yet

- IJERTV2IS80178Document16 pagesIJERTV2IS80178jack macNo ratings yet

- Four-Channel Sequential Tester: Application NoteDocument2 pagesFour-Channel Sequential Tester: Application Notejack macNo ratings yet

- 4-Channel Concurrent Tester: Application NoteDocument2 pages4-Channel Concurrent Tester: Application Notejack macNo ratings yet

- Programmable Regulator: Application NoteDocument2 pagesProgrammable Regulator: Application Notejack macNo ratings yet

- Mass Flow Theory: Application NoteDocument2 pagesMass Flow Theory: Application Notejack macNo ratings yet

- 4-Channel Concurrent and Sequential Tester: Application NoteDocument2 pages4-Channel Concurrent and Sequential Tester: Application Notejack macNo ratings yet

- Occlusion Testing An 20Document2 pagesOcclusion Testing An 20jack macNo ratings yet

- Quantifi Ed Leak Rate Using Mass Flow: Application NoteDocument2 pagesQuantifi Ed Leak Rate Using Mass Flow: Application Notejack macNo ratings yet

- Ateq Leak Testing: Quality Control SpecificationDocument11 pagesAteq Leak Testing: Quality Control Specificationjack macNo ratings yet

- Leak Test Instrument For Industrial Quality Control: HighlightsDocument2 pagesLeak Test Instrument For Industrial Quality Control: Highlightsjack macNo ratings yet

- Tips and Tricks From The Experts: Virtual Leaks: Formation, Detection, and AvoidanceDocument4 pagesTips and Tricks From The Experts: Virtual Leaks: Formation, Detection, and Avoidancejack macNo ratings yet

- Pressure Decay Tester: Application NoteDocument2 pagesPressure Decay Tester: Application Notejack macNo ratings yet

- Vtech Leak DetectionDocument42 pagesVtech Leak Detectionjack macNo ratings yet

- Ateq Air Leak Testing: Automobile TransmissionDocument12 pagesAteq Air Leak Testing: Automobile Transmissionjack macNo ratings yet

- Palmer CAR-Series Sand Reclamation SystemsDocument2 pagesPalmer CAR-Series Sand Reclamation SystemsJORGE RUBENNo ratings yet

- DDocument47 pagesDshaonaaNo ratings yet

- 4 Versus 8 Counterweights For An I4Document10 pages4 Versus 8 Counterweights For An I4cyberjuanNo ratings yet

- Stanzbiegeautomat RM 40b Bihler enDocument2 pagesStanzbiegeautomat RM 40b Bihler enJonny AnstettNo ratings yet

- Debre Tabor University Faculty of Technology, Department of Mechanical EngineeringDocument3 pagesDebre Tabor University Faculty of Technology, Department of Mechanical EngineeringVenkata DineshNo ratings yet

- 2007 Engine ManagementDocument51 pages2007 Engine ManagementFausto TrentiniNo ratings yet

- Experiment Reaction TurbineDocument13 pagesExperiment Reaction TurbinemahabubNo ratings yet

- Deflection of A Curved BarDocument2 pagesDeflection of A Curved Bartariqlewis07No ratings yet

- Electrovalvula Norgren V52Document4 pagesElectrovalvula Norgren V52Base SistemasNo ratings yet

- ERMETO ORIGINAL Valves - WVDocument1 pageERMETO ORIGINAL Valves - WVDaniel MarNo ratings yet

- ZH 750 ManualDocument15 pagesZH 750 ManualCesar MoraNo ratings yet

- Centrifugal Compressor Power-US Field UnitsDocument4 pagesCentrifugal Compressor Power-US Field UnitssurawutwijarnNo ratings yet

- Kinematics of Linear MotionDocument96 pagesKinematics of Linear MotionJoanne SohNo ratings yet

- Design, Analysis of A Two-Bladed Wind Turbine HubDocument33 pagesDesign, Analysis of A Two-Bladed Wind Turbine Hub1234rakNo ratings yet

- PSC I Girder Design by IRC Code (Old)Document109 pagesPSC I Girder Design by IRC Code (Old)Structural SpreadsheetsNo ratings yet

- TW10 Flanged Thermowell: Part of Your BusinessDocument2 pagesTW10 Flanged Thermowell: Part of Your BusinessogyriskyNo ratings yet

- C3 HazopDocument9 pagesC3 HazopGian Michael Boyero100% (1)

- LT32559 - FH230 Series - Fuel ProDocument2 pagesLT32559 - FH230 Series - Fuel ProShananda SoniNo ratings yet

- EDU Detailed Drawings Exercises 2017Document51 pagesEDU Detailed Drawings Exercises 2017SmrileNo ratings yet

- Honda CB400 CM400 CB CM 400 Service Specifications ManualDocument13 pagesHonda CB400 CM400 CB CM 400 Service Specifications ManualNirmala IddawalaNo ratings yet

- Lift and Drag Review and Renew - Correlations of 50 Years of NACA and NASA Test Data On The Effects of Wing Planform and ThicknessDocument17 pagesLift and Drag Review and Renew - Correlations of 50 Years of NACA and NASA Test Data On The Effects of Wing Planform and ThicknessHaliunaa BatboldNo ratings yet

- STOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionDocument20 pagesSTOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionAHMED AMIRANo ratings yet

- Jet - Lube Industrial CatalogDocument25 pagesJet - Lube Industrial CatalogJeremias UtreraNo ratings yet

- 800D Product Guide Imperial 2022 10Document24 pages800D Product Guide Imperial 2022 10Alejandro DuarteNo ratings yet

- ME3431-part 1Document107 pagesME3431-part 1tfhfnrnNo ratings yet