Professional Documents

Culture Documents

JGS 420 GS-S.L: Low Methane - Coal Mine Methane

Uploaded by

Dexterous EngineeringOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JGS 420 GS-S.L: Low Methane - Coal Mine Methane

Uploaded by

Dexterous EngineeringCopyright:

Available Formats

Technical Description

Genset

JGS 420 GS-S.L

J 420 Low Methane - Coal Mine Methane

Electrical output best effort 1300 kW el.

Electrical output Guaranteed 1200 kW el.

Emission values

NOx < 500 mg/Nm³(5% O2)

low gas pressure: 30mbarg (target value)

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

1/35

0.01 Technical Data (at genset) 4

Main dimensions and weights (at genset) 5

Connections 5

Output / fuel consumption 5

0.02 Technical data of engine 6

Thermal energy balance 6

Exhaust gas data 6

Combustion air data 6

Sound pressure level 7

Sound power level 7

0.03 Technical data of generator designed for 1450KW mech. power 8

Reactance and time constants (saturated) based on 1450KW mech. 8

connection variant 1K 9

0.05 Cooling water circuit 10

Oil - heat (Engine jacket water cooling circuit) 10

Engine jacket water - heat (Engine jacket water cooling circuit) 10

Mixture Intercooler (1st stage) (Engine jacket water cooling circuit) 10

Mixture Intercooler (2nd stage) (Low temperature circuit) 10

0.10 Technical parameters 11

0.11 Reference conditions / Potential Engine Output 13

1.00 Scope of supply - Genset 15

1.01 Spark ignited gas engine 15

1.01.01 Engine design 15

1.01.02 Engine accessories 16

1.01.03 Standard tools (per installation) 17

1.02 Generator-low voltage 17

1.03 Module accessories 20

1.03.01 Engine jacket water system 21

1.03.02 Automatic lube oil replenishing system 21

1.05 Gas train 22

1.07 Painting 22

1.11 Engine generator control panel – DIA.NE XT 22

1.11.02 Remote information by MODBUS-RTU 27

1.11.03 Remote Data-Transfer with DIA.NE XT - HERMES 27

1.20.01 Starting system 30

1.20.03 Electric jacket water preheating 30

1.20.04 Flexible connections 31

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

2/35

1.20.27 Return temperature control 31

2.00 Electrical equipment 31

3.10 Cooling system – Two-circuits-radiator - electrical control only! 31

4.00 Delivery, installation and commissioning 32

4.01 Carriage 32

4.02 Unloading 32

4.03 Assembly and installation 32

4.04 Storage 32

4.05 Start-up and commissioning 32

5.01 Limits of delivery - Genset 33

5.02 Factory tests and inspections 33

5.02.01 Engine tests 34

5.02.02 Generator tests 34

5.02.03 Module tests 34

5.03 Documentation 34

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

3/35

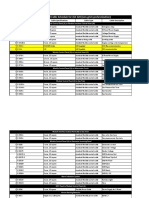

0.01 Technical Data (at genset)

Data at:

Fuel gas LHV minum value for gas train design kWh/Nm³ 1 2

best guaranteed

effort values

Energy input kW [2] 3.200 2.990

Gas volume Nm³/h *) 3.200 2.990

Mechanical output kW [1] 1.337 1.237

Electrical output kW el. [4] 1.300 1.200

Heat to be dissipated [5]

~ Intercooler 1st stage (Engine jacket water cooling circuit) kW 223

~ Intercooler 2nd stage (Low temperature circuit) kW 101

~ Lube oil (Engine jacket water cooling circuit) kW 186

~ Jacket water kW 385

~ Surface heat ca. kW [7] 113

Spec. fuel consumption of engine kWh/kWh [2] 2,40 2,42

Lube oil consumption ca. kg/h [3] 0,40 ~

Electrical efficiency % 40,6% 40,3%

*) approximate value for pipework dimensioning

Engine output derating: for plants installed at > 500m above sea level and/or intake temperature > 30°C, the reduction of engine

power is determined for each project.

[_] Explanations: see 0.10 - Technical parameters

All heat data is based on standard conditions according to attachment 0.10. Deviations from the standard conditions can result in a

change of values within the heat balance, and must be taken into consideration in the layout of the cooling circuit/equipment

(intercooler; emergency cooling; ...). In the specifications in addition to the general tolerance of +/- 8% on the thermal output a

further reserve of 10% is recommended for the dimensioning of the cooling requirements.

Island mode operation only special request.

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

4/35

Main dimensions and weights (at genset)

Length mm ~ 7.100

Width mm ~ 1.900

Height mm ~ 2.200

Weight empty kg ~ 16.400

Weight filled kg ~ 17.100

Connections

Jacket water inlet and outlet DN/PN 100/10

Exhaust gas outlet DN/PN 300/10

Water drain ISO 228 G ½''

Condensate drain mm 18

Safety valve - jacket water ISO 228 DN/PN 2x1½''/2,5

Lube oil replenishing (pipe) mm 28

Lube oil drain (pipe) mm 28

Jacket water - filling (flex pipe) mm 13

Intercooler water-Inlet/Outlet 1st stage DN/PN 80/10

Intercooler water-Inlet/Outlet 2nd stage DN/PN 65/10

Output / fuel consumption

ISO standard fuel stop power ICFN kW 1.337

Mean effe. press. at stand. power and nom. speed bar 17,51

Fuel gas type Coalmine gas

Based on methane number|Min. methane number MZ d) 94|70

Compression ratio Epsilon 11,80

Min./Max. fuel gas pressure at inlet to gas train mbar 30 - 200 c)

Allowed Fluctuation of fuel gas pressure % ± 10

Max. rate of gas pressure fluctuation mbar/sec 10

Maximum Intercooler 2nd stage inlet water temperature °C 40

Spec. fuel consumption of engine kWh/kWh 2,40

Specific lube oil consumption g/kWh 0,30

Max. Oil temperature °C 85

Jacket-water temperature max. °C 95

Filling capacity lube oil (refill) lit ~ 437

c) design target gas pressure subject to pilot test results

d) based on methane number calculation software AVL 3.1

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

5/35

0.02 Technical data of engine

Manufacturer GE Jenbacher

Engine type J 420 GS-B105 - low CH4

CMG

Working principle 4-Stroke

Configuration V 70°

No. of cylinders 20

Bore mm 145

Stroke mm 185

Piston displacement lit 61,10

Nominal speed rpm 1.500

Mean piston speed m/s 9,25

Length mm 3.750

Width mm 1.580

Height mm 2.033

Weight dry kg 7.200

Weight filled kg 7.900

Moment of inertia kgm² 11,64

Direction of rotation (from flywheel view) left

Radio interference level to VDE 0875 N

Starter motor output kW 13

Starter motor voltage V 24

Thermal energy balance

Energy input kW 3.200

Intercooler kW 324

Lube oil kW 186

Jacket water kW 385

Exhaust gas total kW 879

Exhaust gas cooled to 180 °C kW 548

Exhaust gas cooled to 100 °C kW 720

Surface heat kW 65

Exhaust gas data

Exhaust gas temperature at full load °C [8] 425

Exhaust gas temperature at bmep= 14,3 [bar] °C ~ 446

Exhaust gas temperature at bmep= 9,5 [bar] °C ~ 481

Exhaust gas mass flow rate, wet kg/h 7.155

Exhaust gas mass flow rate, dry kg/h 6.636

Exhaust gas volume, wet Nm³/h 5.654

Exhaust gas volume, dry Nm³/h 5.032

Max.admissible exhaust back pressure after engine mbar 60

Combustion air data

Combustion air mass flow rate kg/h 6.924

Combustion air volume Nm³/h 5.356

Max. admissible pressure drop at air-intake filter mbar 10

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

6/35

Sound pressure level

Aggregate b) dB(A) re 20µPa 97

31,5 Hz dB 79

63 Hz dB 87

125 Hz dB 98

250 Hz dB 95

500 Hz dB 91

1000 Hz dB 86

2000 Hz dB 88

4000 Hz dB 92

8000 Hz dB 89

Exhaust gas a) dB(A) re 20µPa 115

31,5 Hz dB 95

63 Hz dB 117

125 Hz dB 115

250 Hz dB 113

500 Hz dB 108

1000 Hz dB 105

2000 Hz dB 108

4000 Hz dB 109

8000 Hz dB 107

Sound power level

Aggregate dB(A) re 1pW 117

Measurement surface m² 107

Exhaust gas dB(A) re 1pW 123

Measurement surface m² 6,28

a) average sound pressure level on measurement surface in a distance of 1m according to DIN 45635, precision class 2.

b) average sound pressure level on measurement surface in a distance of 1m (converted to free field) according to DIN 45635,

precision class 3.

The spectra are valid for aggregates up to bmep=19 bar. (for higher bmep add safety margin of 1dB to all values per increase of 1

bar pressure).

For operation with 1200 rpm see above values, for operation with 1800 rpm add 3 dB to the above values.

Engine tolerance ± 3 dB

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

7/35

0.03 Technical data of generator designed for 1450KW mech. power

Manufacturer Leroy-Somer e)

Type LSA 52.2 L70 e)

Type rating kVA 1.970

Driving power kW 1.337

Ratings at p.f. = 1,0 kW 1.302

Ratings at p.f. = 0,8 kW 1.289

Rated output at p.f. = 0,8 kVA 1.611

Rated reactive power at p.f. = 0,8 kVar 967

Rated current at p.f. = 0,8 A 2.325

Frequency Hz 50

Voltage V 400

Speed rpm 1.500

Permissible overspeed rpm 2.250

Power factor (lagging - leading) 0,8 - 1,0

Efficiency at p.f. = 1,0 % 97,4%

Efficiency at p.f. = 0,8 % 96,4%

Moment of inertia kgm² 47,80

Mass kg 4.425

Radio interference level to VDE 0875 N

Construction B3/B14

Protection Class IP 23

Insulation class H

Temperature (rise at driving power) F

Maximum ambient temperature °C 40

Reactance and time constants (saturated) based

on 1450KW mech.

xd direct axis synchronous reactance p.u. 2,07

xd' direct axis transient reactance p.u. 0,19

xd'' direct axis sub transient reactance p.u. 0,10

x2 negative sequence reactance p.u. 0,11

Td'' sub transient reactance time constant ms 24

Ta Time constant direct-current ms 45

Tdo' open circuit field time constant s 3,23

e) GE Jenbacher reserves the right to change the generator supplier and the generator type. The contractual data of the

generator may thereby change slightly. The contractual produced electrical power will not change.

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

8/35

0.05 Cooling water circuit

Oil - heat (Engine jacket water cooling circuit)

Nominal output kW 186

Max. Oil temperature °C 85

Loss of nominal pressure of engine jacket water bar 0,50

Safety valve - max press. set point bar 2,50

Engine jacket water - heat (Engine jacket water cooling circuit)

Nominal output kW 385

Max. engine jacket water temperature (outlet engine) °C 90

Engine jacket water flow rate m³/h 38,2

Safety valve - max press. set point bar 2,50

Mixture Intercooler (1st stage) (Engine jacket water cooling circuit)

Nominal output kW 223

Max. inlet cooling water temp. (intercooler) °C 74,7

Nominal pressure of cooling water / (operating pressure) PN / (bar) 10 / (6)

Loss of nominal pressure of engine jacket water bar 0,30

Safety valve - max press. set point bar 2,50

Mixture Intercooler (2nd stage) (Low temperature circuit)

Nominal output kW 101

Max. inlet cooling water temp. (intercooler) °C 40

Aftercooler water flow rate m³/h 20,0

Nominal pressure of cooling water / (operating pressure) PN / (bar) 10 / (6)

Intercooler water pressure drop bar 0,80

Safety valve - max press. set point bar 2,50

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

10/35

0.10 Technical parameters

All data in the technical specification are based on engine full load (unless stated otherwise) at specified

temperatures and the methane number and subject to technical development and modifications.

All pressure indications are to be measured and read with pressure gauges (psi.g.).

(1) At nominal speed and standard reference conditions ICFN according to DIN-ISO 3046 and DIN 6271,

respectively

(2) According to DIN-ISO 3046 and DIN 6271, respectively, with a tolerance of + 5 %.

Efficiency performance is based on a new unit (immediately upon commissioning).Effects of

degradation during normal operation can be mitigated through regular service and maintenance work.

(3) Average value between oil change intervals according to maintenance schedule, without oil change

amount

(4) At p. f. = 1.0 according to VDE 0530 REM / IEC 34.1 with relative tolerances

(5) Total output with a tolerance of +/- 8 %

(6) According to above parameters (1) through (5)

(7) Only valid for engine and generator; module and peripheral equipment not considered (at p. f. = 0,8)

(8) Exhaust temperature with a tolerance of +/- 8 %

Radio interference level

The ignition system of the gas engines complies the radio interference levels of CISPR 12 and EN 55011

class B, (30-75 MHz, 75-400 MHz, 400-1000 MHz) and (30-230 MHz, 230-1000 MHz), respectively.

Definition of output

• ISO-ICFN continuous rated power:

Net break power that the engine manufacturer declares an engine is capable of delivering continuously,

at stated speed, between the normal maintenance intervals and overhauls as required by the

manufacturer. Power determined under the operating conditions of the manufacturer’s test bench and

adjusted to the standard reference conditions.

• Standard reference conditions:

Barometric pressure: 1000 mbar (14.5 psi) or 500 m (328 ft) above sea level

Air temperature: 25°C (77°F) or 298 K

Relative humidity: 30 %

• Volume values at standard conditions (fuel gas, combustion air, exhaust gas)

Pressure: 1013 mbar (14.7 psi)

Temperature: 0°C (32°F) or 273 K

Output adjustment for turbo charged engines

Standard rating of the engines is for an installation at an altitude ≤ 500 m and an air intake temperature ≤

30 °C (T1)

Maximum room temperature: 50°C (T2) -> engine stop

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

11/35

If the actual methane number is lower than the specified, the knock control responds. First the ignition

timing is changed at full rated power. Secondly the rated power is reduced. These functions are carried

out by the engine management system.

Exceedance of the voltage and frequency limits for generators according to IEC 60034-1 Zone A will lead

to a derate in output.

Parameters for the operation of GE Jenbacher gas engines

The genset fulfills the limits for mechanical vibrations according to ISO 8528-9.

The following "Technical Instruction of GE JENBACHER" forms an integral part of a contract and must be

strictly observed: TI 1100-0110, TI 1100-0111, and TI 1100-0112.

If possible, railway trucks must not be used for transport (TI 1000-0046).

Parameters for the operation of control unit and the electrical equipment

Relative humidity 50% by maximum temperature of 40°C.

Altitude up to 2000m above the sea level.

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

12/35

Technical parameters for operation with low methane coal mine gas:

The design parameter of the engine allows an operation down to a minimum CH4 content of 10%vol (wet),

and a maximum O2 content of 15%vol up to a maximum CH4< 30Vol%wet and a minimum gas pressure

of 30mbarg at the GE Jenbacher gas train interface (clean/dry gas filter).

Lower CH4 concentrations (target CH4>8Vol% wet) are targeted but are subject to the results of the pilot

phase.

Gas quality according TI 1000-0301 (general requirements)

Acceptable deviations to TI1000-0301 for pilot test/final confirmation subject to pilot test result

Ö Gas train design based on CH4>10Vol%

Ö CH4 content: target value (8)10 - 30Vol%(wet)

Ö CH4/CO2 ratio >10; rest air (N2/O2)

Ö LHV fluctuations <5%/30sec

Ö Gas pressure fluctuation < 15mbar/sec

Ö Relative humidity requirement TI 1000-0301 (<80% rel, humidity/<40°C)

o The required relative humidity of 80% should avoid condensate in the sensible devices like

the gas control valve (TEC JET) respectively gas train.

o This requirement can only be achieved by a condenser system (chiller+ re-heater), which

were not allowed in the past

o For the pilot a condenser system (chiller+ re-heater) should be installed, during pilot test

phase an operation without chiller should be tested to learn about the sensitivity at this

particular application.

o Depending on the results future system can be designed accordingly without chiller system

Remark

Both - LHV fluctuation and gas pressure fluctuation – may cause trips of the engine, the system

will protect itself and an exceeding of the limits will not cause damage to the engines in general. A

higher output will create a lower tolerance of the system regarding LHV or gas pressure

fluctuations. Target of the pilot test is to proof, if the J420 genset can be operated with these

conditions and define the acceptable max. output for stable operation.

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

13/35

1.00 Scope of supply - Genset

Design:

The genset is built as a compact package. Engine and generator are connected through a coupling and

are mounted to the base frame. To provide the best possible isolation from the transmission of vibrations

the engine is mounted to the frame by means of anti-vibrational mounts. The remaining vibrations are

eliminated by mounting the module on isolating pads (e.g. Sylomer). This, in principle, allows the genset

to be placed directly on any floor capable of carrying the static load. No special foundation is required.

Prevention of sound conducted through solids has to be provided locally.

1.01 Spark ignited gas engine

Four-stroke, air/gas mixture turbocharged, after cooled, with high performance ignition system and

electronically controlled air/gas mixture system.

The engine is equipped with the most advanced

LEANOX® LEAN-BURN COMBUSTION SYSTEM

developed by GE JENBACHER.

1.01.01 Engine design

Engine block

Single-piece crankcase and cylinder block made of special casting; crank case covers for engine

inspection, welded steel oil pan.

Crankshaft and main bearings

Drop-forged, precision ground, surface hardened, statically and dynamically balanced; main bearings

(upper bearing shell: 3-material bearing / lower bearing shell: sputter bearing) arranged between crank

pins, drilled oil passages for forced-feed lubrication of connecting rods.

Vibration damper

Maintenance free viscous damper

Flywheel

With ring gear for starter motor

Pistons

Single-piece, made of light metal alloy, with piston ring carrier and oil passages for cooling; piston rings

made of high quality material, main combustion chamber specially designed for lean burn operation.

Connecting rods

Drop-forged, heat-treated, big end diagonally split and toothed. Big end bearings (upper bearing shell:

sputter bearing / lower bearing shell: sputter bearing) and connecting rod bushing for piston pin.

Cylinder liner

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

14/35

Chromium alloy gray cast iron, wet, individually replaceable.

Cylinder head

Specially designed and developed for GE JENBACHER-lean burn engines with optimised fuel

consumption and emissions; water cooled, made of special casting, individually replaceable; Valve seats,

valve guides and spark plug sleeves individually replaceable; exhaust and inlet valves made of high

quality material.

Crankcase breather

Connected to combustion air intake system.

Valve train

Camshaft, with replaceable bushings, driven by crankshaft through intermediate gears, valve lubrication

by splash oil through rocker arms.

Combustion air/fuel gas system

Motorized carburetor for automatic adjustment according to fuel gas characteristic. Exhaust driven

turbocharger, mixture manifold with bellows, water-cooled intercooler, throttle valve and distribution

manifolds to cylinders.

Ignition system

Most advanced, fully electronic high performance ignition system, external ignition control.

MORIS: Automatically, cylinder selective registration and control of the current needed ignition voltage.

Lubricating system

Gear-type lube oil pump to supply all moving parts with filtered lube oil, pressure control valve, pressure

relief valve and full-flow filter cartridges. Cooling of the lube oil is arranged by a heat exchanger.

Engine cooling system

Jacket water pump complete with distribution pipework and manifolds.

Exhaust system

Turbocharger and exhaust manifold

Exhaust gas temperature measuring

Thermocouple for each cylinder

Electric actuator

For electronic speed and output control

Electronic speed monitoring for speed and output control

By magnetic inductive pick up over ring gear on flywheel

Starter motor

Engine mounted electric starter motor

1.01.02 Engine accessories

Insulation of exhaust manifold:

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

15/35

Insulation of exhaust manifold is easily installed and removed

Sensors at the engine:

• Jacket water temperature sensor

• Jacket water pressure sensor

• Lube oil temperature sensor

• Lube oil pressure sensor

• Mixture temperature sensor

• Charge pressure sensor

• Minimum and maximum lube oil level switch

• Exhaust gas thermocouple for each cylinder

• Knock sensors

• Gas mixer / gas dosing valve position reporting.

Actuator at the engine:

• Actuator - throttle valve

• Bypass-valve for turbocharger

• Control of the gas mixer / gas dosing valve

1.01.03 Standard tools (per installation)

The tools required for carrying out the most important maintenance work are included in the scope of

supply and delivered in a toolbox.

1.02 Generator-low voltage

The 2 bearing generator consists of the main generator (built as rotating field machine), the exciter

machine (built as rotating armature machine) and the digital excitation system.

The digital regulator is powered by an auxiliary winding at the main stator or a PMG system

Main components

• Enclosure of welded steel construction

• Stator core consist of thin insulated electrical sheet metal with integrated cooling channels.

• Stator winding with 2/3 Pitch

• Rotor consists of shaft with shrunken laminated poles, Exciter rotor, PMG (depending on Type) and fan.

• Damper cage

• Excitation unit with rotating rectifier diodes and overvoltage protection

• Dynamically balanced as per ISO 1940, Balance quality G2,5

• Drive end bracket with re grease able antifriction bearing

• Non-drive end bracket with re grease antifriction bearing

• Cooling IC01 - open ventilated, air entry at non-drive end , air outlet at the drive end side

• Main terminal box includes main terminals for power cables

• Regulator terminal box with auxiliary terminals for thermistor connection and regulator.

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

16/35

• Anti-condensation heater

• 3 PT100 for winding temperature monitoring+3 PT100 Spare

• 2 PT100 for bearing temperature monitoring

Option:

Current transformer for protection and measuring in the star point

xx/1A, 10P10 15VA , xx/1A, 1FS5, 15VA

Electrical data and features

• Standards: IEC 60034, EN 60034, VDE 0530, ISO 8528-3, ISO 8528-9

• Voltage adjustment range: +/- 10 % of rated voltage (continuous)

• Frequency: -6/+4% of rated frequency

• Overload capacity: 10% for one hour within 6 hours, 50% for 30 seconds

• Asymmetric load : max. 8% I2 continuous, in case of fault I2 x t=20

• Altitude: < 1000m

• Max permitted generator intake air temperature: 5°C - 40°C

• Max. relative air humidity: 90%

• Voltage curve THD Ph-Ph: <3,5% at idle operation and <5% at full load operation with linear

symmetrical load

• Generator suitable for parallel operating with the grid and other generators

• Sustained short circuit current at 3-pole terminal short circuit: minimum 3 times rated current for 5

seconds.

• Over speed test with 1.2 times of rated speed for 2 minutes according to IEC 60034

Digital Excitation system ABB Unitrol 1010 mounted within the AVR Terminal box with following

features:

• Compact and robust Digital Excitation system for Continuous output current up to 10 A (20A Overload

current 10s)

• Fast AVR response combined with high excitation voltage improves the transient stability during LVRT

events.

• The system has free configurable measurement and analog or digital I/Os. The configuration is done via

the local human machine interface or CMT1000

• Power Terminals

3 phase excitation power input from PMG or auxiliary windings

Auxiliary power input 24VDC

• Excitation output

• Measurement terminals: 3 phase machine voltage, 1 phase network voltage, 1 phase machine current

• Analog I/Os: 2 outputs / 3 inputs (configurable), +10 V / -10 V

• Digital I/O: 4 inputs only (configurable), 8 inputs / outputs (configurable)

• Serial fieldbus: RS485 for Modbus RTU or VDC (Reactive power load sharing for up to 31 GEJ engines

in island operation), CAN-Bus for dual channel communication

• Regulator Control modes: Bump less transfer between all modes

Automatic Voltage Regulator (AVR) accuracy 0,1% at 25°C ambient temperature

Field Current Regulator (FCR)

Power Factor Regulator (PF)

Reactive Power Regulator (VAR)

• Limiters: Keeping synchronous machines in a safe and stable operation area

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

17/35

Excitation current limiter (UEL min / OEL max)

PQ minimum limiter

Machine current limiter

V / Hz limiter

Machine voltage limiter

• Voltage matching during synchronization

• Rotating diode monitoring

• Dual channel / monitoring: Enables the dual channel operation based on self diagnostics and setpoint

follow up over CAN communication.. As Option available

• Power System Stabilizer (PSS) is available as option. Compliant with the standard IEEE 421.5-2005

2A / 2B, the PSS improves the stability of the generator over the highest possible operation range.

• Computer representation for power system stability studies: ABB 3BHS354059 E01

• Certifications: CE, cUL certification according UL 508c (compliant with CSA), DNV Class B,

• Commissioning and maintenance Tool CMT1000 (for trained commissioning/ maintenance

personal)

• With this tool the technician can setup all parameters and tune the PID to guarantee stable operation.

The CMT1000 software allows an extensive supervision of the system, which helps the user to identify

and locate problems during commissioning on site. The CMT1000 is connected to the target over USB

or Ethernet port, where Ethernet connection allows remote access over 100 m.

• Main window

• Indication of access mode and device information.

• Change of parameter is only possible in CONTROL access mode.

• LED symbol indicates that all parameter are stored on none volatile memory.

• Setpoint adjust window

• Overview of all control modes, generator status, active limiters status and alarms.

• Adjust set point and apply steps for tuning of the PID.

• Oscilloscope

• 4 signals can be selected out of 20 recorded channels. The time resolution is 50ms.Save files to your

PC for further investigation.

• Measurement

• All measurements on one screen.

Routine Test

Following routine tests will be carried out by the generator manufacturer

• Measuring of the DC-resistance of stator and rotor windings

• Check of the function of the fitted components (e.g. RTDs, space heater etc.)

• Insulation resistance of the following components

Stator winding, rotor winding

Stator winding RTDs

Bearing RTDs

Space heater

Bearings

• Polarisation index

• No Load saturation characteristic (remanent voltage)

• Stator voltage unbalance

• Direction of rotation, phase sequence

• No-Load Vibration Test per IEC 34-14 --- Rigid Mounting at min. medium and max. speed

• Excitation Test

• Setting of AVR System Parameters

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

18/35

• High voltage test of the stator windings (2 x Unom. + 1000 V) and the rotor windings (min. 1500 V)

1.03 Module accessories

Base frame

Welded structural steel to accommodate engine, generator and heat exchangers.

Flexible coupling

With torque limiter to couple engine with generator. The coupling isolates the major subharmonics of

engine firing impulses from the generator.

Bell housing

To connect engine with generator housing. With two ventilation and control windows.

Anti-vibration mounts

Arranged between engine/generator assembly and base frame. Isolating pads (SYLOMER) for placement

between base frame and foundation, delivered loose.

Exhaust gas connection

Connection of exhaust gas turbocharger; including flexible connection to compensate for expansions and

vibrations.

Combustion air filter

Dry type air filter with replaceable filter cartridges, including flexible connection to carburetor and service

indicator.

Interface panel

Totally enclosed sheet steel cubicle with front door, wired to terminals, ready to operate. Cable entry at

bottom.

Painting: RAL 7035

Protection: IP 54 external, IP 20 internal (protection against direct contact with live parts)

Design according to IEC 439-1 (EN 60 439-1/1990) and DIN VDE 0660 part 500, respectively.

Ambient temperature: 5 - 40 °C (41 - 104 °F),Relative humidity:70 %

Dimensions:

• Height: 1000 mm (39 in)

• Width: 1000 mm (39 in)

• Depth: 300 mm (12 in)

Power supply from the starter battery charger.

Power distribution to the engine mounted auxiliaries (power input from the supplier of the auxiliaries

power supply):

3 x 400/231 V, 50 Hz, 16 A

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

19/35

Essential components installed in interface panel:

• Terminal strip

• Decentralised input and output cards, connected by a data bus interface to the central engine control of

the module control panel.

• Speed monitoring

• Relays, contacts, fuses, engine contact switch to control valves and auxiliaries

• Measuring transducer for excitation voltage

• Air conditioning system

1.03.01 Engine jacket water system

Engine jacket water system

Closed cooling circuit, consisting of:

• Expansion tank

• Filling device (check and pressure reducing valves, pressure gauge)

• Safety valve(s)

• Thermostatic valve

• Required pipework on module

• Vents and drains

• Electrical jacket water pump, including check valve

• Jacket water preheat device

1.03.02 Automatic lube oil replenishing system

Automatic lube oil replenishing system:

Includes float valve in lube oil feed line, including inspection glass. Electric monitoring system will be

provided for engine shut-down at lube oil levels "MINIMUM" and "MAXIMUM". Solenoid valve in oil feed

line is only activated during engine operation. Manual override of the solenoid valve, for filling procedure

during oil changes is included.

Oil drain

By set mounted cock

Pre-lubrication- and aftercooling oil pump:

Mounted on the module base frame; it is used for pre-lubrication and aftercooling of the turbochargers.

Period of operation: Pre-lubrication: 1 minute

Aftercooling: 15 minutes from engine stop

Consisting of:

• 1 piece oil pump 1500 W, 24 V

• All necessary vents

• Necessary pipework

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

20/35

1.05 Gas train

Pre-assembled, delivered loose, for installation into gas pipework to the module.

Consisting of:

• Shut off valve

• Gas filter, filter fineness <3 µm

• Pressure gauge with push button valve

• Gas admission pressure regulator

• Solenoid valves

• Leakage detector

• Gas pressure switch (min.)

• TEC JET (has to be implemented horizontal)

• Gas flow meter (option)

• p/t compensation (option)

The gas train complies with DIN - DVGW regulations.

Maximum distance from TEC JET outlet to gas entry on engine, including flexible connections, is 1 m

(39,37 in).

1.07 Painting

• Quality: Oil resistant prime layer

Synthetic resin varnish finishing coat

• Colour: Engine: RAL 6018 (green)

Base frame: RAL 6018 (green)

Generator: RAL 6018 (green)

Module interface

panel: RAL 7035 (light grey)

Control panel: RAL 7035 (light grey)

1.11 Engine generator control panel – DIA.NE XT

Dimensions:

• Height: 2200 mm (87 in) [including 200 mm (8 in) pedestal]

• Width: 1000 mm (40 in)

• Depth: 600 mm (24 in)

Control supply voltage from starter and control panel batteries: 24V DC

Supply of power for auxiliaries from auxiliary power panel:

3 x 400/231 V, 50 Hz, xx A

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

21/35

Consisting of:

DIA.NE XT 3 (Dialog Network new generation) motor management system

System elements visualisation with central engine and module control

1) Visualisation:

Industrial control with 10,4“ QVGA TFT colour graphics display and 8 function keys.

10-key numeric keyboard for parameter input.

Keys for START, STOP, Generator circuit breaker OPEN, Generator circuit breaker

CLOSED/SELECTED, display selection keys and special functions.

Interfaces:

• Ethernet (twisted pair) for connection to DIA.NE WIN server

• CAN-Bus: bus connection to the intelligent sensors and actuators

• Data bus connection to the control in- and outputs

OPTION: Interfacing with the customer’s plant management according to GE JENBACHER list of

options (MODBUS-RTU slave, PROFIBUS-DP slave)

Protection class: IP 65 (front)

Dimensions: W x H x D = approx. 212 x 255 x 95 mm (8,4 x 10 x 3,75 in)

A clear and functional graphic compilation of measured values is displayed on the screen. User prompts

are by means of direct-acting display selection keys and function keys.

Main displays:

• Electrical schematic

• Oil and hydraulic schematic

• Gas data

• Engine controllers

• Cylinder data

• Exhaust gas data

• Auxilliaries controllers

• Spare screen for customer specific purposes

• System display screens

• Parameter manager

• User setting

• Alarm management

Recipe handling:

Setting, display and storage of all module parameters

Alarm management:

Efficient diagnostic instrumentation listing all active fault messages both tabular and chronologically, with

the recorded time.

2) Central engine and module control:

A real-time, modular industrial control system which handles all jobs for module and engine-side

sequencing control (start preparation, start, stop, synchronizing, after-cooling, control of auxiliaries), as

well as all control functions.

Control functions:

• Speed control in no-load and isolated operation

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

22/35

• Power output control in parallel operation system; job-specific with respect to internal and external set

point values.

• LEANOX control system for control of boost pressure; dependent upon the generator terminal power

and the mixture temperature via the engine-driven air-gas mixer

• Knocking control: adjustment of the ignition point, power output and (insofar as is locally possible) the

mixture temperature in the event of detection of knocking.

• Load sharing between several modules in isolated operation

• Linear reduction of power output in the event of excessive mixture temperature and ignition failures

• Interface relays as per the interface list

• Multi-transducer, to record the following electrically measured variables of the generator:

• Phase current (with slave pointer)

• Neutral conductor current

• Voltages Ph/Ph and Ph/N

• Active power (with slave pointer)

• Reactive power

• Apparent power

• Power factor

• Frequency

An additional 0 - 20 mA output is produced for active power, as well as a pulse output for active power

demand.

The following alternator supervisions are integrated with the multi-transducer (max. 8 functions

simultaneous):

• Overload/short-circuit [51], [50]

• Over voltage [59]

• Undervoltage [27]

• Asymmetric voltage [64], [59N]

• Unbalance current [46]

• Failure Exitation [40]

• Overfrequency [81>]

• Underfrequency [81<]

• Lockable operation mode selector switch positions:

• "OFF"

No operation is possible, running set will shut down;

• "MANUAL"

Manual operation using (start, stop) is possible, unit is not available for fully automatic operation.

• "AUTOMATIC"

Fully automatic operation, according to remote demand signal:

• Automatic start

Fully automatic operation at full load

• Stop with cooling down run for 1 minute

Continuous operation of auxiliaries for 5 minutes after engine shutdown

• Demand switch with the positions:

• Demand OFF

• Demand ON

• Remote demand

• Supply disconnecting device for auxiliaries with lockable circuit breaker

Shut-down functions with display:

• Low lube oil pressure

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

23/35

• Low lube oil level

• High lube oil level

• High lube oil temperature

• Low jacket water pressure

• High jacket water pressure

• High jacket water temperature

• Overspeed

• Emergency stop/safety loop

• Gas train failure

• Start failure

• Stop failure

• Engine start blocked

• Engine operation blocked

• Misfiring

• High mixture temperature

• Measuring signal failure

• Overload/output signal failure

• Generator overload/short circuit

• Generator over/undervoltage

• Generator over/underfrequency

• Generator asymmetric voltage

• Generator unbalanced load

• Generator reverse power

• High generator winding temperature

• Synchronising failure

• Cylinder selective Knocking failure

Warning functions with display:

• Low jacket water temperature

• CPU battery failure

Operational functions with display:

• Ready to start

• Operation (engine running)

• Generator circuit breaker "CLOSED"

Remote signals:

(volt free contacts)

1NO = 1 normally open

1NC = 1 normally closed

1 COC = 1 change over contact

• Ready for automatic start (to Master control) 1NO

• Operation (engine runs) 1NO

• Collective signal "shut down" 1NC

• Collective signal "warning" 1NC

External (by others) provided command/status signals:

• Engine demand (from Master control) 1NO

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

24/35

Single synchronizing Automatic

With voltage balance

For automatic synchronizing of the module with the generator circuit breaker to the grid by PLC-

technology, integrated within the module control panel.

Consisting of:

• Lockable synchronizing mode selector switch, with positions "MANUAL - 0FF - AUTOMATIC"

• AUTOMATIC:

Automatic module synchronization, after synchronizing release from the control panel

• MANUAL:

Manual initiation of synchronizing by push button. Speed adjustment and closing of the circuit breaker

is automatically controlled via microprocessor

• OFF:

Synchronization is disabled

• Additional PLC hardware for the fully automatic synchronizing of each module, and monitoring of the

"CIRCUIT BREAKER CLOSED" signal.

Logic for monitoring of:

• Non-logic breaker positions

• Switch ”ON” trouble

• Switch ”OFF” trouble

• Automatic synchronizing device to control the electronic speed governor adjustment, double voltmeter,

double frequency meter and synchronoscope

• Automatic voltage balancing

• Luminous push button “GENERATOR CIRCUIT BREAKER OPEN / SELECT”

• To indicate synchronizing mode

• To indicate “Generator circuit breaker closed”

• For manual synchronizing selection with the synchronizing mode selector switch in the MANUAL

position

• For manual closing of the generator circuit breaker to the voltage free bus bar (first connection) with

synchronizing mode selector switch in the MANUAL position

• Luminous push button “GENERATOR CIRCUIT BREAKER OPEN”

• To indicate “Generator circuit breaker open”

• To manually open the generator circuit breaker

• Control switch

• Required relays for control and monitoring

• Voltage relay for monitoring of bussbar voltage (only for island operation)

Operational indications for:

• Generator circuit breaker CLOSED

• Generator circuit breaker OPEN

Fault indications for:

• Generator circuit breaker return signal fault

• Generator circuit breaker closing fault

• Generator circuit breaker opening fault

Remote signals

(Volt free contacts)

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

25/35

• Generator circuit breaker CLOSED 1 NO

The following reference and status signals must be provided by the switchgear supplier:

Generator circuit breaker CLOSED 1 NO

Generator circuit breaker OPEN 1 NO

Generator circuit breaker READY TO CLOSE 1 NO

Mains circuit breaker CLOSED 1 NO

Mains circuit breaker OPEN 1 NO

• Mains voltage 3 x 400/231V or 3x 110V/v3 – other measurement voltages available on request

• Bus bar voltage 3 x 400/231 V or 3x 110V/v3 – other measurement voltages available on request

• Generator voltage 3 x 400 V or 3x 110V/v3 – other measurement voltages available on request

Voltage transformers in star point with minimum 50VA, Class 1

The following volt free interface-signals will be provided by GE Jenbacher to be incorporated in

switchgear:

• CLOSING/OPENING command for generator circuit breaker

(permanent contact) 1 NO + 1 NC

• Signal for circuit breaker undervoltage trip 1 NO

1.11.02 Remote information by MODBUS-RTU

Data transfer from GE JENBACHER-module control to customer's plant management system by

MODBUS-RTU-network (RS 485).

The Jenbacher module control panel works as a SLAVE.

The data transmission by the customer's MASTER shall be cyclical.

Transmitted data:

Individual failure information, plant operating information, measuring values for generator power, oil

pressure, oil temperature, jacket water pressure, jacket water temperature

GE Jenbacher limit of delivery:

Interface connector at the PLC in the module control panel.

1.11.03 Remote Data-Transfer with DIA.NE XT - HERMES

General

HERMES is the remote data transfer solution for DIA.NE XT. HERMES is available via three connection

methods and two applications.

Connections methods

1.) Modem

Site - Customer connection via a Modem (analogue, ISDN, GSM).

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

26/35

Scope of supply

• DIA.NE WIN – Server (Industrial PC without display, keyboard or mouse, built into the control panel,

including operating system)

• Modem (analogue, ISDN, GSM)

Customer Requirements

• Modem (analogue, ISDN, GSM) in the customers PC

• Public telephone connection with connection port for the DIA.NE WIN – Server (in the control panel)

including over-voltage protection corresponding to the local telecommunication regulations.

• Public telephone connection with connection port for the customer’s PC corresponding to the local

telecommunication regulations.

2.) LAN

Site - Customer connection via a local network.

Scope of supply

• DIA.NE WIN – Server (Industrial PC without display, keyboard or mouse, built into the control panel,

including operating system)

• Ethernet – Network card (10/100 BASE T)

Customer Requirements

• Ethernet – Network card (10/100 BASE T)

• Ethernet – Cabling between the DIA.NE WIN – Server the customers PC.

3.) Internet (OPTION)

Site – Customer connection via secure Internet access

See comments under Technical instruction TI 2300 - 0006

Scope of Supply

• DIA.NE WIN – Server (Industrial PC without display, keyboard or mouse, built into the control panel,

including operating system)

• Ethernet–Network card (10/100 BASE T)

• Firewall–Appliance with connection feasibility to a customer network with a maximum of 10 Hosts

(Installation and service by GE Jenbacher; during warranty period included, afterwards as a service

package with costs) (built into the control panel)

• Feature – service package (access monitoring, clock synchronization for server)

Customer Requirements

• Broad band Internet access with at least two official IP addresses.

Connection feasibility for the Firewall–Appliance to the Internet–Router via Ethernet

(RJ45 Connector, Network Address Translation (NAT) is not permitted)

Applications

1.) DIA.NE WIN (OPTION)

DIA.NE WIN is the Windows based „man-machine interface“ for GE Jenbacher gas engines. The system

offers extensive facilities for commissioning, monitoring, servicing and analysis of the site. The option

DIA.NE WIN extends the visualization of DIA.NE XT with respect to user friendliness, historical analysis

and remote use. Several service stations can be independently operated in parallel. The system consists

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

27/35

of a central PC (DIA.NE WIN – Server) which is built in to the control panel and one or more service

stations (DIA.NE WIN – Clients). The system runs on a Microsoft Internet Explorer platform.

Function

Service and monitoring, trend analysis, alarm management, parameter management, long-term data

analysis, multi-user system, remote control, OPC (OLE for process control), print and export functions,

operating data protocols, available in several languages.

Scope of supply

• Software package DIA.NE WIN on the DIA.NE WIN – Server

• DIA.NE WIN – Client License (Right to access of the user to the server on site)

Customer requirements

• Standard PC with keyboard, mouse and monitor (min. resolution 1024*768)

• 231 V supply for the customers’ PC

• Operating system Windows 98, Windows NT, Windows 2000 or Windows XP

• Microsoft Internet Explorer (min. Version 6.0) including Java support

2.) DIA.NE RMC (OPTION)

DIA.NE RMC (Remote Message Control) is the automatic alarm system for DIA.NE XT. DIA.NE RMC can

fully automatically transmit essential operational information from the DIA.NE XT Alarm Management to a

remote station. The messages can be forwarded to an e-mail address, fax machine or mobile phone

(SMS). Furthermore the stored messages can be visualized at the remote station. The system consists of

a central PC (DIA.NE WIN – Server) which is built into the control panel and one or more customer

remote stations.

Function

Automatically transfer of messages to the customer via email, fax or SMS. Display and printing of the

messages (also distributed via LAN). Automatically and manually transfer of messages, trend data and

operating data protocols.

Scope of supply

• Software package DIA.NE message on the DIA.NE WIN – Server

• Software package DIA.NE control and DIA.NE report on the remote station

Only for connection method “Internet”:

• Firewall–Appliance for customer computer with connection feasibility to a customer network with a

maximum of 10 Hosts (Installation and service by GE Jenbacher; during warranty period included,

afterwards as a service package with costs)

Customer requirements

• Standard PC with keyboard, mouse and monitor (min. resolution 1024*768)

• 231 V supply for the customers’ computer.

• Operating system Windows 2000 (Professional and Server), Windows XP Professional or

Windows Server 2003.

• Internet connection (provider account) for the case that messages from the RMC should be forwarded

to an email receiver (incl. SMS for mobiles and pagers). (Mobiles and pagers to be provided by the

customer).

• Customer fax software for message forwarding via fax

Only for connection method “Internet”:

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

28/35

• Broad band Internet access with at least two official IP addresses.

Connection feasibility for the Firewall–Appliance to the Internet–Router via Ethernet

(RJ45 Connector, Network Address Translation (NAT) is not permitted)

1.20.01 Starting system

Starter battery:

2 piece 12 V Pb battery, 200 Ah (according to DIN 72311), complete with cover plate, terminals and acid

tester.

Battery voltage monitoring:

Monitoring by an under voltage relay.

Battery charging equipment:

Capable for charging the starter battery with I/U characteristic and for the supply of all connected D.C.

consumers.

Charging device is mounted inside of the module interface panel or module control panel.

• General data:

• Power supply 3 x 320 - 550 V, 47 - 63 Hz

• max. power consumption 1060 W

• Nominal D.C. voltage 24 V(+/-1%)

• Voltage setting range 24V to 28,8V ( adjustable)

• Nominal current (max.) 40 A

• Dimensions 240 x 125 x 125 mm

• Degree of protection IP20 to IEC 529

• Operating temperature 0 °C - 60 °C

• Protection class 1

• Humidity class 3K3, no condensation.

• Natural air convection

• Standards EN60950,EN50178

UL/cUL (UL508/CSA 22.2)

Signaling:

Green Led: Output voltage > 20,5V

Yellow Led: Overload, Output Voltage < 20,5V

Red Led: shutdown

Control accumulator:

• Pb battery 24 VDC/18 Ah

1.20.03 Electric jacket water preheating

Installed in the jacket water cooling circuit, consisting of:

• Heating elements

• Water circulating pump

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

29/35

The jacket water temperature of a stopped engine is maintained between 56°C (133 °F) and 60°C

(140°F), to allow for immediate loading after engine start.

1.20.04 Flexible connections

Following flexible connections per module are included in the GE Jenbacher -scope of supply:

No. Connection Unit Dimension Material

2 Warm water in-/outlet DN/PN 100/10 Stainless steel

1 Exhaust gas outlet DN/PN 300/10 Stainless steel

1 Fuel gas inlet DN/PN 125/16 Stainless steel

2 Intercooler in-/outlet DN/PN 100/10 Stainless steel

2 Lube oil connection mm 28 Hose

Sealings and flanges for all flexible connections are included.

1.20.27 Return temperature control

Control of the return temperature ensures a constant warm water temperature at the inlet of the module.

This is made possible by mixing warm water from the outlet flow into the return flow.

Consisting of:

• 1 x 3-way valve with electrical regulating control (delivered loose)

• 1 PT 100 (mounted on the engine or delivered loose)

• 1 PID-regulation (installed in the control panel)

2.00 Electrical equipment

Totally enclosed floor mounted sheet steel cubicle with front door wired to terminals. Ready to operate,

with cable entry at bottom. Naturally ventilated.

Protection: IP 42 external

IP 20 internal (protection against direct contact with live parts)

Design according to EN 60439-1 / IEC 60439-1 and ISO 8528-4.

Ambient temperature 5 - 40 °C (41 - 104 °F), 70 % Relative humidity

Standard painting: Panel: RAL 7035

Pedestal: RAL 7020

3.10 Cooling system – Two-circuits-radiator - electrical control only!

For high temperature circuit

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

30/35

The heat produced by the engine (jacket water, lube oil, intercooler) is dumped through a radiator,

installed outside.

Sound pressure level 65 dB(A) at 10 m (32 ft) (as measuring area level according to ISO 3744 bzw. EN

13487)

Consisting of:

• Radiator (not include GEJ’s scope)

• Pump (not include GEJ’s scope)

• Electrical control

• Expansion tank (not include GEJ’s scope)

The radiator is designed for an ambient temperature of 35°C (95°F). Special versions for higher ambient

temperatures are available upon request.

For low temperature circuit

Radiator is used to dissipate the heat from the intercooler circuit.

Sound pressure level 65 dB(A) at 10 m (32 ft)

(as measuring area level according to ISO 3744 bzw. EN 13487)

Consisting of (delivered loose):

• Radiator (not include GEJ’s scope)

• Pump

• Short-circuit thermostat & Electrical TCV

• Safety valve

• Expansion tank

4.00 Delivery, installation and commissioning

4.01 Carriage

According to contract.

4.02 Unloading

Unloading, moving of equipment to point of installation, mounting and adjustment of delivered equipment

on intended foundations is not included in GE Jenbacher scope of supply.

4.03 Assembly and installation

Assembly and installation of all GE Jenbacher -components is not included in GE Jenbacher scope of

supply.

4.04 Storage

The customer is responsible for secure and appropriate storage of all delivered equipment.

4.05 Start-up and commissioning

Start-up and commissioning with the GE Jenbacher start-up and commissioning checklist.

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

31/35

5.01 Limits of delivery - Genset

Electrical:

• Genset:

• At terminals of genset interface panel

• At terminals of generator terminal box

(screwed glands to be provided locally)

• Genset control panel:

At terminal strips

• Auxiliaries:

At terminals of equipment which is supplied separately

Cooling water

At inlet and outlet flanges on genset

Exhaust gas

At outlet flange of the genset

Combustion air

The air filters are set mounted

Fuel gas

At inlet and outlet flange of gas train

At inlet flange of gas pipework on genset

Lube oil

At lube oil connections on genset

Draining connections and pressure relief

At genset

Insulation

Insulation of heat exchangers and pipework is not included in our scope of supply and must be provided

locally.

First filling

The first filling of genset, (lube oil, engine jacket water, anti freeze-, anti corrosive agent, battery acid) is

not included in our scope of supply.

The composition and quality of the used consumables are to be strictly monitored in accordance with the

"Technical Instructions" of GE JENBACHER.

Suitable bellows and flexible connections must be provided locally for all connections.

Cables from the genset must be flexible.

5.02 Factory tests and inspections

The individual module components shall undergo the following tests and inspections:

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

32/35

5.02.01 Engine tests

Carried out as combined Engine- and Module test according to DIN ISO 3046 at GE Jenbacher test

bench. The following tests are made at 100%, 75% and 50% load, and the results are reported in a test

certificate:

• Engine output

• Fuel consumption

• Jacket water temperatures

• Lube oil pressure

• Lube oil temperatures

• Boost pressure

• Exhaust gas temperatures, for each cylinder

5.02.02 Generator tests

Carried out on test bench of the generator supplier.

5.02.03 Module tests

The engine will be tested with natural gas (Russian Natural gas with methane number 94). The technical

data according to the specification can only be demonstrated to a certain extent with the available natural

gas.

Carried out as combined Engine- and Module test commonly with module control panel at GE Jenbacher

test bench, according to ISO 8528, DIN 6280. The following tests are made and the results are reported

in a test certificate:

Visual inspection of scope of supply per specifications.

• Functional tests per technical specification of control system.

• Starting in manual and automatic mode of operation

• Power control in manual and automatic mode of operation

• Function of all safety systems on module

• Measurements at 100%, 75% and 50% load:

• Frequency

• Voltage

• Current

• Generator output

• Power factor

• Fuel consumption

• Lube oil pressure

• Jacket water temperature

• Boost pressure

• Mixture temperature

• Exhaust emission (NOx)

The module test will be carried out with the original generator, except it is not possible because of the

delivery date. Then a test generator will be used for the module test.

To prove characteristics of the above components, which are not tested on the test bench by GE

JENBACHER, the manufacturers’ certificate will be provided.

5.03 Documentation

Preliminary documentation 60 days after receipt of a technically and commercially clarified order:

• Module drawing 1)

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

33/35

• Technical diagram 1)

• Drawing of control panel 3)

• List of electrical interfaces 2)

• Technical specification of control system 2)

• Technical drawing auxiliaries (if included in GE Jenbacher-limit of delivery) 1)

At delivery:

• Wiring diagrams 3)

• Cable list 3)

At start-up and commissioning (or on clients request):

• Operating and maintenance manual 4)

• Spare parts manual 4)

• Operation report log 4)

Available Languages

1) DEU, GBR

2) DEU, GBR, FRA, ITA, ESP

3) DEU, GBR, FRA, ITA, ESP, NLD, HUN, RUS, POL, TUR, CZE

4) DEU, GBR, FRA, ITA, ESP, NLD, HUN, RUS, POL, TUR, CZE, SLOWEN, SLOWAK, SERB,

SCHWED, ROM, PRT, NORWEG, LITAU, LETT, BULGAR, CHINA, DNK, ESTN, FIN, GRC, KROAT

25.10.2013/GE TS420 Coal Mine gas 2013_10_22.doc

34/35

You might also like

- Jenbacher J420Document38 pagesJenbacher J420Regi Risman Sandi100% (4)

- Jenbacher JMS 616 GS-N.L Natural Gas Module Technical SpecsDocument4 pagesJenbacher JMS 616 GS-N.L Natural Gas Module Technical SpecsMartin KratkyNo ratings yet

- Cylinder Head: Maintenance InstructionDocument12 pagesCylinder Head: Maintenance InstructionReny NapitupuluNo ratings yet

- 1000-1109 - Index 17 GE Jenbacher Gas EnginesDocument14 pages1000-1109 - Index 17 GE Jenbacher Gas EnginesDavid PomaNo ratings yet

- Ge Jenbacher - Jgs 616dsDocument4 pagesGe Jenbacher - Jgs 616dsabdulkidwai2009No ratings yet

- X20CM0985 1 Eng - V1.42Document72 pagesX20CM0985 1 Eng - V1.42rushaNo ratings yet

- J420 GS LL Container PDFDocument36 pagesJ420 GS LL Container PDFAshutosh Sharma100% (1)

- JGS 320 GS-B.L: Technical Description GensetDocument11 pagesJGS 320 GS-B.L: Technical Description GensetAmir QayyumNo ratings yet

- Especificação Técnica - TD 20729-0Document39 pagesEspecificação Técnica - TD 20729-0Geovane FonsecNo ratings yet

- JGS 420 B05 - 1500 KW (Nox - 500)Document11 pagesJGS 420 B05 - 1500 KW (Nox - 500)Ibrahim Ahmed FarrukhNo ratings yet

- TS J420 E900 at BMEP 12bar, Pure H2Document12 pagesTS J420 E900 at BMEP 12bar, Pure H2d_macuraNo ratings yet

- GE Type 3 Technical Instructions 07-30-2012 - Isolated OperationDocument224 pagesGE Type 3 Technical Instructions 07-30-2012 - Isolated OperationSerg MarushkoNo ratings yet

- J312V02 enDocument4 pagesJ312V02 enMartin KratkyNo ratings yet

- Expt 6 The Split Phase MotorDocument4 pagesExpt 6 The Split Phase MotorCapalar KyleNo ratings yet

- Iil C249Document206 pagesIil C249Khalid RafiqNo ratings yet

- Spax (Safi Pickup Amplifier Extended) : Technical InstructionDocument26 pagesSpax (Safi Pickup Amplifier Extended) : Technical InstructionAli QaziNo ratings yet

- GE Jenbacher High Efficiency ConceptDocument9 pagesGE Jenbacher High Efficiency Conceptjulihardo parulian simarmataNo ratings yet

- J612V22 enDocument4 pagesJ612V22 enMartin Kratky100% (1)

- GE - 200802 - Technical Specs Jenbacher Type 6 PDFDocument2 pagesGE - 200802 - Technical Specs Jenbacher Type 6 PDFsakthivelNo ratings yet

- 0606 - TD - E2842 LE312 - Nat - EngDocument8 pages0606 - TD - E2842 LE312 - Nat - EngfaridNo ratings yet

- J320V21 enDocument4 pagesJ320V21 enMartin KratkyNo ratings yet

- Stand-By Aggregate Deutz MWM TBG 616 V12: Technical DetailsDocument1 pageStand-By Aggregate Deutz MWM TBG 616 V12: Technical DetailsKamieshiNo ratings yet

- W 0700m6 - Gas Mixer PDFDocument5 pagesW 0700m6 - Gas Mixer PDFPopa MihaiNo ratings yet

- Tedom Handbook For Designers 2008Document57 pagesTedom Handbook For Designers 2008ManretyNo ratings yet

- GE Power Retrofitting Sensor Modules to Improve Engine MonitoringDocument38 pagesGE Power Retrofitting Sensor Modules to Improve Engine MonitoringPopa MihaiNo ratings yet

- 320Document61 pages320Rashid Mahmood JaatNo ratings yet

- 1 X Jgs 420-Bl-BopDocument25 pages1 X Jgs 420-Bl-Bophaji atinNo ratings yet

- Jgs616 Ds Preliminary DataDocument4 pagesJgs616 Ds Preliminary DataEdutamNo ratings yet

- Hydrogen As Future Fuel For Gas Engines: WorldwideDocument8 pagesHydrogen As Future Fuel For Gas Engines: WorldwideАндрейNo ratings yet

- TBG616K PDFDocument4 pagesTBG616K PDFTyler GoodwinNo ratings yet

- ST-124 New Gear Train PDFDocument21 pagesST-124 New Gear Train PDFPopa MihaiNo ratings yet

- Schaltplan JGS420 - SO#36824 JY108 - 7458609 - 258Document249 pagesSchaltplan JGS420 - SO#36824 JY108 - 7458609 - 258Muhammad Mujtaba TariqNo ratings yet

- JMS 320 GS-B.L: Jenbacher Gas EnginesDocument4 pagesJMS 320 GS-B.L: Jenbacher Gas EnginesSergioNo ratings yet

- Technical Datasheet TCG2020V20 @2000kW - 220222 - 182253Document1 pageTechnical Datasheet TCG2020V20 @2000kW - 220222 - 182253Jack ElhaqNo ratings yet

- Reference Cable Schedule - JGS 320 - Non-Grid SynchronizationDocument2 pagesReference Cable Schedule - JGS 320 - Non-Grid SynchronizationfaisalnadimNo ratings yet

- 1560 kWel gas generator technical dataDocument1 page1560 kWel gas generator technical dataabsahkahNo ratings yet

- Jenbacher 1.946kW Biogas Engine Module Technical SpecsDocument4 pagesJenbacher 1.946kW Biogas Engine Module Technical SpecsMartin KratkyNo ratings yet

- G3306Document4 pagesG3306carlucido247970100% (1)

- 1.4 MTU Operating Instructions MS150118 - 04EDocument235 pages1.4 MTU Operating Instructions MS150118 - 04EheisumairNo ratings yet

- PI734F - Winding 312: Technical Data SheetDocument9 pagesPI734F - Winding 312: Technical Data SheetivanNo ratings yet

- Jenbacher Type 6 Fs en Metric 2016Document2 pagesJenbacher Type 6 Fs en Metric 2016laiquz zamanNo ratings yet

- (PDF) Maintenance Schedule For Gas Genset - GE JENBACHER - CompressDocument5 pages(PDF) Maintenance Schedule For Gas Genset - GE JENBACHER - CompressArie AozNo ratings yet

- Jenbacher JMS 616 GS-N.L Natural Gas Module Technical SpecsDocument4 pagesJenbacher JMS 616 GS-N.L Natural Gas Module Technical Specsmxnoxn100% (1)

- Jenbacher: 1. Key To Module Diagrams and Technical Schema: - 1Document14 pagesJenbacher: 1. Key To Module Diagrams and Technical Schema: - 1Jamil Ahmed100% (1)

- PandarosDocument9 pagesPandarosTempest_LNo ratings yet

- JMS 620 GS-N.L: Technical SpecificationDocument4 pagesJMS 620 GS-N.L: Technical SpecificationjoellopezzNo ratings yet

- J612V02 enDocument4 pagesJ612V02 enMartin KratkyNo ratings yet

- 05-07-02-03-01 - Dezentrale Peripherie 01 PDFDocument17 pages05-07-02-03-01 - Dezentrale Peripherie 01 PDFTariqMaqsoodNo ratings yet

- 176kVA Natural Gas Generator SetDocument6 pages176kVA Natural Gas Generator SetTomas Leon JuliaNo ratings yet

- PT Indah Jaya II + III: 2 X JMS 620 GS-N.L J C345Document369 pagesPT Indah Jaya II + III: 2 X JMS 620 GS-N.L J C345SaasiNo ratings yet

- QSK60 G6 PDFDocument2 pagesQSK60 G6 PDFShahzad Ali100% (2)

- Champion Industrial Spark Plugs - DigipubZDocument8 pagesChampion Industrial Spark Plugs - DigipubZiyan22suryana_827197No ratings yet

- Technical Specifiaction of Control SystemDocument34 pagesTechnical Specifiaction of Control SystemLidef SellenrofNo ratings yet

- GE Type 3 TECHNICAL SPECIFICATION OF THE CONTROLDocument24 pagesGE Type 3 TECHNICAL SPECIFICATION OF THE CONTROLSerg MarushkoNo ratings yet

- Exhaust Emission Data Sheet 880DFHD: 50 HZ Diesel Generator SetDocument1 pageExhaust Emission Data Sheet 880DFHD: 50 HZ Diesel Generator Setmohsen_cumminsNo ratings yet

- Catalist: Crompton Instruments Preferred Range CatalogueDocument28 pagesCatalist: Crompton Instruments Preferred Range CataloguemunhNo ratings yet

- Jenbacher: 1. Ignition System: - 1Document2 pagesJenbacher: 1. Ignition System: - 1ArîfNo ratings yet

- What Is The Difference Between A Cogeneration Power Plant and A Combined Cycle Power PlantDocument1 pageWhat Is The Difference Between A Cogeneration Power Plant and A Combined Cycle Power PlantRajesh RavindranNo ratings yet

- JGC 320GS-L.L Technical DescriptionDocument33 pagesJGC 320GS-L.L Technical Descriptionlaiquz zaman100% (1)

- GERMANY - Engineering JGS620Document40 pagesGERMANY - Engineering JGS620Ali Ramezani KhoozestaniNo ratings yet

- Deutz, TBG 616 K (323 - 700 KW)Document4 pagesDeutz, TBG 616 K (323 - 700 KW)Dexterous EngineeringNo ratings yet

- The state-of-the-art TCG 2020 gas engine from DEUTZDocument4 pagesThe state-of-the-art TCG 2020 gas engine from DEUTZJoy DasNo ratings yet

- b3540v Leanburn Gas GensetDocument2 pagesb3540v Leanburn Gas GensetDexterous EngineeringNo ratings yet

- Rolls - Royce, B35-40 V12AG (5100 KW)Document3 pagesRolls - Royce, B35-40 V12AG (5100 KW)Dexterous EngineeringNo ratings yet

- JMS-320 GS NL (1065kw)Document4 pagesJMS-320 GS NL (1065kw)Dexterous EngineeringNo ratings yet

- 01 JMS 312 GS-BL 1065 KWDocument6 pages01 JMS 312 GS-BL 1065 KWSyed Mohammad NaveedNo ratings yet

- Technical Description: Cogeneration UnitDocument12 pagesTechnical Description: Cogeneration UnitDexterous Engineering100% (1)

- Lmx2370/Lmx2371/Lmx2372 Pllatinum Dual Frequency Synthesizer For RF Personal CommunicationsDocument16 pagesLmx2370/Lmx2371/Lmx2372 Pllatinum Dual Frequency Synthesizer For RF Personal Communications40818248No ratings yet

- Practical 7 - Angiosperms Marking Guide Exercise 1: Class DicotyledonsDocument3 pagesPractical 7 - Angiosperms Marking Guide Exercise 1: Class DicotyledonsDitiro Maletsanake50% (2)

- Aam April 2023Document198 pagesAam April 2023Adhitya DewantaraNo ratings yet

- LUKAS Product Information-2Document2 pagesLUKAS Product Information-2Flavian ZfmNo ratings yet

- 6kW V2G EV Charger Module Datasheet (2018)Document2 pages6kW V2G EV Charger Module Datasheet (2018)pysogaNo ratings yet

- MayankDocument38 pagesMayankmayank13430No ratings yet

- 3rd Periodic Test in English4Document7 pages3rd Periodic Test in English4Santa Dela Cruz Naluz100% (1)

- Ic M802 UDocument79 pagesIc M802 Uharis_fikriNo ratings yet

- Column FootingDocument57 pagesColumn Footingnuwan01100% (7)

- Shangqiu Jinpeng Industrial Co., LTD.: Widely Used Waste Rubber Pyrolysis Equipment (XY-7)Document2 pagesShangqiu Jinpeng Industrial Co., LTD.: Widely Used Waste Rubber Pyrolysis Equipment (XY-7)Salma FarooqNo ratings yet

- Rental Range Powered by YANMAR Diesel GeneratorDocument6 pagesRental Range Powered by YANMAR Diesel GeneratorJonathan CastilloNo ratings yet

- Siemens 810dDocument13 pagesSiemens 810dAdo ŠehićNo ratings yet

- Estimation of Fabric Opacity by ScannerDocument7 pagesEstimation of Fabric Opacity by ScannerJatiKrismanadiNo ratings yet

- Surat Kecil Untuk TuhanDocument9 pagesSurat Kecil Untuk TuhanAsgarPurnamaNo ratings yet

- Imsa Catalog Imsa CatDocument16 pagesImsa Catalog Imsa CatDaniel TelloNo ratings yet

- Assess The Knowledge and Attitude On Prevention of Dengue Among The Patients AttendantsDocument6 pagesAssess The Knowledge and Attitude On Prevention of Dengue Among The Patients AttendantsIJAR JOURNALNo ratings yet

- Make A Selection: Choose An Alloy and Correlating Casting ProcessDocument5 pagesMake A Selection: Choose An Alloy and Correlating Casting ProcessSarath ChandraNo ratings yet

- Path Loss Models and Wireless Propagation EffectsDocument17 pagesPath Loss Models and Wireless Propagation EffectsAhsan RafiqNo ratings yet

- Anatomy of A Plated HoleDocument5 pagesAnatomy of A Plated Holepbs0707No ratings yet

- Manual Bot With Relay CircuitDocument4 pagesManual Bot With Relay CircuitKarishma MishraNo ratings yet

- Resume Curt JerromeDocument5 pagesResume Curt JerromeAashish MuraliNo ratings yet

- Jean NouvelDocument1 pageJean Nouvelc.sioson.540553No ratings yet

- Effect of Water Immersion On Mechanical Properties of Polyurethane ...Document8 pagesEffect of Water Immersion On Mechanical Properties of Polyurethane ...konshoeNo ratings yet

- SaponificationDocument2 pagesSaponificationK.SaravananNo ratings yet

- Changing Landscape and Ecotourism Development in A Large Dam SiteDocument16 pagesChanging Landscape and Ecotourism Development in A Large Dam Siteವಿನಯ್ ಎಮ್. ಆರ್No ratings yet

- Cefiget-Range-Leaflet-PakistanDocument2 pagesCefiget-Range-Leaflet-PakistanZafran KhanNo ratings yet

- Negative Compressibility and PVT Extrapolation WarningsDocument17 pagesNegative Compressibility and PVT Extrapolation WarningsMarcelo SaezNo ratings yet

- Exercitii AdjectivDocument3 pagesExercitii AdjectivFirma GSCNo ratings yet

- Ex 2013 1 (Recurrent)Document30 pagesEx 2013 1 (Recurrent)alh basharNo ratings yet

- Measurement of Level in A Tank Using Capacitive Type Level ProbeDocument13 pagesMeasurement of Level in A Tank Using Capacitive Type Level ProbeChandra Sekar100% (1)