Professional Documents

Culture Documents

Wika 910.11 Shut-Off Valve Catalog Page

Uploaded by

M MCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wika 910.11 Shut-Off Valve Catalog Page

Uploaded by

M MCopyright:

Available Formats

Accessories

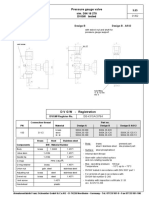

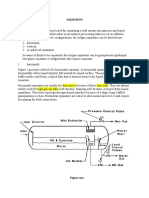

Shut-off valve for pressure measuring instruments

Model 910.11, brass, steel or stainless steel

WIKA data sheet AC 09.02

Applications

■■ Shut-off and throttle valve for pressure measuring

instruments, for measuring liquids, gases and vapours

■■ In stainless steel version for aggressive media, also in

aggressive environments

■■ Process industry: Machine building, general plant

construction, chemical/petrochemical, power plants,

mining, on- and offshore and environmental technology

Special features

■■ Shut-off valve without test connection per DIN 16270

(with vent screw)

■■ Shut-off valve with test connection per DIN 16271

(with vent screw) Shut-off valve per DIN 16270,

■■ Shut-off valve with separate isolating test connection per LH-RH adjusting nut / male G ½, PN 250

DIN 16272

■■ Nominal pressures to 400 bar

Description

Form A version of the shut-off valves is supplied with LH/

RH union, and Form B version with shaft for the mounting

bracket, with nipple and union nut. Shut-off valves with a test

connection are intended for the simultaneous connection

of operating pressure measuring instruments and test

connection pressure gauges to the pressure pipeline. With

shut-off valves per DIN 16271, the test pivot is sealed by a Shut-off valve with separately isolated test

lens-type sealing ring and a screw cap placed on top; with connection per DlN 16272, LH/RH union/male G ½,

valves per DIN 16272, the test pivot is separately isolated by with test pivot M20 x 1.5, PN 400

an additional valve spindle. Shut-off valves are silicone-free.

WIKA data sheet AC 09.02 ∙ 02/2017 Page 1 of 4

Data sheets showing similar devices:

Stopcocks for lower pressures; model 910.10; see data sheet AC 09.01

Standard version Options

Pressure connection ■■ Free from oil and grease

G ½, test connection M20 x 1.5 ■■ Acceptance test certificate per DIN 50049 / EN 10204 3.1

■■ DVGW version, PN 100, DlN 16270

Wetted parts (valve body) ■■ Connection M20 x 1.5, ½ NPT

Brass: ■■ With bellows sealing up to PN 100

PN 250, temperature range -10 ... +120 °C ■■ Design per NACE

Steel, phosphated:

PN 400, temperature range -10 ... +120 °C

Stainless steel: Versions for oxygen use

PN 400, temperature range -20 ... +200 °C

■■ With PN 100 bar to max. 60 °C

Needle and seating ■■ With PN 160 bar to max. 60 °C

Corrosion and acid resistant stainless steel ■■ With PN 250 bar to max. 60 °C

■■ With PN 230 bar to max. 200 °C (graphite packing)

Packing

PTFE With wetted parts from steel or stainless steel

■■ With special packing (pure graphite) up to 250 °C

Hand wheel ■■ Up to PN 640 bar

Heat-resistant plastic

Nominal pressures

See table below

Design Connection PN in bar Wetted parts Order number

Form A Form B

DIN 16270 G½ 250 Brass 9090169 9095098

G½ 400 Steel 9090177 9095101

G½ 400 1.4571 9090967 9095110

DIN 16271 G½ 250 Brass 9090975 9095128

G½ 400 Steel 9090983 9095136

Test connection M20 x 1.5 G½ 400 1.4571 9091157 9095144

DIN 16272 G½ 250 Brass 9090991 9095152

G½ 400 Steel 9091009 9095160

Test connection M20 x 1.5 G½ 400 1.4571 9091017 9095179

Adapter piece for valves with test connection

A suitable adapter piece is available for valves with test connection

(test female G ½ / female M20 x 1.5).

Design Material Order number

Adapter piece Brass 9091700

1.4571 9091726

Test female G ½ / female M20 x 1.5

Page 2 of 4 WIKA data sheet AC 09.02 ∙ 02/2017

Dimensions in mm

Form A, LH/RH union / male

DIN 16270 DIN 16271 DIN 16272

Test connection LH-RH union

LH-RH union LH-RH union

wheel per DIN 16283

per DIN 16283 per DIN 16283

Pressure gauge

wheel

Form B, nipple and union nut / male, with shaft for mounting bracket

DIN 16270 DIN 16271 DIN 16272

Test connection Sealing nipple

wheel connection

Sealing nipple Sealing nipple DIN 16284

connection connection

DIN 16284 DIN 16284

Pressure gauge

wheel

Design Dimensions in mm Weight in kg

a b ±5 Brass Steel 1.4571

DIN 16270 Form A 100 ±1 85 0.54 0.52 0.52

Form B 120 ±5 85 0.61 0.56 0.56

DIN 16271 Form A 100 ±1 85 0.67 0.65 0.65

Form B 120 ±5 85 0.79 0.74 0.74

DIN 16272 Form A 100 ±1 85 0.95 0.95 0.95

Form B 120 ±5 85 1.00 1.00 1.00

WIKA data sheet AC 09.02 ∙ 02/2017 Page 3 of 4

Ordering information

To order, the 7-digit order number is sufficient. Other options require additional specification.

© 03/2003 WIKA Alexander Wiegand SE & Co. KG, all rights reserved

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

Page 4 of 4 WIKA data sheet AC 09.02 ∙ 02/2017

02/2017 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

You might also like

- Pressure Gauge CockDocument3 pagesPressure Gauge CockRamesh arumugamNo ratings yet

- FK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsDocument2 pagesFK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsNguyen KhaNo ratings yet

- NKM-G NKP-G: Standardised Enbloc Centrifugal PumpsDocument36 pagesNKM-G NKP-G: Standardised Enbloc Centrifugal PumpsRoberthNo ratings yet

- 094 Pressure Gauge Cocks and ValvesDocument3 pages094 Pressure Gauge Cocks and ValvesRISHABH VERMANo ratings yet

- Wafer 150Document1 pageWafer 150torobelkaNo ratings yet

- Piping Material Specification-Rev0Document25 pagesPiping Material Specification-Rev0Mohsen Ardestani100% (4)

- Pressure Gauge Valve: Sim. DIN 16 270 DVGW TestedDocument1 pagePressure Gauge Valve: Sim. DIN 16 270 DVGW TestedMohamed MusaNo ratings yet

- Wika Diaphragm Seal, Flange Connection Model 990.27Document4 pagesWika Diaphragm Seal, Flange Connection Model 990.27Syed Imtiaz HussainNo ratings yet

- DK DIN Bite Type Tube FittingDocument62 pagesDK DIN Bite Type Tube FittingLuisFranciscoMarinMedranoNo ratings yet

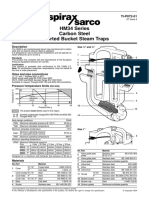

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDocument2 pagesHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaNo ratings yet

- 04 Mobile Foam Cart CMFCDocument6 pages04 Mobile Foam Cart CMFCuki12345No ratings yet

- Comparison Table For Tubes, Line Pipes and FittingDocument2 pagesComparison Table For Tubes, Line Pipes and FittingNamye Yelus100% (1)

- Spirax Sarco Fig 33Document2 pagesSpirax Sarco Fig 33Jacobus CalvelageNo ratings yet

- Safety Relief Valve VSEODocument4 pagesSafety Relief Valve VSEOShashank HNo ratings yet

- EN 13480 (UE Standard) - A16Document8 pagesEN 13480 (UE Standard) - A16keduse100% (1)

- SY Rubber Disc Check ValveDocument2 pagesSY Rubber Disc Check ValvePhú Song LongNo ratings yet

- 3251 enDocument14 pages3251 enmlachenal5237No ratings yet

- Control LiDocument5 pagesControl LiLuis TeixeiraNo ratings yet

- Sistema de Gases de EscapeDocument4 pagesSistema de Gases de Escapejorge alcivarNo ratings yet

- Temp. Control ValveDocument7 pagesTemp. Control Valvesaurabh kumarNo ratings yet

- Bite Type Tube Fittings (DIN 2353) : The Best Partner For Value Creation We Support The Innovations of CustomersDocument54 pagesBite Type Tube Fittings (DIN 2353) : The Best Partner For Value Creation We Support The Innovations of CustomersNIKESHNo ratings yet

- Goetze 2781 Datasheet enDocument4 pagesGoetze 2781 Datasheet enrosiNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- DCV Spirax PDFDocument2 pagesDCV Spirax PDFVaitheeswaran PalaniNo ratings yet

- BombasDocument8 pagesBombasDiego Fernando GaviriaNo ratings yet

- Cooling Tower and Chilled Water SpecificationDocument42 pagesCooling Tower and Chilled Water SpecificationEugen LupanNo ratings yet

- k2 02 Techinfo eDocument48 pagesk2 02 Techinfo enursultanNo ratings yet

- LitRD10ENDocument6 pagesLitRD10ENlesonspkNo ratings yet

- Avk Fire Hydrant PN 10 09/90Document2 pagesAvk Fire Hydrant PN 10 09/90Ashwin DSNo ratings yet

- SCHNEIDER - 9-03 - DIN16270 - eDocument1 pageSCHNEIDER - 9-03 - DIN16270 - eMohamed MusaNo ratings yet

- PDS01.09.001 - Wouter Witzel - EVMLDocument5 pagesPDS01.09.001 - Wouter Witzel - EVMLSiniša MorasNo ratings yet

- Vanessa Basic Datasheet-Valves PDFDocument10 pagesVanessa Basic Datasheet-Valves PDFGogyNo ratings yet

- Resilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionDocument6 pagesResilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- Gas Pipeline SpecDocument4 pagesGas Pipeline SpecA_bener100% (1)

- SAMSON Globe 3241Document12 pagesSAMSON Globe 3241Shaheen HydrosNo ratings yet

- Z P R G A R C: ERO Ressure Egulator AND AS/ IR Atio OntrolDocument7 pagesZ P R G A R C: ERO Ressure Egulator AND AS/ IR Atio OntrolPablo MartinezNo ratings yet

- Flange Adaptors PDFDocument4 pagesFlange Adaptors PDFTache MihaiNo ratings yet

- WIKA - Data Sheet For SnubberDocument2 pagesWIKA - Data Sheet For Snubberyasser hamzaNo ratings yet

- ENG - BD - TDS170-PN-S-GATE-PN Gate ActuatorsDocument9 pagesENG - BD - TDS170-PN-S-GATE-PN Gate Actuatorslungelo.dlaminiNo ratings yet

- 45-BC AVK Gate Valve OSYDocument2 pages45-BC AVK Gate Valve OSYAnonymous X3PnFL6No ratings yet

- KBV21i and KBV40i Key Operated Boiler Blowdown Valves-Technical InformationDocument5 pagesKBV21i and KBV40i Key Operated Boiler Blowdown Valves-Technical Informationunnamed90No ratings yet

- 1) Wouter Witzel EVTLSDocument7 pages1) Wouter Witzel EVTLSAizat RomainoNo ratings yet

- Check Valve DSDocument2 pagesCheck Valve DSsinamicsNo ratings yet

- Hydraulic Tubes and PipesDocument18 pagesHydraulic Tubes and Pipeshp_vijaykNo ratings yet

- Fig - 33 TI S60 03 ENDocument5 pagesFig - 33 TI S60 03 ENAditomo PutrantoNo ratings yet

- SS Case Brass Pressure Gauge - Economical - India Pressure GaugeDocument6 pagesSS Case Brass Pressure Gauge - Economical - India Pressure GaugeIndiapressure gaugeNo ratings yet

- Circular Sightglas e Malux Din28120Document2 pagesCircular Sightglas e Malux Din28120ivanoliveira3261No ratings yet

- Avk Gate Valve, Flanged, Pn10/16 02/59-003: EN 558-2 S.15/DIN F5, Position Indicator, Replaceable Stem Sealing, NBRDocument2 pagesAvk Gate Valve, Flanged, Pn10/16 02/59-003: EN 558-2 S.15/DIN F5, Position Indicator, Replaceable Stem Sealing, NBRbrilian pungkyNo ratings yet

- 1409 HOBAS CC Pressure Pipe Systems WebDocument40 pages1409 HOBAS CC Pressure Pipe Systems WebShaun WongNo ratings yet

- PDS01.11.001 - Wouter Witzel - EVFLDocument7 pagesPDS01.11.001 - Wouter Witzel - EVFLVilius BukysNo ratings yet

- Kitazawa 3Document1 pageKitazawa 3Nam Nguyễn ĐứcNo ratings yet

- Flange AdaptorDocument4 pagesFlange Adaptorعلاء البناءNo ratings yet

- TR2000 - Fhat101rDocument1 pageTR2000 - Fhat101rJoernNo ratings yet

- 4 - Check Valves MuellerDocument14 pages4 - Check Valves MuellerFIRSON ANDRES SerranoNo ratings yet

- Tosaca Catalogue PDFDocument16 pagesTosaca Catalogue PDFgabNo ratings yet

- 400E EngineeringDocument8 pages400E EngineeringDenis Oliveira CostaNo ratings yet

- High Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFDocument2 pagesHigh Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFjayakumarNo ratings yet

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Innovative Solutions For The Toughest RequirementsDocument16 pagesInnovative Solutions For The Toughest RequirementsM MNo ratings yet

- ITALVALV-Actuators CatalogueDocument31 pagesITALVALV-Actuators CatalogueM MNo ratings yet

- 243 New-EnDocument4 pages243 New-Enjaskaran singhNo ratings yet

- Valvotubi Dismantling Joints PN 63Document2 pagesValvotubi Dismantling Joints PN 63M MNo ratings yet

- ECOLOC Locking Assemblies USDocument24 pagesECOLOC Locking Assemblies USLuis OroscoNo ratings yet

- JUMO flowTRANS MAGS01 Technical DataDocument57 pagesJUMO flowTRANS MAGS01 Technical DataM MNo ratings yet

- J+J - Hand Book J4CDocument53 pagesJ+J - Hand Book J4CM MNo ratings yet

- Stauffenberg RBW5RUL PDFDocument172 pagesStauffenberg RBW5RUL PDFErikas AbepaNo ratings yet

- Wika 910.11 Shut-Off Valve Catalog PageDocument4 pagesWika 910.11 Shut-Off Valve Catalog PageM MNo ratings yet

- KSB Globe Valve NORI 160 ZXL-ZXLDocument12 pagesKSB Globe Valve NORI 160 ZXL-ZXLM MNo ratings yet

- Pressure Transmitter For General Industrial Applications Model A-10Document12 pagesPressure Transmitter For General Industrial Applications Model A-10Anonymous PkAjjOZBNo ratings yet

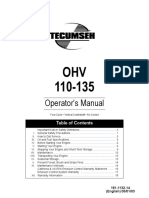

- Tecumseh Overhead Valve ManualDocument94 pagesTecumseh Overhead Valve ManualGTRocketmanNo ratings yet

- Rexnord Tollok Locking Assemblies: CatalogDocument47 pagesRexnord Tollok Locking Assemblies: CatalogArjav DesaiNo ratings yet

- Pressure Transmitter For General Industrial Applications Model A-10Document12 pagesPressure Transmitter For General Industrial Applications Model A-10Anonymous PkAjjOZBNo ratings yet

- Rexnord Tollok Locking Assemblies PT2-001 - LTR - CatalogDocument60 pagesRexnord Tollok Locking Assemblies PT2-001 - LTR - CatalogM MNo ratings yet

- Wika 213.53 Pressure Gauge Catalog PageDocument4 pagesWika 213.53 Pressure Gauge Catalog PageM MNo ratings yet

- Medium Voltage Technical Guide: Basics For MV Cubicle DesignDocument84 pagesMedium Voltage Technical Guide: Basics For MV Cubicle DesignVasu Devan100% (3)

- Seagate Barracuda PRO Product ManualDocument32 pagesSeagate Barracuda PRO Product ManualM MNo ratings yet

- Ball Valve PN63 ErhardDocument1 pageBall Valve PN63 ErhardM MNo ratings yet

- Operator's Manual: 181-1132-14 (English) 05/01/03Document20 pagesOperator's Manual: 181-1132-14 (English) 05/01/03M MNo ratings yet

- ECOLOC Locking Assemblies USDocument24 pagesECOLOC Locking Assemblies USLuis OroscoNo ratings yet

- Tecumseh Parts List OHV 135Document5 pagesTecumseh Parts List OHV 135M MNo ratings yet

- Valvotubi Dismantling Joints PN 63Document2 pagesValvotubi Dismantling Joints PN 63M MNo ratings yet

- Ball Valve PN63 ErhardDocument1 pageBall Valve PN63 ErhardM MNo ratings yet

- Bermad Combination Air Valve C70 - Product-Page - English - 9-2018Document4 pagesBermad Combination Air Valve C70 - Product-Page - English - 9-2018M MNo ratings yet

- Bermad Combination Air Valve C75 - Product-Page - English - 9-2018Document4 pagesBermad Combination Air Valve C75 - Product-Page - English - 9-2018M MNo ratings yet

- ERHARD Dismantling Joints EN PDFDocument5 pagesERHARD Dismantling Joints EN PDFM MNo ratings yet

- ERHARD Dismantling Joints EN PDFDocument5 pagesERHARD Dismantling Joints EN PDFM MNo ratings yet

- KSB Product Portfolio Valves 2019Document72 pagesKSB Product Portfolio Valves 2019M MNo ratings yet

- Mutual harm: The potential and risks of using allelopathic chemicals in agricultureDocument11 pagesMutual harm: The potential and risks of using allelopathic chemicals in agricultureMinh Anh NguyễnNo ratings yet

- Flashcards - CP4 Preparation of A Standard Solution and Titration - Edexcel IAL Chemistry A-LevelDocument37 pagesFlashcards - CP4 Preparation of A Standard Solution and Titration - Edexcel IAL Chemistry A-LevelTravel UnlimitedNo ratings yet

- Intro To GymnasticsDocument69 pagesIntro To GymnasticsMichaela Celerio50% (2)

- Revised Provisional Selection List 30122022 1Document150 pagesRevised Provisional Selection List 30122022 1onlinetrash45No ratings yet

- Project Execution ProcedureDocument4 pagesProject Execution Procedurecyno2167% (3)

- Filipino Nurses United OrientationDocument30 pagesFilipino Nurses United OrientationErlinda PosadasNo ratings yet

- Aiesha Edward Resume2Document2 pagesAiesha Edward Resume2api-491571342No ratings yet

- Separators: Figure OneDocument8 pagesSeparators: Figure OneMohamed Moder100% (1)

- Ni 2 WordDocument2 pagesNi 2 WordLeigh Angelika Dela CruzNo ratings yet

- Torsion of Circular Shaft: Torque or Turning Moment or Twisting MomentDocument13 pagesTorsion of Circular Shaft: Torque or Turning Moment or Twisting Momentmahmudul adilNo ratings yet

- 2018 Ibc Seaoc Structural Seismic Design Manual Volume 2 Examplespdf CompressDocument385 pages2018 Ibc Seaoc Structural Seismic Design Manual Volume 2 Examplespdf Compressvkch saipavan100% (3)

- Importance and Uses of Medicinal Plants - An Overview: December 2016Document8 pagesImportance and Uses of Medicinal Plants - An Overview: December 2016safamanz001 safaNo ratings yet

- Top 50 Most Delicious Taco Reci - Julie HatfieldDocument267 pagesTop 50 Most Delicious Taco Reci - Julie HatfieldMazhar Aslam100% (2)

- 2 - FNCPDocument5 pages2 - FNCPIlda Lekka RequizaNo ratings yet

- Herbal MedicineDocument38 pagesHerbal MedicineBurei KouNo ratings yet

- En JV Catalogue 2Document56 pagesEn JV Catalogue 2Yudhi Tri IndrawanNo ratings yet

- Thai Occupational Safety, Health and Environment Act B.E. 2554 (A.d. 2011)Document32 pagesThai Occupational Safety, Health and Environment Act B.E. 2554 (A.d. 2011)DibbaSotaNanaNo ratings yet

- RESOLUTION 2022-08 Denial of Setback VarianceDocument5 pagesRESOLUTION 2022-08 Denial of Setback VarianceMatt McKinneyNo ratings yet

- Providing Shelter and Safety: A Proposed Evacuation and Rehabilitation Center for Masbate CityDocument62 pagesProviding Shelter and Safety: A Proposed Evacuation and Rehabilitation Center for Masbate CityBenjamae MaqueNo ratings yet

- Perineal Care Procedure GuideDocument2 pagesPerineal Care Procedure GuideAlhadzra AlihNo ratings yet

- The Dilemma of The Neighborhood BoardDocument2 pagesThe Dilemma of The Neighborhood BoardRosaNo ratings yet

- Understanding the Relationship Between Place and HealthDocument14 pagesUnderstanding the Relationship Between Place and HealtheNo ratings yet

- Mill Housings Mangal SinghDocument5 pagesMill Housings Mangal SinghGun SmithNo ratings yet

- Discontinued Tymphany LAT Products LAT500 001 PDFDocument2 pagesDiscontinued Tymphany LAT Products LAT500 001 PDFOgie FermoNo ratings yet

- 02 - Purulent Inflammatory DiseaseDocument60 pages02 - Purulent Inflammatory Diseaseshekhawatyuvraj051No ratings yet

- Yıldız Technical University - Program Information Form - Page 1/9Document9 pagesYıldız Technical University - Program Information Form - Page 1/9Elsaadawi MohamedNo ratings yet

- Bio 2 - 2.4 - Consolidated Assessments (Photosynthesis)Document8 pagesBio 2 - 2.4 - Consolidated Assessments (Photosynthesis)Lena ManibaNo ratings yet

- Chemistry in Everyday LifeDocument33 pagesChemistry in Everyday LifeArya StarkNo ratings yet

- Earth First! Climbers Guild Vol. 2Document16 pagesEarth First! Climbers Guild Vol. 2CascadiaDefenders100% (2)