Professional Documents

Culture Documents

ERMETO ORIGINAL Valves - WV

Uploaded by

Daniel MarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ERMETO ORIGINAL Valves - WV

Uploaded by

Daniel MarCopyright:

Available Formats

Valves

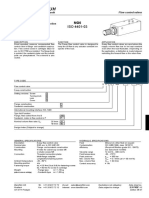

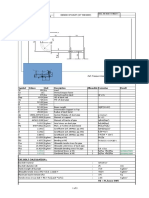

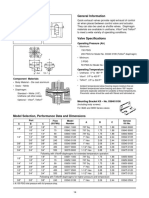

WV Alternating valve

EO 24° cone end / EO 24° cone end / EQ 24° cone end

These valves permit the passage of flow from either inlet 1 or 2 to the outlet port whilst shutting of the inlet port not in use.

The shutting off, of an inlet is achieved by a floating ball bearing which moves by the pressure of the flow.

Material: steel Directions of flow:

Surface finish: Cr(VI)-free.

D1 → D3 = D2 closed

Valves are not recommended for compressed air and gases.

D2 → D3 = D1 closed

WV-valves are not to be used in connection with weld nipples, swivel nuts

etc. where there is no contact with a shoulder stop in the inner cone.

Temperature range without pressure reductions: –40°C up to +120°C.

Recommended fitting position as shown in the picture.

Leakage rate for alternating valves hydraulic test

with test pressure = Pmax: approx. 20 drops (test period of 1 minute).

D1 PN

Weight (bar)1)

Series a T1 DN L1 L2 L3 S1 S2 g/1 piece Order code* CF

L3) 8 M 14×1.5 4.5 21 14 29 14 17 53 WV08LOMD 160

10 M 16×1.5 6.0 22 15 30 17 19 73 WV10LOMD 160

12 M 18×1.5 7.5 24 17 32 19 22 96 WV12LOMD 160

15 M 22×1.5 10.0 28 21 36 19 27 134 WV15LOMD 160

1) Pressure shown = item deliverable

3) L = light series

PN (bar)

= PN (MPa)

10

Delivery without nut and ring. Information on ordering complete

fittings or alternative sealing materials see page P56.

Order code suffixes

Material Suffix Example Standard

surface sealing material

and material (no additional

*Please add the suffixes suffix needed)

below according to the material/

surface required. Steel, zinc plated, Cr(VI)-free CF WV08LOMDCF Steel ball

P56 Catalogue 4100-10/UK

P56 Geeve Hydraulics 2017 © | Catalog 2017 Valves

You might also like

- RHDIDocument1 pageRHDIxlzyydf2015No ratings yet

- Check Valve Hydraulically Pilot Operated PDFDocument8 pagesCheck Valve Hydraulically Pilot Operated PDFnemi90No ratings yet

- Z P R G A R C: ERO Ressure Egulator AND AS/ IR Atio OntrolDocument7 pagesZ P R G A R C: ERO Ressure Egulator AND AS/ IR Atio OntrolPablo MartinezNo ratings yet

- 3-Way Flow Control Valve Flange-And Sandwich Construction Q 42 L/min Q 40 L/min P 350 BarDocument2 pages3-Way Flow Control Valve Flange-And Sandwich Construction Q 42 L/min Q 40 L/min P 350 BarЕвгений ШкарупеловNo ratings yet

- tsf2 h2 Coalescing Filter Data Sheet enDocument4 pagestsf2 h2 Coalescing Filter Data Sheet enCLAUDIA RAMIREZ SAUCEDONo ratings yet

- Wika 910.11 Shut-Off Valve Catalog PageDocument4 pagesWika 910.11 Shut-Off Valve Catalog PageM MNo ratings yet

- T Beam To BS 8110Document11 pagesT Beam To BS 8110Samitha SoysaNo ratings yet

- Ari 23046 - Stop ValvesDocument1 pageAri 23046 - Stop ValvesPedro Montes MarinNo ratings yet

- 2008 - 2 - Tube & PipeDocument7 pages2008 - 2 - Tube & PipecanettijNo ratings yet

- FK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsDocument2 pagesFK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsNguyen KhaNo ratings yet

- T4638 DatasheetDocument12 pagesT4638 DatasheetMUHAMMAD ABHAR AMZAR BIN ZAMZURINo ratings yet

- (31000 - 31200) Series: Butterfly Valve Wafer TypeDocument9 pages(31000 - 31200) Series: Butterfly Valve Wafer TypefotopredicNo ratings yet

- 9900 Series DatasheetDocument3 pages9900 Series DatasheetHans HongNo ratings yet

- 4/2 and 4/3 Way Proportional Directional Valve, Pilot Operated, Without Electrical Feedback, Seawater Resistant Types 4WRZ J and 4WRH JDocument6 pages4/2 and 4/3 Way Proportional Directional Valve, Pilot Operated, Without Electrical Feedback, Seawater Resistant Types 4WRZ J and 4WRH JАлександр БулдыгинNo ratings yet

- S-16 16s eDocument4 pagesS-16 16s eedark2009No ratings yet

- Pioneer cdj-350-s Multiplayer Serv-Info 2011 SMDocument2 pagesPioneer cdj-350-s Multiplayer Serv-Info 2011 SMEsmir MarinNo ratings yet

- 1offtake Gates DesignDocument26 pages1offtake Gates Designprasadnn2001No ratings yet

- GW WS020 1004 E TankcoolDocument3 pagesGW WS020 1004 E TankcoolNiki PratamaNo ratings yet

- Swing Check Valve Rubber DiscDocument2 pagesSwing Check Valve Rubber DiscsathishNo ratings yet

- 4133 - GV Sub Fig7012Document6 pages4133 - GV Sub Fig7012Bryan STNo ratings yet

- Yokogawa: Y/11DM Pneumatic Differential Pressure Transmitter User's ManualDocument5 pagesYokogawa: Y/11DM Pneumatic Differential Pressure Transmitter User's ManualRabah AmidiNo ratings yet

- VSO-SE-DL 055211X03Z Pilot Operated Check SingleDocument2 pagesVSO-SE-DL 055211X03Z Pilot Operated Check SingleCarlos Andrés CuelloNo ratings yet

- DMP4015SK3: P-Channel Enhancement Mode MosfetDocument7 pagesDMP4015SK3: P-Channel Enhancement Mode MosfetpaulpuscasuNo ratings yet

- Planta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEDocument1 pagePlanta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEAnthony InostrozaNo ratings yet

- Ductworkissues PDFDocument51 pagesDuctworkissues PDFKaffelNo ratings yet

- 2/2-Way Coaxial Valve CX03F To CX05F Direct Acting Flange VersionDocument4 pages2/2-Way Coaxial Valve CX03F To CX05F Direct Acting Flange VersionvishadkapadiaNo ratings yet

- Symbol Values Unit Description Allowable Formulae Result: Eye Bolt CalculationDocument12 pagesSymbol Values Unit Description Allowable Formulae Result: Eye Bolt CalculationNaveen JeevaNo ratings yet

- Valvula Accionamiento Asiento Inclinado Buschjost 84660Document2 pagesValvula Accionamiento Asiento Inclinado Buschjost 84660Base SistemasNo ratings yet

- Level Switch NS 10/NS 25 ..-AM: FluidcontrolDocument7 pagesLevel Switch NS 10/NS 25 ..-AM: FluidcontrolNguyễn Kim HùngNo ratings yet

- Sulfur Hy SealDocument6 pagesSulfur Hy SealodeinatusNo ratings yet

- Tosaca: CX 45-21 RFQ PSVDocument2 pagesTosaca: CX 45-21 RFQ PSVichi ezzahraNo ratings yet

- Application For Witness Inspection: Ly Hong Huan Hong River Surface Water Treatment Plant ProjectDocument2 pagesApplication For Witness Inspection: Ly Hong Huan Hong River Surface Water Treatment Plant ProjectPhu PhuocNo ratings yet

- P-42 - Tank Monitoring SystemDocument118 pagesP-42 - Tank Monitoring SystemCengiz İyiceNo ratings yet

- Linuo Model DecodingDocument3 pagesLinuo Model DecodingMuhammad RidwanNo ratings yet

- Globe Stop Check Valves FK 33.75 (9) GB: Primary CharacteristicsDocument2 pagesGlobe Stop Check Valves FK 33.75 (9) GB: Primary CharacteristicsNguyen KhaNo ratings yet

- Re 29175 2021-11Document20 pagesRe 29175 2021-11Rafael RicardoNo ratings yet

- TLV SJ3FXDocument2 pagesTLV SJ3FXÁlvaro Martínez FernándezNo ratings yet

- 2.25.e.rp45 Pressure Reducing Valve DN15-100-EnDocument5 pages2.25.e.rp45 Pressure Reducing Valve DN15-100-EnMa KiepNo ratings yet

- Heated HoseDocument24 pagesHeated HoseMethodes BceramNo ratings yet

- VSO-DE Pilot Operated Check, DualDocument2 pagesVSO-DE Pilot Operated Check, DualHector MoragaNo ratings yet

- 4TB & 8TB Moment ConnectionDocument13 pages4TB & 8TB Moment ConnectionShamik Ghosh0% (1)

- Diaphragm ValveDocument2 pagesDiaphragm ValveHardik ShahNo ratings yet

- KHB / KHM: Ball ValvesDocument6 pagesKHB / KHM: Ball ValvesJaime AmadorNo ratings yet

- Pillar 2009Document28 pagesPillar 2009GoodBikesNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Project: 2201-236 - Design and Construction of KIZAD Gas Network - Phase 1Document2 pagesProject: 2201-236 - Design and Construction of KIZAD Gas Network - Phase 1Habibur Rehman MNo ratings yet

- Gs01f06a00 50eDocument8 pagesGs01f06a00 50eDaniloNo ratings yet

- Special Packings For Rod Seals Nitrile Rubber (NBR) : MaterialDocument2 pagesSpecial Packings For Rod Seals Nitrile Rubber (NBR) : MaterialTeddy NsNo ratings yet

- Van Cong Ty Chim Ydk Apt2Document2 pagesVan Cong Ty Chim Ydk Apt2Le NghiNo ratings yet

- Biztonsági SzelepDocument2 pagesBiztonsági SzelepSándor PetrovicsNo ratings yet

- SD12D08F01 02eDocument1 pageSD12D08F01 02eHélio SousaNo ratings yet

- Lift Check Valve: Straight, Flanged EndsDocument1 pageLift Check Valve: Straight, Flanged Endsadvantage025No ratings yet

- SMC Pressure GaugeDocument12 pagesSMC Pressure Gaugeringo limNo ratings yet

- Licad86061000010 F06Document1 pageLicad86061000010 F06Sakeel WagirkhanNo ratings yet

- Application For Witness Inspection: (Kesv Application No. 20O036/20-PM-18 MQ-KESV-002)Document2 pagesApplication For Witness Inspection: (Kesv Application No. 20O036/20-PM-18 MQ-KESV-002)Phu PhuocNo ratings yet

- Proportional Flow Control Valve, Without Position Control: List of Contents FeaturesDocument16 pagesProportional Flow Control Valve, Without Position Control: List of Contents FeaturesAsifNo ratings yet

- Pressure Filter, Series DA 2215: Nps 4" Class 150 PsiDocument2 pagesPressure Filter, Series DA 2215: Nps 4" Class 150 PsiRidha AbbassiNo ratings yet

- Valve - Flanged, Ball E5512 - KHMFF - DN65 - 125 - HYDACDocument4 pagesValve - Flanged, Ball E5512 - KHMFF - DN65 - 125 - HYDACAlexander SNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Pliovic GoodyearDocument1 pagePliovic GoodyearDaniel MarNo ratings yet

- Thrust CylindersDocument11 pagesThrust CylindersDaniel MarNo ratings yet

- FILTROS Maxiflow - Series PARKERDocument5 pagesFILTROS Maxiflow - Series PARKERDaniel MarNo ratings yet

- Valvula de Flotador DanffossDocument14 pagesValvula de Flotador DanffossDaniel MarNo ratings yet

- Piston Seal Kit 0995-M12Document2 pagesPiston Seal Kit 0995-M12Daniel MarNo ratings yet

- Industrial Hoses BrochureDocument7 pagesIndustrial Hoses BrochureDaniel MarNo ratings yet

- Flowmeters MonitorsDocument12 pagesFlowmeters MonitorsDaniel MarNo ratings yet

- Performance Information Series PVP 100/140 Pressure Compensated, Variable Volume, Piston PumpsDocument10 pagesPerformance Information Series PVP 100/140 Pressure Compensated, Variable Volume, Piston PumpsDaniel MarNo ratings yet

- Vacuum Hose KURIYAMADocument2 pagesVacuum Hose KURIYAMADaniel MarNo ratings yet

- Manual Measuring Instrument: The Service MasterDocument2 pagesManual Measuring Instrument: The Service MasterDaniel MarNo ratings yet

- Bomba Pavc100 ParkerDocument10 pagesBomba Pavc100 ParkerDaniel MarNo ratings yet

- M2T - MegaFlex - Hose GATESDocument4 pagesM2T - MegaFlex - Hose GATESDaniel MarNo ratings yet

- Series D1FB Characteristics: Direct Operated Proportional DC ValveDocument12 pagesSeries D1FB Characteristics: Direct Operated Proportional DC ValveDaniel MarNo ratings yet

- GUARDAS PARA MANGUERAS PARKER - PolyGuard - ParKoilDocument1 pageGUARDAS PARA MANGUERAS PARKER - PolyGuard - ParKoilDaniel MarNo ratings yet

- Chiller o Enfriador Parker Hiross Bulice-03-EnDocument4 pagesChiller o Enfriador Parker Hiross Bulice-03-EnDaniel MarNo ratings yet

- Pump Series D-H-M-HD-PGH ParkerDocument13 pagesPump Series D-H-M-HD-PGH ParkerDaniel MarNo ratings yet

- V-Pak Unidades Hidraulicas ParkerDocument20 pagesV-Pak Unidades Hidraulicas ParkerDaniel MarNo ratings yet

- AirGuard Protection System PARKERDocument2 pagesAirGuard Protection System PARKERDaniel MarNo ratings yet

- BOLETIN BOBINAS Bul HY14-2543-M10 D3W C-Style 32 DesignDocument20 pagesBOLETIN BOBINAS Bul HY14-2543-M10 D3W C-Style 32 DesignDaniel MarNo ratings yet

- MP Filtri Accessories HydraulicsDocument12 pagesMP Filtri Accessories HydraulicsDaniel MarNo ratings yet

- Valvula de Control Parker N164203Document3 pagesValvula de Control Parker N164203Daniel MarNo ratings yet

- Hmi TS8006 ParkerDocument8 pagesHmi TS8006 ParkerDaniel MarNo ratings yet

- Service Valvula Directair-4Document8 pagesService Valvula Directair-4Daniel MarNo ratings yet

- Series DSL082 Technical Information General DescriptionDocument2 pagesSeries DSL082 Technical Information General DescriptionDaniel MarNo ratings yet

- Hydraulic Calculation FOR Automatic Wet Sprinkler Systems: Design of Plumbing SystemsDocument18 pagesHydraulic Calculation FOR Automatic Wet Sprinkler Systems: Design of Plumbing Systemshrstga100% (1)

- 유체 정리Document17 pages유체 정리음오아예No ratings yet

- OLSS & EOLSS Valves - S&F - A3 SizeDocument4 pagesOLSS & EOLSS Valves - S&F - A3 Sizeprem sagar100% (3)

- 2 in LACT PipelineDocument4 pages2 in LACT PipelineeugeniuciobanuNo ratings yet

- Metrado Lineas 28swc y 42cwcDocument65 pagesMetrado Lineas 28swc y 42cwcDiego AlonsoNo ratings yet

- Joy Twist AirDocument49 pagesJoy Twist AirChris SlyNo ratings yet

- Detail of Damper Pipe Size 200 NBDocument2 pagesDetail of Damper Pipe Size 200 NBRonak PanchalNo ratings yet

- Check Horizontal PDFDocument2 pagesCheck Horizontal PDFJorge CarionNo ratings yet

- Steam Gas Turbine 2 Assignment (18%)Document12 pagesSteam Gas Turbine 2 Assignment (18%)Khairul HishamNo ratings yet

- Ehs E076 Ics Das CNL 0000 90010 00Document13 pagesEhs E076 Ics Das CNL 0000 90010 00Okoro KennethNo ratings yet

- Inventory Record - FinalDocument6 pagesInventory Record - FinalParag WadekarNo ratings yet

- Norpar Pipenet PresentationDocument35 pagesNorpar Pipenet PresentationTON0% (1)

- 15.7 Exhaust - SolutionDocument4 pages15.7 Exhaust - SolutionLeo NardoNo ratings yet

- What Is The Coanda EffectDocument49 pagesWhat Is The Coanda EffectSebastian CarterNo ratings yet

- Full Report Thermo Lab 2Document24 pagesFull Report Thermo Lab 2ahmad pidotNo ratings yet

- Safety Instrument For Ammonia Aiche-16-020Document8 pagesSafety Instrument For Ammonia Aiche-16-020Hsein WangNo ratings yet

- PASS Hydrosystem DatasheetDocument2 pagesPASS Hydrosystem DatasheetSrashmi100% (1)

- PrysDocument40 pagesPrysteddy tavaresNo ratings yet

- 461 LMI P5 Serie Ibv EngDocument24 pages461 LMI P5 Serie Ibv EngsunanNo ratings yet

- Universiti Malaysia Perlis: Borang Penawaran Kursus BaruDocument5 pagesUniversiti Malaysia Perlis: Borang Penawaran Kursus Barukhai9000No ratings yet

- SOP For Well Test REV 1.01 - ENIDocument4 pagesSOP For Well Test REV 1.01 - ENIibraheem alsarrajNo ratings yet

- Mep UscgDocument120 pagesMep UscgAdwaith KrishnanNo ratings yet

- Revision Question Bank ME 2204Document11 pagesRevision Question Bank ME 2204Rajendra Kumar YadavNo ratings yet

- Axc Catalogue PDFDocument4 pagesAxc Catalogue PDFSanket SinghNo ratings yet

- Boq Mep A R3Document14 pagesBoq Mep A R3ixanzNo ratings yet

- Power Trim Assembly ComponentsDocument2 pagesPower Trim Assembly ComponentsAlex DiazNo ratings yet

- De2435 5780Document3 pagesDe2435 5780Edinson Ariel Chavarro QuinteroNo ratings yet

- Augusta, Maine 04336. York 14649. 14649.Document17 pagesAugusta, Maine 04336. York 14649. 14649.deepaNo ratings yet

- H1 SteeringDocument225 pagesH1 SteeringVinay Kumar NeelamNo ratings yet

- A 130Document1 pageA 130AnuranjanNo ratings yet