Professional Documents

Culture Documents

05 300 R1 Aluminium Anodes

Uploaded by

sams1101Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05 300 R1 Aluminium Anodes

Uploaded by

sams1101Copyright:

Available Formats

Sacrificial Anodes

Aluminium anodes German Cathodic Protection

Document No.: 05-300-R1

Sheet: 1 of 2

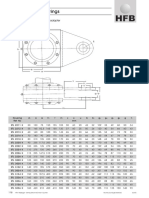

Standard Aluminium Hull Anodes

Anode Aluminium

Type weight weight A B H L

kg kg mm mm mm mm

15 Al 1.5 1.1 220 100 30 300

25 Al 2.5 2.0 270 120 32 350 L

43 Al 4.3 3.4 370 120 32 450

60 Al 6.0 5.2 600 120 41 700

H

80 Al 8.0 7.5 350 150 62 450

90 Al 9.0 7.8 960 120 37 1060

114 Al 11.4 10.6 600 120 76 700

A B

170 Al 17.0 15.8 960 120 73 1060

350 Al 35.0 31.6 1920 120 71 2000

All types can be delivered for bolting. All weights and dimensions are nominal.

Standard Aluminium Anodes - Static Structures

Anode Aluminium

Type weight weight A B H L

kg kg mm mm mm mm

280 HAL 27.3 21.5 1000 112 90 1500

385 HAL 37.7 30.0 1400 112 90 2000 L

485 HAL 47.7 40.0 1450 130 100 2000

H

516 HAL 51.6 40.0 2015 110 85 3000

566 HAL 56.6 45.0 2250 110 85 3000

A B

585 HAL 57.7 50.0 1500 140 110 2000

Extending core Ø 25 mm

616 HAL 61.6 50.0 2480 110 85 3000

625 HAL 62.5 54.8 1500 140 120 2000

HAL Type anodes with variable lengths up to 2.5 m are available upon request.

All weights and dimensions are nominal.

Standard Aluminium Tank Anodes

L B

Anode Aluminium

H

Type weight weight L B H OH

OH

kg kg mm mm mm mm

44 TAL 4.4 3.8 400 70 60 140

96 TAL 9.6 8.5 750 77 65 135 Centre stand-off leg for welding or bolting

Anode Aluminium

L B

Type weight weight A B H L

kg kg mm mm mm mm H

100 TAL 10.0 8.7 1235 62 45 1415

A

125 TAL 12.5 11.2 1235 68 57 1415

200 TAL 20.0 18.4 1600 76 63 1780 L B

All weights and dimensions are nominal and subject to variation A

in material compositions. Extending core Ø 12 mm

Alternative configurations may be cast to requirements.

Sacrificial Anodes

Aluminium anodes German Cathodic Protection

Document No.: 05-300-R1

Sheet: 2 of 2

Anode Aluminium

Type weight weight L B H OH

kg kg mm mm mm mm

L B

105 TAl 10.3 8.7 1235 64 51 145

130 TAL 12.8 11.2 1235 68 58 145

H

160 TAL 15.7 13.7 1600 70 52 145

OH

200 TAL 19.7 17.7 1600 76 63 145

230 TAL 22.6 20.0 2100 74 56 145

320 TAL 31.7 29.7 1600 95 84 165

900

All anodes can be manufactured with double cranked insert. Other anode types

can be manufactured according to requirements or specifications. All weights Centre stand-off leg for welding or bolting

and dimensions are nominal and subject to variation in material compositions.

Alternative configurations may be cast to requirements.

Chemical Compositions and Electrochemical Properties

BERALIN ALLOY BECALIN ALLOY

Zn 3.5 - 6.5 % 3.5 - 6.5 %

In 0.01 - 0.03 % 0.01 - 0.03 %

Mn 0.01 % max. 0.1 - 0.25 %

Fe 0.13 % max. 0.22 % max.

Si 0.10 % max 0.10 % max.

Cu 0.006 % max. 0.01 % max.

Al remainder remainder

Closed circuit potential -1100 mV vs Ag/AgCl -1120 mV vs Ag/AgCl

Current capacity max. 2680 Ah/kg max. 2550 Ah/kg

Efficiency 90 % 86 %

Consumption 3.27 kg per A/year 3.45 kg per A/year

Special advantages High current capacity, especially High driving voltage, especially

suited to applications where suited to applications where water

lowanode weights are desirable, resistivity precludes the use of

e.g. offshore structures. standard aluminium alloy.

You might also like

- 05 200 R1 Zinc AnodesDocument2 pages05 200 R1 Zinc Anodessams1101No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Y Strainer ND100 150Lbs E2501 F 641 - Data Sheet 8117 PDFDocument1 pageY Strainer ND100 150Lbs E2501 F 641 - Data Sheet 8117 PDFMahmoud AbuzaidNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Efb Jis Series Dimension (MM) Battery Type Capacity Polarity Nomenclature L W H (MF) H (SMF)Document16 pagesEfb Jis Series Dimension (MM) Battery Type Capacity Polarity Nomenclature L W H (MF) H (SMF)arifNo ratings yet

- Technical Data K-Ball VibratorDocument1 pageTechnical Data K-Ball VibratorautomatizacionNo ratings yet

- Q Panel SpecDocument2 pagesQ Panel SpecJohn TigerNo ratings yet

- Orbinox Ex PDFDocument2 pagesOrbinox Ex PDFRio PurnamaNo ratings yet

- Rivulis F1000 English Metric 20190507 Web-1Document4 pagesRivulis F1000 English Metric 20190507 Web-1Mehdi BassouNo ratings yet

- ABB Oil Xfrecodesign - dtr-30-06-2015 PDFDocument1 pageABB Oil Xfrecodesign - dtr-30-06-2015 PDFRAULNo ratings yet

- CI Wafer / DI Lug Butterfly Valves: Series 0160Document2 pagesCI Wafer / DI Lug Butterfly Valves: Series 0160Vignesh NadimuthuNo ratings yet

- World's Largest Science, Technology & Medicine Open Access Book PublisherDocument21 pagesWorld's Largest Science, Technology & Medicine Open Access Book PublisherAnshuman RoyNo ratings yet

- 105 AWB ModelDocument1 page105 AWB ModelBajak HatiNo ratings yet

- W100 Multi TurnDocument2 pagesW100 Multi TurnParthibanNo ratings yet

- Cast Steel Y-Strainers ANSI 150-600 LB: 0062 API 6D-0444Document1 pageCast Steel Y-Strainers ANSI 150-600 LB: 0062 API 6D-0444Camilo SanchezNo ratings yet

- Cathodic Protection Electrolytic AntifoulingDocument8 pagesCathodic Protection Electrolytic Antifoulingcatalintoader1969No ratings yet

- Forged Steel GlobeDocument3 pagesForged Steel GlobeFaisal NovredanaNo ratings yet

- ECG-Calculation Sheets: Design of Concrete StructuresDocument5 pagesECG-Calculation Sheets: Design of Concrete StructuresBahaa Gaber100% (1)

- BV261 - U Type Butterfly ValveDocument2 pagesBV261 - U Type Butterfly ValveFAIYAZ AHMEDNo ratings yet

- Column & Footing DetailDocument111 pagesColumn & Footing DetailKUSHADITYANo ratings yet

- BV232 Series DSDocument1 pageBV232 Series DSFAIYAZ AHMEDNo ratings yet

- Crane Rails: Standard European ProfilesDocument1 pageCrane Rails: Standard European ProfilesEric LarrondoNo ratings yet

- Various Kinds of API Valves Products ListDocument80 pagesVarious Kinds of API Valves Products ListMOHAMEDNo ratings yet

- Ever CM Main Entrance - Crack Repair SummaryDocument1 pageEver CM Main Entrance - Crack Repair SummaryJohn Rheynor MayoNo ratings yet

- Agitator Vessel Design CostingDocument20 pagesAgitator Vessel Design CostingneelNo ratings yet

- Knife Gate Valve: Product DescriptionDocument2 pagesKnife Gate Valve: Product DescriptionTamil SelvanNo ratings yet

- BV263 - U Type Butterfly ValveDocument2 pagesBV263 - U Type Butterfly ValveFAIYAZ AHMEDNo ratings yet

- Cast Iron Swing Check Valves With Counter Weight and Lever PN 10 and 16Document2 pagesCast Iron Swing Check Valves With Counter Weight and Lever PN 10 and 16Baskaran RathinamNo ratings yet

- Sluice Valve With ISI MarkDocument3 pagesSluice Valve With ISI Markatul.mankarNo ratings yet

- Aluminium Anode Data SheetDocument10 pagesAluminium Anode Data SheetMohamed WALINo ratings yet

- Woltman Flange DN50-300-KATALOG CALIBRATEDocument4 pagesWoltman Flange DN50-300-KATALOG CALIBRATENurdin FahimNo ratings yet

- Renew Woltman Flange DN50-300-KATALOG CALIBRATE (2) (1) - DikompresiDocument4 pagesRenew Woltman Flange DN50-300-KATALOG CALIBRATE (2) (1) - DikompresiIrwan PangaribuanNo ratings yet

- Maverick Valves CatalogueDocument84 pagesMaverick Valves Cataloguer4mms3sNo ratings yet

- Section 9 PRM AluminiumDocument10 pagesSection 9 PRM Aluminiumprasanth cpNo ratings yet

- FlangeDocument10 pagesFlangeNurul LailyahNo ratings yet

- MS Fabricated Y-Type StrainerDocument1 pageMS Fabricated Y-Type StrainerGourav SharmaNo ratings yet

- Applications: For Repairing of Cast Iron ProductsDocument1 pageApplications: For Repairing of Cast Iron ProductsLasandu WanniarachchiNo ratings yet

- SLD New Panel KotabaruDocument3 pagesSLD New Panel KotabaruKhaliqus ShabirNo ratings yet

- DIN A Rail SectionsDocument1 pageDIN A Rail SectionsAlanSoo100% (1)

- PetroCor BrochureDocument14 pagesPetroCor BrochuredediodedNo ratings yet

- Aluminium PCMDocument25 pagesAluminium PCMKarthi Kaiean100% (2)

- 3 Brochure 2 SUNGO Hollow Jet Valve (Updated) FINALDocument2 pages3 Brochure 2 SUNGO Hollow Jet Valve (Updated) FINALtendyNo ratings yet

- ZULFI E 7018: Brand Name & Classification Approvals GradeDocument1 pageZULFI E 7018: Brand Name & Classification Approvals GradeadnanNo ratings yet

- 07 Forged Cryogenic Gate GlobeDocument2 pages07 Forged Cryogenic Gate GlobeAndri AjaNo ratings yet

- Welded Steel Chain Renold JeffreyDocument7 pagesWelded Steel Chain Renold JeffreyRodrigo esprtanoNo ratings yet

- Up To 35kV TransformerDocument23 pagesUp To 35kV TransformerRatnagiri RamkumarNo ratings yet

- Valves 1234Document13 pagesValves 1234Goutham KSNo ratings yet

- HILCO E4043 ALUMINIL Si5 Welding Electrode - Data SheetDocument1 pageHILCO E4043 ALUMINIL Si5 Welding Electrode - Data SheetDieter van RooyenNo ratings yet

- Gate Valve CatalogDocument1 pageGate Valve CatalogHoang Cong DungNo ratings yet

- Electric Wire Rope HoistDocument5 pagesElectric Wire Rope HoistpoojaNo ratings yet

- End FittingsDocument1 pageEnd FittingsjoseNo ratings yet

- TDL GB 0810 DimDocument1 pageTDL GB 0810 DimAlfredo LacompoenganNo ratings yet

- Soportes Take UP STL Series - Rodamientos SmilovicDocument4 pagesSoportes Take UP STL Series - Rodamientos SmilovicAlejandro SmilovicNo ratings yet

- Wire Rope HoistDocument2 pagesWire Rope HoistNikhil BhattNo ratings yet

- Thanh đồng busbar GBDL-Kumwell Thái Lan. 0918527890 Mr. Thuận-New Ground Bar- GPDLDocument1 pageThanh đồng busbar GBDL-Kumwell Thái Lan. 0918527890 Mr. Thuận-New Ground Bar- GPDLThuan NguyenNo ratings yet

- 2022 Automotive Range (Small)Document20 pages2022 Automotive Range (Small)wilfredo hidalgoNo ratings yet

- Austlift Part-4.MaterialHandlingDocument18 pagesAustlift Part-4.MaterialHandlingNeil WayneNo ratings yet

- Conductors Fuse RatingDocument2 pagesConductors Fuse Ratingdhlix00100% (1)

- Sluice Valve PN.1.0 1.6 RisingDocument5 pagesSluice Valve PN.1.0 1.6 RisingDeepak PatelNo ratings yet

- Metals 02 00353 PDFDocument24 pagesMetals 02 00353 PDFwidjai10No ratings yet

- 06-000-R2 Types and FunctionsDocument1 page06-000-R2 Types and Functionssams1101No ratings yet

- Standard (NA 2020)Document27 pagesStandard (NA 2020)sams1101No ratings yet

- Metals 02 00353 PDFDocument24 pagesMetals 02 00353 PDFwidjai10No ratings yet

- CP-Data Management System CPDMS Created For Corrosion Protection Data Management by Corrosion Protection ExpertsDocument4 pagesCP-Data Management System CPDMS Created For Corrosion Protection Data Management by Corrosion Protection Expertssams1101No ratings yet

- 06-100-R1 Model TP-001 and TP-002Document1 page06-100-R1 Model TP-001 and TP-002sams1101No ratings yet

- PMI - PBA Exam Questions (Very Important) #Elzatwana - PBA - 1Document31 pagesPMI - PBA Exam Questions (Very Important) #Elzatwana - PBA - 1sams1101100% (1)

- 15-520-R1 Mobile WorkshopDocument2 pages15-520-R1 Mobile Workshopsams1101No ratings yet

- 14-410-R0 Decoupling Device DASDDocument2 pages14-410-R0 Decoupling Device DASDsams1101No ratings yet

- 14-501-R1 Kirk Polarisation CellsDocument1 page14-501-R1 Kirk Polarisation Cellssams1101No ratings yet

- 15-510-R1 Measurement Van For CP-ServicesDocument3 pages15-510-R1 Measurement Van For CP-Servicessams1101No ratings yet

- 14-000-R2 Pipeline Accessories SummaryDocument13 pages14-000-R2 Pipeline Accessories Summarysams1101No ratings yet

- 15-510-R1 Measurement Van For CP-ServicesDocument3 pages15-510-R1 Measurement Van For CP-Servicessams1101No ratings yet

- 14-102-R1 Spark Gap EXFS KUDocument1 page14-102-R1 Spark Gap EXFS KUsams1101No ratings yet

- 04-603-R1 Groundbed Head StructureDocument1 page04-603-R1 Groundbed Head Structuresams1101No ratings yet

- 14-201-R1 Flange Insulating KitsDocument2 pages14-201-R1 Flange Insulating Kitssams1101No ratings yet

- 14-301-R1 Carrier Pipeline InsulatorsDocument1 page14-301-R1 Carrier Pipeline Insulatorssams1101No ratings yet

- 14-202-R1 Monobloc Insulating JointsDocument1 page14-202-R1 Monobloc Insulating Jointssams1101No ratings yet

- 14-103-R2 Spark Gap EXFS 100 and 100 KUDocument1 page14-103-R2 Spark Gap EXFS 100 and 100 KUsams1101No ratings yet

- NCHRGDocument1 pageNCHRGsams1101No ratings yet

- 04-001-R1 Types of Groundbeds and Anode ApplicationsDocument1 page04-001-R1 Types of Groundbeds and Anode Applicationssams1101No ratings yet

- 14-401-R1 AC Voltage LimiterDocument1 page14-401-R1 AC Voltage Limitersams1101No ratings yet

- 04 100 R1 Magnetite AnodesDocument5 pages04 100 R1 Magnetite Anodessams1101No ratings yet

- 2 Lida Tubular Anodes HR PDFDocument2 pages2 Lida Tubular Anodes HR PDFAnonymous zNZYnINo ratings yet

- 03-300-R1 Wind GeneratorsDocument1 page03-300-R1 Wind Generatorssams1101No ratings yet

- 02 201 R2 Oilr Cooled Type TR OC 01Document1 page02 201 R2 Oilr Cooled Type TR OC 01sams1101No ratings yet

- 04-200-R1 Silicon Iron AnodesDocument2 pages04-200-R1 Silicon Iron Anodessams1101No ratings yet

- 05-100-R1 Magnesium AnodesDocument2 pages05-100-R1 Magnesium Anodessams1101No ratings yet

- 02 101 R1 Air Cooled Type TR AC 01Document1 page02 101 R1 Air Cooled Type TR AC 01sams1101No ratings yet

- Hayek - Planning, Science, and Freedom (1941)Document5 pagesHayek - Planning, Science, and Freedom (1941)Robert Wenzel100% (1)

- IA 05 Formal MethodsDocument5 pagesIA 05 Formal MethodsAuthierlys DomingosNo ratings yet

- A Guide To Sample Size For Animal-Based Studies (VetBooks - Ir)Document292 pagesA Guide To Sample Size For Animal-Based Studies (VetBooks - Ir)Jonathan MannNo ratings yet

- Sample File: The Ultimate Adventurers Guide IDocument6 pagesSample File: The Ultimate Adventurers Guide IDingusbubmisNo ratings yet

- 2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessDocument11 pages2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessOne PlusNo ratings yet

- Catálogo StaubliDocument8 pagesCatálogo StaubliJackson BravosNo ratings yet

- Package-Related Thermal Resistance of Leds: Application NoteDocument9 pagesPackage-Related Thermal Resistance of Leds: Application Notesalih dağdurNo ratings yet

- Electric PotentialDocument26 pagesElectric PotentialGlitchNo ratings yet

- Routine (27th April)Document1 pageRoutine (27th April)SoumitNo ratings yet

- TOPIC: Movable and Immovable Property Under Section-3 of Transfer of Property ActDocument10 pagesTOPIC: Movable and Immovable Property Under Section-3 of Transfer of Property ActRishAbh DaidNo ratings yet

- 22-28 August 2009Document16 pages22-28 August 2009pratidinNo ratings yet

- Soil Liquefaction Analysis of Banasree Residential Area, Dhaka Using NovoliqDocument7 pagesSoil Liquefaction Analysis of Banasree Residential Area, Dhaka Using NovoliqPicasso DebnathNo ratings yet

- Analysis of Green Entrepreneurship Practices in IndiaDocument5 pagesAnalysis of Green Entrepreneurship Practices in IndiaK SrivarunNo ratings yet

- DJF 41032 Manufacturing Workshop Practice 3 Plastic Lab: Mini Project (Transfer Moulding)Document7 pagesDJF 41032 Manufacturing Workshop Practice 3 Plastic Lab: Mini Project (Transfer Moulding)Lokhman HakimNo ratings yet

- FhryhfhfhDocument3 pagesFhryhfhfhAffan AhmadNo ratings yet

- Aerated Concrete Production Using Various Raw MaterialsDocument5 pagesAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- Introducing Eventstorming-4Document1 pageIntroducing Eventstorming-4Alex TrujilloNo ratings yet

- AZ 103T00A ENU TrainerHandbook PDFDocument403 pagesAZ 103T00A ENU TrainerHandbook PDFlongvietmt100% (2)

- ZH210LC 5BDocument24 pagesZH210LC 5BPHÁT NGUYỄN THẾ0% (1)

- Chapter 07Document16 pagesChapter 07Elmarie RecorbaNo ratings yet

- 3-Waves of RoboticsDocument2 pages3-Waves of RoboticsEbrahim Abd El HadyNo ratings yet

- Reading Proficiency Level of Students: Basis For Reading Intervention ProgramDocument13 pagesReading Proficiency Level of Students: Basis For Reading Intervention ProgramSONY JOY QUINTONo ratings yet

- Stevenson Chapter 13Document52 pagesStevenson Chapter 13TanimNo ratings yet

- Ge 6 Art Appreciationmodule 1Document9 pagesGe 6 Art Appreciationmodule 1Nicky Balberona AyrosoNo ratings yet

- Online Dynamic Security Assessment of Wind Integrated Power System UsingDocument9 pagesOnline Dynamic Security Assessment of Wind Integrated Power System UsingRizwan Ul HassanNo ratings yet

- Practical Research 2.9Document22 pagesPractical Research 2.9Michael GabertanNo ratings yet

- The Logic of Repetition: A Guide To Trading, Thinking, and The Cycles of LifeDocument10 pagesThe Logic of Repetition: A Guide To Trading, Thinking, and The Cycles of LifeRaghvendra kNo ratings yet

- TOA Project Presentation (GROUP 5)Document22 pagesTOA Project Presentation (GROUP 5)Khadija ShahidNo ratings yet

- RV900S - IB - Series 3Document28 pagesRV900S - IB - Series 3GA LewisNo ratings yet

- Disney - QMDocument14 pagesDisney - QMSyarifuddin Zulkifli0% (1)