Professional Documents

Culture Documents

IHC Control Box C-34 - Users Manual

IHC Control Box C-34 - Users Manual

Uploaded by

George Zormpas0 ratings0% found this document useful (0 votes)

60 views14 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

60 views14 pagesIHC Control Box C-34 - Users Manual

IHC Control Box C-34 - Users Manual

Uploaded by

George ZormpasCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 14

C3 Hydrohammer .V.

EV 6 ova00s User's manual 6-34

— Te Document no: C-34( 163 and upjUMIGS

USER’S MANUAL.

FOR

CONTROL BOX C-34

Serial numbers 1163 and up

HC Hyoronammer BPO box 25,2960 AA Kinde The Hatianas

7eeo10202. Fan ¥31 76.1090

c3 Hydrohammer B.V.

& v.6 ov2006 User's manual C-34

Dosmerk ne CATS ard up NCB

PREFACE

‘This manual provides the instructions for safe installation and operation of the portable

Control box C-34. No maintenance is required other than keeping the equipment clean,

Operation shall be performed by qualified personnel only

Qualified means that the persons know how to operate the control box and where to look for the

respective details in this manual to ensure proper functioning

Normally, during first commissioning, the user(s) willbe instructed accordingly by IHC HYDROHANMER

Intended use

The Control box C-34 is solely intended for use as control system for HYOROHAMMER hydraulic piling

hammers in non hazardous area

This manual must be used in combination with the user's manual of the selected Hydrohammer® and

hydraulic power pack.

References to other documentation, figures etc. are indicated in italics

Read this manual carefully before actually working with the unit.

‘Special application: for use in combination with the Hydrohammer® RockBREAKER, see par. 4.7.

‘An optional Piling recorder P-32 and Printer P-31 can be supplied to record piling data,

Also a remote control unit 8-34 can be supplied as an option see par. 4.5

If problems occur for which no solution can be found in this manual, please contact IHC HYDROHAMMER,

Repairs to the C-34 may only be carried out by IHC HYDROHANMER maintenance personnel or other

Persons, recognised by IC HYDROHANINER as qualified.

GUARANTEE/LIABILITY

The terms for guarantee and liability as specified in the general conditions of INC (October 1991) shall

apply, unless otherwise mentioned in this manual or agreed between IHC and the customer in writing

‘SAFETY PRECAUTIONS

IHC HYDROHAMMER points out that the execution of the safety precautions as specified below and

abidance with the safety rules can only be the fll responsibilty ofthe user.

IHC HYDROHAMMER therefore, denies any claim which should arise from failure to execute the necessary

safety precautions or negligence of the rules as laid down by user's management or safety officer.

+ Tum the applicable power supply’ switch (depending on the installation arrangement see fig. 1) in

Position off (0) prior to start maintenance work on the power pack or hammer, or before disconnecting

cables

‘+ Keep the contro! box C-34 always diy and clean,

‘+ Do not expose the EPROM DS in the C-34 box to ultraviolet light, to prevent possible erasing of the

program

‘The Header WARNING is used where failure to observe the instruction could result in injury to the

opérator or exposed persons.

‘The header CAUTION is used where failure to observe the instruction could result in damage to the

‘equipment,

os0e Fax +9.73 do10v04

(9 vers nmer a.

CONTENTS:

Title page

Preface

Guarantee / liability,

Safety precautions.

1 INTRODUCTION... =

2. TECHNICAL SPECIFICATIONS AND DATA,

3. LAYOUT AND FUNCTIONS C-34

4 OPERATION.

4.4. General

42 Normal operating procedure

43 Automatic stops.

44 Restart after trip.

45 Use of the remote control unit 8-34

48 Uso of G24 with 2 P-220 powerpack.

4.7 Use of the rock breaker.

5 ADJUSTMENTS.

5.1. Fixed parameters

5.2 Adjustable parameters

6 TROUBLE SHOOTING

Tables

Table 1 Trip codes.

Table Il Mass of ram weight and energy of Hydrohammers

Table Ill Default settings.

Table IV Trouble shooting

Table V_ Other symptoms.

List of figures

Fig. 1A Arrangement with A-34 engine panel.

1B Arrangement with A-32 engine panel

4 Arrangement with C-20 engine panel

1D Arrangement with L-32 air control box.

Cable connections.

Layout inner side of C-34

Remote control unit 8-34,

‘Mounting plate with printer connector.

Internal terminal blocks.

Fig. Exchangeable front plate...

Noonen

Operating controls and indicators on control box C-34

REV. 6 0172006 User's manual C-34

‘Document ro, C-34(1163 ad upJUNGB

Page

10

10

10

4

‘ATTACHMENTS

The attached electrical drawings are only available in the English language for diagnostic purposes by

qualified persons oniy.

ForC-34: |-408 series Connection diagrams

ForB-34: 107 series Connection diagrams

SHC Hydrohammer BV. P.0 80425, 2609

(Sk, Tho Netherands

3

7a 6910304

(9 veetenmer av

4 INTRODUCTION

‘The actual piling operation is controlled

{rom the portable Control box C-34.

‘The control box C-34 contains the piling

program (Eprom DS) and the instruments,

for:

+ tead-out of rpm and total blow counter

+ read-out of trip codes

+ setting changes to the piling program.

‘The location of the contro! box C-34 with a

cable length of 15 m (or 1,5 m) is

‘customer's option:

~ outside

+ in the cabin of the crane

- in the power pack or

= inside the C-64 control unt

‘The various options for installation of the

C-34 are shown in fig. 1A/BICID.

REMARKS,

‘The engine panels A-34, A-32 and A-20

are part of the several power packs of

different generations.

The air control box L-32/VB is mounted

ina separate control cabin in case of

underwater operation of the

Hydrohammer®

IHC Hycronammer B.V. P.O

REV 6 0172008 User’s manual C-34

Document no, C347 163 ard upjUMiG

Fig. 1A: Arrangement with A-34 engine panel

= =

‘nae! began!

Fig. 1C: Arrangement with A-20 engine panel

8, 2860 AA Kinder, The Newwrancs. Phone #21.78 910202 Fax +31.78 6010004

4

Cc Hydrohammer B.V.

REV.6 0172006 User’s manual C-34

‘Dosument no, C-34(1165 and up/UNGS

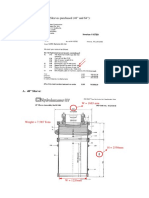

2 TECHNICAL SPECIFICATIONS AND DATA

Portable control box C-34.

Protection class

‘Temperature range:

Dimensions 1x b x h (without handle)

Weight

Materials

box

door

‘mounting plate

front plate (exchangeable)

Fuse (see fig. 4)

FIA)

Available as an option: Remote control unit 8-34

IHC Code no

8668 07 20,

ips

operational between -10 and + 40 °C

300 60 x200 mm

5g

stee! plate, 1,38 mm

steel plate, 1.25 mm,

steel plate, 2’mm

Plastic, available with text in the English, Dutch,

French or German language)

.-86 60 90 20

86 66 07 40

aT

Neo TalnlelaleICE|

ees a

Fig. 2: Cable connections

Cable connection (Corresponding eabies IHe'Partnio:

Male connector (8p) Connection to Ping recorder / Printer set P-31/32

U=15m 88 600325

connate 3 at

ae L=1,5m, 86 60 03 26

REMARK: Connector with mounting plate to be removed when 6-34 is used (see par. 4.5)

Male connector (24 p).

L=15m.

Letm

Female connector (16 p)

Connection to engine panel A-35, A-34 or A-20 (or indirect with A-32)

86 6002 01

86 60.02.02

‘Connection to Hydrohammer®

Control cable length and type depends on hammer application

SHC Hyeronammer BV. P.O 00x25, 2

960 RA Kndard, The Ne

Fax +3178 6010004

c3 Hydrohammer 2.V.

REV. 6 01/2005 User’s manual C34

‘Document no. C-34(1183 and upjUMGB

3 LAYOUT AND FUNCTIONS C-34

Operating controls indicators

1 Display wih 6 characters

2 Display with 4 charactors

Bat Keys: EM en BA

‘The (yolow) LED *noxt tothe

selected parameter comes fog

REMARK: tun selector site S7,

Inside the box. to postion 0

before using the keys

4 Koy Hd

5 Tip (6d LED")

Unis (yotow LEDS *)

7. Sensor signaling

A,B, C and D (yelow LEDs")

‘81 Push button

Emergency Stop

2. Selector entsy RPM / Flow

vw te posions:

a

SS Selector svtch PUMP 1

Diesel engine win the postions:

1

2

3

4 Selector switch withthe

ppsitons

PILING.

EXTRACT

8, Selector omten

wit the postions

RESET ©

stor 0

START 1

56 Selector switch Back

Preseure withthe postions:

OFF

on

Rt Petentiometer ENERGY with

aca of 0-10

* LED = Light Emitting Diode

Fig.

IHC HysrotammerB.V.°.0 box 28,20

Function

‘Seo fr deal fig. 4

For restout order of prety of

the ip codes

= Deerergy

Piling Increase / docreate of sting or

Setecing harmer ype tale

Readout on dsl # of any ofthe

selected parameters:

Velocity “Soke - Blows -rpm.

Blow counter Cap pressure

‘Working pressure

‘Rock baking: Bypass of permissive

Star coraton (sensors Aen) a

feracion, se par. 47

Exclusive use to Reset the Blow Count parameter when selected with keys El and

Read out vibe on slay 4

LUghters curing an active tp (ip code

Binks when a delayed tip is active.

‘Selectod uit ahtens ($7 n poston 'F'}0= Met T.

Ingato he status of the four sonsr signa:

‘n= sensor “sees steel of be ram weight) or Sensors not connected (asi the case for ©

‘20d D wit) use ofan samme).

fff = sensor coos not "soe" ston,

Both And 8 mst be on ta beable to taping operation.

During ile cng. A and B scr alenating on and of when the ram passes

NOTE: Sensors C and’ are ony used in SG-hammers,

‘Te sensors ae also used fr the calculation o the ram veloc.

Fr an immediate stop of engire and ping process

‘Tip 01 aopoare onthe slay. Make a quarter turn toe ght to RESET.

‘CAUTION: use the emergency stop for emergency case ONLY.

visible on display 2,

Non-retic tbs:

‘Switch i spring loaded to postion 0. ‘wth P75 P-460C/0;P-8001;P-16008

vain P.250 470 750. (ee also par 42 punt 3)

Reducing engine rom Reducing the pump few

Maintaining engine rpm Mabtarng the pump tow

Ineressing engine rom Increasing te pump tow

wh P-250 410, 7501 wh 8-175 -40c10;P-8001;P-16008

imum cumber of pump heads connected. ide

Bara pup heads connected Auto (folows start sto ofharame)

‘Maximum numberof pump heads connecte, Ful spe0d

Pllng

Extracting (ving upwards) + activating punches of extvacon cap

Positon RESET is eping Icaded to poston STOP.

‘To reset tip and dspiay information tus.

‘To stop be png operation, with P-175, P4650, P-2008 and P-16008 see par 42 point 7

To sar the ping process. See alsa pa. 47 when using he rock breaker

Backpressure valve (7D) open, slencd nt activated, na back pressure,

TD closed (ctoncidacivated = 50 bar back pression return Ins).

To tthe requred evel of energy tobe supple by the hammer

NOTE: the near scale is NOT proportional tothe developed energy, but carves at reference

‘orpostion oft

: Operating controls and indicators on control box C-34,

AA Ko erands Phono +31.78.691

2 Faxs31 78.601

ct Hydrohammer BV.

Operating controls indicators

x2, x4

x1, X8

see par. 48

(Ct: Total Blows counter.

Fi: Fuse

DS: Eprom

'STSELECTOR switch

‘wi 16 postions.

o "Readout

"sap press

2 Workpress.

Function

be LED string, | Winer cornetting

REV.6 0172006 User’s manual C-34

Document io 6-34(1783 and upjUMGB

Ietrmal terminal

Blocks, see par 45

‘when Using B34

Ietemal termina

Books, se par 48

24 to a power pack

with A-20. engine

Panel (96 fig 10)

Indicates the TOTAL

uber of bows an

Ean NOT be reset fo

Ampere } ee

Sofware fr i

= pli.

“reek breaking a

Readout | seting

visible on dspay 2

69

‘See ays Sab for slecton and readout ofthe parameters (9.3)

100 bar (default seting) (Range of optional pressure sensorin power pack)

40 bar default seting) (Range of optional pressure senso in power pack),

3 Spare (Reser)

Spore - (esere)

8 :Mammer ype Harner type (See fable)

8 timaxier ths (Rangetormax iting tina ofram weight)

7 Nelms 2 ms Oday timetac)

® “B|msf| ms (dayne bac)

ry td ms (Delay mete extracting)

® “6ims? {© ms (Delay ime bd. extraction)

a ‘WImsp_ 7 ms (Step/tp tine exracton)

c "elmsy 18 ms 0 Pllng: Time delay Rafter sonsr B ,defaut sating 0

© Roux breaking: Energy tation o 70k fr chisoh, se par. 47

0 "Pulsesiey* | Pusesre tom tackometer (depending on engine ype)

For power packs with continuous variable pump: stings‘ or fow instead of rem

e “Program| Application = pling ‘= rock breaking 2=C-4 '3'= Demo

co unis! Unis ‘9 = mati a) += nen meme (Ribs)

Toggle switches for valves [A= Main roe vaive, P= pressure ve, R= reun vavo

wih the postons: LED of Avave

a Automatic ‘Soe also par 46

ie Handal (Hand) ) LED to the ight ofthe wich i on

1: LED (Green) LUphtons when 24V power suply is connected 0 O34

4; Layout inner side of C-34

IHC Hydrobammer BY. P.0'00%25, 2960 AR Kinder The Neerance Prone 494.7OGG0002 Fax +94 72

7

(EQ Peotanmer a

4 OPERATION

44° General

The start and control of the piling operation is

controled from the portable control box C-34.

Ensure that the cables are installed in

accordance with the selected arrangement

(see fig. 1, B, C of D).

4.2 Normal operating procedure

‘Assumed is that the preparations for operating

the power pack and hammer have been cartied

‘out correctly, as described in their users

manuals.

The normal start procedure is as follows

1 Turn on the power supply switch on the A-34

or other panel (see fig. 1). Displays and

LEDs (see. fig. 3) of the C-34 ighten

Display 2 (fig. 3) indicate: ‘C-34'

2 Check the switch positions on the cover of

the C-4 (see fig. 3)

‘© EMERGENCY STOP (S1) not locked

(Moke a quater tun to the right to Reser.)

‘+ RESETISTOPISTART ($5) in position STOP.

If the right display shows a trip code, S5

eed to be turned fo the RESET position

If the trip code returns, the source of

trouble need to be corrected fist.

‘+ ENERGY (R1) in position ‘', 2" of 3

‘= Stin position as required

3 Check the positions /settings inside the

C-34, see fig, 5)

‘+ Valve switches A, P and R in position ‘A’.

+ SELECTOR (S7) in position ‘5’ (Hammer

type). The last selected hammer type is

shown in the display. if hammer to be

used does not correspond with displayed

hammer type, adjustment must be made

as follows:

+ Press key BI o © following the

sequence of table Il until the required

hammer type is shown in the left

display.

© Enter the selected hammer type in the

Eprom by tuming S7 in another

position.

Adjust the required settings with S7 as

far as they deviate from the default

values listed in table Ill

«This is particularly required to adjust

the number of pulses for correct

‘speed pick-up of the diesel-engine in

use:

IHC Hyerohammer BV. P.0 box 26.2

REV 6 017006 _User’s manual C-34

Document no. C-24(1168 and up)UMGB.

Setting:

160-P-250 Pens, Volo TO ST0/71A

Pars Voivo TAD S206

250 Do1 Volvo TAD 72:VE

250 D-eeres — Yova TAD 72:VE

P40 ove TO 1216.

80 0 Volvo TAD 1261 GE

P-TSOLP-1600W Vivo TD 1630,

P750W/P-1500W Cummins KTA 19

800. P-16008 () Voto TADIS#IGE

of Soho Ky

‘CAUTION:

‘change the setting of D (pulse) only with the

‘engine running.

+ Both SensorLEDs A and 8 (fig. 3/7) must

light, indicating that the hammer is correctly

placed on the pil

+ Tum $7 in positon‘! (Re«0.0u7) and select

RPM with the keys Ml or M4 for display

reading

+ Adjust the speed with 2 between 1200 and

1500 rpm. Compare the reading withthe rpm

shown on the engine panel A-34

CAUTION: Only when using the power pack

(1) (see table above) with variable pump

plunger stroke, $3 switch

Position 1 & 3

{or test purposes and warming up

Position 2: at start of hammer, the engine rpm is

‘automaticaly raised to 1800 and the stroke

adjuster moves to the last used position,

4 Turn S4 in position START to start piling

operation.

5 Reach the required blow rate by matching

rpm ($2) and pump capacity ($2).

6 Adjust the required level of energy with

Energy switch Rt

7 Piling operation can be stopped at any time

by switching $5 to position stop.

CAUTION: Only when using the following

hhydr. power pack types: P-175; P-460CID,

P-800L and P-1600B

the swash plate (for stroke adjustment)

‘swings to the minimum position and after 15

‘seconds the engine rpm drops to idle speed.

NOTE: The user will soon get the feeling for the

optimal settings for steps 5 and 6 for a particular

soll resistance and type of pile.

ct Hydrohammer BV.

REV.6 01/2006 User's manual C34

Documeni no. 6-34 768 and upjUMGB

4.3 Automatic stops

‘A number of malfunctions or faulty actions will ‘The various trip codes are listed on the front

automatically stop pile driving with or without plate of C-34 with a short description. A full

delay and in some cases the engine is stopped. description is given in table |

In these cases, the red trip LED (see fig. 3) is on

or ig blinking and the trip code appears in the ‘Always RESET with 85, having solved the trouble

display (see fig. 3).

‘which has caused the trip, (see par. 4.4).

Trip, | Short desertion | Full description possibi caueos

or | Emergency top ‘The emergency stop bston S1 has been pressed. Engine and ling cperation stop

immectatay.

02 | Pingeract Poston of $4 has been changed prior ting SS in poston STOP,

03 | Ramtwo ign (Only for S-hanmmor: The ram weight ses oo fr Signal ight A biks while signal ight

remains on. Reduce Energy (ig. 7) or increase cap pressure.

0% | Ramtootow “Te rm weight loners too far, Pe penetrates to fast (00 much energy) cr hemes

hangs ln erane (hammer ot crrecton ple).

05. | Energy teoigh During pling the measured impact eneray of te ram weight has exceeded the tip

value (= 108% of max eneray, ee tae I) during ve consecutive Blows. For

‘acon, the ip veloc for al ecracion hammer ypes s 2075

0s | Power faire 24V ‘Suppiywatage is ess than 20,8 V. (100 ms day, System stops

NOTE: during start of engine, supply wotage wil shot crop beow 208 V.

or | Onpressuretoorign | The nycrauic a presture, measured nthe pomer pack, 00 high

Bing Cperaton stops ate 4 seconds dey (contact X16) on wring dagram

‘Too mach alo harm cap pressure is igh.

os | itor cogges ‘Too high a press. op arotssucton or retum titer. Ping aperation stop ate delay

(of 60 seconds (contact XA).

Cc Max temperature or rinimur ol level has been reaches. pling operation stops ater

2

6

6

2

24

IHC Hyerohammer BL. P.O box 26, 2060 AA Kinder, The Netherton

Hydrauc ol levettemp

Tat witch of son

wave

Engine alam

Hammer not corect on

ple

ter too high

Overcad oP valve

Ovedoad of Rave

Hammertow

Rem intop

‘System faire

delay of60 eoconcs (contact x1A.4),

‘Seton vatve's nat uly open (some power packs have limit switch insta), engine

Sops media

Engine tps on ow ube ol pressure or high cols temperature

Engine anc pling operation stop immediatly (contac x17)

oth sensors A and 8 do ntsc” te am weight ia baton pesion.

Piling operation cannot be started

eter evel inthe stove has isn to Fgh deg underwater png

‘The pling operation is siopped when te signal ofthe "water electrodes in the sieves

Is present for more than to seconds.

‘Shortcut or dtacive scloneid oP valve Reps and allow for cooling down fr 60s.

‘Shortcut or defective sclanald of vale. Repair and alow fr cooing down or 608

Fock breakor has reached is max pentraton dept, Rock breaking stops, activated

Dy it etch on leader guide

Oniy for SC-hammers. Willoscur whan stating, wile sensor C'ses' ste! (ram weight

intop)

REMARK: thistrip has priovty over tip 11

‘This ip can oly oes when etching onthe power supply

‘vero has been detects by the ultin check oe ajuable parameters

Table I: Trip codes,

202 Fax +31.78 6910504

9

Cc Hydrohammer B.V.

44 Restart after trip

Procedure is as follows:

+ Tuin $8 in position sto».

= Solve the problem (see table IV trouble

shooting)

= Turn $5 to position RESET (spring loaded); the

trip LED 5 on the front (see fig. 3) will go off

and the trip code disappears from display 2.

~ Check for correct positions and settings of the

C-34 (see par. 4.2 item 3 and 4), since

changes may have been made during

corrective action,

Restart by switching $5 to position starr.

4.5. Use of the remote control ut

To use the 8-34 proceed as follows:

B34

ig. 6: Mintng. plate with printer connector

‘= Loosen the mounting plate (with integral

printer connector (fg.6/1)

‘+ Open C-34. Pull the 5 poles terminal block

XS from the print board (see fig. 7) and

remove it together with the mounting plate

from the C-34.

Pull the 20 poles terminal block X4 from its

socket and press it gently in the terminal

strip X3 next to it (as in fact the parking

position),

‘© Guide both connectors of the B-34 through

the opening of the removed mounting plate

land connect them to the terminal strips X4

and x8.

‘+ Install the mounting plate of the B-34 cable.

Use the same screws from fig 6/1

* Close door of the C-34.

SHC Hyerohammer Bx. P.0 60425,

10

lather,

REV.6 012008 User’s manual C-34

‘Dosument ro, C-34(1183 ad up)UNGS

4.8 Use of C-34 with a P-220 power pack

‘The C-20 control box of a P-220 power pack

has the opposite polarity of the C-34 and also

the emergency stop circuit differs (Normally

Open).

‘To enable the use of the C-34 in combination

with the A-20 engine panel of a P-220 power

pack, the 12 poles terminal block X8 (see fig.7)

must be relocated in the terminal strip X7 (ust

above X8) in an over 180 ° tured position.

‘The other yellow LED of valve A will

now lighten. ®

Fig. 7: Internal terminal blocks

47 Use ofthe rock broaker

‘The Eprom of the C-34 is already suitable for

use of a Hydrohammer” ROCK BREAKER. It gives.

‘the possibility to limit the energy level in order to

prevent damage tothe chisel

$e imi set as follows

= Open C-34 to reach selector S7 (see fig. 4)

© Tuim'S7 tothe postion ©. () and set the

value °70" kJ with the Wo M2 key.

= After that tum’ S7 10" the. postion ‘E

(Program) and set“ withthe Bor RE key

In case the rock breaker is resting on the chisel

housing as result of too deep @ penetration,

sensors A and B do not “see the ram weight,

thus preventing start of operation. To

‘overcome this, proceed as follows:

= try to pull the rock breaker free with the

cylinders or the crane, if not successful

~ put S4 in position EXTRACT

= press both keys Bl and BA for at least three

seconds while tuming $5 in position

START.

= while extracting, pull also the chisel out of

the soil with help ofthe cylinders or crane.

Fox 451.78 6010906

Cc Hydrohammer BV.

5 ADJUSTMENTS

REV.6 012006 User's manual C-34

‘Document no. C-34(7185 and upjUMGB

‘The user can choose from 28 types of hammer with the selector switch S7 in position ‘5!

Select the hammer ype fom the table I below using the keys Bd

‘Table Il lists the fixed parameters of each hammer.

‘Table lists the parameters which can be adjusted by the user.

5.1 Fixed parameters

ana Bl on the front of C-34.

Hammer Mass Energyé | Energy Et

type (ko) (rd) (te)

(caleulatea | (Trip loved

value)

S30 100 0 2

895 soo 35 7

$40 2175 “0 2

545 7200 45

$60 ey o os

S170 3800 m0 1%

3.60 500 0 95

S20 6200 ‘0 ‘7

S150 7580 10 19

200 ‘o100 200 22

200 12600 220 27

s-400 22000 “00 a

$00 2000 sao 0

00 200 600 65

750 rego 790 735

S20 cs00 ‘00 smn

$1800 7000 ‘co 1608

2000 ‘s700 200 28

sco 1700 » a

sca 2500 Py 2

sco ‘900 so =

sceo ‘000 0 o

$075 70 75 0

sc%0 700 0 6

sono 7900 110 "

sc-150 11000 180 19

80-200 12800 x0 22

sc-260 17800 250 5

NOTE:

‘The trip values during pling are set 6% above the max. calculated energy from table I.

In case of extracting, the trip velocity forall extraction hammer types is 2.0 m/sec

See also Table | trip code 05 “Energy too high’.

Table Il: Mass of ram weight and energy of Hydrohammers

IHC Hycronammer BY. P.0 bow 26

2960 AA Kinder, The

902 Fax «81.78 6910

Cc Hydrohammer B.V.

Rev. 01/006 User's manual C-24

i ~ ‘Docuert no. C-54(1763 ane up)UNGB

5.2 Adjustable parameters

‘The parameters which can be adjusted by the user are listed in the table below. Their values are stored

in the C-34 software (EPROM DS) and can be changed by means of the selector switch S7 (see fig. 4).

‘The switch position is given in brackets under its corresponding function in the header of the table.

REMARKS:

‘+ Achanged value is only stored in the EPROM afer turing S7 in another position,

+ During piling, a changed value becomes active immediately, with the exception of ttmax, for which

‘switch $5 must be turned again in position START.

‘The column ‘display-code' shows the actual appearance of the selected hammer type on display 2 (fig. 3)

+ {4 and t6 are only applicable for extraction

+ t8 has two different functions: piling and rock breaking

Hammer | aipiay Stare ps) My fe peer

ode

‘ype Puss | prosram [Unie

co) fon fee fer jem fe fee fro fee fie

$30 0 a la

S40 o @ |@

sis 8 @ |@

580 o a |e

so ” e |e

300 2 @ |2

Sim 20 = |e

Sa 60 fo | ao

5200 200 | a0

Sam 200 |e

5400 rr fo | a0

Soo 00 |e

S90 = so | oo

Sa0a wots |i |e

82300 2300 ia | te ‘se able

20 wo fe fro [o | paree ojo

sca0 coo 2

sew0 Go a

eo @

Geo 2

es, @

0

sc200 ceo ry

ST Range cap ‘00

oe Range we rr

Table Ill: Default sottings

timax Maximum iting time. Adjustable range is €7 Stopitip. time (R-closed after stop during

0-9.9 s. In the full right position of R1 (end of extraction). Adjustable range 0-9.9 s in 0,1 s-steps.

scale = 10), the timer t1 is set at its maximum

value. ‘8 Delay time R to close after B sensor during

pile driving, Adjustable range 0-999 me.

{2 Delay time R to open after P closes during pile

driving. Adjustablo range is 0-999 ms (t.d.c). Pulse Number of pulses per engine revolution,

generated by the speed pick-up.

{3 Delay time P to open after R closes during pile For use of P-460: set at ‘0° with I or BU for fow

driving, Adjustable range is 0-999 ms (b.d.). reading

{4 Delay time R to open after P closes during "Program" Set at intended application

extraction. Adjustable range is 0-999 ms (Ld.c) ling, 1" = rock breaking

{6 Delay time P to open after R closes during pile Units” set at required unit

driving. Adjustable range Is 0.999 ms (odo).

IHC Hycrohammer BV, P.0 bow 26, 2060 AA Kinde

The Neteranes

2

C3 Hydrohammer B.V.

TROUBLE SHOOTING

REV.6 01/2006 User's manual C-34

‘Dosument no C-34(1763 and upjUMGB

Generally, malfunctions in the control box will have an effect on the Hydrohammer®.

Possible cause

Remedy

11_Hydrohammer® does not star while power pack

‘in operation.

Power supply switch on A-34, A-32 or A-20 in

positon ff (0)

‘Atip code Is indicated on display

‘2 Turn switch in positon (I), both windows (fig. Jaret it

‘check main fuse F4 (fg. 8)

Conect cause of tip (see table I) and restart (see par. 44).

‘Any ofthe suitches P, A and R is notin position © Put elevant switch in poston A

‘Alutoratic)

LED A or B or both are not aight

LED A or B or both remain of, while hammer i

on pile.

No pressure builtup in the system

Polarity switching connector in wrong terminal

block (X7 oF XB)

]d. Hammer not corecton pile,

is [© Ram weight can not reach lowest postion, check sleeve-

adapter fing for corect instalation

{ - Putswitches P and A in position H: pressure must be 350 bar

Itnot

= check fuse Ft (fg. 4),

= check cable and connector ofthe main valve, if OK

= replace solencid of main valve,

if pressure is zero:

=P valves stuck in open positon

if pressure remains 90 bar

= main valve A" on hycraulic manifold malfunctioning,

1g. SeetabieV

‘No data display during pling operation.

LED A remains alight

'@ = Check cable connection of hammer with A-34, A-32 or

4.20 (fg. 1)

= Check Sensor on the hammer.

= Check contra box C-34

Hydrohamme? skes inegulaiy

Pressure valve malfunctioning

{strong pressure fuctuations notcesbie).

Return valve maifunetioning,

‘2 Tum switch P to positon H (fig 4: pressure must be 90 bar,

if not

check cable connection of pressure valve,

itoK

= Solenoid or plot valve defective: replace valve cover

assembly

Tum switch R to positon H (fig. 4: pressure must be 90 bar

not

= check cable connection of pressure valve,

toK

= solenoid or plot valve detective: replace valve cover

assombly

Ram weight remains in top

LED 8 or A and B remain alight

Hammer will eventually tip on too high ol pressure (tip 7).

check connection of contol cable

sensor ots ampitier malfunctioning

Table IV:

IHC Hyerohammer B.V.P.0 20% 26, 2960 AA Kind

‘Trouble shooting C-34

The Methesnds, Phan

413

81.78 6910202 Fex-+3178 6910304

Cc Hydrohammer B.V.

: EV. 6 012008 User's manual C-34

Docent C16 UUM

Other symptoms.

The following symptoms may arise i polarity switching connector is placed in wrong terminal block (X7 of XB)

Power pack does not start and no trip indication on display 2

Power pack starts while emergency stop is pressed (tio 01) but pling operation ie blocked by tp Of

oer pac sa eral ulin opment pone esersane neioeace

SS en tach Soper peri becars b

‘See matrix below for correct position of polarity

switching connector

C34

from serial no. 1163

(po side sch instal)

P60

x7

220

250

P-460 x8

P-750L

Table V: Other symptoms

Hp Impact eneray ick fbe

Velocity mis, rs) 1 Emergency top 10 Engine aac

‘Stroke m 1 Puingatrect 11 Hummer not eortest on pile

Blowsnnin © Ramtoonigh 42 Watertoo hgh

om Flow 0) 14 Ram too lowe 14 Overland Pete

{5 Energytoohigh 45 Overload Reale

6 Power falure 20 48 Hammer low

8 oipressure too high 22 Ram intop.

0 Fiter clogged 24 System feluro

9 Hyaraute on

‘vee Engine

Fiow Je hata. Fullspees

emergency tp \ pump / ingest Reset Stop Start Back press Eneray

sp o» es oe 4 on on

TIT C3 GB EXCHANGEABLE FRONT PLRTE-bap

Fig. 8: Exchangeable front plate

(plastic, avaitable with text in the English, Dutch, French or German language)

“IHC Hydrohemmer BL. F.0'b0% 26, 500 AA Kinder, Tha Natherianos Phone +347

“4

910902 Fax +31 78 6510208

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Kobelco 6D24-TLU2D - Parts Manual PDFDocument172 pagesKobelco 6D24-TLU2D - Parts Manual PDFGeorge Zormpas100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HITACHI - EX1200-6 - Technical Manual Operational - TO18J-E-00Document314 pagesHITACHI - EX1200-6 - Technical Manual Operational - TO18J-E-00George Zormpas75% (12)

- UntitledDocument147 pagesUntitledGeorge Zormpas100% (1)

- HITACHI - EX1200-6 - Workshop Manual - W18J-E-00 PDFDocument590 pagesHITACHI - EX1200-6 - Workshop Manual - W18J-E-00 PDFGeorge Zormpas100% (3)

- Cylinder Liner: SpecificationsDocument2 pagesCylinder Liner: SpecificationsGeorge Zormpas100% (1)

- HITACHI 850, 850LC, 870H, 870LCH Components Parts Catalog (151-419) Page RecognitionDocument138 pagesHITACHI 850, 850LC, 870H, 870LCH Components Parts Catalog (151-419) Page RecognitionGeorge ZormpasNo ratings yet

- General Instruction ManualDocument1 pageGeneral Instruction ManualGeorge ZormpasNo ratings yet

- CamshaftDocument2 pagesCamshaftGeorge Zormpas100% (1)

- Connecting Rod: SpecificationsDocument3 pagesConnecting Rod: SpecificationsGeorge Zormpas100% (1)

- Connecting Rod and Main Bearing Journals: SpecificationsDocument2 pagesConnecting Rod and Main Bearing Journals: SpecificationsGeorge Zormpas100% (1)

- Hensley Full Catalogue GZDocument161 pagesHensley Full Catalogue GZGeorge ZormpasNo ratings yet

- 12 - 0048 Distributor 4641147 3611 5' E12 Saloon 518 ECE L M 1976/06Document54 pages12 - 0048 Distributor 4641147 3611 5' E12 Saloon 518 ECE L M 1976/06George ZormpasNo ratings yet

- EngineDocument68 pagesEngineGeorge ZormpasNo ratings yet

- Method of Estimating The Volumetric Carrying Capacity of A Truck BodyDocument25 pagesMethod of Estimating The Volumetric Carrying Capacity of A Truck BodyGeorge ZormpasNo ratings yet

- Cummins QSB6.7C - Parts CatalogDocument85 pagesCummins QSB6.7C - Parts CatalogGeorge Zormpas100% (3)

- 51 - 0217 Glazing 4641147 3611 5' E12 Saloon 518 ECE L M 1976/06Document130 pages51 - 0217 Glazing 4641147 3611 5' E12 Saloon 518 ECE L M 1976/06George ZormpasNo ratings yet

- Cat Electronic Technician 2014A v1.0 Product Status ReportDocument6 pagesCat Electronic Technician 2014A v1.0 Product Status ReportGeorge ZormpasNo ratings yet

- The BMW Carburetor: - :::::: : I:::::: :: !: J L I I: : IDocument32 pagesThe BMW Carburetor: - :::::: : I:::::: :: !: J L I I: : IGeorge ZormpasNo ratings yet

- Fuel Preparation SystemDocument30 pagesFuel Preparation SystemGeorge ZormpasNo ratings yet

- LIMA 2400 Specifications-Lifting CapacitiesDocument12 pagesLIMA 2400 Specifications-Lifting CapacitiesGeorge Zormpas100% (4)

- Capacity ChartDocument33 pagesCapacity ChartGeorge ZormpasNo ratings yet

- 151-323 - Clark Lima 2400B (SN - 712B-105) Parts Manual - INDEXDocument22 pages151-323 - Clark Lima 2400B (SN - 712B-105) Parts Manual - INDEXGeorge Zormpas100% (2)

- Cat Electronic Technician 2014A v1.0 Product Status ReportDocument10 pagesCat Electronic Technician 2014A v1.0 Product Status ReportGeorge ZormpasNo ratings yet

- Cat Electronic Technician 2014A v1.0 Product Status ReportDocument6 pagesCat Electronic Technician 2014A v1.0 Product Status ReportGeorge ZormpasNo ratings yet

- Cat Electronic Technician 2014A v1.0 Product Status ReportDocument6 pagesCat Electronic Technician 2014A v1.0 Product Status ReportGeorge ZormpasNo ratings yet

- Cat Electronic Technician 2014A v1.0 Product Status ReportDocument12 pagesCat Electronic Technician 2014A v1.0 Product Status ReportGeorge ZormpasNo ratings yet

- 68BDocument4 pages68BGeorge ZormpasNo ratings yet

- IHC SC-150 - Details and Specifications (Complete)Document4 pagesIHC SC-150 - Details and Specifications (Complete)George ZormpasNo ratings yet

- IHC SC-150 - Details and Specifications (Sleeve - Pile Cap)Document2 pagesIHC SC-150 - Details and Specifications (Sleeve - Pile Cap)George ZormpasNo ratings yet

- 2007 AnualHammertypesDocument22 pages2007 AnualHammertypesGeorge ZormpasNo ratings yet