Professional Documents

Culture Documents

I.H.M, Kolkata: B. SC (H & H.A) BHM 202 F&B (S) Operations 2021-2022 Fermented Beverage - Beer Page 1 of 14

Uploaded by

Souvik SenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

I.H.M, Kolkata: B. SC (H & H.A) BHM 202 F&B (S) Operations 2021-2022 Fermented Beverage - Beer Page 1 of 14

Uploaded by

Souvik SenCopyright:

Available Formats

I.H.

M, KOLKATA

BEER

Introduction

Beer is one of the most widely consumed beverages in the world after water and tea. It is

probably the oldest of alcoholic beverages. Beer is a potable fermented alcoholic beverage made

from barley, with an alcoholic content ranging from 3.5– 8 per cent. In rare case, it may range

from less than 1 per cent alcohol by volume. Most beers are flavored with hops, which add

bitterness and act as natural preservatives. The word ‘beer’ is originated from baire meaning

‘barley’. Beer was discovered accidentally by the nomadic tribes of Middle East when they

decided to settle and establish an agricultural life. In times of an excellent crop, part of the grain

was stored as a reserve for times when the harvest might fail. Inevitably, the crude stores would

allow moisture to seep in and the grain would germinate. In order to save something from the

spoilt grain, they were made into porridge. The natural yeast in the atmosphere would act on

porridge and convert it into a crude beer with a light alcoholic strength. This accidentally made

liquor was then developed into a more sophisticated beverage by the modern techniques.

Beer is in existence for around 7,000 years old and was well known in ancient Egypt. In the

early times, it was brewed for private consumption in households and monasteries. During and

after the Dark Ages, Christian abbeys were the centers of brewing. Initially, abbeys made beers

for the Brothers and visiting pilgrims, later as a means of financing their communities. The

Greeks and Romans produced beers of acceptable quality and diffused it along the trade routes.

By the late Middle Ages, beer making was developed into a commercial business. Today, beer is

usually produced by fermentation of starches, mainly derived from cereal grains– most

commonly barley, although maize, wheat and rice are widely used. Beer is treated as a thirst

quencher and refreshing drink particularly in the summer. An interesting fact about beer is that

countries that are well known for their beer are generally not noted for their wines.

Definition

Beer is an alcoholic beverage made by brewing and fermenting malted barley (and sometimes

other cereals) with hops added to flavor and stabilize it.

ΩΩΩΩΩΩ

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 1 of 14

I.H.M, KOLKATA

Ingredients used for Beer manufacturing process:

o Barley

o Water

o Hops

o Yeast

o Finings

Barley

The grain traditionally used for making beer is barley. Barley is preferred as it can be easily

malted for brewing. As different grape varieties are used for making different wines, different

varieties of barley are used to make different beers. The barley chosen for beer production must

have high starch, low protein and a little flavour. The two–row barley that has two rows of seeds

on its head is considered as the best for making beer. Barley in its malted form gives unrivalled

taste to the beer. Malt refers to germinated grains that have been roasted in a process known as

malting. Grains are soaked in water to allow them to germinate.

Germination is necessary to produce malt enzymes called diastase, which modifies the grain

starches into maltose sugar that can be fermented easily. Germination is stopped when maximum

maltose sugar is achieved, by roasting the grain. Malted grain is roasted according to the

brewer’s choice. Often grains such as maize, wheat, rice, millet, sorghum termed as adjuncts are

used in conjunction with barley to induce a different character and balance to the beer. However,

the weight of the adjuncts should not be more than 10 per cent of the barley content. The amount

of each starch source in a beer recipe is collectively called the grain bill.

Water

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 2 of 14

I.H.M, KOLKATA

Water is the most important ingredient in bear-making, simply because beer is approximately

90 per cent water. In the brewing parlance, it is called liquor. Water can be soft or hard. Each

type of water is good for making certain style of beer. Hard water is ideal for lager and soft water

is more suitable for bitter ales. The mineral content of the water also makes it more favourable

for certain types of beers. If the gypsum content is more, the water would be good for producing

pale ale, and if chlorine content is more, water would be more suitable for porter beers.

HOPS (Humulus lupulus)

Hops come from mulberry family, especially Humulus Lupulus. The flower of the female

hop plant is harvested, dried and used. They come in the form of cone, pellets and as

concentrated hop extract in liquid form.

• Hops give beer its dry and tannic taste.

• This contributes bitterness that balances the sweetness of the malt

• They aid in ‘head retention’, (i.e., the foamy head created by carbonation lasts long)

• They have an antibiotic effect that favours the activity of brewer’s yeast over the undesirable

microbes.

• The acidity of hops acts as a natural preservative.

• Hops contribute floral, citrus, and herbal aromas and flavours to beer.

Credit goes to Brabant Monastery for introducing HOPS to beer. The following are examples of

hops:

1. Hallertau Mittelfrüh- Germany

2. Goldings- UK

3. Saaz- Czech Republic

4. Cascade – USA

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 3 of 14

I.H.M, KOLKATA

YEAST - Yeast is a micro-organism which helps in the process of fermentation.

Fermentation - is the process by which bacteria, yeast or any other micro- organism converts

sugar into alcohol and carbon di-oxide in the presence of moisture and oxygen.

Yeasts used in Beer Production are:

Saccharomyces Cerevisiae and Saccharomyces Carlsbergensis

Finings

Finings are used to clarify the beer. Isinglass, the bladder of sturgeon fish, is the traditional

fining agent. Carefully measured quantity of finings is added into each cask. It attracts all the

sediments to the bottom of the cask, making the beer clear and bright. In true sense, finings are

not the constituents of beer, but are purely an agent of clarification. Other fining agents like

Bentonite Clay and Gelatin are most widely used in modern days.

ΩΩΩΩΩΩ

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 4 of 14

I.H.M, KOLKATA

THE BREWING PROCESS

The process of making beer is known as brewing. Beer production involves a series of

complicated process that calls for close monitoring, as the final quality and character depend on

the output at each stage. Following are the steps involved in beer brewing process.

Malting

Malting is carried out in malt houses. This process has three distinct steps:

• Steeping: Barley is soaked in a tank full of water for about three days. Grain absorbs water to

its full strength and expands in its body.

• Germination: Moist barley is spread on the malting floor and is allowed to germinate. The

grain is frequently turned to regulate the growth and temperature and provide oxygen to assist

germination. During the germination process, the insoluble starch in the cereal is converted into

soluble maltose sugar by the action of diastase enzyme. Germination is stopped when maximum

maltose sugar is achieved in the grain. The sprouted cereal is called as green malt.

• Kilning: The green malt is gently roasted in a kiln and the moisture content is reduced.

Depending on the intensity and duration of roasting, different types of malts are produced - pale

malt, crystal malt, chocolate malt and black malt. In pale malt, the grains are roasted just to stop

germination. If the roasting continues after the stage of pale malt, it produces brown malt or

crystal malt, chocolate malt and finally dark burnt black malt. The choice of particular malt gives

the beer its dryness, colour and flavour.

Mashing

The malted barley is crushed in a mill to produce a coarse powder called ‘grist’. At this

stage, the other grains such as maize, wheat, or rice can be introduced to give more subtle

characteristics to the beer. The grist is then sent to the mash tun and mixed with hot water to

produce a sort of porridge called mash. The mash is heated for a few hours at around 65⁰ C.

During this process, the enzyme amylase converts the adjunct starch into maltose.

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 5 of 14

I.H.M, KOLKATA

Lautering

The mash is transferred to a vessel called a lauter tun and is filtered to remove any grain

residue. The filtered sweet, brown liquid produced after the lautering is known as ‘wort’. The

leftover solids from the lauter tun are used as cattle feed.

Kettle

The Wort is put into a huge copper brewing kettle, where hops and sugar are added. The

quantity of sugar and hops added depend on the style of beer brewer wants to produce. The wort

is then boiled for two hours to extract the flavour from the hops. The ‘spent hops’ are separated

from the liquid in a whirlpool and removed. The hopped wort is then pumped through a paraflow

(heat exchanger), where it is cooled to a temperature of 15⁰ C.

Fermentation

The wort is transferred to fermentation tanks and yeast is added. During fermentation, the

sugar is converted into alcohol and carbon dioxide. Once the desired alcohol is achieved, or the

yeast runs out of sugar, the fermentation stops. Basically, beer is fermented by two different

processes:

• Top fermentation

• Bottom fermentation

Saccharomyces Cerevisiae is the yeast responsible for top fermentation. This fermentation

happens at a warmer temperature of 15-25⁰ C. Top fermentation is vigorous, fast, and takes only

a week of time. The most-common top fermented beers are ales, porters and stouts.

Saccharomyces Carlsbergensis is the yeast responsible for bottom fermentation. This

fermentation takes place at the bottom of the tank and is visible only by few tiny bubbles of

carbon dioxide that float to the surface. This kind of fermentation is a slow process and requires

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 6 of 14

I.H.M, KOLKATA

a cooler temperature of 5-9⁰ C. Usually, lager beers are produced by this method of

fermentation.

Filtration

Beer is racked for some time, to remove any of the solid particles. Carefully measured

quantity of isinglass, bentonite clay or gelatin is added into each tank. It attracts all the sediments

to the bottom of the tank, making the beer clear and bright.

Aging

The beer is placed in a tank and is aged for up to 2 months. Ageing permits the beer to

mature and develop smooth, desirable flavours. Ales are generally needed to age for at least 10-

14 days, whereas lagers need a minimum of 21 days. Some breweries let their beer age on its

lees.

Pasteurization

It is a process of sterilization by rapid heating and cooling. This process kills bacteria and

left-over yeast cells and prevents the beer from being spoiled. Canned or bottled beer must

undergo pasteurization at 60 – 65⁰ C. Usually, draft beer is not pasteurized and, therefore needs

to be refrigerated at 2-6⁰ C.

Carbonation

This is a process in which carbon dioxide is added to a beverage to make it fizzy and

sparkling. In the brewing process, carbonation is done by any one of the following two methods:

(1) The first method consists of impregnating the beer with carbon dioxide before packaging.

(2) The second method consists of inducing second fermentation in the cask or bottle by adding a

small dosage of yeast and unfermented wort to the fermented brew. The carbon dioxide produced

during second fermentation is unable to escape because it is locked in the bottle by the bottle cap.

Packaging

Beer are packed in various containers from bottles and cans to stainless steel kegs.

Generally, beer is bottled in dark-glass bottles to protect it from the sun light. However, most

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 7 of 14

I.H.M, KOLKATA

breweries bottle their product in clear-glass bottles, which should be stored away from the

sunlight. Beers are packed in cans to reduce the risk of breakage, spoilage and for better storing.

The cans are usually coated inside with lacquer to avoid any reaction of beer with the metal cans.

Beer is also packed in kegs. Kegs are metal containers with a capacity of 10 gallons. These are

vertically stored in the cellar.

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 8 of 14

I.H.M, KOLKATA

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 9 of 14

I.H.M, KOLKATA

TYPES OF BEER

Beer is mainly divided into two families – ales and lagers. The colours, flavours and

aromas of beers can be the same, regardless of the type of beer they are. Ales are top fermented

beers and lagers are bottom fermented beers. Each type is available in various styles.

Ale Beer

Ale is a type of beer produced by top fermentation. Saccharomyces Cerevisiae is the

yeast, used for fermentation of this kind of beer. Fermentation occurs in an open vessel at

warmer temperatures 15 to 25⁰ C. Ale beer comes in various styles.

Lager Beer

The name comes from a German word lagern, which means ‘to store’. Lager beer is

bottom-fermented. After fermentation, the beer is stored in refrigerated casks for 6 months.

Saccharomyces Carlsbergensis is the yeast used in the fermentation of this beer. Fermentation is

done at low temperatures in an enclosed vessel. Most of the American and Indian beers are

lagers.

Draught / Draft beer

Draught / Draft beer is either lager or ale that is drawn directly from the keg. The beer

trade calls it as ‘bulk beer’. The level of fermentation and carbonation is usually lower in draught

beer. Draught beer is usually unpasteurized and, therefore, suffers no loss of taste due to the

heating process. As draught beer is unpasteurized, it is more fragile and so utmost care is

required while storing. It should be kept refrigerated between 2⁰C and 4⁰C. Generally, in well-

stored conditions draft beer last for 20–30 days before it loses its fresh taste and aroma. Draught

beer should be consumed after being tapped. It should be drunk straight from the pitchers, as it

tends lose its crispness inside the glass. Draught beer dispensing system uses gas, usually carbon

dioxide, to maintain the carbonation in the beer. Modern breweries are using a mix of CO2 and

nitrogen gas, to reduce the effect of over–carbonation. The function process of a beer dispensing

system is explained below with the help of a diagram. It gives a basic idea to the reader how a

dispending system works in a bar.

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 10 of 14

I.H.M, KOLKATA

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 11 of 14

I.H.M, KOLKATA

BRAND NAMES

Ale

• Boddington’s

• Ballantine

• King of Ales

• Provisie

Stout

• Guinness

• Russian Imperial Stout

• Murphy

• Young’s Stout

• Beamish

Lager

• Heineken

• Budweiser

• Carlsberg

• San Miguel

• Lowenbrau

• St. Pauli Girl

• Olympia

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 12 of 14

I.H.M, KOLKATA

Pilsner

• Pilsener Urquell

• Tuborg

• Konig

• Heineken Pils

POPULAR BRAND NAMES

o Budweiser – U.S.A

o Hoegarden – Belgium

o Corona – Mexico

o Amstel, Heineken – Netherlands

o Fosters, Millers – Australia

o Carlsberg, Tuborg – Denmark

o Asahi – Japan

o Guinness – Ireland

STORAGE OF BEER

Beer must be stored at 13–15°C (55–58°F) in a well-ventilated cellar.

Spile (Small Wooden Peg/Stopper) control should be done to ensure the quality of the beer

and control the pressure inside the cask.

Tapping should be carried out 24 hours before it is required.

High temperature fluctuations will spoil the beer.

Bottled beers should not be exposed to sun light.

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 13 of 14

I.H.M, KOLKATA

FAULTS IN BEER

Sour Beer

o Deposits of yeast in the pipes and dispensing equipment

o Adding stale beer to a fresh cask of Beer

o Not exhausting the beer on time

o Exposing the beer to heavy fluctuations of temperature

o Exposed to heavy lighting

Cloudy Beer

o Stored in low temperature

o Uncleaned or poorly cleaned pipes

o Trying to pull the beer from the cask without removing the spile

Flat Beer

o Poor or faulty spile control – having a soft spile when a hard/firm spile is required

o Beer stored at a very low temperature

o Served in a greasy glass

o Poured and left in the glass for a long time

ΩΩΩΩΩΩ

Source: adapted from Grossman’s Guide to Wines, Beer and Spirits, ISBN 0- 684-

17772–2 and F&B Service Simplified by R. Gopikrishna and PVS Vara Prasad,

Pearson’s, ISBN : 978-93-5407-126-3

Authorship: Shane Joseph.

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 14 of 14

I.H.M, KOLKATA

B. Sc (H & H.A) BHM 202 F&B (S) OPERATIONS 2021-2022

Fermented Beverage - Beer Page 15 of 14

You might also like

- BeerDocument6 pagesBeerMatthew PriestNo ratings yet

- Beer: 3 /4 Sem Prepared by Pramod S V Page 1 of 7Document7 pagesBeer: 3 /4 Sem Prepared by Pramod S V Page 1 of 7Abhishek KumarNo ratings yet

- Ancient Beer History: Origins Dating Back 7,000 YearsDocument8 pagesAncient Beer History: Origins Dating Back 7,000 YearsFarhaan MohammedNo ratings yet

- Alcoholic Beverage: C H O Yeast 2C H OH 2CODocument13 pagesAlcoholic Beverage: C H O Yeast 2C H OH 2COYash ChhabraNo ratings yet

- By, Kunjal Patel, M.sc. Microbiology .Document30 pagesBy, Kunjal Patel, M.sc. Microbiology .gaurangHpatelNo ratings yet

- Alcoholic BeveragesDocument13 pagesAlcoholic BeveragesVikas BansalNo ratings yet

- 1461_Beer (1)Document8 pages1461_Beer (1)Krishna KumarNo ratings yet

- Edward, Michael - Production of Wine Beer Spirits and LiquersDocument179 pagesEdward, Michael - Production of Wine Beer Spirits and LiquersGabriel Reyes SahagúnNo ratings yet

- Beer Notes 1Document9 pagesBeer Notes 1shreeya guptaNo ratings yet

- How To Brew Your Own BeerDocument6 pagesHow To Brew Your Own BeerJohan RiosNo ratings yet

- Beer Production Process FlowchartDocument20 pagesBeer Production Process FlowchartEduardo AmezcuaNo ratings yet

- 1 - Beer Making ProcessDocument5 pages1 - Beer Making ProcessClarince Joyce Lao DoroyNo ratings yet

- Food and Beverage Beer-HandoutDocument23 pagesFood and Beverage Beer-HandoutSuruchi BhatnagarNo ratings yet

- Beer ProductionDocument8 pagesBeer ProductionArush SidanaNo ratings yet

- Beer ProductionDocument12 pagesBeer ProductionYonas Addam100% (1)

- Beer: A Refreshing Drink Made From Barley, Hops & YeastDocument6 pagesBeer: A Refreshing Drink Made From Barley, Hops & YeastAmanSethiyaNo ratings yet

- Beer PresentationDocument27 pagesBeer PresentationRuben MarquezNo ratings yet

- Manufacturing Process of BeerDocument43 pagesManufacturing Process of Beerabhys_raghuNo ratings yet

- 3rd QUARTER WEEK 1 MODULE BEERDocument26 pages3rd QUARTER WEEK 1 MODULE BEERJayr GiananNo ratings yet

- Beer 101: A Concise Introduction to Beer History, Styles, and TastingDocument31 pagesBeer 101: A Concise Introduction to Beer History, Styles, and TastingVISHAL PATELNo ratings yet

- Microbiological Production of BeerDocument24 pagesMicrobiological Production of BeerMd. Babul AktarNo ratings yet

- Beer ManufacturingDocument23 pagesBeer ManufacturingDivya AggarwalNo ratings yet

- UntitledDocument30 pagesUntitledPrakhar RingeNo ratings yet

- Notes For BeersDocument10 pagesNotes For Beersxindinzafal100% (1)

- Notes For Beer Mash & Chill Proofing, Molecular Markers Notes SummaryDocument24 pagesNotes For Beer Mash & Chill Proofing, Molecular Markers Notes SummaryANUPAM SINGLA0% (1)

- Beer Industry Process GuideDocument3 pagesBeer Industry Process Guidejonathantjioe123No ratings yet

- The Main Fermentation in the Beer Brewing Process - Selected QuestionsFrom EverandThe Main Fermentation in the Beer Brewing Process - Selected QuestionsRating: 5 out of 5 stars5/5 (1)

- Project Report On BeerDocument29 pagesProject Report On BeerKailash JoshiNo ratings yet

- Sunil Kumar: Desinged byDocument75 pagesSunil Kumar: Desinged byVipul KispattaNo ratings yet

- 3 BeerDocument16 pages3 BeerJatin Kumar SinghNo ratings yet

- Chapter 2 - BeerDocument7 pagesChapter 2 - BeerVeena TiwariNo ratings yet

- Beer Production SummaryDocument4 pagesBeer Production SummarySakshi SangleNo ratings yet

- BeerproductionDocument57 pagesBeerproductionÖmer Ferkan KemikNo ratings yet

- Handout BeverageDocument34 pagesHandout BeverageNitin DurgapalNo ratings yet

- 101 Old Time Receipts for Beer, Wine, Whiskey, other Spirits and AccoutrementsFrom Everand101 Old Time Receipts for Beer, Wine, Whiskey, other Spirits and AccoutrementsNo ratings yet

- Beer Production 1Document30 pagesBeer Production 1Lingaraj Kumar100% (1)

- Beer Factory Project ReportDocument13 pagesBeer Factory Project ReportImran ShaikNo ratings yet

- IjgyhgDocument53 pagesIjgyhgMarc DiongcoNo ratings yet

- Beer (Introduction, Types, Productions & Storage)Document12 pagesBeer (Introduction, Types, Productions & Storage)RHTi BDNo ratings yet

- Beer - Types, Production & SpoilageDocument17 pagesBeer - Types, Production & SpoilagePallaviNo ratings yet

- Types of BeerDocument12 pagesTypes of BeerFrank FernandesNo ratings yet

- Review: Beer Production Process and Health BenefitsDocument15 pagesReview: Beer Production Process and Health Benefitsdat tran nguyenNo ratings yet

- CHAPTER 1.2 Alcoholic BeveragesDocument58 pagesCHAPTER 1.2 Alcoholic BeveragesFaraiyzNo ratings yet

- Emerging: Brewing Is The Production ofDocument16 pagesEmerging: Brewing Is The Production ofSheerin SulthanaNo ratings yet

- FermationDocument12 pagesFermationshujat_786No ratings yet

- 1. How color of beer can be developed?: Giang Thị Thanh Hương - BTFTIU18240Document2 pages1. How color of beer can be developed?: Giang Thị Thanh Hương - BTFTIU18240Giang Thị Thanh HươngNo ratings yet

- Bacteria Part in BeerDocument1 pageBacteria Part in BeerMalik Muhammad Tabish BilalNo ratings yet

- 3 Beer1Document6 pages3 Beer1Ajay BishtNo ratings yet

- Objective: To Study The Ever Popular Beverage With Emphasis OnDocument28 pagesObjective: To Study The Ever Popular Beverage With Emphasis OnPrashant100% (1)

- How Beer Works: Main Home FoodDocument16 pagesHow Beer Works: Main Home FoodNeelajit ChandraNo ratings yet

- Chapter 7 - GlossaryDocument12 pagesChapter 7 - Glossaryandr100% (1)

- The Foodie's Beer Book: The Art of Pairing and Cooking with Beer for Any OccasionFrom EverandThe Foodie's Beer Book: The Art of Pairing and Cooking with Beer for Any OccasionNo ratings yet

- Everything You Need to Know About BeerDocument5 pagesEverything You Need to Know About BeerMicro ShamimNo ratings yet

- Beer and WhiskyDocument20 pagesBeer and WhiskyNidharshana.SNo ratings yet

- History of Beer - How It's Made, Types & BrandsDocument8 pagesHistory of Beer - How It's Made, Types & BrandsKetan ChandeNo ratings yet

- PPT-Alcoholic Beverages ClassificationDocument69 pagesPPT-Alcoholic Beverages ClassificationAshiqur Rahman100% (3)

- Alcoholic Beverages: A Concise History and GuideDocument55 pagesAlcoholic Beverages: A Concise History and GuideKricel Maquera0% (1)

- Beer: Guidance in Mixology, Pairing & Enjoying Life’s Finer ThingsFrom EverandBeer: Guidance in Mixology, Pairing & Enjoying Life’s Finer ThingsNo ratings yet

- Yeast ViabilityDocument6 pagesYeast ViabilityYng Dmb Broke GuyNo ratings yet

- Adjuncts and Coloured MaltsDocument33 pagesAdjuncts and Coloured MaltsEyoel AwokeNo ratings yet

- HeinekenDocument4 pagesHeinekenIonuţ Tudor UrdéşNo ratings yet

- Raw Materials Selection and Medium Development For Industrial Fermentation ProcessesDocument10 pagesRaw Materials Selection and Medium Development For Industrial Fermentation ProcessesIsaacNo ratings yet

- Tabela de LúpulosDocument52 pagesTabela de LúpulosLuiz VilaniNo ratings yet

- A Practical Guide To Yeast ManagementDocument8 pagesA Practical Guide To Yeast Managementalvaromviegas_191514No ratings yet

- Brewers On The RiseDocument46 pagesBrewers On The RiselstntNo ratings yet

- British Flora Medica Vol 2Document574 pagesBritish Flora Medica Vol 2Andrew Lange100% (4)

- Brewing Recipe TemplateDocument10 pagesBrewing Recipe Templatealexstevenson01No ratings yet

- Bira 91Document48 pagesBira 91Kirti Suryawanshi33% (3)

- BYO 2015 Vol 21-04 July-AugustDocument108 pagesBYO 2015 Vol 21-04 July-AugustAndoni M100% (1)

- Local BeerDocument5 pagesLocal BeerPatricia DinglasanNo ratings yet

- The Brewing Process: MaltingDocument2 pagesThe Brewing Process: MaltingAndrea CasillasNo ratings yet

- Substance AbuseDocument217 pagesSubstance Abusevibin0% (1)

- Jamil's Ordinary BitterDocument2 pagesJamil's Ordinary BitterCraig GardnerNo ratings yet

- The Craft Brewing Industry: The Boston Beer Company (A) BAB026Document6 pagesThe Craft Brewing Industry: The Boston Beer Company (A) BAB026unochaetaNo ratings yet

- U3/SRU: Installation & Operating GuideDocument9 pagesU3/SRU: Installation & Operating GuiderodrurenNo ratings yet

- Craft Beer & Brewing - February-March 2015Document124 pagesCraft Beer & Brewing - February-March 2015satanic_drugs_thing100% (2)

- Measuring alcohol strength with hydrometers and slide rulesDocument24 pagesMeasuring alcohol strength with hydrometers and slide rulesaguilaquecaeNo ratings yet

- MRP 2022 23Document55 pagesMRP 2022 23Bhabani Sankar DhalNo ratings yet

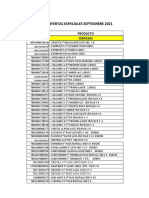

- Ofertas Bebidas, Licores y Snacks SeptiembreDocument18 pagesOfertas Bebidas, Licores y Snacks SeptiembreHans Henry SeguelNo ratings yet

- Popular Mechanics - February 2015Document102 pagesPopular Mechanics - February 2015up4all100% (3)

- Craft Beer & Brewing - February-March 2015 PDFDocument124 pagesCraft Beer & Brewing - February-March 2015 PDFManuel GonzálezNo ratings yet

- LAGUNITASDocument2 pagesLAGUNITASRicardo MachadoNo ratings yet

- Brewed in Japan: The Evolution of The Japanese Beer IndustryDocument10 pagesBrewed in Japan: The Evolution of The Japanese Beer IndustrylijiaweiNo ratings yet

- The Global Branding of Stella ArtoisDocument8 pagesThe Global Branding of Stella ArtoisBhawna MalhotraNo ratings yet

- Full Report PT 2Document50 pagesFull Report PT 2AIDANINo ratings yet

- Comparison of Fermentation RatesDocument16 pagesComparison of Fermentation RatesDaksh ChouhanNo ratings yet

- Marketing Project - Beer Market AnalysisDocument11 pagesMarketing Project - Beer Market AnalysisIrina StefanaNo ratings yet

- 85 Amazing AIP Breakfast Recipes by Eileen LairdDocument114 pages85 Amazing AIP Breakfast Recipes by Eileen LairdChinyere Egesi Ede80% (5)