Professional Documents

Culture Documents

Behaviour of RC Frame With Strong Masonr

Behaviour of RC Frame With Strong Masonr

Uploaded by

Ranjan MedagodaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Behaviour of RC Frame With Strong Masonr

Behaviour of RC Frame With Strong Masonr

Uploaded by

Ranjan MedagodaCopyright:

Available Formats

V. Sigmund, J. Zovkić, I.

Guljaš Ponašanje a-b okvira s jakim zidnim ispunom na horizontalno cikličko opterećenje

ISSN 1330-3651 (Print), ISSN 1848-6339 (Online)

UDC/UDK 624.012.45.072.33.04.046:519.87

BEHAVIOUR OF RC FRAME WITH STRONG MASONRY INFILL IN RESPONSE TO CYCLIC

HORIZONTAL LOADING

Vladimir Sigmund, Jurko Zovkić, Ivica Guljaš

Original scientific paper

This paper gives an overview of the experimental results obtained by testing three reinforced concrete (RC) frame models with strong infill walls and one

bare RC frame model for comparison. The experimental results of the RC frame models with and without a strong masonry infill are presented in terms of

the collapse mechanism, lateral resistance, lateral stiffness and hysteretic energy. Based on those results, we obtained the ductility coefficients, behaviour

factors, and equivalent damping coefficients of the RC frames with strong infill walls ("frame-wall") and the bare RC frame, all of these variables

depending on storey drifts. The experimental and analytical results of frame-wall and RC frames, regarding their lateral capacity and lateral stiffness, were

compared. Experiments showed that the masonry infill contributed to the lateral capacity, lateral stiffness, hysteretic energy, changed behaviour, as well as

the equivalent damping coefficient of RC frames. It is shown that "frame-wall" composite behaved as full-fledged building type having lower

vulnerability than RC frames and enough displacement capacity to sustain displacement cycles in the nonlinear range of response.

Keywords: reinforced-concrete frame, strong infill wall, cyclic loading, experimental results, analytical results, comparison

Ponašanje a-b okvira s jakim zidnim ispunom na horizontalno cikličko opterećenje

Izvorni znanstveni rad

U radu je dan prikaz eksperimentalnih rezultata tri ispitivana modela armirano-betonskih okvira (a-b) s jakim zidnim ispunama ("uokvireno ziđe") i

jednog modela praznog a-b okvira. Prikazani su eksperimentalni rezultati u pogledu mehanizma sloma ispuna, poprečne nosivosti, poprečne krutosti kao i

histereznih energija. Na osnovu eksperimentalnih rezultata dobiveni su koeficijenti duktilnosti, faktori ponašanja i koeficijenti ekvivalentnog prigušenja

uokvirenog ziđa i praznog a-b okvira u ovisnosti o nivou relativnog katnog pomaka. Utvrđene su razine oštećenja zidnog ispuna koje su povezane s

nivoima relativnih katnih pomaka. Eksperimentalni rezultati, dobiveni na uokvirenom ziđu, uspoređeni su s analitičkim rezultatatima iz literature, glede

poprečne nosivosti i poprečne krutosti. Iz eksperimentalnih rezultata vidljiv je doprinos zidnog ispuna na poprečnu nosivost, poprečnu krutost, histerezne

energije, koeficijent duktilnosti, faktor ponašanja, i na koeficijent ekvivalentnog prigušenja u odnosu na prazan a-b okvir. Uokvireno ziđe može se korisiti

kao ravnopravan nosivi element za preuzimanje horizontalnih opterećenja, unutar ograničenja promatranih parametara.

Ključne riječi: analitički model, armirano-betonski okvir, cikličko opterećenje, eksperimentalni rezultati, jaki zidni ispun, usporedba rezultata

1 Introduction distinction. A strong frame typically means a frame

designed for seismic actions that has the following

Reinforced concrete (RC) frame structures filled in characteristics: strong columns – weak beams; small

with brick masonry walls are commonly used in low and spacing of transverse reinforcement in columns, beams,

medium-high buildings in the Republic of Croatia. Infill and their connections; higher compressive strength of

walls primarily serve architectural purposes and demands, concrete. The strength of the masonry infill almost always

while their constructive contribution is ignored; thus, the refers to its compressive strength, which can be roughly

wall should be detached from the frame. This kind of divided into soft, medium, and strong categories. The

construction is very rare, and usually the infill is glued to failure mechanism and ductility of frame-masonry

the frame or is even used as its form work. However, the buildings depend on additional factors such as geometry

composite behaviour of the infill and frame often remains (bay span to height ratio), relative stiffness and strength of

unconsidered, as a consensus by the research community the frame and masonry infill, ductile detailing of the

on the effects of masonry infill has not yet been reached frame, reinforcement of the infill when the infill controls

[1]. Indeed, testing these structures is quite active, as the failure and on the infill distribution in the building

shown by a number of recent experiments [2, 3, 4]. plan and the elevation of the building. If brittle inelastic

Besides having some adverse effects, these structures effects can be prevented (e.g. extensive cracking of the

often exhibit increased stiffness, strength, and dissipation infill, bond-slip failure in the frame, or shear failure in

capacity along with decreased displacement and second- frame members), then stiffness degradation and strength

order effects. Nevertheless, design provisions for new deterioration under cyclic loading are acceptable [7, 8].

frame-masonry buildings, as in EN 1998-1 [5], are mainly The designs of contemporary earthquake-resistant

devoted to avoiding any potential consequences of infill structures should reliably limit damage in low and

wall; however, it does not account for the benefits of their medium-strong earthquakes and prevent collapse during

contribution. EN 1998-3 [6] does not include any strong earthquakes. The goal of these designs is to meet

provisions that consider infill, even as a strengthening customer requirements with rationally designed and

intervention, when evaluating the safety of existing constructed buildings for a given level of reliability. Thus,

buildings. Thus, this article as well as the works cited deal this research will contribute to a better understanding of

with RC frame structures designed for some lateral action the composite behaviour of RC frames and masonry infill.

while disregarding the influence of masonry infill. Frame-

wall structures are composite structures made of an RC

frame and masonry infill. These structures are often

divided into weak and strong categories without clear

Tehnički vjesnik 21, 2(2014), 389-399 389

Behaviour of RC frame with strong masonry infill in response to cyclic horizontal loading V. Sigmund, J. Zovkić, I. Guljaš

2 The physical model

2.1 Introduction

20

20

D E

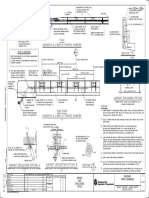

To obtain the RC frame test model, we chose a

20

common seven-storey reinforced-concrete office building D φ6/10(20)cm

E

(prototype) [9, 10]. The prototype was selected in order to

obtain its cross-sectional dimensions (columns and

φ6/7,5(15)cm

φ6/7,5(15)cm

150

beams), span, and height, as well as to determine the REINFORCEMENT: B500B

212,5

130

CONCRETE: C30/37

required/selected reinforcement in the columns and

beams, as well as the corresponding vertical load, which

simulates the load from the upper floors. The actual C C C C

dimensions of the prototype are scaled in order to produce A B

the corresponding test model.

42,5

42,5

In this paper, a model represents either a bare RC

frame or an infilled RC frame test structure. This study is A φ8/15cm B

a part of the Croatian project "Seismic design of infilled 34 20 20 180 20 20

frames", in which a total of ten models were created and 54 220 20

tested [9]. The results of four models: three RC frame 294 [cm]

models with strong masonry infill built with commonly

used hollow clay block masonry units and one bare RC SECTION A-A SECTION B-B

frame model for comparison are presented in this paper. 4φ16mm 4φ16mm

All models used in this report are designed and

constructed at a 1:2,5 scale (Fig. 1). 2φ16mm 2φ16mm

φ8/15cm φ8/15cm

425

425

20 20 180 20 20 12

20

12

8φ16mm 4φ16mm

300 300

20 20

20

SECTION C-C SECTION D-D SECTION E-E

12φ10mm 6φ10mm 2φ10mm

2φ6mm 2φ6mm

STRONG φ6/7,5

200

200

200

(15)cm φ6/10cm φ6/20cm

150

MASONRY INFILL

130

4φ10mm 2φ10mm

(EMPTY) 200 120 120

Figure 2 Geometric and reinforcement details of the model specimens

A concrete cube samples were taken from each frame

42,5

42,5

and the mechanical properties of the concrete (mean

compressive strength, fck) were obtained according to the

norms [13]. The concrete tensile strength, fct,m, and the

20

30

modulus of elasticity, Ecm, were obtained by using the

34 20 20 180 20 20 20

equations [13]:

54 220 20 30 [cm]

Figure 1 Scaled model of the reinforced-concrete frame

f ct ,m = 0,3 ⋅ f ck 2 / 3 , (1)

2.2 Models data

2.2.1 Reinforced-concrete frame

Ecm = 9500 ⋅ ( f ck + 8)1/ 3 . (2)

The models of the reinforced-concrete frames were

made at a 1:2,5 scale based on a prototype, which The mechanical properties obtained from the concrete

represents the middle ground floor bay from the middle samples are shown in Tab. 1.

frame of the prototype [9, 10, 11, 12]. The specimens

Table 1 Mechanical properties of concrete

were produced as practical true models meaning that the

Compressive Tensile Modulus of

prototype and the models had the same material properties RC frame

strength, strength, elasticity,

and the same axial stress in the columns, thus simulating model

fck / N/mm2 fct,m / N/mm2 Ecm / N/mm2

the loading from the upper floors. All the RC frame K-7 41,50 3,60 34 881

models were designed and constructed to comply with the

K-5 51,50 4,15 37 088

C30/37 concrete strength class and the B500B

K-8 43,50 3,71 35 345

reinforcement grade according to the Eurocodes [5, 6,

13]. Geometric and reinforcement details of the K-9 35,00 3,21 33 282

specimens are shown in Figs. 1 and 2.

The longitudinal reinforcement ratio of the columns The mechanical properties of the reinforcement used

was ρv = 2,36 %, while for the beams was ρv =1,31 % in in the models were obtained by tensile tests on three

reinforcement bars with diameters of 8, 10 and 12 mm, all

the mid-span and ρv =3,27 % at their ends.

390 Technical Gazette 21, 2(2014), 389-399

V. Sigmund, J. Zovkić, I. Guljaš Ponašanje a-b okvira s jakim zidnim ispunom na horizontalno cikličko opterećenje

in accordance with the corresponding norms. All tests joints. The dimensions of the scaled wall elements are

were carried out in the Laboratory for Experimental shown in Tab. 5.

Mechanics at the Faculty of Civil Engineering in Osijek.

The results are presented in Tab. 2. Table 5 Dimension of scaled wall elements

Dimensions of

Dimensions of scaled

Table 2 Mechanical properties of reinforcement Type of infill original infill wall

infill wall elements,

Tensile Modulus of wall element elements,

Rebar Yield strength, lu/wu/hu / mm

strength, elasticity, lu/wu/hu / mm

diameter, mean value

mean value mean value Brick block

Φ / mm fy / N/mm2 250/190/190 190/120/90

fu / N/mm2 E/ N/mm2 MO10

8 583 654 201 385

10 594 700 206 957 The masonry infill wall panels were produced with

12 574 605 198 599 general purpose lime-cement mortar made "in situ" with a

Mean values 584 653 202 314 volume proportion of cement:lime:sand=1:1:5 and with

the bed and head-joint thicknesses of 10 mm.

2.2.2 Masonry infill

The masonry infills were produced by hollow clay

masonry units V-5 that belonged to Group 2 under

Eurocode 6 with a nominal compressive strength of 15

MPa. The mechanical properties of masonry units, mortar

and masonry wallets were tested according to the

European norms, and are presented in Tab. 3.

Figure 3 Construction of infill walls

Table 3 Mechanical properties of the mortar

Mean tensile

Mean 2.2.3 Test models

compressive

Type of test strength,

strength, All tested specimens were divided in two groups, as

fmt,sr / N/mm2

fmc,sr / N/mm2 shown in Tab. 6, in order to simplify their identification

Masonry units 7,80 38,39 and interpretation and analysis of the results.

Wallets/compression tests 1,09 5,13

Wallets/ shear tests 1,33 6,02 Table 6 Test models

Infill wall tests 1,26 5,11 RC frame

Group Model Infill type

model

The compressive strength of masonry units was tested MODEL7 K-7 Brick block

on six randomly selected elements with prepared units’ GROUP I MODEL8 K-5 MO10

pressed surfaces. The units were prepared for testing by MODEL9 K-8 (strong infill)

using cement mortar with mechanical properties listed in GROUP IV MODEL10 K-9 No infill

Tab. 3.These results showed that the masonry units had a

mean compressive strength of fmc,sr=fb,sr=13,21 N/mm2. 3 Testing of the specimens

The compressive strength of the masonry infill 3.1 Introduction

samples (wallets) were tested in accordance with

EN1052-1:1998[14, 15]. Masonry panels were built with Model testing was performed in a closed steel frame,

hollow clay masonry units connected with lime-cement as shown in Fig. 4. The steel testing frame was

mortar produced in-situ in volume proportions of 1:1:5 horizontally supported with braces in order to prevent

(lime:cement:sand). The bed joints were 10 mm thick and horizontal movement. The test setup (steel frame and

the head joints were completely filled. Three masonry corresponding braces) was connected to the strong floor.

wall samples (wallets) were tested. Cyclic lateral load was applied to the beam ends of

The initial shear strength of the masonry infill was the specimen by using two double-acting hydraulic jacks

determined in accordance with prEN1052-3:2001 [14, fixed to the steel columns of the test frame. The

15], and the measured mechanical properties are listed in specimens were adequately insured against adverse

Tab. 4. developments (i.e. out of plane behaviour). Vertical load

was applied to the tops of the columns by using two

Table 4 Mechanical properties of masonry infill walls hydraulic jacks placed on a carriage wheel, which allowed

Mean compressive strength, fcw,sr / N/mm2 2,62 them to move horizontally and prevented their rotation

Mean modulus of elasticity, E / N/mm2 6572 (Fig. 4).

Mean initial shear strength, fvo / N/mm2 0,536 The foundation beam of each specimen was fixed to

Mean internal friction coefficient, α / ° 22,17 the steel frame and to the strong floor.

The masonry infill wall panels were produced with 3.2 Measuring devices

scaled masonry units cut from the original panels,

preserving the amount and area of the holes (with the Measuring devices were placed on all models

same percentage of voids) and the same number of bed (groups) in the same manner as that shown in Fig. 4.

Tehnički vjesnik 21, 2(2014), 389-399 391

Behaviour of RC frame with strong masonry infill in response to cyclic horizontal loading V. Sigmund, J. Zovkić, I. Guljaš

Displacements were measured with Linear displacement A cyclic horizontal (lateral) load was applied by

velocity transducers (LVDT), forces with force using two double-acting hydraulic jacks, with a 350 kN

transducers: horizontal (FORCE_HL and FORCE_HD) capacity, each. This load was increased in 10 kN steps

and vertical (FORCE_VL and FORCE_VD), as is shown until the specimen yielded. At this point, the load was

in Fig. 4. increased so that the lateral displacement increased in

1mm steps (Fig. 5). Once the masonry infill was severely

damaged, we applied a lateral load from only one side

until the masonry infill was heavily damaged.

45°

The vertical loads were not entirely constant during

the tests (Fig. 5). Differences to the designed values

FORCE_HR

occurred due to the boundary conditions and they were

LVDT_HR

II.

LOAD

CELL

LVDT_VR

corrected by pressure valves. Any differences in the

LOAD

CELL

DEF. 8

LVDT_2

DEF. 6 horizontal forces were within the permissible range.

I.

FORCE_VR

DEF. 2

LVDT_3

FORCE_VL FORCE_VR MEAN VALUE FORCE_HL FORCE_HR

420 350

410 300

400 250

YLS-50/60 YLS-35/150

200

MASONRY INFILL

Vertikal force, Nmi,d / kN

Horizontal force, H / kN

390

150

700 bara

380 100

150mm

II.335kN

370 50

359

STRONG

360 0

350 -50

340 -100

-150

330

700 bara

-200

A

I. 500kN

60mm

320 -250

310 -300

300 -350

0 20 40 60 80 100 120 0 20 40 60 80 100 120

Steps Steps

FORCE_VL

Figure 5 Vertical (left) and horizontal (right) time history loadings

DEF. 3

(MODEL 7)

LVDT_6

DEF. 7

I.

LVDT_7

A

20 20 180 20 20

LVDT_VL

LOAD

CELL

DEF. 4

LVDT_HL

LOAD

20

FORCE_HL

12

CELL

II.

Nmi,d Nmi,d

H H

20

20

45°

20

0

Figure 4 Test setup

The vertical and horizontal displacements of the STRONG

150

specimens were measured at the beam and columns ends MASONRY INFILL

130

by displacement transducers (vertical LVDT_VL and (EMPTY)

LVDT_VD and horizontal LVDT_HL and LVDT_HD)

attached to separate scaffolding, detached from the closed

steel frame, in order to measure the absolute

42,5

42,5

displacements. Deformations of the diagonals were

measured on the frame and on the infill panels by strain

gauges. 20

30

All data from the measuring instruments were 34 20 20 180 20 20

collected with two Dewetron measurement systems and 54 220 20 [cm]

were analysed using DEWEsoftver.6.6.7 software. Figure 6 Vertical (N) and horizontal (H) model loads

3.3 Test loadings 4 Test results

The vertical load simulated loading from the upper The obtained results from the specimens’ tests are

floors was applied to the tops of the columns by two presented for the model dimensions and loads. Presented

hydraulic jacks, with 500 kN capacity each. Designed are the crack patterns, corresponding failure mechanism,

magnitudes of the vertical loads in prototype were scaled the cyclic experimental response curves (hysteresis loops)

to 1:2,52 for the specimens’ loading. In that way the axial and the obtained primary curves (resistance envelope

stress in the columns was the same in the Prototype and curves) for the cyclic lateral loading.

Model. In Tab. 7, designed and achieved axial loads in the

columns are presented. 4.1 Crack patterns and the infill's failure mechanism

Table 7 Vertical loads The final crack patterns of the specimens at drift

Designed axial load Achieved mean axial levels of 0,98 to 1,34 % are shown in Figs. 7 ÷ 9. For the

Group

Nmi / kN load, Nmi,d / kN

specimens in GROUP I, the cracks spread (advance)

GROUP I 362 357 diagonally along the vertical and horizontal joints; thus,

GROUP IV 354 346 the shear strength of these models depended on their

mortar joints. Notably, the horizontal cracks in these

392 Technical Gazette 21, 2(2014), 389-399

V. Sigmund, J. Zovkić, I. Guljaš Ponašanje a-b okvira s jakim zidnim ispunom na horizontalno cikličko opterećenje

models prevented the formation of diagonal cracks in the Photographs of the cracks in the bare RC frame are shown

upper half of the infill wall. in Fig. 10.

At higher loads a notable separation between the infill

wall and the frame elements appeared. Eventually, the

masonry infill crushed at the beam-column joints and

parts of masonry units fell out. The failure mechanism 18

6 10

24 16 12 8

could be described as a combination of shear-sliding and

14 23

22 8 20 11 23

diagonal-tension failure. Finally, tensile cracks appeared 14

17 14 11 21

22 14

at the columns’ toes. By correlating the forces and 5 13

12 12

9 9 21

corresponding displacements at particular damage levels, 22 18

15

15

we found out that first cracks in GROUP I always

22 12 9 23 19

22 22 16 19

15 16

occurred at storey drift values near 0,05 %. Their 15

15 11

14

11 12

11

maximum capacity was achieved at storey drifts of 0,25 ÷

20 12

17 17 14

0,30 %. 7 11 18

The interstorey drift, IDR, was calculated for both 9

ELIMINATED EXTERNAL FRONT SIDE

GROUPS as the mean value of horizontal LVDT readings WALLS OF MASONRY UNITS

(strain gauges) according to the expression: MODEL 9

Figure 9 Final crack pattern for MODEL 9 (IDR=1,34 %)

IDR={[(LVDT_HL+LVDT_HD)/2]×l00}/1500 (%), (3)

where:

LVDT_HL, LVDT_HD, according to Fig. 4, 1500 is

model height (mm).

20

19

22 18 10 8 21

15

5 10 19 10

Figure 10 Crack patterns observed on the MODEL 10 columns

8 11 18 25

15 10 19 8 12 20

15 7

11 9

4.2 Hysteretic behaviour

18 8 7 20

21 21 12 7 20 20

17

9

16 16 11 2

19

18

9

20 The measured hysteretic relationships between the

12 14

10 18

17

20

12

11 lateral load and displacement of the specimens are

17 9 presented in Figs. 11 ÷ 14, together with the primary

16

19 19 17

curves (resistance envelope curves) for horizontal force

11 17 and displacement. On the secondary axes presented are

ELIMINATED EXTERNAL FRONT SIDE the base-shear ratios (measured base shear in relation to

WALLS OF MASONRY UNITS

MODEL 7 the total weight of the model) as well as the storey drifts.

The hysteresis loops for each model were calculated

Figure 7 Final crack pattern for MODEL 7 (IDR=1,10 %) as the mean horizontal displacements according to the

expression (4)

23

d=(LVDT_HL+LVDT_HD)/2 (mm), (4)

21 5 9 23 13 21 13

23 17

15 16 17 23 16 while the inter storey drift ratio, IDR, was calculated for

23 14

15 13

17

6

20 22 8

2

20

20

7 15

10

17 18

each model according to expression (3).

15 1 24 15 20

21 28 12

21 16 22

11 20

24 16 23 25 11 18 22

23 10 7 21 18 9 Inter-story drift, IDR / %

1 9 1123

23 -1,00 -0,75 -0,50 -0,25 0,00 0,25 0,50 0,75 1,00

4 16 7

25 350 0,49

9

300 0,42

23

3 13 250

MODEL 7 0,35

200 0,28

Horizontal force, H / kN

9

Base shear ratio, H/(2N)

150 0,21

ELIMINATED EXTERNAL FRONT SIDE 100 0,14

WALLS OF MASONRY UNITS 50 0,07

MODEL 8 0

-50

0,00

-0,07

-100 -0,14

Figure 8 Final crack pattern for MODEL 8 (IDR=0,98 %) -150 -0,21

-200 -0,28

-250 Hysteresis curve -0,35

For the specimen in GROUP IV (RC bare frame), -300 Primary curve -0,42

cracks appeared at the columns’ toes, on both columns. -350 -0,49

-15,00 -11,25 -7,50 -3,75 0,00 3,75 7,50 11,25 15,00

When the lateral force was increased, cracks widened, and Displacement, d / mm

plastic hinges in the vicinity of the foundation beam-

column joints were formed. At higher horizontal forces, Figure 11 Lateral load – displacement curve of the Model 7

cracks appeared in the beam-column joints of the frame.

Tehnički vjesnik 21, 2(2014), 389-399 393

Behaviour of RC frame with strong masonry infill in response to cyclic horizontal loading V. Sigmund, J. Zovkić, I. Guljaš

Each primary curve was obtained as the envelope of find a function y with two linear and two nonlinear

the peak values of the corresponding hysteresis loops. parameters for the measured data according to (5).

Inter-tory drift, IDR / %

y = C (1) ⋅ exp(−λ (1) ⋅ t ) + C (2) ⋅ exp(−λ (2) ⋅ t ) . (5)

-1,00 -0,75 -0,50 -0,25 0,00 0,25 0,50 0,75 1,00

350 0,49

300 0,42 For the vertical load, the mean of the actual vertical

MODEL 8

250 0,35 loads on each model group was taken, as shown in Tab. 7.

200 0,28

Horizontal force, H / kN

Base shear ratio, H/(2N)

150 0,21

100 0,14

50 0,07 Inter-story drift, IDR / %

0 0,00 0,00 0,25 0,50 0,75 1,00 1,25 1,50 1,75 2,00

-50 -0,07 350 0,49

-100 -0,14

-150 -0,21 300 0,42

Base shear ratio, H/(2NmI,d )

-200 -0,28

Horizontal force, H / kN

-250 Hysteresis curve -0,35 250 0,35

-300 Primary curve -0,42

-350 -0,49 200 0,28

-15,00 -11,25 -7,50 -3,75 0,00 3,75 7,50 11,25 15,00 H=266.9155e(0.0020 d)-249.3199e(-1.0735 d)

Displacement, d / mm 150 0,21

MODEL 7

Figure 12 Lateral load – displacement curve of the MODEL 8 100 MODEL 8 0,14

50 MODEL 9 0,07

GROUP I

Inter-story drift, IDR / % 0 0,00

-1,00 -0,75 -0,50 -0,25 0,00 0,25 0,50 0,75 1,00 0,00 3,75 7,50 11,25 15,00 18,75 22,50 26,25 30,00

350 0,49 Displacement, d / mm

300 0,42

250

MODEL 9 0,35 Figure 15 Primary curves for models in GROUP I and

Base shear ratio, , H/(2N)

200 0,28

Horizontal force, H / kN

150 0,21

the optimized primary curve

100 0,14

50 0,07

0 0,00 Inter-story drift, IDR / %

-50 -0,07 0,00 0,25 0,50 0,75 1,00 1,25 1,50 1,75 2,00

-100 -0,14

350 0,51

-150 -0,21

-200 -0,28

Hysteresis curve 300 0,43

Base shear ratio, H/(2NmIV,d )

-250 -0,35

H=181.7583e(0.0093 d)-178.3226e(-0.2575 d)

Horizontal force, H / kN

-300 Primary curve -0,42

250 0,36

-350 -0,49

-15,00 -11,25 -7,50 -3,75 0,00 3,75 7,50 11,25 15,00 200 0,29

Displacement, d / mm

150 0,22

Figure 13 Lateral load – displacement curve of the MODEL 9

100 0,14

50 MODEL 10 0,07

Inter-story drift, IDR / % GROUP IV

-2,00 -1,67 -1,33 -1,00 -0,67 -0,33 0,00 0,33 0,67 1,00 1,33 1,67 2,00 0 0,00

350 0,51 0,00 3,75 7,50 11,25 15,00 18,75 22,50 26,25 30,00

300 0,43

MODEL 10 Displacement, d / mm

250 0,36

200 0,29

Horizontal force, H / kN

Base shear ratio, H/(2N)

150 0,22 Figure 16 Primary curves for model in GROUP IV and

100 0,14 the optimized primary curve

50 0,07

0 0,00

-50 -0,07 4.3 Lateral strengths

-100 -0,14

-150 -0,22

-200 -0,29 From the compared optimized curves shown in Fig.

-250 Hysteresis curve -0,36

-300 -0,43

17 it is obvious that the lateral stiffness of the frames with

Primary curve

-350 -0,51 infill was much higher than that of the bare frame,

-30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30 especially at lower drift levels.

Displacement, d / mm

The initial linear portion of the primary curve reveals

Figure 14 Lateral load – displacement curve of the MODEL 10 that the infilled frames acted as composite "framed-

masonry" element, up to drifts of about 0,1 %. As the

In Figs. 15 and 16 shown are the primary curves of infill and the frame separated from each other, the infill

each tested model as well as their averaged optimized and the frame elements were damaged, and system

primary curve that describe the behaviour of the group. stiffness decreased gradually until the resistance reached

The optimized curve represents only the positive branches its maximum value (Hmax) at drifts of 0,25 ÷ 0,30 %. After

of the primary curves for model sets. It was obtained by that point an almost horizontal force-deformation

the MATLAB ver. 2013 "Optimal Fit of a Non-linear relationship followed (yielding) up to the moment when

Function" method. This method finds the optimal fit of the frame overtook the lateral carrying capacity.

non-linear functions from a data set by using the The details of that branch depended on the

FMINSEARCH function, which implements the Nelder– degradation process of the infill, indicating that the RC

Mead simplex algorithm (direct search) to reduce the frame took on an increasing portion of the overall

nonlinear function with several variables. Its goal is to capacity. In all tested specimens, the first cracks appeared

at drifts of about 0,05 % and their behaviour was

394 Technical Gazette 21, 2(2014), 389-399

V. Sigmund, J. Zovkić, I. Guljaš Ponašanje a-b okvira s jakim zidnim ispunom na horizontalno cikličko opterećenje

essentially linear-elastic. The systems retained their load- Three limit states of the idealised experimental

carrying capacity up to drifts of 0,5 % with much lower envelopes were determined as:

stiffness. The results presented in Fig. 15 show that 1 – Crack limit, corresponding to a displacement at

frames with infill retained their load-carrying capacities the formation of the first significant cracks in the wall, as

up to drift ratio of about 1 %, at which point the infill a fraction of the maximum resistance (H1/Hmax=0,60 and

contribution was completely lost and the infill was 0,05 % storey drift);

heavily damaged. Above that drift level, the positive 2 – Ultimate resistance calculated by equalizing the

contribution of the infill was lost, and a negative areas under the experimental load curve and the bilinear

contribution could dominate if the RC frame elements idealisation curve;

were not properly designed for shear. MODEL 10 (bare- 3 – Ultimate state, determined by maximum

frame specimen) was much more flexible at small drifts, displacement attained during actual test.

but retained its lateral load-carrying capacity up to drifts

of about 2 % (Fig. 16). Inter-story drift, IDR / %

0,00 0,25 0,50 0,75 1,00 1,25 1,50 1,75 2,00

350 0,49

Inter-story drift, IDR / %

0,00 0,25 0,50 0,75 1,00 1,25 1,50 1,75 2,00 300 0,42

Base shear ratio, H/(2NmI,d )

2

Horizontal force, H / kN

350 0,49 3

250 0,35

300 0,42

Base shear ratio, H/(2NSR)

200 0,28

Horizontal force, H / kN

H2 =Hu =269kN

250 0,35 IDRu =0,09-1,34%

150 1 0,21

Ke=208kN/mm

200 0,28

100 0,14

150 0,21

50 BI-LINEAR IDEALISATION 0,07

100 0,14 GROUP I

0 0,00

50 GROUP I 0,07 0,00 3,75 7,50 11,25 15,00 18,75 22,50 26,25 30,00

GROUP IV Displacement, d / mm

0 0,00

0,00 3,75 7,50 11,25 15,00 18,75 22,50 26,25 30,00 Figure 18 Idealisation of the primary curve for GROUP I

Displacement, d / mm

Figure 17 Comparison of the primary curves of GROUP I and GROUP

Inter-story drift, IDR / %

IV 0,00 0,25 0,50 0,75 1,00 1,25 1,50 1,75 2,00

350 0,51

The base shear capacity of the "framed-masonry" 300 0,43

Base shear ratio, H/(2NmIV,d )

H2 =Hu =205kN

structure related to that of the bare frame is presented in

Horizontal force, H / kN

IDRu =0,41-1,86%

250 0,36

Tab. 8 for various drifts. 2

Ke=33kN/mm

200 3 0,29

Table 8 Lateral load capacity, H / kN, at certain drifts (displacements)

150 0,22

IDR / % 0,10 0,25 0,50 0,75

1

100 0,14

219 264 271 273

GROUP I

(3,43) (2,17) (1,60) (1,42) 50 BI-LINEARNA IDEALIZACIJA 0,07

GRUPA IV

64 122 169 193

GROUP IV 0 0,00

(1,00) (1,00) (1,00) (1,00) 0,00 3,75 7,50 11,25 15,00 18,75 22,50 26,25 30,00

Displacement, d / mm

IDR / % 0,83 1,34 1,68 1,86

273 278 Figure 19 Idealisation of the primary curve for GROUP IV

GROUP I – –

(1,39 (1,27)

GROUP IV

197 218 230 236 Structural performance beyond the elastic range is

(1,00) (1,00) (1,00) (1,00) usually expressed in terms of the ductility ratio, μ.

Because the lateral resistance never decreased under 90 %

If we normalize the capacity of the bare frame as 1, of the Hmax, we calculated the displacement ductility ratio

the capacity of the MODEL 8 for a 0,1 % drift was 2,8 as the ratio between the displacement at which the infill

times bigger, and so on. The infill contribution, which was heavily damaged and the idealised yield

decreased with increased drift, was about 30 % for a 1 % displacement, i.e. according to (6):

drift, although the masonry wall was severely damaged

and started to fall out of the plane. µ = d3 / d 2 . (6)

4.4 Idealization of experimental results The obtained ductility ratios of each group, based on

bilinear idealisation of the experimental results, are

The experimental resistance envelope curves (primary presented in Tab. 9. We set the ultimate displacement to

curves) are represented by a bi-linear idealisation in Figs. be the moment when the infill lost its integrity while the

18 and 19. To idealise the experimentally obtained reinforced-concrete frame remained almost intact. The

primary curve, we used the equations for calculating the structural behaviour factor, q, shows that the infill walls

lateral resistance and deformability of confined masonry contributed notably and that all tested specimens

walls as described in Tomaževič [16]. performed well under lateral loads simulating earthquake

forces. These values are close to those suggested for RC

Tehnički vjesnik 21, 2(2014), 389-399 395

Behaviour of RC frame with strong masonry infill in response to cyclic horizontal loading V. Sigmund, J. Zovkić, I. Guljaš

wall structures. The behaviour factor was calculated amount of the absorbed energy notably increased with

according to the expression (7): increase of the storey drifts in all groups. Addition of the

masonry infill within the RC frame improved the energy

q= 2 ⋅ µ −1 . (7) absorption capacity of the frame.

Table 9 Ductility ratios and the behaviour factors of specimens at H H

various drift ratios

IDR 0,50 % 0,75 % 0,83 %

Group µ q µ q µ q EA ED

GROUP I 5,79 3,25 8,68 4,05 9,61 4,28

GROUP IV 1,22 1,20 1,84 1,63 2,03 1,76 d d

IDR 1,34 % 1,68 % 1,86 %

Group µ q µ q µ q

GROUP I 15,11 5,47 – – – – a) b)

GROUP IV 3,28 2,36 4,11 2,69 4,55 2,85 Figure 21 Determination of the a) absorbed energy and b) dissipated

hysteretic energy

4.5 Lateral stiffness

Inter-story drift, IDR / %

The secant stiffness degradation values of our 4.000

0,00 0,25 0,50 0,75 1,00 1,25 1,50 1,75 2,00

specimens are presented in Fig. 20. It was computed for

ENERGY ABSORPTION

Energy absorption, EA / kNmm

each drift level and normalised with the initial pre- 3.200

cracked stiffness (stiffness at the onset of the first cracks)

using the optimized primary curves of each group. The 2.400

initial stiffness, K0, for GROUP I was calculated as the

stiffness at a storey drift of 0,05 % and 0,22 % for 1.600

GROUP IV (RC bare frame), respectively. The initial

800

stiffness was an elastic stiffness (K0=Ke) with the values GROUP I

shown in Figs. 18 and 19. GROUP IV

0

0,00 3,75 7,50 11,25 15,00 18,75 22,50 26,25 30,00

Displacement, d / mm

Inter-story drift, IDR / %

0,00 0,25 0,50 0,75 1,00 1,25 1,50 1,75 2,00 Figure 22 Energy absorption at various drifts for both groups

1,0

GROUP I

The same conclusion applies for the energy

Relationship stiffness, K/K0

0,8 GROUP IV

dissipation in Fig. 23.

0,6

Inter-story drift, IDR / %

0,4 0,00 0,13 0,25 0,38 0,50 0,63 0,75

12.000

0,2 ENERGY DISSIPATION

Energy dissipation, ED / kNmm

10.000

0,0

8.000

0,00 3,75 7,50 11,25 15,00 18,75 22,50 26,25 30,00

Displacement, d / mm

6.000

Figure 20 Degradation of stiffness for all specimens

4.000

Because the initial stiffness of the "framed-masonry" 2.000 GROUP I

specimens (GROUP I) was much higher, they also GROUP IV

0

exhibited more pronounced stiffness degradation 0,00 1,88 3,75 5,63 7,50 9,38 11,25

compared to the bare-frame specimen (GROUP IV). This Displacement, d / mm

behaviour correlates well with the lateral strength of the Figure 23 Energy dissipation at various drifts for both test groups

specimens.

Based on earthquake-simulation testing of RC

4.6 Hysteretic energy structures modelled as single-degree-of-freedom (SDOF)

systems (SDOF), Gulkan and Sozen (1976) concluded

The amount of the absorbed and dissipated hysteretic that it was possible to describe the inelastic response of

energy was calculated according to Fig. 21 [17]. Note that the RC structure as an elastic SDOF system with reduced

the dissipated energy was calculated as the cumulative stiffness and increased damping, calculated by using the

area within the hysteresis curve for each cycle up to a following expression:

particular storey drift.

The amount of absorbed energy in each group as a

function of storey drift is shown in Fig. 22. "Framed- ξ e = 0,2 ⋅ 1 − 1 / µ + 0,02 , ( ) (8)

masonry" specimens absorbed more energy (GROUP I)

than the bare RC frame (GROUP IV) specimen. The

396 Technical Gazette 21, 2(2014), 389-399

V. Sigmund, J. Zovkić, I. Guljaš Ponašanje a-b okvira s jakim zidnim ispunom na horizontalno cikličko opterećenje

where µ is the displacement ductility ratio, calculated exposed to seismic loadings. The seismic capacity of

by using expression (6). "framed-masonry" structures depends on a number of

The damping coefficients as functions of the ductility factors, including size of the elements, quality of concrete

coefficients at various storey drifts are shown in Fig. 24. and rebars, quality and type of masonry units and mortar,

They increase with increase in ductility and storey drifts. construction quality of the infill wall, and details of the

Additionally, Fig. 24 shows that the contribution of the RC frame and infill wall connections.

infill wall (GROUP I) to the damping coefficient was

significant compared to the bare RC frame (GROUPIV). 5.2 Seismic capacity of the RC infilled frames according to

the Slovenian research

Inter-story drift, IDR / %

0,00 0,25 0,50 0,75 1,00 1,25 1,50 1,75 2,00 Based on the previous experiments, Žarnić suggested

20 two possible modelling assumptions for the inelastic

behaviour of infilled-frames. The first model, which will

Damping coeffcient, ξ e /%

15 be shown here [18], characterizes a response of the

structure in terms of a load-displacement relationship,

while the second model allows full dynamic analysis of

10

the infill walls modelled with a set of diagonal springs. A

three-part linear force–displacement relationship diagram

5

is shown in Fig. 25, where:

GROUP I

GROUP IV

HRcr − shear resistance of the RC infilled frame at the

0 onset of the first cracks,

0,00 3,75 7,50 11,25 15,00 18,75 22,50 26,25 30,00

HRe − shear resistance of the RC infilled frame at the time

Displacement, d / mm

of separation between the infill wall and the RC frame,

Figure 24 Damping coefficient as a function of drift levels HRu − ultimate shear force/capacity of the RC infilled

frame,

4.7 Damage grades of the masonry infill wall Ki − initial stiffness of the RC infilled frame,

Ke − stiffness of the RC infilled frame at the time of

Based on the experimental results analysed and separation between the infill wall and the RC frame,

according to the categorized damage levels, as suggested Ku − stiffness of the RC infilled frame when the capacity

in EMS98 and some other available methods, we is reached.

classified the damage according to the storey drifts.

On the basis of the observed damage levels (onset of HR

cracks in the infill wall, separation between the infill and

RC frame, fallout of wall fillings, etc.), we defined storey

drift levels with corresponding damage classifications in Ki Ke Ku

HRu

Tab. 10. B

Table 10 Damages and drift ratios according to EMS98

Technical and HRe

Structural Damage

Drift ratio, IDR / economical A

damage level,

% feasibility of

description S/°

repair

0,0<IDR<=0,1 Insignificant Repairable 1°

HRcr

0,1<IDR<=0,3 Moderate Repairable 2°

Moderately

0,3<IDR<=0,5 Repairable 3°

difficult

0,5<IDR<1,0 Extensive Repairable 4° dcr de du d

Excessive, Figure 25 Linear idealisation of the structural behaviour of an RC

IDR>=1,0 Irreparable 5°

collapse infilled frame

5 The analytical model Expressions for determining the above-mentioned

5.1 Introduction parameters can be found in [10, 15, 16], as well as the

necessary parameters for their calculation.

The RC frames with masonry infill have recently

been intensively investigated [15, 16, 18]. The results Nmi,d Nmi,d

presented in this paper (as well as from previous Nmi,d Nmi,d

literature) showed that the composite "framed-masonry" HR HR

hb

structure had much higher stiffness, especially at smaller ld

drifts, and higher base shear capacity (that depended on

ht=2/3 h

h

the infill strength and infill/frame relationship) than the ls

bare frame structure and absorbed and dissipated more

ϕ

hysteretic energy. However, higher stiffness also leads to lc l lc l+lc

the increase of demand when the system becomes Figure 26 Collapse mechanism models of infilled frame structures

Tehnički vjesnik 21, 2(2014), 389-399 397

Behaviour of RC frame with strong masonry infill in response to cyclic horizontal loading V. Sigmund, J. Zovkić, I. Guljaš

The stiffness of the RC infilled frame with large Table 11 Comparison of the lateral strength

cracks, Ku, is calculated as the stiffness of the crack-free HA/IDR HB/IDR HC/IDR

Group

RC frame supported by a wall filled to 2/3 of its height kN / % kN / % kN / %

(ht= 2/3 h), as shown in Fig. 26. Analytical

The cross-sectional area, Ad, of the equivalent strut 67/0,01 270/0,06 270/1,34

GROUP I

and its width, w, are calculated using expression (9). The Experimental

geometric characteristics of the equivalent strut are shown 156/0,05 269/0,09 269/1,34

in Fig. 27:

The analytical model gave higher values for the

lateral stiffness than those obtained experimentally. The

Ad = K u ⋅ (ld / E ) , ld = h + l and w = Ad / t . 2 2

(9)

differences are shown in Tab. 12.

Nmi,d Nmi,d

x2 x1 Table 12 Comparison of the lateral stiffness

HR

Analytical Experimental Difference

Group

hb

Ku=Ke /

ld

Ku / kN·mm %

t kN·mm

GROUP I 286,16 207,83 38

w

h

y1

ϕ

a) lc l lc b) 6 Conclusion

The masonry infill wall significantly contributed to

tb

tc

t

Figure 27 a) Test setup of the infilled frame model, the overall structural performance of the structure. We

b) Idealised stress states in the vicinity of compression diagonal ends found that it significantly increased the stiffness, lateral

strength, and absorbed and dissipated hysteretic energy of

5.3 Comparison of the analytical and experimental results the RC infilled frame up to a storey drift of about 1 %.

Within conventional seismic design, which focuses

We compared the presented analytical results on accelerations and strength, it may be difficult to

(especially ultimate lateral resistance and stiffness) with recognize the benefits of increases in stiffness. However,

experimental results described by bi-linear idealized research and field evidence has shown that increases in

curves [15, 16], as shown in Fig. 28. Analytical results stiffness are beneficial because they lead to reductions in

were good in predicting the ultimate lateral resistance the magnitude of the deformations induced by ground

with the error margin less than 5 %. motions.

Our experiments showed that the lateral resistance of

Inter-story drift, IDR / % the RC infilled frame ("framed-masonry") is much higher

0,00 0,25 0,50 0,75 1,00 1,25 1,50 1,75 2,00 than that of the bare RC frame, especially at low storey

350

drifts. The initial linear portions of the hysteresis

300 B 2 C envelopes (primary curves) indicate that the infilled

Horizontal force, H / kN

250 3

frames act as composite "frame-masonry" elements. We

200

observed the onset of the first cracks in all tested models

at storey drift of about 0,05 %, a behaviour which was

150 1

essentially linear-elastic. The systems retained their load-

100

ANALYTICAL

carrying capacity up to drift of 0,5 % with much lower

A

50 BI-LINEARN IDEALISATION-EXP. stiffness. The frame-masonry composites retained their

GROUP I load-carrying capacities up to drift ratio of 1 %, at which

0

0,00 3,75 7,50 11,25 15,00 18,75 22,50 26,25 30,00 point the infill contribution was almost completely lost

Displacement, d / mm and the infill was significantly damaged. After that drift

level, the positive contribution of the infill could be

Figure 28 Comparison of the analytical and experimental results

neglected and the negative contribution could have

dominated if the RC frame were not properly designed for

In Fig. 28 and Tab. 11, the characteristic points are as

shear.

follows:

As for the lateral stiffness, our conclusions

A = HRe − yield force of infill wall under joint vertical and

correspond well with the one that correlates the lateral

horizontal loads at low strain levels;

strength of the specimens. For cyclic loading, the secant

B = HRu − ultimate lateral resistance of the infilled RC

stiffness of the infilled frame gradually approached that of

frame;

the bare frame as the lateral load and corresponding drift

C − extended horizontal branch of point B up to the final

level increased. In other words, the secant stiffness of the

experimentally determined storey displacement;

infilled frame decreased at displacement levels up to 1 %

1 - lateral force at storey drift of 0,05 %, corresponding

and above.

to the onset of the first significant cracks in the wall;

The amount of the absorbed and dissipated hysteretic

2 - ultimate lateral force obtained from bi-linear

energy in the "frame-masonry" system is much higher

idealisation of the experimental curve;

than in the bare RC frames, especially at small

3 - extended horizontal branch of point 2, up to the final

displacement levels.

experimentally determined storey displacement.

398 Technical Gazette 21, 2(2014), 389-399

V. Sigmund, J. Zovkić, I. Guljaš Ponašanje a-b okvira s jakim zidnim ispunom na horizontalno cikličko opterećenje

The structural behaviour factor, q, and equivalent masonry infill. // Earthquake Engineering & Structural

damping coefficient, calculated by using the ductility Dynamics. 42, 8(2013), pp. 1131-1149.

ratio, μ, shows the contribution of the infill walls and the [10] Zovkić, J. Seismic Behaviour of Reinforced-concrete

good performance of all test models under lateral loads Frames with Masonry Infill, Josip Juraj Strossmayer

University of Osijek; Doctoral Dissertation, 2013.

that simulate earthquake forces. Our obtained values can [11] Crisafulli, F. J.; Carr, A. J. Proposed macro-model for the

be used when designing a "frame-masonry" structural analysis of infilled frame structures. // Bulletin of the New

system to match an expected level of seismic behaviour. Zealand Society for Earthquake Engineering. 40, 2(2007),

Based on our experimental results, we classified the pp. 69-77.

damage to the infill walls based on storey drift. By [12] Das, D.; Murty, C. V. R. Brick masonry infills in seismic

observing differing levels of damage to the infill walls design of RC frame buildings: Part 2 – Behavior. // The

across various storey displacement levels, we defined and Indian Concrete Journal. August 2004.

classified a set of storey drift levels with corresponding [13] Eurocode 2: Design of concrete structures. EN 1992, CEN,

damage levels. The experimental program has shown that Brussels; 2004.

[14] Eurocode 6: Design of Design of masonry structures. EN

frame-masonry composite has enough displacement 1996, CEN, Brussels; 2005.

capacity to sustain displacement cycles in the nonlinear [15] Sorić, Z. Zidane konstrukcije I, 2. izd. vlast. nakl. Zagreb;

range of response. If the idea of damage control is to be 2004.

used for the frame-masonry composite, drift should be [16] Tomaževič, M. Earthquake-Resistance Design of Masonry

kept under 0,5 %. Buildings (Series on Innovation in Structures and

Finally, we obtained analytical results based on Construction - Vol. 1). Imperial College Press, London,

existing research models of RC infilled frames. To 1999.

simulate the local response of the masonry infill panel, we [17] Crisafulli, F. J. Seismic behavior of reinforced concrete

used the equivalent diagonal strut model. The initial structures with masonry infills. Doctoral Dissertation. 1997,

University of Canterbury, Christchurch, New Zealand.

analytical model gave very good results in terms of lateral [18] Žarnić, R. Inelastic Model of the R/C frame infilled by

capacity, while it failed to predict the expected horizontal Masonry Wall. // Engineering Modelling. 7, 1-2(1994), pp.

displacements and drifts. 47-54.

Acknowledgements

Authors’ addresses

The research presented in this paper is a part of the

Vladimir Sigmund, prof. dr. sc., dipl. ing. građ.

research project "Seismic design of in-filled frames", no. Josip Juraj Strossmayer University of Osijek

149-1492966-1536, supported by the Ministry of Science, Faculty of Civil Engineering Osijek

Education and Sports of the Republic of Croatia, whose Crkvena 21

31000 Osijek, Croatia

support is gratefully acknowledged.

E-mail: sigmund@gfos.hr

7 References Jurko Zovkić, doc.dr. sc., mag. ing. aedif.

Josip Juraj Strossmayer University of Osijek

[1] Mainstone, R. On the Stiffness and Strength of Infilled Faculty of Civil Engineering Osijek

Drinska 16A

Frames. // Proceedings of the Institution of Civil Engineers,

31000 Osijek, Croatia

Supplement, 48, (1971), pp. 57-90. E-mail: jzovkic@gfos.hr

[2] Colangelo, F. Pseudo-dynamic seismic response of

reinforced concrete frames infilled with non-structural brick Ivica Guljaš, prof. dr. sc., dipl. ing. građ.

masonry. // Earthquake Engng. & Struct. Dyn. 34, (2005), Josip Juraj Strossmayer University of Osijek

pp. 1219-1241. Faculty of Civil Engineering Osijek

[3] Han-Seon, Lee; Sung-Woo, Woo. Effect of masonry infills Crkvena 21

on seismic performance of a 3-storey R/C frame with non- 31000 Osijek, Croatia

E-mail: iguljas@gfos.hr

seismic detailing. // Earthquake Engng. & Struct. Dyn. 31,

(2002), pp. 353-378 (DOI: 10.1002/eqe.112).

[4] Kakaletsis, D. J.; Karayannis, C. G. Influence of Masonry

Strength and Openings on Infilled R/C Frames under

Cycling Loading. // Journal of Earthquake Engineering. 12,

(2008), pp. 197-221.

[5] Eurocode 8: Design of structures for earthquake resistance

– Part 1: General rules, seismic actions and rules for

buildings. EN 1998-1, CEN, Brussels; 2005.

[6] Eurocode 8: Design of structures for earthquake resistance

– Part 3: Assessment and retrofitting of buildings. EN

1998-3, CEN, Brussels; 2005.

[7] Federal Emergency management Agency (FEMA),

Evaluation of Earthquake Damaged Concrete and Masonry

Wall Buildings, Basic Procedures Manual, ATC-43, FEMA

306, ATC, California, 1999.

[8] Paulay, T.; Priestley, M. J. N. Seismic Design of

Reinforced Concrete and Masonry Buildings. J. Wiley and

Sons, NY, 1992.

[9] Zovkić, J.; Sigmund, V.; Guljaš, I. Cyclic testing of a single

bay reinforced concrete frames with various types of

Tehnički vjesnik 21, 2(2014), 389-399 399

You might also like

- Ata 38Document54 pagesAta 38Geovanni Riquelme LooNo ratings yet

- PLUMBING CODE Answer-KeyDocument9 pagesPLUMBING CODE Answer-KeyJustin Fernandez0% (1)

- Alloy Chain Sling InspectionDocument2 pagesAlloy Chain Sling InspectionIky Pui Yee0% (1)

- Carpentry Works Man-Hour PDFDocument2 pagesCarpentry Works Man-Hour PDFHenry Tugano50% (2)

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDocument5 pagesNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- Dynamic Response of Flexible Rockfall Barriers With Different Block ShapesDocument17 pagesDynamic Response of Flexible Rockfall Barriers With Different Block ShapesRodrigo MorgadoNo ratings yet

- Recycling 07 00069 v2Document20 pagesRecycling 07 00069 v2Brixter SantosNo ratings yet

- Accommodation of Structural Movement inDocument9 pagesAccommodation of Structural Movement inwal1547No ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Hanson ManualDocument410 pagesHanson ManualJohn StanleyNo ratings yet

- Damage Assessment of RC Flat Slabs Partially Collapsed Due To Punching ShearDocument13 pagesDamage Assessment of RC Flat Slabs Partially Collapsed Due To Punching ShearEng mohammadNo ratings yet

- Resistance of Reinforced Concrete Frames With Masonry Infill Walls Due To Sudden Loss of ColumnDocument17 pagesResistance of Reinforced Concrete Frames With Masonry Infill Walls Due To Sudden Loss of ColumnHemanth KumarNo ratings yet

- 7.KSCE Journal of Civil Engineering (2015)Document12 pages7.KSCE Journal of Civil Engineering (2015)Ahmet TükenNo ratings yet

- Masonry InfillDocument6 pagesMasonry InfillAnand G RajNo ratings yet

- In-Plane Cyclic Performance of Confined Partially Grouted Masonry Walls With Joint and Vertical ReinforcementDocument12 pagesIn-Plane Cyclic Performance of Confined Partially Grouted Masonry Walls With Joint and Vertical ReinforcementPanayioti ZoupantisNo ratings yet

- BashaDocument13 pagesBashaTariqul IslamNo ratings yet

- 1 s2.0 S1687404814000996 Main PDFDocument16 pages1 s2.0 S1687404814000996 Main PDFgeorgeispasoiuNo ratings yet

- Exploration Study On Energy Dissipation in Beam and Column Joint With Semi Rigid ConnectionDocument12 pagesExploration Study On Energy Dissipation in Beam and Column Joint With Semi Rigid ConnectionIJRASETPublicationsNo ratings yet

- CDP SmesredDocument10 pagesCDP SmesredTAMANA SHAMSINo ratings yet

- Buildings 13 00437Document18 pagesBuildings 13 00437jarumy cantorin lazaroNo ratings yet

- 184-Brodsky-Paper-1 MasonryDocument11 pages184-Brodsky-Paper-1 MasonryHemanth KumarNo ratings yet

- Influence of Wall Openings On Nonlinear Lateral Load Response of Reinforced Concrete Frames With Masonry Infills-A Finite Element StudyDocument19 pagesInfluence of Wall Openings On Nonlinear Lateral Load Response of Reinforced Concrete Frames With Masonry Infills-A Finite Element StudyAurela BallaNo ratings yet

- Engineering Structures: SciencedirectDocument13 pagesEngineering Structures: SciencedirectJHON WILMAR CARDENAS PULIDONo ratings yet

- Research ArticleDocument19 pagesResearch ArticleAngga AriefNo ratings yet

- 5022 - KIM S. ELLIOTT - The Stability of Precast Concrete Skeletal StructuresDocument19 pages5022 - KIM S. ELLIOTT - The Stability of Precast Concrete Skeletal StructuressamiNo ratings yet

- Engineering Structures: SciencedirectDocument14 pagesEngineering Structures: SciencedirectAliNo ratings yet

- Numerical Study of Progressive Collapse Resistance of RC Beam-SlabDocument14 pagesNumerical Study of Progressive Collapse Resistance of RC Beam-Slabمحمد حارثNo ratings yet

- Tobctj 8 104Document18 pagesTobctj 8 104Ing Fredy William Campos FloresNo ratings yet

- Experimental Study On Lateral-Load-Resisting CapacDocument17 pagesExperimental Study On Lateral-Load-Resisting CapacravirajNo ratings yet

- Seismic Performance Assessment of Masonary Infilled RC Frames by Using Staad PRODocument13 pagesSeismic Performance Assessment of Masonary Infilled RC Frames by Using Staad PROIJRASETPublicationsNo ratings yet

- Effect of Masonry Infill Wall Configuration and Modelling Approach On The Behaviour of RC Frame StructuresDocument16 pagesEffect of Masonry Infill Wall Configuration and Modelling Approach On The Behaviour of RC Frame StructuresYanfei ZhuNo ratings yet

- Capacity Design of Infilled Frame Structures: Francisco J CRISAFULLI, Athol J CARR and Robert PARKDocument8 pagesCapacity Design of Infilled Frame Structures: Francisco J CRISAFULLI, Athol J CARR and Robert PARKDebby KrisnandiNo ratings yet

- 损伤可控的含减震外挂墙板RC框架结构抗震性能分析 蒋庆Document8 pages损伤可控的含减震外挂墙板RC框架结构抗震性能分析 蒋庆Wang haoqiangNo ratings yet

- Évaluation de L'aptitude Au Service Des Ponts À Poutres en Caisson en Béton Post-Tendu, Basée Sur La Fissuration.Document12 pagesÉvaluation de L'aptitude Au Service Des Ponts À Poutres en Caisson en Béton Post-Tendu, Basée Sur La Fissuration.Sebahi LakhalNo ratings yet

- Cyclic Loading Test of Lightly Reinforced Concrete Wall Piers With Slit Dampers in RC FramesDocument12 pagesCyclic Loading Test of Lightly Reinforced Concrete Wall Piers With Slit Dampers in RC FramesFerdinand ThamrinNo ratings yet

- Influence of Masonry Infills On Seismic Response of RC Frames Under Low Frequency Cyclic LoadDocument13 pagesInfluence of Masonry Infills On Seismic Response of RC Frames Under Low Frequency Cyclic LoadAlex PantiruNo ratings yet

- Comparative Study On The Behavior of Slender RC Walls With TwoDocument8 pagesComparative Study On The Behavior of Slender RC Walls With TwoAmina AzlafNo ratings yet

- Engineering Structures: Ran Feng, Yanwen Li, Ji-Hua Zhu, Feng XingDocument15 pagesEngineering Structures: Ran Feng, Yanwen Li, Ji-Hua Zhu, Feng XingEng mohammadNo ratings yet

- Analysis of Equivalent Flexural Stiffness of SteelDocument21 pagesAnalysis of Equivalent Flexural Stiffness of SteelAsad KhanNo ratings yet

- Soil Dynamics and Earthquake Engineering: Quanmin Peng, Xiaojie Zhou, Chenghao YangDocument15 pagesSoil Dynamics and Earthquake Engineering: Quanmin Peng, Xiaojie Zhou, Chenghao YangmgrubisicNo ratings yet

- Dynamic Analysis of Flanged Shear Wall Using Staad Pro: T. Subramani, B. Saravanan, J. JayalakshmiDocument6 pagesDynamic Analysis of Flanged Shear Wall Using Staad Pro: T. Subramani, B. Saravanan, J. JayalakshmiPandal RajNo ratings yet

- Slab Deflections in The Cardington In-Situ Concrete Frame BuildingDocument12 pagesSlab Deflections in The Cardington In-Situ Concrete Frame BuildingwaynectwNo ratings yet

- Dinesh PanditDocument9 pagesDinesh PanditDr-Rahul PanditNo ratings yet

- Finite Element Modeling of Shear Strength of Infilled Frames With OpeningsDocument10 pagesFinite Element Modeling of Shear Strength of Infilled Frames With OpeningsGalal El-DarratNo ratings yet

- Analysis of Flectural Stiffness of Composite BeamsDocument22 pagesAnalysis of Flectural Stiffness of Composite BeamsVictorNo ratings yet

- Effect of Infills On Seismic Performance of Reinforced Concrete Frame Structures A Full Scale ExperimentalDocument30 pagesEffect of Infills On Seismic Performance of Reinforced Concrete Frame Structures A Full Scale Experimentalsadi1988No ratings yet

- Shear and Flexural Stiffnesses of Reinforced ConcrDocument19 pagesShear and Flexural Stiffnesses of Reinforced ConcrKillian WismanNo ratings yet

- 1 s2.0 S0045794905002452 Main PDFDocument19 pages1 s2.0 S0045794905002452 Main PDFAvinash Bhakta 18MST0043No ratings yet

- Lateral Stiffness Characteristics of Tall PDFDocument19 pagesLateral Stiffness Characteristics of Tall PDFLaila Monteiro A MeloNo ratings yet

- (Asce) ST 1943-541X 0003217Document17 pages(Asce) ST 1943-541X 0003217Kim HyeonJinNo ratings yet

- Numerical Dynamic Tests of Masonry Infilled RC Fra 2013 Engineering StructurDocument13 pagesNumerical Dynamic Tests of Masonry Infilled RC Fra 2013 Engineering StructuraditNo ratings yet

- 1 s2.0 S0141029622009658 MainDocument14 pages1 s2.0 S0141029622009658 MainMoiz TariqNo ratings yet

- Shear Resistance of Masonry Walls and Eurocode 6: Shear Versus Tensile Strength of MasonryDocument20 pagesShear Resistance of Masonry Walls and Eurocode 6: Shear Versus Tensile Strength of MasonryScribd2015No ratings yet

- A Simplified Shear Model For Reinforced Concrete Elements Subjected To Reverse Lateral LoadingsDocument10 pagesA Simplified Shear Model For Reinforced Concrete Elements Subjected To Reverse Lateral Loadingsjiliang liuNo ratings yet

- 1.1 General: Chapter 1. IntroductionDocument4 pages1.1 General: Chapter 1. Introductionci_balaNo ratings yet

- P17ENC BuildingsDocument18 pagesP17ENC BuildingsEduardo Nuñez CastellanosNo ratings yet

- Engineering Structures: Y.P. Yuen, J.S. KuangDocument16 pagesEngineering Structures: Y.P. Yuen, J.S. KuangAdel AdelNo ratings yet

- EFFECT OF CONFINEMENT ON CURVATURE DUCTILITY OF REINFORCED CONCRETE BEAMS Ijariie20729Document10 pagesEFFECT OF CONFINEMENT ON CURVATURE DUCTILITY OF REINFORCED CONCRETE BEAMS Ijariie20729chaitanya krishnaNo ratings yet

- Engineering Structures: Guoqing Xu, Bruce R. EllingwoodDocument12 pagesEngineering Structures: Guoqing Xu, Bruce R. EllingwoodHamza AlpaslanNo ratings yet

- Engineering Structures: Tev Fik Terzioglu, Kutay Orakcal, Leonardo M. MassoneDocument14 pagesEngineering Structures: Tev Fik Terzioglu, Kutay Orakcal, Leonardo M. MassoneMilton Alexander Rivera TorresNo ratings yet

- J Engstruct 2018 12 064Document17 pagesJ Engstruct 2018 12 064Mladen MilićevićNo ratings yet

- Seismic Strengthening of RC Structures PDFDocument6 pagesSeismic Strengthening of RC Structures PDFGajendra JoshiNo ratings yet

- Macro-Modeling of Reinforced Concrete Structural Walls: State-of-the-ArtDocument28 pagesMacro-Modeling of Reinforced Concrete Structural Walls: State-of-the-ArtHemant SonawadekarNo ratings yet

- DamodarDubey-Kute2013 Article ExperimentalInvestigationOnTheDocument10 pagesDamodarDubey-Kute2013 Article ExperimentalInvestigationOnThechristian castilloNo ratings yet

- Son Vu Et Al - EngStruct - 2014 PDFDocument12 pagesSon Vu Et Al - EngStruct - 2014 PDFsarain_alvarezNo ratings yet

- 104-s49 Strength, Stiffness, and Cyclic Deformation CapacityDocument11 pages104-s49 Strength, Stiffness, and Cyclic Deformation CapacityAmr KemalNo ratings yet

- Dashti - Dhakal - Pampanin - (2014) - Numerical Simulation of Shear Wall Failure Mechanisms - NZSEE - ConferenceDocument12 pagesDashti - Dhakal - Pampanin - (2014) - Numerical Simulation of Shear Wall Failure Mechanisms - NZSEE - ConferenceWendy Wiegand DaviesNo ratings yet

- Cni17-0091-1 Ind - Steel - en 10346 S450GD Z275Document3 pagesCni17-0091-1 Ind - Steel - en 10346 S450GD Z275Việt NguyễnNo ratings yet

- 1.1.1 ISOLINE MG Anode StandardDocument2 pages1.1.1 ISOLINE MG Anode StandardJaka SembungNo ratings yet

- H20 Formwork For Walls AU EN 2009-10 PDFDocument36 pagesH20 Formwork For Walls AU EN 2009-10 PDFAndreea NanNo ratings yet

- Questionnaire: Position: Engineer IDocument3 pagesQuestionnaire: Position: Engineer IClifford Jan Tabada AtigNo ratings yet

- Catch Basin and Inlet Technical BrochureDocument3 pagesCatch Basin and Inlet Technical BrochuresvsvfafcesNo ratings yet

- Rediset WMX Ecuador RDocument34 pagesRediset WMX Ecuador RDiego Fernando ChicaizaNo ratings yet

- 3.5 Bitshield Rbe-5 - RevbDocument2 pages3.5 Bitshield Rbe-5 - RevbCristal Haze VictoriaNo ratings yet

- Apr May 2021Document32 pagesApr May 2021Lai Kok UeiNo ratings yet

- MondiDocument8 pagesMondikalyanvarmanNo ratings yet

- Maldaner Brochure English PDFDocument4 pagesMaldaner Brochure English PDFSaad KhanNo ratings yet

- Forging Rolling DefectsDocument16 pagesForging Rolling DefectsAshley JacksonNo ratings yet

- Section-220516 Expansion Fittings and Loops For Plumbing Piping Rev 1Document3 pagesSection-220516 Expansion Fittings and Loops For Plumbing Piping Rev 1刘盘石No ratings yet

- Drilling & GroutingDocument18 pagesDrilling & GroutingSantosh Laxman PatilNo ratings yet

- Siemens Liner Full PDFDocument31 pagesSiemens Liner Full PDFTATIANA BASTOS MORENONo ratings yet

- Material Science SyllabusDocument2 pagesMaterial Science Syllabus1DA20ME023 Girish M BNo ratings yet

- SIFS Product Submision PDFDocument72 pagesSIFS Product Submision PDFmahmoud IbrahemNo ratings yet

- HIT-RE 100 Injection Mortar: Anchor Design (ETAG 001) / Rods&Sleeves / ConcreteDocument7 pagesHIT-RE 100 Injection Mortar: Anchor Design (ETAG 001) / Rods&Sleeves / ConcreteSangramkeshari BejaNo ratings yet

- KMT Technology Description ENG 101019Document16 pagesKMT Technology Description ENG 101019Cristiana SoaresNo ratings yet

- Bridge Engineering Drawings 10.2 - A3 - 3Document1 pageBridge Engineering Drawings 10.2 - A3 - 3Adnan NajemNo ratings yet

- ROYAL BUILDING SOLUTIONS Garage Brochure 2017Document7 pagesROYAL BUILDING SOLUTIONS Garage Brochure 2017yuhimeNo ratings yet

- Material History Record: Ogsp Cutter Process Solutions India Private LimitedDocument5 pagesMaterial History Record: Ogsp Cutter Process Solutions India Private LimitedSumit SinghNo ratings yet

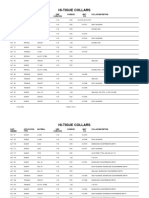

- HltcollarsDocument4 pagesHltcollarschampyjm6532No ratings yet

- Vendor Document Cover SheetDocument11 pagesVendor Document Cover SheetSagar SawantNo ratings yet