Professional Documents

Culture Documents

EK Instruction Manual

Uploaded by

Thanh XuânOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EK Instruction Manual

Uploaded by

Thanh XuânCopyright:

Available Formats

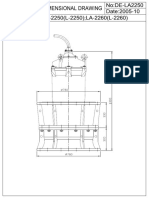

SECTIONAL DRAWING

FIG.4 NO. Name Material

1 Pump Casing FC200

9 10 8

7 6 2 Impeller SUS304

1

2

3

3

4

Mechanical Seal

Shaft

CA+CE+NBR

SUS410 EK-SERIES

4 5 Base ABS

5 6 Motor Shell Aluminum Alloy SILENT DOMESTIC WATER PUMP

7 Wiring Box ABS

8 Outlet Flange FC200 INSTRUCTION MANUAL

9 Inlet Flange FC200

10 Priming Plug PC

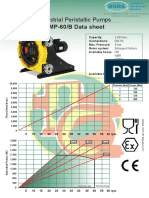

OPERATING CONDITIONS PERFORMANCE CURVES

1. Liquid temperature: +5 0C~+60 0C 50Hz

2. Ambient temperature: Max. 40 OC

TOTAL HEAD (M)

3. Working pressure: Max. 6 kg/cm 2 EK400

4. Suitable for clean water, without

solid particles or non-corrosive fluids.

50

60HZ

TOTAL HEAD (M)

40

30 EK

80

20 EK4 0 CAPACITY (L/min)

00

10

0

0 10 20 30 40 50 60 70 80 90 100

CAPACITY (L/min)

SPECIFICATION

Power PH Voltage Rated Suction Rated Rated Max. Max. Dia. Net Package

MODEL Current Lift Head Flow Head Flow Weight Dimensions

50HZ HP V A M M L/min M LPM MM KG CM

EK400 1/2 1 220~240 3.1 5 20 36 28 70 20/25 11.2 33X21X26

SILENT OPERATION

Power PH Voltage Rated Suction Rated Rated Max. Max. Dia. Net Package

MODEL Current Lift Head Flow Head Flow Weight Dimensions GREAT WATER VOLUME

60HZ HP V A M M L/min M LPM MM KG CM

EK400 1/2 1 11 0 / 2 2 0 5.6/2.8 5 20 32 27 70 20/25 11.2 33X21X26

EK800 1 1 11 0 / 2 2 0 11/5.5 5 28 65 45 100 25 13.8 38.5X21X26

ASIA AUTOMATIC PUMP CO.,LTD

MADE IN TAIWAN

~3~

OPERATION 5. The location must be dry with good 2. When charge pump with electricity 3. If you can't get rid of the bug,

ventilation and adequate space. and the pump revolve normally but please call to sales agent or the

6. Do not run without water actually you find no water supply, please distributive service station.

pumping.Do not operate hot water check it as followings.

0

(more than 60 C), or the other liquid a. The pump casing should be full of Coverage of Application:

water , if shortage, please open To be used on supplying water:

except normal water.

the red water plug (FIG.4-10, 1. For the apartment and residences.

7. Be careful not to allow the foreign

and pour into water anew till quite 2. For the heater and agricultural

matter (chips, dirt, sand, glue, etc)

brimming. irrigation.

into the pump, or the will damage and

b. If water is leaking out from the pipe 3. For the garden pump and sprinkle

shorten the life of pump.

please install again there's a water.

8. Piping joints should be fitted carefully

to prevent leakage. blockade in the drain-pipe, please

FIG.1 a. Leakage in the suction piping will clean it out.

1. Make sure of using the right voltage. cause the pump does not function

2. Remove the priming cap and pour well. Diagram:

water into the pump and suction b. If an "outlet for water " is leaking

piping ,then secure the plug. out, then the water pressure will

connect to

3. Insert a screw driver cross into the be lowered. tap water

shaft slot , and turns the shaft 2-3 9. Please install a check valve on

rounds to check if the pump runs suction piping.

normally , then open one faucet on 10. TO avoid your furniture damage, do

the delivery side , the turn the power not install the pump on ceiling, carpet FIG.2

switch ON.(FIG.1) or any place close to electrical

appliance, outdoor installation must

4. After the power switch on, the motor

covered by tent.

should turn immediately . After a few

seconds, the water should be

delivered. TROUBLE SHOOTING

5. If the water does not be delivered (Turn the power switch OFF before fixing.)

immediately turn the power OFF. 1. MOTOR FAILS TO START OR

Repeat step 2 and set power ON/OFF RESTART AFTER A SHORT-TERM

continuously to make the suction RUNNING

The overheating protector is mounted

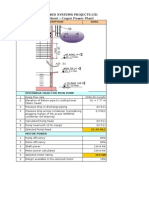

Dimension:

piping be filled with water.

W

directly on the motor windings. It will stop 4 9

IMPORTANT NOTE D

L1

the motor automatically when the motor

1. Use the right voltage and wiring by temperature is up to abnormal, and

the connecting diagram. Motor must restart the motor after the temperature

202

174

be grounded in compliance with back to normal in 20 minutes. H

L

applicable electrical code to avoid a. Check the electrical power source, H1

accident. fuse, and circuit breaker. 130

2. please use a sturdy foundation and b. Check if pump is locked by rust or 158

bolt the pump to it securely. foreign objects.

3. Be sure to arrange earthling or circuit c. Check if the ventilation of the FIG.3

MODEL L L1 H H1 W D

breaker against electric leakage. location is bad for causing the

4. The pump should be installed as overheating of motor. EK400 235 70 235 151 190 20/25

close as to the reservoir or well to

avoid the low efficiency due to the EK800 250 90 235 151 190 25

long suction pipe.

~1~ ~2~

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Operating Conditions: Model Output Pole Dimensions (MM) Capacity Flow SpeedDocument1 pageOperating Conditions: Model Output Pole Dimensions (MM) Capacity Flow SpeedJavierNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Shakti PumpDocument5 pagesShakti Pumpbagus saputraNo ratings yet

- BE/BE12: ISO 5599/1 ValvesDocument12 pagesBE/BE12: ISO 5599/1 ValvesDaniel MilenkovicNo ratings yet

- WEDA 40 (60 HZ) 2935 0823 32 - tcm1658-3572086Document1 pageWEDA 40 (60 HZ) 2935 0823 32 - tcm1658-3572086emai2012No ratings yet

- KTM40F-000 (Cast Iron) - 60HzDocument6 pagesKTM40F-000 (Cast Iron) - 60HzLuís Felipe GuimaraesNo ratings yet

- Dynaflo: Rugged, Single Stage Centrifugal PumpDocument2 pagesDynaflo: Rugged, Single Stage Centrifugal Pumptvshow zeeNo ratings yet

- Data Sheet Aton Pump 3 CompressedDocument4 pagesData Sheet Aton Pump 3 Compressedfajar kusumaNo ratings yet

- La 2250Document5 pagesLa 2250patulNo ratings yet

- 4" End Port Pressure Vessel: Working Pressure: Assembly Drawing: Working Temperature: Design CodeDocument2 pages4" End Port Pressure Vessel: Working Pressure: Assembly Drawing: Working Temperature: Design CodeStathis MoumousisNo ratings yet

- ABO Ball ValveDocument6 pagesABO Ball ValveSunil BajpaiNo ratings yet

- Min2104400015 Datasheet FMP-40Document2 pagesMin2104400015 Datasheet FMP-40Frank RodriguezNo ratings yet

- Toggle Switches Serie 12000X778Document8 pagesToggle Switches Serie 12000X778NelsonNo ratings yet

- Data Sheet Micro 50Hz 2013.10 PD521211-INT Rev 1.0 Tetra Line 8121.211Document1 pageData Sheet Micro 50Hz 2013.10 PD521211-INT Rev 1.0 Tetra Line 8121.211testNo ratings yet

- Bianco 50mm High Head SubpumpDocument1 pageBianco 50mm High Head SubpumpDave WallaceNo ratings yet

- Bomba Weda D60Document1 pageBomba Weda D60CARLOS DAVILANo ratings yet

- Nel Dubbio Chiedere / If in Doubt AskDocument1 pageNel Dubbio Chiedere / If in Doubt AskMena KamelNo ratings yet

- DataBook LPC4Document35 pagesDataBook LPC4Anonymous 9vF9XUU2ZKNo ratings yet

- HydropompeDocument4 pagesHydropompeReggie TopsNo ratings yet

- Bravo: Technical Catalogue Compressor - CSL 40BR/250L 2 STAGES - 175 PsigDocument4 pagesBravo: Technical Catalogue Compressor - CSL 40BR/250L 2 STAGES - 175 PsigALINE CARDOSONo ratings yet

- IOL Series Filter Housings: Design RatingsDocument2 pagesIOL Series Filter Housings: Design RatingsDaniel HernándezNo ratings yet

- Super Power Pump Leaflet English Double Page VersionDocument2 pagesSuper Power Pump Leaflet English Double Page VersionalexanderNo ratings yet

- Valvula Bola C-316Document1 pageValvula Bola C-316almacen911listoNo ratings yet

- DataBook Jesx - 60 PDFDocument12 pagesDataBook Jesx - 60 PDFyossef rojas taparaNo ratings yet

- Pro Line Drainage Major 50 Data SheetDocument1 pagePro Line Drainage Major 50 Data SheetMARFV06No ratings yet

- 1.9.4.7 RBT 100 Data Sheet - 2021Document2 pages1.9.4.7 RBT 100 Data Sheet - 2021CésarNo ratings yet

- Data Teknis Pompa EbaraDocument3 pagesData Teknis Pompa EbaraCendrawasih PrNo ratings yet

- IFS Stancor SEW50 DatasheetDocument2 pagesIFS Stancor SEW50 DatasheetMaruRojaNo ratings yet

- MastraisingcylindersDocument5 pagesMastraisingcylindersAyman AkrabNo ratings yet

- Evosta Ts EngDocument3 pagesEvosta Ts Engmky_roNo ratings yet

- 150x125 FS4LA 5 45 - 50HzDocument5 pages150x125 FS4LA 5 45 - 50Hzhoàng đình sơnNo ratings yet

- Weda S08NDocument2 pagesWeda S08NJohan TanNo ratings yet

- Wenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicateDocument1 pageWenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicatePerumal Govindan100% (1)

- EW - TECHNICAL CATALOGUE - Vol.21031 - 50HZ-R3Document41 pagesEW - TECHNICAL CATALOGUE - Vol.21031 - 50HZ-R3Linda MadlalaNo ratings yet

- Pumps Dynaflo6000 Medium Datasheet PDFDocument2 pagesPumps Dynaflo6000 Medium Datasheet PDFMohammad ZeeshanNo ratings yet

- Catalogue DGDocument2 pagesCatalogue DGVu DangNo ratings yet

- FMP-60B Data SheetDocument2 pagesFMP-60B Data Sheetbilbao bombeoNo ratings yet

- HCP SF-50Hz DSAEN5Document4 pagesHCP SF-50Hz DSAEN5Camilo José Rivera NavarroNo ratings yet

- Quick Release Snap Type CouplingDocument1 pageQuick Release Snap Type Couplingpeters petersNo ratings yet

- Consumbles List Section Wise.Document9 pagesConsumbles List Section Wise.engineeringNo ratings yet

- Technical DataDocument1 pageTechnical DatarijadhNo ratings yet

- GARLOCKSPIRALWOUNDDocument4 pagesGARLOCKSPIRALWOUNDjose manuel perez gomezNo ratings yet

- EK Series Catalogue v1 SDocument4 pagesEK Series Catalogue v1 SNgân NgânNo ratings yet

- MP Priority Valve - 301-P-900002-EnDocument3 pagesMP Priority Valve - 301-P-900002-EnCésaire Aimé NdjemNo ratings yet

- DSC Dsca3 TdataDocument30 pagesDSC Dsca3 TdatahungNo ratings yet

- EHYD6 Hydraulic Valves HY14-2502k001Document9 pagesEHYD6 Hydraulic Valves HY14-2502k001Ahmet SaygılıNo ratings yet

- Myers Serie ME40 CiDocument2 pagesMyers Serie ME40 CiIsrael GarciaNo ratings yet

- Fan Coil Unit: YPHBC 200 1600 OptionalDocument1 pageFan Coil Unit: YPHBC 200 1600 Optionalcm08909No ratings yet

- Ebara CMDDocument4 pagesEbara CMDAlireza KhodabandehNo ratings yet

- HF 410 02 T eDocument2 pagesHF 410 02 T eNuñez JesusNo ratings yet

- Thomas Vacuum Pump 3003-SeriesDocument6 pagesThomas Vacuum Pump 3003-Seriesnishant.vatsNo ratings yet

- Schlumberger ESP Catalog pdf.1 PDFDocument189 pagesSchlumberger ESP Catalog pdf.1 PDFFredy NavasNo ratings yet

- Assembly Drawings With Dimensions and Details For Mounting: 2.38 2" Pipe SupportDocument1 pageAssembly Drawings With Dimensions and Details For Mounting: 2.38 2" Pipe Supporttatiana araujoNo ratings yet

- Sa Series: Submersible Stainless Steel PumpsDocument36 pagesSa Series: Submersible Stainless Steel PumpsĐình Sơn HoàngNo ratings yet

- Bap 01 T B PDFDocument4 pagesBap 01 T B PDFyoberNo ratings yet

- Fixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsDocument4 pagesFixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsДаниил СторчеусNo ratings yet

- Fixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsDocument4 pagesFixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsДаниил СторчеусNo ratings yet

- Bap 01 T A PDFDocument4 pagesBap 01 T A PDFyoberNo ratings yet

- EN12845Brochure PDFDocument4 pagesEN12845Brochure PDFvaisakhpillaiNo ratings yet

- YB Lucky Cement Limited: Work InstructionDocument9 pagesYB Lucky Cement Limited: Work Instructionshani5573No ratings yet

- Product Bulletin 21Document2 pagesProduct Bulletin 21RANAIVOARIMANANANo ratings yet

- Aircraft Pneumatic Systems and Air SystemDocument11 pagesAircraft Pneumatic Systems and Air SystemRaihan AkbarNo ratings yet

- Alert Codes 30GTNDocument4 pagesAlert Codes 30GTNJose Suriel86% (7)

- Etna - Fire Pump Systems in Accordance With EN 12845 Standard Technical LeafletDocument28 pagesEtna - Fire Pump Systems in Accordance With EN 12845 Standard Technical LeafletRedha Sabr100% (1)

- Akta Pure Chromatography SystemDocument14 pagesAkta Pure Chromatography SystemCeli OlmedoNo ratings yet

- Guia de Fallas de Transmision 416eDocument4 pagesGuia de Fallas de Transmision 416eJosé GonzalezNo ratings yet

- A Review of ISO and ANSI Pump Standards - KSBDocument2 pagesA Review of ISO and ANSI Pump Standards - KSBGerencia Rigar Colombia SASNo ratings yet

- 7T04-CS-00-PC-034 R01 Procedure For Maintentance and PreservationDocument16 pages7T04-CS-00-PC-034 R01 Procedure For Maintentance and PreservationMohamad Shafey100% (2)

- MCW Pump Head & Piping Pressure DropDocument3 pagesMCW Pump Head & Piping Pressure DropKarthy GanesanNo ratings yet

- Ale-1000-User ManualDocument23 pagesAle-1000-User ManualMarco AguirreNo ratings yet

- Compressed Air Production Using Vehicle SuspensionDocument13 pagesCompressed Air Production Using Vehicle SuspensionManideep padala0% (1)

- Thermo Water Lifting PumpDocument1 pageThermo Water Lifting PumpAshish BhuvanNo ratings yet

- Water Hammer in Steam LinesDocument5 pagesWater Hammer in Steam LinesVijaita Vikas GandhiNo ratings yet

- SU 300 - Service Manual - 2003Document158 pagesSU 300 - Service Manual - 2003Centrifugal SeparatorNo ratings yet

- Wartsila O E W 38 TRDocument12 pagesWartsila O E W 38 TRbunguiaoNo ratings yet

- III B.tech. (Autonomous)Document62 pagesIII B.tech. (Autonomous)divya dungaNo ratings yet

- Proposal EPC Open Access PT Pertamina (Persero) RU VII KasimDocument14 pagesProposal EPC Open Access PT Pertamina (Persero) RU VII KasimAgus MarpaungNo ratings yet

- Viking 4324A Oandm TSM6303 PDFDocument11 pagesViking 4324A Oandm TSM6303 PDFQOBITNo ratings yet

- IHI's Unique Technology Behind Jet Engines: Automated Shaft CoatingDocument4 pagesIHI's Unique Technology Behind Jet Engines: Automated Shaft CoatingnrNo ratings yet

- Bomba Manual HPDocument4 pagesBomba Manual HPCristianNo ratings yet

- Servo-Pump Hydraulic Control System Performance and Evaluation For CVT Pressure and Ratio ControlDocument7 pagesServo-Pump Hydraulic Control System Performance and Evaluation For CVT Pressure and Ratio ControlSamber MataNo ratings yet

- Hydraulic Quick Couplings General Purpose Couplings: Special Order InformationDocument5 pagesHydraulic Quick Couplings General Purpose Couplings: Special Order Informationshahrol effendy rodziNo ratings yet

- Vacuum Technology Book II Part 1 PDFDocument88 pagesVacuum Technology Book II Part 1 PDFdilsonramosNo ratings yet

- Design PhilosophyDocument7 pagesDesign Philosophymohit19dNo ratings yet

- XE27U AustraliaDocument8 pagesXE27U AustraliaRedzicMNo ratings yet

- Serck Audco Valves: Sealants and Injection EquipmentDocument21 pagesSerck Audco Valves: Sealants and Injection EquipmentsterlingNo ratings yet

- Wfi UrsDocument43 pagesWfi UrsMohsinShaikh100% (1)

- WSE 2 Marks With AnswersDocument18 pagesWSE 2 Marks With AnswersAravindhan MurugesanNo ratings yet

- Self Closing Flood Barrier A Preventive System To Defense Extreme High Flood Events IJERTV4IS010581Document3 pagesSelf Closing Flood Barrier A Preventive System To Defense Extreme High Flood Events IJERTV4IS010581Winjoe CapiliNo ratings yet