Professional Documents

Culture Documents

FlightSafety MTM LEAR 35

FlightSafety MTM LEAR 35

Uploaded by

eduardo ruiz50%(2)50% found this document useful (2 votes)

206 views522 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

50%(2)50% found this document useful (2 votes)

206 views522 pagesFlightSafety MTM LEAR 35

FlightSafety MTM LEAR 35

Uploaded by

eduardo ruizCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 522

————

Sessa)

LEARJET 35/36

MAINTENANCE

TRAINING

MANUAL

VOLUME 1

LaINCE NAN eter

DET aoe CTEM ietolgs

Flushing, New York 11371

(CA eoee ar)

FOR TRAINING PURPOSES ONLY

NOTICE

The material contained in this training manual is based on information

obtained from the aircraft manufacturer's Pilot Manuals and Mainte-

' eee tana itis to be used Tor familiarization and training Purposes

only

At the time of printing it contained then-current information. In the

=a ‘event of conflict between data provided herein and that in publications

issued by the manufacturer or the FAA, that of the manufacturer or the

FAA shall take precedence |

We at FlightSafety want you to have the best training possible. We

welcome any suggestions you might have for improving this manual or

any other aspect of our training program.

OR TRAINING PURPOSES ONLY

CONTENTS

VOLUME 1

Chapter Title

INTRODUCTION

ATA 100

AIRCRAFT GENERAL

AIR CONDITIONING

AVIONICS

ELECTRICAL POWER

FIRE PROTECTION

FLIGHT CONTROLS

FUEL

HYDRAULIC POWER

ATA

Number

FlightSafety

£ LEARJET 35/36 MAINTENANCE TRAINING MANUAL

a INTRODUCTION

This training manual provides a description of the major airframe and engine systems installed

in the Learjet 35/36. This information is intended as an instructional aid only. it does not super:

ede, nor is it meant to substitute for, any of the manufacturer's maintenance or operating manuals

This material has been prepared from the basic design data, and all subsequent changes in air

plane appearance or system operation will be covered during academic training and subsequent

revisions 10 this manual

the secondchaperofhis manual, "ATA 00," mal for sll ATA 100 Mainenane Mana! chap

ens AS

Ee tes FOR TRACING PURPOSES ONLY "

Each chapter following “ATA 100" of this book

hhas listed on the divider tab the ATTA chapterts)

included, suc as 24 Electrical In some cases

it was appropriate, for training purposes, t0 i

‘clude more than one ATA chapter in one chap-

{er of this book, such as Chapters 4 through 12

in “Aircraft General."” ‘The tab marked “4-12

Aircraft General” indicates that applicable ATA

100 Maintenance Manual Chapters 4 through 12

are covered in that chapter, Any chapter not in-

‘cluded in the manufacturer's Maintenance Man-

ual for that particular airplane is not included

in that chapter of this training manual

The basic Maintenance Training Manual eon:

tains schematics to be used only as 2 tool in un-

derstanding a system. They are not kept current

the corresponding schematic(s) in the Maunte

nance Manual must be used when performing

‘maintenance.

Appendix in this manual contains a pictorial

‘Walkaround on a Learjet 35/36. Appendix B dis-

lays all light indications and should be folded

‘ou for reference while reading this manual.

‘The goal of this course is to provide the very

best training possible for the clients in our main-

tenance programs. So that there is no uncertainty

about what is expected of the client, the follow-

ing basic objectives are presented for this course.

Given the Maintenance Manual, class notes, and

this training manual (as specified by: the

FlightSafety instructor), the client will be able

to pass a written examination upon completion

ofthis course to the grading level prescribed by

12 FOR TRAINNG PUBPOSES ONLY

FlightSafety

LEARJET 85/36 MAINTENANCE TRAINING MANUAL

‘The main-

the FightSafety Director of Training

tenance technician will beable 10

+ Outline the ATA 100 system of mainte

ange documentation, incuing the Major

Chuprer headings and symbol

‘© Describe the meaning and application of

teach piece of manufacturer's maintenance

Uocumentation and use the documentation

in practical appl

# Outline the manufacturer's spares. tech-

nical support, and warranty procedures,

tand name the principal contacts

© Outline the recommended maintenance

schedule and the applicable options.

‘© Locate major components without refer

tence to documentation and other compo-

nents with the aid of documentation,

‘© Describe the operation of all major sys=

tems in the normal and various abnormal

‘operating, modes.

‘© Perform maintenance preflight and post

Might inspections,

* Perform selected normal and emergency

‘cockpit procedures as required for engine

startrunup, APU start, battery check, a

plane aating. ete. (requires use of

simulator)

‘The FlightSafety instructor will modify the stated

‘overall objective conditions and criteria to satisfy

selected performance requirements, when appro-

priate. The performance levels specified ill not

vary from those diected by the FighSatety

rector of Training,

NOVEMBER 1960

<

J

INTRODUCTION.

GENERAL

DOCUMENTATION

General

Revisions,

Serialization

‘Test Definitions

ATA 100

CONTENTS

HOW TO USE THE MAINTENANCE MANUAL.

Division of Subject Matter

Standard Numbering System

SUMMARY

FOR TRAINNG PURPOSES ONLY

FightSafety

LEARJET 35/36 MAINTENANCE TRAINING MANUAL

- 22

23

23

23

24

25

INTRODUCTION

FightSafety

LEARJET 35/96 MAINTENANCE TRAINING MANUAL

ATA 100

‘The purpose of this chapter is to describe the arrangement, numbering system, and special fea:

tures of the Air Transport Association format for aircraft maintenance manuals. To take advat

ial presented in an ATA 100-format manual, maintenance personnel must

tage of all the mat

become thoroughly familiar with the outline and contents presented for any given airplane

GENERAL

ATA Specification No. 100 is issued by the Air

Transport Association of America as the Spec

fication for Manufacturers’ Technical Data. W

Cslablishes a standard for the presentation of cer

tain data produced by aircraft, engine, und com:

ponent manufacturers required for the support

Df their respective products. Under this format,

the maintenance manual 1s broken down into

ward chapters as defined by ATA 100, Each

sta

NOVEMGER 1980

chapter covers a specific area of maintenance

information, such as Chapter 10, “Parking and

Mooring,”” or a specific system, such as Chap-

ter 32, “Landing Gear.”* All data pertaining to

‘given system is located within its chapter, re

gardless af whether it ts mechanical, hydraulic

Or electrical in nature. The chapters are arranged

‘in alphabetical order.

FOR TRAINING PURPOSES ONLY 2

FightSafety

<2 LEARJET 35/36 MAINTENANCE TRAINING MANUAL

DOCUMENTATION

GENERAL

The Learjet 35/36 Maintenance Manual is pre:

pared from manufacturer's technical data in ac-

Sordance with the Air Transport Association, The

Maintenance Manual provides sutticient infor

mation to enable a mechanic who is unfamiliar

With the aitplane to service, troubleshoot, test,

adjust, and repair systems and to remove and in-

stall any unit normally requiring such action on

the line or in the maintenance hangar

REVISIONS

General

ATA 100 allows the manufacturer a great deal

of leeway or freedom in the area of Maintenance

Manual revisions and their dissemination. Vir

tually every aircraft manufacturer has a system

different from any other manufacturer; some

differences are great while others are barely

noticeable, but all are intended to get mai

nance information, routine or vital, to the field

in a timely manner,

Because changes, particularly new temporary

changes, may be vital to ground and/or airborne

Safety, maintenance personnel should be thor-

oughly familiar with the methodology used

fa particular manufacturer to incorporate chan;

into the Maintenance Manual. The manufac:

turer's methods are listed in detail in the Main

tenance Manual “Introduction” for a given

airplane.

Two types of revisions are issued forthe Learjet

33/30 "Maintenance Manual’) Normal and

Temporary

Normal Revisions

Normal Revisions are printed on white paper and

isstied to qualified holders as required to update

the Learjet 35/36 Maintenance Manual. Addi-

tions, deletions, of revisions to the text are iden-

tified in the Table of Contents and on the text

page by a black bar inthe left margin of the page.

oe FOR TRAINING PURPOSES ONLY

Revisions are logged on the “*Log of Revisions’

page in the front of the manual. The revision

umber, date inserted, and initials of the post

ing individual are required.

ach page revised or added to the initial man

val Heed y the dato evi at to

tom of the page. Pages issved withthe original

mana are nenified with the sue date of the

Each revision als contains a “List of Effective

Pages foreach ehaptersection being revised

Thi conta the caper, page nu, and

Soance ofthe ial manual Ths ist updated

for cach revision, Pages revise

Gelted by the curren revision are ented with

amasterbk (#) entered adjacent to the section

umber

Temporary Revisions

‘Temporary revisions are used to provide addi

tional information and changes as they become

available. Temporary revisions provide, with the

least possible delay, new information which a

sists in maintaining safe and efficient flight

‘ground operation,

Temporary revisions are normally incorporated

at the next regularly scheduled revision and be-

come permanent part of the maintenance

Upon receipt of a temporary revision it should

be logged on the “Record of Temporary Revi-

sions * sheet in the front of the applicable chapter

and then filed in the chapter in accordance with

filing instructions that appear on the title page

‘Temporary revisions should be removed from

the maintenance manual only when removal in-

structions are noted on the regular revision sum-

mary sheet or by instructions noted ona

superseding temporary revision

SERIALIZATION

Airplane serial numbers are placed in the ait-

lane effectivity block in the lower left corner

NOvEWsER 1009

co

of each page and denote that the mainte

ata on that individual page relates to the listed

Serial numbers on that page. Also, specific ai

number effectivity may be included

TEST DEFINITIONS

General

Although not listed in the Learjet 35/36 Main

tenance Manual rodcton the flowing te

lefinitions are generally accepted as the stan

dard for ATA 100-tormat, Maintenance

Manuals. Some variations exist Fromm one an

facturer to another

Operational Test

An operational test ascertains that a system or

component is in operable condition. Tt can be

performed with the facilities installed in. the

airplane

Functional Test

A functional test ascertains that a system or unit

is functioning properly in all aspects in confor

mance with minimum acceptable design specif

Cations. This test may require supplemental

‘ground support oF test equipment.

FlightSafety

LEARJET 35/86 MAINTENANCE TRAINING MANUAL

‘and “Power Plant."” Depending on the manu.

facturer and the particular airplane type, some

maintenance manuals may be broken down into

fewer or more major sections, if required. Each

major section is, in turn, separated into chap-

ters, with each chapter having its own effectivity

page and table of contents. Only the applicable

Chapters are included in any particular airplane

‘Maintenance Manual.

‘The Learjet35/36 Maintenance Manual division

is as follows

MAJOR SECTION 1—AIRCRAFT GENERAL

CHAPTER TITLE

5 Time Limits/Maintenance

Checks

6 Dimensions and Areas

Lifting and Shoring

Leveling and Weighing

9 ‘Towing and Taxiing

10 Parking and Mooring

ut Required Placards

2 Servicing

MAJOR SECTION 2~AIRFRAME SYSTEMS

CHAPTER

Bench Test aa

A bench est rogues , Airrame

ire dian iapeouins faire, need foe fbr 4 Bit Comision

‘tion, need for repair or replacement of parts. and: 22, Auto Flight

teres adjustifent or calibraion «0 design a ete

specifications. a ee:

24 Electrical Power

25 Equipment Furnishings

HOW TO USE THE Ps Fire Protection

MAINTENANCE MANUAL 5, Eee

DIVISION OF SUBJECT MATTER z a oe

‘The Learjet 35/36 Maintenance Manual is di- 4 ere cer

The [info four major, sections: Aireraft 20 Jee and Rain Protection

CesalAtrrame Systems,” “Structures,” a testruments

FOR TRARING PURPOSES ONLY 23

NOVEMBER 1965

|

~

Oak

we

32 Landing Gear

33 Lights

M Navigation

35 Oxygen

36 Pneumatic

39 Electrical/Electronic

Panels and Multipurpose

Pants

MAJOR SECTION 3—STRUCTURES

CHAPTER TITLE,

2 Doors

33 Fuselage

38 Stabilizers

56 Windows

7 Wings

MAJOR SECTION 4—POWER PLANT

CHAPTER TITLE

a Power Plant

B Engine Fuel and Control

1” Ignition

16 Engine Controls

n Engine Indicating

78 Exhaust

9 oil

80. Starting

STANDARD NUMBERING

SYSTEM

‘The numbering system identifies and segrevates

subject matter by chapter (system), section (sub-

system), and subject (unit). ‘The system isa con:

Yentional -dash-number breakdown. When

referred to as a unit, the three-element number

(chapter/section/subject) is called the “chap:

ter/section™ number. The chapter/section num

ber is located in the lower right comer of each

page with the page number and date

ter number is single- or double-

24 FOR TRAINING PURPOSES ONLY

FlightSafety

LEARJET 35/36 MAINTENANCE TRAINNG MANUAL

ton an sujet munbers may be singles or

Uoubledigit, depending upon the manutacturer

sau the parculr section andr subject. Page

umfers used inthe Learjt 35/36 Maintenance

Manual consist of thrce-clement numbers sepa

rated by dashes, under which the page number

and date are printed

_——— 2620.01

| |

Chapter/System Subject Unit

{Fire Protection) | (Extinguisher

| Container)

Section/Subsystem

(Extinguishing)

Whenever the chapter/system element number

i followed by zeros in the section/subsystem and.

subject/unit positions (26-00-00). the informa-

tion is applicable to the entire system.

Whenever the section/subsystem element num.

ber is followed by zeros in the subject/unit po-

sition (26-20-00), the information is applicable

to the subsystems within the system.

‘The subject/unit element number is used to iden:

lify information applicable to units within. The

subject/unit clement number progresses from the

number ~O1 in accordance with the number of

subsystem units covered.

All system/subsystern/unit data is separated into,

specific (ypes of information. Blocks of page

numbers are used to identify the type of

information

+ Pages 1 through 100... Deseription and

Operation

25101

through 200

+ Pages 201 through 300

Practices: .

‘Troubleshooting

Maintenane:

Some units may not requir all he information

iste in these thre backs ot numbers. n which

case these blocks of mumiers ate one

‘Some units may require many types of mainte

hance practices. in which case page block 201

NOVEMBER 1999

FlightSafety

through 300i omit and the maintenance prac

tices are broken out ay Tallow

© Pages 301 through 400. Servicing

+ Pages 401 through 500 Removal/

Installation

Pages 501 through 600 Adjustment/Test

+ Pages 601 through 700, Inspection/Check

‘© Pages 701 through 800 Cleaning/ Painting

‘+ Pages 801 through 900 Approved Repairs

Extinguishing Subsystem

Fire Protection Extinguisher

System | Conse Uni

ee

Second Page of Fire— Page 202

Extinguisher Container Mar 1/74

Maintenance Practices

Date of Issue

Hlustrations use the same figure number as the

page block in which they appear. For example,

Frgure 202 will be the second lustration appear-

ing in the Maintenance Practices section

NOVEMBER 1909,

SUMMARY

“The Inroduetion to an ATA 100-format Main

a ee anual provides an explanation ofthe

piccataion procedures used for thal pari:

tier uirplane nuanual, Although the ATA 100

saat chapter wecton/subjct specification does

lay f great dcal among alveraft man

fiery tee are ws minor ferences

sinomg marntenance manuals, particularly 1

ren ot technics for marking changes and ther

disemination, which do vary from one man

ffeturer to another. That is why: maintenance

personne! should. read. and understand the

Frwroduction to Uie manual for any parteula air

plane wich requires maintenance. The introduc.

fon iss the Key, to. understanding

Mhanufacturer-peculiat techniques. used. in the

tnanwalt help maintenance personnel find the

required information in a.munimum of time

RRebiew it occasionally {hasbeen put thereto

help you

FOR TRAINING PURPOSES ONLY 25

CHAPTER 4

AIRCRAFT GENERAL

CONTENTS

Page

INTRODUCTION. ..sesssosssessenees : eee 44

GENERAL “

TIME LIMITS AND MAINTENANCE CHECKS (CHAPTER 5)......- 43

| Periodic Inspections ..... See tant 43

| Special Inspections. Poe aca : 43

Replacement/Overhaul Schedule -.....se0 Ses 43

Unscheduled Maintenance Checks ...1.ssscssesstsseenee 8

DIMENSIONS AND AREAS (CHAPTER 6)...... a5

Dunne ano soninc «cuarrer 7 a7

LEVELING AND WEIGHING (CHAPTER 8) 447

TOWING AND TAXIING (CHAPTER 9) 419

Towing... fe eGA18

Taxing oes. 3 a eS eee M21

PARKING AND MOORING (CHAPTER 10) 4-23

PLACARDS AND MARKINGS (CHAPTER 11) 4.23

SERVICING (CHAPTER 12) ee

General 4-24

Hydraulic System 427

Landing Gear Struts Stee osc abe iret @O7:

Ryo ee te mrcerecetontr tee cite om em ae a osc 482

Refrigeration System .. . 433

NOVEMBER 1989 FOR TRAINING PURPOSES ONLY a

A

FlightSafety

_—_——— TRAINING MANUAL %

4-43

Emergency Air Botle

oe 4-45

Alcohol Anti-ice System

4-47

Oxygen System

4-49

Engine Oil System...

Spi 460.

Fuel System : cae

ste rrr sgl 5S)

Batteries... cs Z secs

ai FOR TRANG PURPOSES ONLY

NOVEMBER 1999

|

FlightSafety

LEARJET 35/36 MAINTENANCE TRAINING MANUAL

CHAPTER 4

AIRCRAFT GENERAL

CONTENTS

Page

INTRODUCTION ...eocnnsnsnnen os a

GENERAL = one at

‘TIME LIMITS AND MAINTENANCE CHECKS (CHAPTER 5) 43

Periodic Inspections pee eee cite Remo Sas 48.

Special Inspections 43

ReplacemenvOverhaul Schedule 43

Unscheduled Maintenance Checks 1... i ee aS

DIMENSIONS AND AREAS (CHAPTER 6) me 45

LIFTING AND SHORING (CHAPTER 7) si pore IANT,

LEVELING AND WEIGHING (CHAPTER 8) ssveneonnintssnnn Soe 47.

TOWING AND TAXIING (CHAPTER 9) .... 419

Towing 419

Tanting sacra negt 2 oes

PARKING AND MOORING (CHAPTER 10) 4-23

PLACARDS AND MARKINGS (CHAPTER 11) svn 423

SERVICING (CHAPTER 12) : as 4-24

Revision 2—Saptmber 1956 FOR TRAINING PURPOSES ONLY at

So

: FlightSafety

<5 MeARUETIBG/@6 VAINTENANCE TRAINING MANUAL

oS meine

ILLUSTRATIONS

Figure Title

at Learjet 35

4-2 Airplane Dimensions

4-3 Airplane Areas

4-4 Fuselage Assembly

45 Fuselage Access Covers...

Floorboards

Left Wing Structural Diagram ..

Wing Access Covers

4-9 Vortex Generator Installation

4-10 Sofiflite Wing

4-12 Horizontal Stabilizer and Elevator Structural Stations Diagram

4-13 Airplane Jacking Provisions .

414 Airplane Leveling...

4-18 Tow Bar Turning Radius

4-16 Tow Bar Installations

4-17 Nose Steering Turning Radius

4-18 Protective Covers and Parking Equipment.

419 Airplane Servicing Points

4-20 Hydraulic Components.

4-21 Nose Gear Strut Servicing

4-22 Main Gear Strut Servicing ......

4-23 Servicing Refrigeration System—York Compressor

NoveMsen 1989 FOR TRAINING PURPOSES ONLY

Page

ait

—e[jej—————

FlightSafety

UmARUET SB/98 MANTENANCE TRANG MANUAL f

4-24 Servicing Refrigeration System—Sankyo Compressor. 4-36

4-25 Freon Compressor Dipsticks aoe

4-26 Sankyo Compressor Components Ae

4-27 Emergency Air Botlle oe

4-28 Alcohol System Servicing : aaa

4-29 Oxygen System Servicing ae

4-30 Oil Servicing Access eset 4-48

431 Blending Antiice Additives : : 4-52

4-32 Aisplane Defueling ..eneren a a os 454

TABLES

Table Title Page

4-1 Servicing .. 4.25 be ad

4-2 Oxygen System Pressure .sssssesessesesentntn 4-46

4-3. Fuel Capacities 2 85

a

oe FOR TRAINING PURPOSES ONLY NOVEMBER 1909

FlightSafety

a ~~

KL teaser as7a0 waerenvcs TARAS HARA

CHAPTER 4

AIRCRAFT GENERAL

INTRODUCTION

This chapter covers Chapters 5 through 12 of the Learjet 35/36/35A/36A Maintenance Man

al, It should be used in conjunction with the current Maintenance Manual. I is not intended

to provide specific procedures to accomplish a given task. For the accomplishment of any specific

maintenance task on the Learjet, use the applicable current Maintenance Manual,

GENERAL

Chapters 5 through 12 of the Learjet Mainte

ance Manual deal with ground handling. ser-

Vieing, and general care of the airplane. They

Cover the following items:

Chapter 5—Time Limits and Maintenance

Checks

Chapter 6—Dimensions and Areas

Chapter 7—Lifting and Shoring

Chapter 8—Leveling and Weighing

Chapter 9—Towing and Taxiing

Chapter 10—Parking and Mooring

Chapter 11—Placards and Markings

Chapter 12—Servicing

NOVEMBER 1899 FOR TAAINNG PURPOSES ONLY 44

FlightSafety

LEARJET 85786 MAINTENANCE TRANING MANUAL S

Figure 4-1. Learjet 35

Mas

42 FOR TRAINNG PURPOSES ONLY NOVEMBER 1989

$$

J

> ee en re

Figure 4-1 shows a 35/36 Series Learjet.

TIME LIMITS AND

MAINTENANCE CHECKS

(CHAPTER 5)

This chapter is a guide to familiarize operation

and maintenance personnel with the Learjet in

spection program and the associated replacement

and overhaul schedule. Periodic, special, and

‘unscheduled maintenance inspections/checks are

identified. The chapter is divided into the fol

lowing sections

NOTE

The Daily, Pretest Flight, and Post-

test Flight Inspections are found in

the Airplane Flight Manual.

PERIODIC INSPECTIONS

This section consists of individual inspections

‘which must be performed at 200-hour and 400-

hour periods

NOTE

Aircraft owners should adhere as

closely as possible (not to exceed 20

hours for hourly mspections or 2

weeks for calender inspections) 10

the recommended inspection inter-

vals. Tolerance time 1s not ac-

cumulative, For example, a

200-hour inspection accomplished

at 220 hours does not add 20 hours

{othe next 400/600-hour inspection

In other words, you may not per

form an inspection at 220 hours,

440 hours, and 660 hours,

SPECIAL INSPECTIONS

‘This section contains special inspections consid-

‘ered necessary to maintain an atrworthy condi-

tion of the fleet. The inspections range from a

period of 6 months to 12,000 flight hours.

NOVEMBER 1989

_ ml

FlightSafety

LEARJET 35/36 MAINTENANCE THAINING MANUAL

REPLACEMENT/OVERHAUL

SCHEDULE

‘This section lists items which shall be either

‘overhauled or replaced at specific time intervals.

UNSCHEDULED

MAINTENANCE CHECKS

This section consists of maintenance checks

required afier abnormal aircraft operation. These

include hard or overweight landings, severe tur-

bulence and/or maneuvers, engine changes,

rejected takeoffs, sod runway landings, and

overspeed recovery with the landing gear

extended,

NOTES

FOR TRAINING PURPOSES ONLY 43

14 FTBIN

4azocm

BFTSIN.

25100m

38 FTN

11610 em

39 FTGIN

1.2080 om Te

12FTSIN 5

373.0 cm

20FT2IN

‘6150cm

1.4800 em

Figure 4-2. Airplane Dimensions

a FOR TRAINING PURPOSES ONLY NOVEMBER 1989

Cee Sunnis tT ee

DIMENSIONS AND id

AREAS (CHAPTER 6)

‘Chapter 6 presents the airplane dimensions, con-

trol surface areas, waterlines, buttock lines, and

station designations,

‘The airplane is divided into reference points to

provide a means of quickly identifying the lo~

‘cation of the bulkheads, components, ete. These

reference points consist of

‘© Fuselage station numbers—Measured in

inches from the nose of the airplane

‘© Water lines—Measured in inches, verti

cally, from the horizontal reference line,

Le, the belly of the airplane

© Buttock lines—Measured in inches left or

| Se

| # Wing station numbers—Measured in

inches Teft or right from the wing

centerline

© Tip tank station numbers—Measured in

inches from the nose of the tip tank

Figures 4-2 through 4-12 show various areas and

structural segments of the airplane.

NOVEMBER 1885, FOR TRAINING PURPOSES ONLY 45

rad

reennnnnnnneeeeeeeeeeeeeeeeeeeeeeeeeeeeee 1

FlightSafety

LEARJET 35/36 MAINTENANCE TRAINNG MANUAL

AILERON

AILERON TRIM TAB

AILERON BALANCE TAB "yL0N

HORIZONTAL STABILIZER

euevaron

Figure 4-3. Airplane Areas c. &

46 FOR TRANING PURPOSES ONLY pone ta

a8

ELECTRONIC EQUIPMENT, AIR BOTTLE, OXYGEN

BOTTLE, AND ANTIICE TANK

FUSELAGE FUEL TANK PROBE

HYDRAULIC LINES

[RUDDER ANO ELEVATOR CABLE TURNBUCKLES

[AND SUUP DRAIN VALVE

FUEL CROSSFLOW SHUTOFF VALVE, HYORAULC

NES, PNEUMATIC LINE. JET PUMP, FUEL CHECK

VALVE, AND FUEL ORAIN VALVE.

FUEL PLUMBING. HYDRAULIC LINES, WING TANK.

RAIN, ORAIN VALVE, AND DEFUEL VALVE

FUEL LINES AND, ON 36 AIRCRAFT, TRANSFER

VALE

WING FUEL PRESSURE SWITCH. FUEL AND

HvORAULIG LINES, AILERON CABLE TURW BUCKLES,

[AND, OW 35 AINCRAFT, FUEL SHUTOFF VALVE

FUEL LINES, FUEL TANK DRAIN VALVE. ELEVATOR

SILERON aNio RUDDER CABLES. AND AILERON

sector

Figure 4-5.

FOR TRAINING PURPOSES ONLY

0

3

6

FUEL PUMP AND FUEL ORAIN VALVE

FUEL DRAIN VALVE

FUSELAGE FUEL TANK PROSE (LOWER FITTING)

FUEL VENT Les

BATTERIES. ELECTRICAL COMPONENTS, FUEL

FILTERS, REFRIGERATION EQUIPMENT, HYDRAULIC

COMPONENTS FIRE EXTINGUISHERS. SECONDARY

YAW SERVO, THROTTLE CABLES

FUDDER AND ELEVATOR CABLES

ELEVATOR SECTOR. PUSH PULL TUBES. ELEVAr

‘AND FIUDDER CONTROL CABLES one

RUDDER CONTROL castes

RUDDER BELLCRANK. PRIMARY Yaw SERVO SEC

oR sorrow ruosen ae Pon SeN

‘TOR CABLES, AND RUDDER CABLES ieee

Fuselage Access Covers

NOVEMBER 1909

FlightSafety

LEARJET 867/36" VANE TAVIS WAN

i "LEARUET 86/98 MARITENANCE TRARING MANUAL L

i

Figure 4-27. Emergency Air Bottle

442 FOR TRAINING PURPOSES ONLY NOVEMBER 1989

FlightSafety

LEARJET 35/26 MAINTENANGE TRAINING MANUAL

EMERGENCY AIR BOTTLE NOTES

General

Pressure in the emer

to extend the landi

ency air both

may be used

and for emergency

braking. The botle (Figure 4-27), located in the

nose compartment, i. accessible through the

right nose compartment access door. The bot-

Ue is serviced with dry air oF nitrogen to between

1,800 and 3,000 psi, Botte pressure is indicated

‘on a direct-feading pressure gage located on the

center instrument patel,

Servicing

Discharging the Air Bottle

Remove the right nose compartment access door.

Remove the cap from the emergency air botle

charging valve.

WARNING

Do not remove the charging valve

before completely discharging pres:

sure or bodily injury may result

Loosen the lock nut, and open the

charging valve % turn 1 slowly

release pressure.

Charging the Air Bottle

‘Attach a high-pressure adapter to the charging

Valve, and loosen the valve end nut

Monitor the emergency air gage on the instru

‘ment panel, and pressurize the air bottle 10 1,800

to 3,000 pi.

Tighten the charging valve end nut, and remove

the high-pressure adapter.

Install the charging valve cap, and replace the

access door:

.

NOVEMBER 1989 FOR TRAINING PURPOSES ONLY 4-43

FlightSafety

LEARJET 35/96 MAINTENANCE TRAINING MANUAL

syste RETURN

TUBE

VENT TUBE

INSTRUCTION PLACARD

FILLER CAP,

Tue (oro

NOZZLE AND.

RADOME SUPPLY)

SUPPLY TANK

PUTER sbee.y Tuae

ROTATED 90" COUNTERCLOCKWISE C=

'SNs 35.002 THROUGH 35-106, 35-108 THROUGH 95-112, AND 36-002 THROUGH 36-031

To SHUTOFF AN

VALVE (REN)

PRESSURIZATION

Tu8e"

SUPPLY TANK (REF)

sueet Tune

‘SNs 95-107, 25-113 AND SUBSEQUENT, AND 36-032 AND SUBSEQUENT

Figure 4-28. Alcohol System Servicing «

444 FOR TRAINING PURPOSES ONLY ears

©.

os

ALCOHOL ANTI-ICE SYSTEM

General

‘The alcohol anti-ice tank, located on the left side

of the nose compartment, is serviced with methyl

alcohol (methanol) O-M-232, Grade A (Figure

4-28).

Draining the Tank

Remove the left nose compartment access door.

SNs 35-002 through 35-112

and 36-002 through 36-031

Disconnect the defog nozrle and radome sup-

ply tube from the tee fitting. Take care to Soak

up any spillage.

Connect a hose tot

twe fiting, and route the

overboard into a suitable container

Set the control switch to RADOME, and pump

the tank empty. Turn the switch OFF.

NOTE

Due to the location of the supply

tube port, some residual alcohol

will remain in the tank

Remove the hose, and reconnect the

defog nozzle and radome supply

tube.

SNs 35-113 and Subsequent and

36-032 and Subsequent

Open and remove the supply tank filler cap per

the instruction placard.

Siphon the alcohol from the tank into a suitable

container.

NOTE

‘Some residual alcohol will remain

in the tank,

NOVEMBER 1989

FOR TRAINING PURPOSES ONLY

FlightSafety

LEARJET 35/36 MAINTENANCE TRAINING MANUAL

lling the Tank

Fr he tank with methyl alcohol (methanol) O-

M-232, Grade A.

NOTE

On airplanes SNs 35-002 through

SB 1Sand 36-003 through 36.082,

the tank will hold 2.2 gallons

On airplanes SNs 35-113 and sub-

Sequent and 36-033 and subsequent,

the Gank will bold 1-75 gallons

Replace the filler cap andthe nose compartment

access door

NOTES

4-45

FlightSafety

2 SO tear ae/ae wanersnce TRanine Manat

~~

HARING

SHUTOFE VALVE AND

REGULATOR ASSEMBLY

DORSAL OXYGEN BOTTLE

CHARGING VALVE

c=

NOSE OXYGEN BOTTLE

/

Figure 4-29. Oxygen System Servicing

Table 4-2. OXYGEN SYSTEM PRESSURE

‘AMBIENT | charcine AMBIENT ‘CHARGING

TEMP | Pressure ‘TEMP, PRESSURE

| fo | (sia) NEA On| reg

° 1,600 70 |

10 i680 0 1950 |

2 1875 %0 2.000

| Ey 175 100 2.050

| a 178 110 2.100

| 50 1825 129, 2.150

| © 1975 eeiwige Se 2200

NOTE

This table prowies approximate pressure fo which aircraft bote may be charged to have 1,800

psig after coating

EXAMPLE.

Ambient temperature is 70° F. Charge battle is 1,925 psig. 6

4-46 FOR TRAINING PURPOSES ONLY Revision January 1990

NN

a

OXYGEN SYSTEM

General

An oxygen bottle is located either in the right

tide of the nose compartment ria the Joe

fin (Figure 439) dae ae

Servicing Standard System

Open the oxygen service door

Remove the filler valve cap, and attach an oxy

gen supply line, z ;

NOTE

‘Some slight Ieakage may be de-

tected when the fill valve cap is

removed.

WARNING

Rapid charging of the oxygen bot-

tle will create a dangerous overheat

condition in the bottle.

Open the supply tank valve, and slowly charge

the system to the pressure specified in the chart

(Table 4-2),

Close the supply valve, and disconnect the sup-

ply line,

Install the filler valve cap, using care to prevent

stripping the threads,

Check the filler valve cap for leaks.

Assure that the shutoff/regulator valve is opened.

Close the oxygen service door.

Depleting Oxygen Bottle

Gain access to the oxygen bottle,

Either remove the bottle from the aircraft (refer

to Chapter 35 in the Maintenance Manual) or

connect a clean hose tothe bottle regulator out

let port

Ss teaver a8/a6 wasvre

Slowly release the oxygen pressure, directing it

into an open area away from the aircraft,

NOTE

Some airplanes may be equipped

‘with an optional long-range oxygen

system. Refer to Chapter 12 in the

Maintenance Manual tor servicing

these systems.

NOTES

NOVEMBER 1989 FOR TRAINING PURPOSES ONLY

4-48

FlightSafety

LEARJET 35/36 MAINTENANCE TRAINNG MANUAL

LEFT EWaINe access RIGHT ENGINE AccESS

Figure 4-30. Oil Servicing Access

NOVEMBER 1269

eee 2:

7

General

Engine il system servicing consists of check-

ing the ot evel, ang and changing the

The oil tank is located on the right side of the

‘engine. The tank drain plug is located on the bot-

tom on the tank:

Oil quantity is checked on the right engine

through the sight glass on the oil tank. The oil

level is checked on the left engine using a dip-

FightSafety

Leanser 26/28 uns renan FER HERE]

Open the right engine oil access door.

Check the oil level against the markings on the

sight glass

‘Open the left engine oil access door.

Remove the dipstick, and check the oil level

against the markings on the dipstick

‘Add oil if necessary until the sight gage or dip-

stick indicates full

Install the filler cap.

stick (Figure 4-30) NOTES

Removal of the ol filer cap is accomplished by

pushing down and rotating the cap coun-

terelockwise

When checking the engine oil level, the engine

must be static Cheek the oil level within one

hour after engine shutdown, When the engine

is inoperative, oil may seep from the tank into

the gearbox. A false indication may result i the

level is checked after the engine has remained

inoperative for a period of time.

The oil should be filtered through a 10-mieron

filter prior to use.

NOTE

For approved oils refer wo the ap-

plicable Learjet “Airplane Flight

Manual.

Servicing

il Quantity Check

NOTE

If the oil level isnot checked within

‘one hour after engine shutdown, or

the oil level checks low, start the

engine and allow it to sabilize at

‘dle rpm. Shut the engine down, and

then check the oil quantity,

NOVEMBER 1989 FOR TRANNG PURPOSES ONLY 449

Draining Engine Oil

NOTE

Whenever possible, drain the oi

while the engine is still warm from

operation,

Remove te engine lower nacelle (fet Cay

ter 71 in the Maintenance Manual). me

Remove the oil plug from the oil tank. Allow

the oil to drain into a suitable container

Examine the drained oil for any contamination

which could indicate internal engine damage

Install the drain plug inthe tank using a new

gasket. Safety-wire the plug. :

Oil Filter Change

Remove the oil filter cap and packing from the

Remove the filter element.

Inspect the filter for any contamination which

could indicate internal engine damage

‘Clean or replace the filter element in accordance

with the engine maintenance manual.

Install the filter and cap, using a new packing.

Filling the Oil Tank after Draining

Remove the oil filler cap.

Fill the tank with oil until the sight gage or di

stick on left engine indicates full: Reinstall the

ap.

Start the engine and operate it for at least five

minutes,

‘Shut the engine down immediately

if oil pressure isnot indicated within

ten seconds after an indication of

ITT,

Recheck the oil level, and add oil if necessary

4-50 FOR TRAINING PURPOSES ONLY

FUEL SYSTEM

General

Fuel servicing includes those procedures nec-

Sosy for refueling, adding ace additives,

and deucling,

Wing and tip tank refueling is accomplished

thragh filler ports on each up tank. The fuse~

Tage fants led from the wing Yanks, Using

electrically operated pups.

Defueling is accomplished through defueling

valves located at the right and left wing tank

sump drains. The airplane may be defueled by

gravity or by suction, using a fuel truck.

NOTES

NOVEMBER 1909

Fuel Additives

Anti-ice Additive

The wide range of temperatures to which jet

fuels are exposed in flight results in substantial

changes in the water solubility of the fuel and,

consequently, in the amount of free water which

‘must be coped with. The anti-ice additive fune-

tions as a freeze point depressant and as a

cide. Its partitioning characteristics make it

especially effective in nullifying the icing effects

of small quantities of water in jet fuels.

Another important characteristic of this additive

| is its action as a biocidal agent to prevent fun-

gal and bacterial growth in the fuel. Thus, when

Used in proper amounts, the additive provides

both anti-icing and a microbial growth protec-

tion in a single product.

Biocidal Additive

Biobor JF is an effective biocide when ithas been

remixed in the proper proportions in the fuel

FlightSafety

LEARJET 35/36 MAINTENANCE TRAINING MANUAL

the fuel truck to the airplane nose gear uplatch

spacer, and ground the fuel nozzle to the tip tank:

grounding jack

Do not attempt to completely fill one tank be-

fore adding {uel to the opposite tank, as exces

sive lateral unbalance may occur. When fueling,

fil both tanks simultaneously, or alternately add

125 gallons to each tip tank until the desired

amount is obtained, Tanks should also be

defueled as evenly as possible to prevent an un-

balance condition.

When defueling, the container or fuel truck used

to catch the fuel must be grounded to the nose

gear uplatch spacer, and the aircraft must be

grounded to an approved grounding source.

Military JP-4 fuel refined in the United States

has anti-icing additive conforming to MIL-I-

27686 blended at the refinery, and no additional

treatment is necessary. However, some nonmili

tary JP-4 fuel does not. Any fuel not containing,

the additive must have it blended during

refueling,

storage tanks. Over-the-wing mixing of Bio-

boris not approved. This additive is strictly for NOTES

microbial protection and is not an ant-icing

agent.

Safety Precautions

WARNING

‘Switeh-fueling, mixing kerosene-

based (IP-5, Jet A, or Jet A-1) fuels

with wide-cut petroleum distillates

(P-4 and Jet B), changes. the

fuel/air mixture ‘flammability

When switch-fueling must be ac-

‘complished, the fueling rate must be

reduced to one-half the normal rate

Airplanes should be fucled and defueled in areas

‘which permit free movement of fie equipment.

Assure that the fuel truck is grounded to an ap-

- proved grounding source. Attach a ground from

NOVEMBER 1969 FOR TRAINNG PURPOSES ONLY 451

Ee

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Beechjet 400A: Cockpit Reference HandbookDocument486 pagesBeechjet 400A: Cockpit Reference Handbookeduardo ruizNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

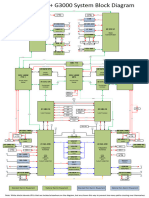

- CJ3+ G3000 System Block DiagramDocument1 pageCJ3+ G3000 System Block Diagrameduardo ruizNo ratings yet

- Changing Registration in G3000 InstructionsDocument2 pagesChanging Registration in G3000 Instructionseduardo ruizNo ratings yet

- CL 600 RJDocument99 pagesCL 600 RJeduardo ruizNo ratings yet

- EASA MMEL Bombardier - CRJ - CL 600 20 18112010Document276 pagesEASA MMEL Bombardier - CRJ - CL 600 20 18112010eduardo ruizNo ratings yet

- Alert 03Document4 pagesAlert 03eduardo ruizNo ratings yet

- SB 60-21-3Document53 pagesSB 60-21-3eduardo ruizNo ratings yet

- SplashDocument1 pageSplasheduardo ruizNo ratings yet

- GII SplashDocument1 pageGII Splasheduardo ruizNo ratings yet

- Touch: Simulator Pilots Operating HandbookDocument17 pagesTouch: Simulator Pilots Operating Handbookeduardo ruizNo ratings yet

- Simavio: Installation and Procedures ManualDocument45 pagesSimavio: Installation and Procedures Manualeduardo ruizNo ratings yet

- Safety Alert - LandingsDocument3 pagesSafety Alert - Landingseduardo ruizNo ratings yet

- 10-LOEP: List of Effective Pages Chapter 10 - Parking and MooringDocument13 pages10-LOEP: List of Effective Pages Chapter 10 - Parking and Mooringeduardo ruizNo ratings yet

- 71-LOEP: List of Effective PagesDocument72 pages71-LOEP: List of Effective Pageseduardo ruizNo ratings yet

- 08-LOEP: List of Effective Pages Chapter 08 - Levelling and WeighingDocument4 pages08-LOEP: List of Effective Pages Chapter 08 - Levelling and Weighingeduardo ruizNo ratings yet

- 700-800-900 A3euDocument51 pages700-800-900 A3eueduardo ruizNo ratings yet