Professional Documents

Culture Documents

87A-100 SERIES: Standard Material List Variations Available

87A-100 SERIES: Standard Material List Variations Available

Uploaded by

kicsnerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

87A-100 SERIES: Standard Material List Variations Available

87A-100 SERIES: Standard Material List Variations Available

Uploaded by

kicsnerCopyright:

Available Formats

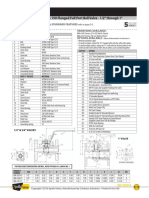

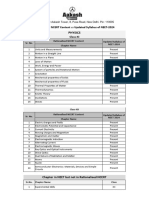

87A-100 SERIES

STAINLESS STEEL ASME CLASS 150 FLANGED STD. PORT BALL VALVE

1-1/2” THRU 2”

FOR STANDARDS COMPLIANCE AND STANDARD FEATURES REFER TO PAGE D-3.

STANDARD MATERIAL LIST VARIATIONS AVAILABLE

PART MATERIAL

• 87H - Hastelloy

• 87M - Monel (1-1/2” to 2” only)

1 Body ASTM A351 CF8M

• 87N - Nickel

2 Retainer ASTM A276 Type 316 • 87S - 304L Stainless Steel

3 Ball ASTM A276 Type 316

4 Stem ASTM A276 Type 316 OPTIONS AVAILABLE

5 Packing Gland ASTM A276 Type 316 (MORE INFORMATION IN SECTION J)

• Minimum quantities apply.

6 Stem Seals PTFE • To specify an option, replace the “01” standard suffix with the suffix of the option.

• To specify multiple options, replace the “01” suffix with the desired suffixes in the

7 Seats TFM 1700 numerical order shown below. NOTE: Not all suffixes can be combined together.

8 Gland Screws ASTM A193 B8 Class 1

(SUFFIX) OPTION

9 Gland Plate 302 or 304 Stainless Steel

-01 Standard Configuration

10 Stem Nut 316 Stainless Steel

-04- 2-1/4” Stem Extension (Carbon Steel, Zinc Plated)

11 Lever 302 or 304 Stainless Steel with Vinyl Grip

-14- Side Vented Ball (Uni-Directional)

12 Stem Bearing RPTFE

-15- Wheel Handle, Steel

13 Stop ASTM A276 Type 316

-21- UHMWPE Seats

14 Stop Screw 18-8 Stainless Steel

Graphite Packing, Spiral Wound Graphite Body Seal,

15 Lock Plate 302 or 304 Stainless Steel -24-

RPTFE Bearing (API 607, 6th Edition, ISO 10497:2010)

16 Body Seal RPTFE

-35- PTFE Seats and Seals

17 Lockwasher 302 or 304 Stainless Steel

-38- PEEK Seats and Graphite Packing

18 Grounding Spring Stainless Steel

-49- No Lubrication. Assembled Dry

-57- Oxygen Cleaned

-65- MPTFE Seats and Graphite Packing (Fire Safe)

-69- Drilled and Tapped Purge Port with Plug

-70- 4” Extended Bonnet

-73- 316 Stainless Steel Spiral Wound Gaskets with PTFE Filler

-76- Live Loaded (Lever)

-77- Live Loaded (Gear, Actuator)

-80- TFM 1600 Seats, PTFE Chevron Packing, Spiral Wound PTFE Body Seal PEEK Bearing

-82- Flat Face Flanges

-90- Double Packed 4” Extended Bonnet

-9P- Double Packed 4” Extended Bonnet with Monitoring Port

-CE- CE Marking. See Page D-3 “Product Approvals” for Availability

-EF- Graphite Packing (API 641 Compliant)

Garlock EVSP Stem Packing with Spiral Wound

-EP-

Graphite Gasket (Fire Safe by Design)

-KF- PCTFE Stem Bearing

-MP- Positive Material Identification

-TC- With Test Certificate

-TD- Tested to API Spec 6D

-UA- AIS (American Iron & Steel) Compliant

-UL- UL & CSA Listed (with Markings)

ACTUATOR MOUNTING

-ZP1- Fugitive Emissions Packing (Viton)

-ZP2- Fugitive Emissions Packing (Buna-N)

-ZP3- Fugitive Emissions Packing (Kalrez)

Pressure/Temperature Ratings - Page M-9, Graph No. 2

DIMENSIONS

PART NO. SIZE A B C D E F G H I J K L M N WT.

87A-107-01 1-1/2” 1.25 6.50 3.50 4.85 6.53 0.47 1.85 2.38 1.392 0.696 0.500 0.287 1/4-20 1.50 9

87A-108-01 2” 1.50 7.00 3.69 4.62 6.65 0.72 2.41 3.09 1.949 0.974 0.625 0.412 5/16-18 2.00 18

REV. 18JUL19

Customer Service (704) 841-6000 industrial.apollovalves.com D-5

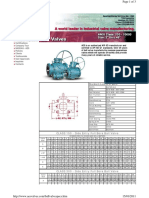

87A-100 SERIES

STAINLESS STEEL ASME CLASS 150 FLANGED STD. PORT BALL VALVE

2-1/2” THRU 3”

FOR STANDARDS COMPLIANCE AND STANDARD FEATURES REFER TO PAGE D-3.

STANDARD MATERIAL LIST VARIATIONS AVAILABLE

PART MATERIAL

• 87H - Hastelloy

• 87N - Nickel

1 Body ASTM A351 CF8M

• 87S - 304L Stainless Steel

2 Retainer ASTM A351 CF8M

3 Ball ASTM A276 Type 316 or A351 CF8M OPTIONS AVAILABLE

4 Stem ASTM A276 Type 316 (MORE INFORMATION IN SECTION J)

• Minimum quantities apply.

5 Packing Gland ASTM A276 Type 316 • To specify an option, replace the “01” standard suffix with the suffix of the option.

Stem Seals PTFE • To specify multiple options, replace the “01” suffix with the desired suffixes in the

6

numerical order shown below. NOTE: Not all suffixes can be combined together.

7 Seats TFM 1700

(SUFFIX) OPTION

8 Gland Screws ASTM A193 B8 Class 1

-01 Standard Configuration

9 Gland Plate 316 Stainless Steel

-04- 2-1/4” Stem Extension (Carbon Steel, Zinc Plated)

10 Stem Nut 18-8 Stainless Steel

-14- Side Vented Ball (Uni-Directional)

11 Lever 316 Stainless Steel

-21- UHMWPE Seats

12 Stem Bearing RPTFE

Graphite Packing, Spiral Wound Graphite Body Seal,

13 Stop ASTM A276 Type 316 -24-

RPTFE Bearing (API 607, 6th Edition, ISO 10497:2010)

14 Stop Screw 316 Stainless Steel

-35- PTFE Seats and Seals

15 Lock Plate 302 or 304 Stainless Steel

-38- PEEK Seats and Graphite Packing

16 Body Seal RPTFE

-49- No Lubrication. Assembled Dry

17 Grounding Spring Stainless Steel

-57- Oxygen Cleaned

18 Body Joint Stud ASTM A193 Grade B8M

-65- MPTFE Seats and Graphite Packing (Fire Safe)

19 Body Joint Nut ASTM A194 Grade 8

-67- Cleaned for Industrial Gases

20 Lockwasher 302 or 304 Stainless Steel

-69- Drilled and Tapped Purge Port with Plugs

-70- 4” Extended Bonnet

-73- 316 Stainless Steel Spiral Wound Gaskets with PTFE Filler

-76- Live Loaded 87A/88A Series (Lever)

-77- Live Loaded (Gear, Actuator)

-80- TFM 1600 Seats, PTFE Chevron Packing, Spiral Wound PTFE Body Seal PEEK Bearing

-82- Flat Face Flanges

-90- Double Packed 4” Extended Bonnet

-9P- Double Packed 4” Extended Bonnet with Monitoring Port

-CE- CE Marking. See Page D-3 “Product Approvals” for Availability

-EF- Graphite Packing (API 641 Compliant)

Garlock EVSP Stem Packing with Spiral Wound

-EP-

Graphite Gasket (Fire Safe by Design)

-KF- PCTFE Stem Bearing

-MG- Gear Operator with Standard Handwheel

-MH- Gear Operator with Standard Handwheel & Locking Device

-MJ- Gear Operator with Oversize Handwheel

-MK- Gear Operator with Oversize Handwheel & Locking Device

-MP- Positive Material Identification

-TC- With Test Certificate

-TD- Tested to API Spec 6D

ACTUATOR MOUNTING -UA- AIS (American Iron & Steel) Compliant

-UL- UL & CSA Listed (with Markings)

-ZP1- Fugitive Emissions Packing (Viton)

-ZP2- Fugitive Emissions Packing (Buna-N)

-ZP3- Fugitive Emissions Packing (Kalrez)

Pressure/Temperature Ratings - Page M-9, Graph No. 2

DIMENSIONS

PART NO. SIZE A B C D E F G H I J K L M N WT.

87A-109-01 2-1/2” 2.00 7.50 3.50 5.61 8.41 0.80 3.31 4.08 1.949 0.974 0.750 0.477 5/16-18 2.50 27

87A-100-01 3” 2.50 8.00 3.51 6.24 8.41 0.80 3.94 4.71 1.949 0.974 0.750 0.477 5/16-18 3.00 34

REV. 18JUL19

D-6 Customer Service (704) 841-6000 industrial.apollovalves.com

87A-100 SERIES

STAINLESS STEEL ASME CLASS 150 FLANGED STD. PORT BALL VALVE

4” THRU 8”

FOR STANDARDS COMPLIANCE AND STANDARD FEATURES REFER TO PAGE D-3.

STANDARD MATERIAL LIST VARIATIONS AVAILABLE

PART MATERIAL

• 87H - Hastelloy

• 87N - Nickel

1 Body ASTM A351 CF8M

• 87S - 304L Stainless Steel

2 Retainer ASTM A351 CF8M

3 Ball ASTM A276 Type 316 or A351 CF8M OPTIONS AVAILABLE

4 Stem ASTM A276 Type 316 (MORE INFORMATION IN SECTION J)

• Minimum quantities apply.

5 Packing Gland ASTM A276 Type 316 • To specify an option, replace the “01” standard suffix with the suffix of the option.

Stem Seals PTFE • To specify multiple options, replace the “01” suffix with the desired suffixes in the

6

numerical order shown below. NOTE: Not all suffixes can be combined together.

7 Seats RPTFE

(SUFFIX) OPTION

8 Gland Screws ASTM A193 B8 Class 1

-01 Standard Configuration

9 Gland Plate 316 Stainless Steel

-14- Side Vented Ball (Uni-Directional)

10 Adapter Screw 18-8 Stainless Steel

-21- UHMWPE Seats

11 Handle Adapter 316 Stainless Steel

Graphite Packing, Spiral Wound Graphite Body Seal,

12 Stem Bearing RPTFE -24-

RPTFE Bearing (API 607, 6th Edition, ISO 10497:2010)

13 Stop ASTM A276 Type 316

-35- PTFE Seats and Seals

14 Stop Screw 316 Stainless Steel

-49- No Lubrication. Assembled Dry

15 Lock Plate 302 or 304 Stainless Steel

-57- Oxygen Cleaned

16 Body Seal RPTFE

-65- MPTFE Seats and Graphite Packing (Fire Safe)

17 Grounding Spring Stainless Steel

-67- Cleaned for Industrial Gases

18 Body Joint Stud ASTM A193 Grade B8M

-69- Drilled and Tapped Purge Ports with Plugs

19 Body Joint Nut ASTM A194 Grade 8

-70- Extended Bonnet

20 Lockwasher 302 or 304 Stainless Steel

-73- 316 Stainless Steel Spiral Wound Gaskets with PTFE Filler

21 Pipe Handle Galvanized Steel (not Shown)

-76- Live Loaded (Lever)

-77- Live Loaded (Gear, Actuator)

-80- TFM 1600 Seats, PTFE Chevron Packing, Spiral Wound PTFE Body Seal PEEK Bearing

-82- Flat Face Flanges

-90- Double Packed 4” Extended Bonnet

-9P- Double Packed 4” Extended Bonnet with Monitoring Port

-CE- CE Marking. See Page D-3 “Product Approvals” for Availability

-EF- Graphite Packing (API 641 Compliant)

Garlock EVSP Stem Packing with Spiral Wound

-EP-

Graphite Gasket (Fire Safe by Design)

-KF- PCTFE Stem Bearing

-MG- Gear Operator with Standard Handwheel

-MH- Gear Operator with Standard Handwheel & Locking Device

-MJ- Gear Operator with Oversize Handwheel

-MK- Gear Operator with Oversize Handwheel & Locking Device

-MP- Positive Material Identification

-TC- With Test Certificate

-TD- Tested to API Spec 6D

-UA- AIS (American Iron & Steel) Compliant

ACTUATOR MOUNTING -UL- UL & CSA Listed (with Markings)

-ZP1- Fugitive Emissions Packing (Viton)

-ZP2- Fugitive Emissions Packing (Buna-N)

-ZP3- Fugitive Emissions Packing (Kalrez)

Pressure/Temperature Ratings - Page M-9, Graph No. 2

DIMENSIONS

PART NO. SIZE A B C D E F G H I J K L M N WT.

87A-10A-01 4” 3.00 9.00 4.18 8.80 3.88 0.50 4.75 5.95 2.840 1.420 1.250 0.725 3/8-16 4.00 73

87A-10C-01 6” 4.00 10.50 4.69 9.99 5.13 0.50 5.94 7.13 2.840 1.420 1.250 0.725 3/8-16 6.00 117

87A-10E-01 8” 6.00 18.00 9.00 13.73 7.00 1.00 7.75 9.48 4.596 2.298 2.000 1.375 3/4-10 8.00 310

REV. 18JUL19

Customer Service (704) 841-6000 industrial.apollovalves.com D-7

87A-100 SERIES

STAINLESS STEEL ASME CLASS 150 FLANGED STD. PORT BALL VALVE

10”

FOR STANDARDS COMPLIANCE AND STANDARD FEATURES REFER TO PAGE D-3.

STANDARD MATERIAL LIST VARIATIONS AVAILABLE

PART MATERIAL

• 87H - Hastelloy

• 87N - Nickel

1 Body ASTM A351 CF8M

• 87S - 304L Stainless Steel

2 Retainer ASTM A351 CF8M

3 Ball ASTM A276 Type 316 or A351 CF8M OPTIONS AVAILABLE

4 Stem ASTM A276 Type 316 (MORE INFORMATION IN SECTION J)

• Minimum quantities apply.

5 Packing Gland ASTM A276 Type 316 • To specify an option, replace the “01” standard suffix with the suffix of the option.

Stem Seals PTFE • To specify multiple options, replace the “01” suffix with the desired suffixes in the

6

numerical order shown below. NOTE: Not all suffixes can be combined together.

7 Seats TFM 1700

(SUFFIX) OPTION

8 Gland Screws ASTM A193 B8 Class 1

-01 Standard Configuration

9 Gland Plate 316 Stainless Steel

-14- Side Vented Ball (Uni-Directional)

10 Stem Bearing RPTFE

-21- UHMWPE Seats

11 Body Seal RPTFE

Graphite Packing, Spiral Wound Graphite Body Seal,

12 Body Joint Stud ASTM A193 Grade B8M -24-

RPTFE Bearing (API 607, 6th Edition, ISO 10497:2010)

13 Body Joint Nut ASTM A194 Grade 8

-35- PTFE Seats and Seals

-49- No Lubrication. Assembled Dry

-57- Oxygen Cleaned

-65- MPTFE Seats and Graphite Packing (Fire Safe)

-69- Drilled and Tapped Purge Port with Plugs

-70- 4” Extended Bonnet

-77- Live Loaded 87A/88A Series (Gear, Actuator)

-80- TFM 1600 Seats, PTFE Chevron Packing, Spiral Wound PTFE Body Seal, PEEK Bearing

-82- Flat Face Flanges

-90- Double Packed 4” Extended Bonnet

-9P- Double Packed 4” Extended Bonnet with Monitoring Port

-CE- CE Marking. See Page D-3 “Product Approvals” for Availability

-EF- Graphite Packing (API 641 Compliant)

Garlock EVSP Stem Packing with Spiral Wound

-EP-

Graphite Gasket (Fire Safe by Design)

-KF- PCTFE Stem Bearing

-MG- Gear Operator with Standard Handwheel

-MH- Gear Operator with Standard Handwheel & Locking Device

-MJ- Gear Operator with Oversize Handwheel

-MK- Gear Operator with Oversize Handwheel & Locking Device

-MP- Positive Material Identification

-TC- With Test Certificate

-TD- Tested to API Spec 6D

-UA- AIS (American Iron & Steel) Compliant

ACTUATOR MOUNTING

-UL- UL & CSA Listed (with Markings)

-ZP1- Fugitive Emissions Packing (Viton)

-ZP2- Fugitive Emissions Packing (Buna-N)

-ZP3- Fugitive Emissions Packing (Kalrez)

Pressure/Temperature Ratings - Page M-9, Graph No. 2

DIMENSIONS

PART NO. SIZE A B C D E F G H I J K L M WT.

87A-10G-01 10” 8.00 21.00 10.37 12.83 9.18 1.00 10.22 4.596 2.298 2.000 1.375 3/4-10 10.00 526

REV. 18JUL19

D-8 Customer Service (704) 841-6000 industrial.apollovalves.com

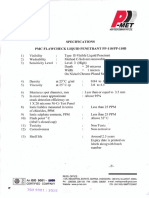

FLOW DATA

FLOW DATA

The listed Cv “factors” are derived from actual flow testing, at Apollo’s Pageland, South Carolina factory. These tests were completed using standard

“off the shelf” valves with no special preparation and utilizing standard schedule 40 pipe. It should be understood that these factors are for the valve

only and also include the connection configuration. The flow testing is done utilizing water as a fluid media and is a direct statement of the gallons of

water flowed per minute with a 1 psig pressure differential across the valve/connection unit. Line pressure is not a factor. Because the Cv is a factor, the

formula can be used to estimate flow of most media for valve sizing.

√ √

FLOW OF LIQUID ∆P FLOW OF GAS (∆P) (P2)

Q = CV Q = 1360 CV

SpGr (SpGr) (T)

or ∆P = (Q) (SpGr) or ∆P = 5.4 x 10 (SpGr) (T) (Q)2

2 -7

(Cv)2 (Cv)2 (P2)

WHERE: WHERE:

• Q = Flow in US gpm • Q = Flow in SCFH

• ∆P = Pressure drop (psig) • ∆P = Pressure drop (psig)

• SpGr = Specific gravity at flowing temperature • SpGr = Specific gravity (based on air = 1.0)

• Cv = Valve constant • P2 = Outlet pressure–psia (psig + 14.7)

• T = (temp. °F + 460)

• Cv = Valve constant

CAUTION: The gas equation shown, is valid at very low pressure drop ratios.

The gas equation is NOT valid when the ratio of pressure drop (∆P) to inlet

pressure (P1) exceeds 0.02.

NOTE: Only use the gas equation shown if (P1-P2)/P1 is less than 0.02.

CV FACTORS FOR APOLLO VALVES (CONTINUED ON M-4)

SIZE (IN.)

VALVE

1/4 3/8 1/2 3/4 1 1.25 1.5 2 2.5 3 4 6 8 10 12

70B-140 Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- --

70-100/200 Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- ---

70-300/400 Series -- -- 15 30 43 48 84 108 -- -- -- -- -- -- --

70-600 Series 2.3 4.5 5.4 12 14 21 34 47 -- -- -- -- -- -- --

70-800 Series 8.4 7.2 15 30 43 48 84 -- -- -- -- -- -- -- --

71-AR Series -- -- -- 30 43 48 84 108 190 370 -- -- -- -- --

71-100/200 Series -- -- -- 30 43 48 84 108 190 370 -- -- -- -- --

72-100/900 Series -- -- 26 48 65 125 170 216 -- -- -- -- -- -- --

72-1xx-A/72-9xx-A Series -- -- 26 48 65 125 170 245 -- -- -- -- -- -- --

73A-100 Series 8.4 7.2 15 30 43 48 84 108 -- -- -- -- -- -- --

73-300/400 Series -- -- 26 48 65 125 170 216 -- -- -- -- -- -- --

74-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- --

75-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- --

76-AR Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- --

76F-100 Series 8.1 15 15 51 68 125 177 389 -- -- -- -- -- -- --

76FJ-100 Series 8.1 15 15 51 68 125 177 389 -- -- -- -- -- -- --

76FK-100 Series 8.1 15 15 51 68 125 177 389 -- -- -- -- -- -- --

76-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

76-300/400 Series -- -- 26 48 65 125 170 216 -- -- -- -- -- -- --

76-600 Series 2.3 4.5 5.4 12 14 21 34 47 -- -- -- -- -- -- --

76J-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

76J-AR Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- --

76K-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

76K-AR Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- --

7K-100 Series -- -- 15 51 68 125 177 389 503 -- -- -- -- -- --

77-AR Series 8.1 15 15 51 68 -- 177 389 -- -- -- -- -- -- --

REV. 21APR17

Customer Service (704) 841-6000 industrial.apollovalves.com M-3

FLOW DATA

FOR APOLLO BALL VALVES

CV FACTORS FOR APOLLO VALVES (CONTINUED FROM M-3)

SIZE (IN.)

VALVE

1/4 3/8 1/2 3/4 1 1.25 1.5 2 2.5 3 4 6 8 10 12

77C-100/200 Series 4.5 7.2 16 36 68 125 177 389 503 -- -- -- -- -- --

77D-140 Series 4.5 7.2 16 36 68 125 177 389 -- -- -- -- -- -- --

77D-640 Series -- -- -- 11 24 35 -- -- -- -- -- -- -- -- --

77G-UL Series 4.5 7.2 16 36 68 125 177 389 503 -- -- -- -- -- --

77W Series -- -- 16 36 68 125 177 389 -- -- -- -- -- -- --

77-100/200 Series 8.1 15 15 51 68 125 177 389 503 -- -- -- -- -- --

79 Series 8.5 8.5 9.8 32 44 66 148 218 440 390 -- -- -- -- --

80 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

82-100/200 Series 8.1 14 26 51 68 120 170 376 510 996 1893 -- -- -- --

83A/83B Series 8.1 14 26 51 68 120 170 376 -- -- -- -- -- -- --

83R-100/200 Series -- -- -- -- -- -- 170 376 -- 996 1893 -- -- -- --

86A/86B Series 8.1 14 26 51 68 120 170 376 -- -- -- -- -- -- --

86R-100/200 Series -- -- -- -- -- -- 170 376 -- 996 1893 -- -- -- --

87A-100 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

87A-200 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

87A-700 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

87A-900 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

87A-F00 Series -- -- -- -- 75 -- 195 410 545 1021 2016 4837 -- -- --

87B-100 Series -- -- -- -- -- -- -- -- -- 375 673 1099 1902 3890 --

87J-100 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

87J-200 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

87J-700 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

87J-900 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

87K-100 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

87K-200 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

87K-700 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

87K-900 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

88A-100 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

88A-200 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

88A-700 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

88A-900 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

88A-F00 Series -- -- -- -- 75 -- 195 410 545 1021 2016 4837 -- -- --

88B-100 Series -- -- -- -- -- -- -- -- -- 375 673 1099 1902 3890 --

89-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

9A-100 Series 8.3 6.7 5.7 10 16 25 40 62 -- -- -- -- -- -- --

90-100 Series 8.3 6.7 5.7 10 16 25 40 62 -- -- -- -- -- -- --

92-100 Series 8.3 6.7 5.7 10 16 25 40 62 -- -- -- -- -- -- --

93-100 Series 8.3 6.7 5.7 10 16 25 40 62 -- -- -- -- -- -- --

94A-100/200 Series 6 7 19 34 50 104 268 309 629 1018 1622 -- -- -- --

96-100 Series 8.3 6.7 5.7 10 16 25 40 62 -- -- -- -- -- -- --

399-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

489-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

M-4 Customer Service (704) 841-6000 industrial.apollovalves.com

PRESSURE/TEMPERATURE RATINGS

ENGINEERING DATA

CLASS 150 (CS) ASTM A216-WCB GRAPH 1

CLASS 150 (SS) ASTM A351-CF8M GRAPH 2

Customer Service (704) 841-6000 industrial.apollovalves.com M-9

You might also like

- Honeywell Air Conditioner MM14CCSDocument20 pagesHoneywell Air Conditioner MM14CCSJabón VelázquezNo ratings yet

- 87a-207-01-Stainless Steel Asme Class 150 Flanged Full Port Ball Valve - 1.5" Thru 2.5Document1 page87a-207-01-Stainless Steel Asme Class 150 Flanged Full Port Ball Valve - 1.5" Thru 2.5Hung NguyenNo ratings yet

- 88A-200 SERIES: Standard Material List Variations AvailableDocument8 pages88A-200 SERIES: Standard Material List Variations AvailableBalotileNo ratings yet

- 88A-200 SERIES: Carbon Steel ASME Class 150 Flanged Full Port Ball Valve - 1/2" Through 1"Document9 pages88A-200 SERIES: Carbon Steel ASME Class 150 Flanged Full Port Ball Valve - 1/2" Through 1"alan quispe coronelNo ratings yet

- 88A-100 SERIES: Carbon Steel ASME Class 150 Flanged Std. Port Ball Valve - 1.5" Through 2"Document9 pages88A-100 SERIES: Carbon Steel ASME Class 150 Flanged Std. Port Ball Valve - 1.5" Through 2"calvin casserlyNo ratings yet

- 88A-100 SERIES: Carbon Steel ASME Class 150 Flanged Std. Port Ball Valve - 1.5" Through 2"Document9 pages88A-100 SERIES: Carbon Steel ASME Class 150 Flanged Std. Port Ball Valve - 1.5" Through 2"Edgar Vilca HuanacuniNo ratings yet

- Val-Comp Z45XDocument1 pageVal-Comp Z45XDaniel04pvNo ratings yet

- Grooved Resilient OS&Y Gate Valve (XZ81X), UL/FM Approved Flanged Resilient OS&Y Gate Valve (XZ41X), UL/FM ApprovedDocument1 pageGrooved Resilient OS&Y Gate Valve (XZ81X), UL/FM Approved Flanged Resilient OS&Y Gate Valve (XZ41X), UL/FM Approvedtaaj77No ratings yet

- VB-02 - Bola CS CL600 SW (Apollo 83B-240)Document4 pagesVB-02 - Bola CS CL600 SW (Apollo 83B-240)joseNo ratings yet

- Val Bola Pollo 2000wog 2pza Mod 73aDocument5 pagesVal Bola Pollo 2000wog 2pza Mod 73akimberly quispe mendozaNo ratings yet

- Keystone K-Lok 360-370 Data SheetDocument12 pagesKeystone K-Lok 360-370 Data SheetMnttoMecNo ratings yet

- Valve Cat-Seats, Offsets Etc..Document12 pagesValve Cat-Seats, Offsets Etc..PRASANTH PRASANTHNo ratings yet

- 88A-200 Series: Standards Compliance Standard Features Variations AvailableDocument5 pages88A-200 Series: Standards Compliance Standard Features Variations AvailableEdgar Vilca HuanacuniNo ratings yet

- S80 - Sales Borchure EnglishDocument2 pagesS80 - Sales Borchure Englishevilnemesis133No ratings yet

- Valvulas OS&YDocument1 pageValvulas OS&Ydaniel manuel garces davilaNo ratings yet

- UL FM OS&Y Gate Valves, AWWA C515 - Water Works - Fire Protection - Model 2030 Series ADocument1 pageUL FM OS&Y Gate Valves, AWWA C515 - Water Works - Fire Protection - Model 2030 Series ASiles LimberdsNo ratings yet

- 02 Mech-OS&Y Gate Valve UL FM (XZ41X VALVULAS 290917Document1 page02 Mech-OS&Y Gate Valve UL FM (XZ41X VALVULAS 290917Roman UgarteNo ratings yet

- MECH - Valvula de Compuerta OSY XZ41XDocument1 pageMECH - Valvula de Compuerta OSY XZ41XAlfredo BravoNo ratings yet

- Plummech OS&Y Gate ValvesDocument1 pagePlummech OS&Y Gate ValvesNguyễn Đăng PhúcNo ratings yet

- Carbon Steel Ball Valve: Design FeaturesDocument1 pageCarbon Steel Ball Valve: Design FeaturesChanchal K SankaranNo ratings yet

- Series 64 Screwed End Ball ValvesDocument2 pagesSeries 64 Screwed End Ball ValvesProcess Controls & Services100% (1)

- 2 Piece Threaded Standard Port Ball Valves: / "-3": Series S70 & Series S90Document2 pages2 Piece Threaded Standard Port Ball Valves: / "-3": Series S70 & Series S90andres12636No ratings yet

- Plummech Post IndicatorDocument1 pagePlummech Post IndicatorNguyễn Đăng PhúcNo ratings yet

- Fig. 2850L / 2851L / 3850L / 3851L / 4850L / 4851L Semi-Lugged Wafer Pattern Lever Operated Butterfly ValvesDocument1 pageFig. 2850L / 2851L / 3850L / 3851L / 4850L / 4851L Semi-Lugged Wafer Pattern Lever Operated Butterfly ValvesAsmaaNo ratings yet

- FLOWTEK - Ficha Tecnica-ComprimidoDocument8 pagesFLOWTEK - Ficha Tecnica-ComprimidoJosé BrionesNo ratings yet

- Fire Pumps 9100 SeriesDocument2 pagesFire Pumps 9100 SeriesBiggie ColdAngelNo ratings yet

- Two Orifice Float Trap: DescriptionDocument4 pagesTwo Orifice Float Trap: DescriptionHiranthaNo ratings yet

- Check Ranurado RH84X MechDocument1 pageCheck Ranurado RH84X MechFLOW INDUSTRIAL SACNo ratings yet

- Plummech Check ValvesDocument1 pagePlummech Check ValvesNguyễn Đăng PhúcNo ratings yet

- Ficha Tecnica Valvula Cortina Ranurada OSYDocument1 pageFicha Tecnica Valvula Cortina Ranurada OSYrobinson18e2No ratings yet

- Hidrante Humedo Fivalco FV-WBH-2H1PDocument1 pageHidrante Humedo Fivalco FV-WBH-2H1PCesar RomeroNo ratings yet

- Norm Teknik 3sv Ac Fire PumpDocument18 pagesNorm Teknik 3sv Ac Fire PumpdinduntobzNo ratings yet

- 2-pc. Screwed End Ball Valve THB Series, Type AV02-121Document3 pages2-pc. Screwed End Ball Valve THB Series, Type AV02-121FCNo ratings yet

- Ball Valve Full PortDocument2 pagesBall Valve Full PortHardik ShahNo ratings yet

- Assembly Part Number Example: 4 in (100 MM), Group 1Document2 pagesAssembly Part Number Example: 4 in (100 MM), Group 1RICHARDNo ratings yet

- Series 45116 Flanged Globe ValveDocument4 pagesSeries 45116 Flanged Globe ValveRahesh MNo ratings yet

- Wafer Butterfly Valve With Tamper Switch (Xd371X), Ul/Fm/Vds Approved Lugged Wafer Butterfly Valve With Tamper Switch (Xd371Xl), Ul/Fm/Vds ApprovedDocument1 pageWafer Butterfly Valve With Tamper Switch (Xd371X), Ul/Fm/Vds Approved Lugged Wafer Butterfly Valve With Tamper Switch (Xd371Xl), Ul/Fm/Vds Approvedtaaj77No ratings yet

- Acpump Fire Serie8100Document2 pagesAcpump Fire Serie8100Anonymous YmXY1bcNo ratings yet

- Butterfly ValvesDocument27 pagesButterfly ValvesИгорь100% (1)

- Fig 4930G 5930G 4930BS Hattersley DS 1219 P36Document1 pageFig 4930G 5930G 4930BS Hattersley DS 1219 P36Prithvi DhakalNo ratings yet

- Optional Fire Safe, API 607 4th Edition Certified: 1 Piece Reduced Port Ball Valves: / "-2"Document2 pagesOptional Fire Safe, API 607 4th Edition Certified: 1 Piece Reduced Port Ball Valves: / "-2"Oscar Horta PolaniaNo ratings yet

- VALVESDocument5 pagesVALVESCastro AnochNo ratings yet

- I2K Ice Maker Box With Nails: Submittal SpecificationDocument2 pagesI2K Ice Maker Box With Nails: Submittal SpecificationPatricio FerradaNo ratings yet

- Model: Heavy Duty Knife Gate ValveDocument10 pagesModel: Heavy Duty Knife Gate Valveviki851No ratings yet

- Forged High Pressure Ball Valves: SBVF360 SeriesDocument4 pagesForged High Pressure Ball Valves: SBVF360 SeriesToty DzNo ratings yet

- Valvula Mariposa FlowsealDocument12 pagesValvula Mariposa Flowsealsakura_jNo ratings yet

- AWWA C-504: Model 3900F & Model 3900MDocument2 pagesAWWA C-504: Model 3900F & Model 3900MPriyanka rajpurohitNo ratings yet

- Valvula AgulhaDocument14 pagesValvula Agulhafagundds2No ratings yet

- Model: Wafer Style Knife Gate ValveDocument16 pagesModel: Wafer Style Knife Gate ValveMohamed RaafatNo ratings yet

- Valvulas Apollo GLPDocument4 pagesValvulas Apollo GLPJuan Carlos Pardo RimachiNo ratings yet

- Howell H61 3pc SanitaryDocument3 pagesHowell H61 3pc SanitaryyahsooyNo ratings yet

- Mget3-Ej-0231-Sci-G00-Mec-Fic-331 Filtro en y 3-6 inDocument3 pagesMget3-Ej-0231-Sci-G00-Mec-Fic-331 Filtro en y 3-6 inAna GranadosNo ratings yet

- Model: Heavy Duty Knife Gate ValveDocument10 pagesModel: Heavy Duty Knife Gate ValveCristhian Niño MartinezNo ratings yet

- AES BallvalvespecsDocument3 pagesAES Ballvalvespecsclaudio godinezNo ratings yet

- Malwaukee - F2885MRWDocument1 pageMalwaukee - F2885MRWSoojaelimNo ratings yet

- Gate Valves - Class 1500 - A105N - LRF PDFDocument1 pageGate Valves - Class 1500 - A105N - LRF PDFismailNo ratings yet

- F-2306 - S19 - 2015-09 Flow TekDocument8 pagesF-2306 - S19 - 2015-09 Flow Tekel ronisNo ratings yet

- B-1050 Resilient-Valves 2020 08 21 5Document4 pagesB-1050 Resilient-Valves 2020 08 21 5satphoenixNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Old POPPET 2000Document8 pagesOld POPPET 2000kicsnerNo ratings yet

- Compact Solenoid Valve - General Purpose: Threaded Port 1/8"-1/4" NPT and Sub-BaseDocument4 pagesCompact Solenoid Valve - General Purpose: Threaded Port 1/8"-1/4" NPT and Sub-BasekicsnerNo ratings yet

- Gas Handling Equipment - PRAXAIRDocument1 pageGas Handling Equipment - PRAXAIRkicsnerNo ratings yet

- DS2006 Classic Eu enDocument5 pagesDS2006 Classic Eu enkicsnerNo ratings yet

- Direct Mounting Pilot Valves: For Process Actuation Banjo ValvesDocument4 pagesDirect Mounting Pilot Valves: For Process Actuation Banjo ValveskicsnerNo ratings yet

- Burkert 454 641 BDocument8 pagesBurkert 454 641 BkicsnerNo ratings yet

- GaspressDocument8 pagesGaspresskicsnerNo ratings yet

- cscrv-0404 Hp500seriesDocument2 pagescscrv-0404 Hp500serieskicsnerNo ratings yet

- Timer DrainDocument4 pagesTimer DrainkicsnerNo ratings yet

- Hydronic and SteamDocument40 pagesHydronic and SteamkicsnerNo ratings yet

- DS2002 3 2way EU ENDocument4 pagesDS2002 3 2way EU ENkicsnerNo ratings yet

- BurkertDocument8 pagesBurkertkicsnerNo ratings yet

- Asco Install - TroubleshootingDocument8 pagesAsco Install - TroubleshootingkicsnerNo ratings yet

- Next Gen 8320 ValvesDocument4 pagesNext Gen 8320 ValveskicsnerNo ratings yet

- ASCO CatalogDocument16 pagesASCO CatalogkicsnerNo ratings yet

- Flange Y-StrainnerDocument12 pagesFlange Y-StrainnerkicsnerNo ratings yet

- 8551 Stainless SteelDocument2 pages8551 Stainless SteelkicsnerNo ratings yet

- Sprinkler SystemDocument40 pagesSprinkler SystemkicsnerNo ratings yet

- Inline Check ValveDocument12 pagesInline Check ValvekicsnerNo ratings yet

- Av11 Av13airventsDocument1 pageAv11 Av13airventskicsnerNo ratings yet

- Iron Gate and Globe ValveDocument16 pagesIron Gate and Globe ValvekicsnerNo ratings yet

- Mixing ValveDocument20 pagesMixing ValvekicsnerNo ratings yet

- Ball ValvesDocument12 pagesBall ValveskicsnerNo ratings yet

- Water Presure Reducing ValveDocument16 pagesWater Presure Reducing ValvekicsnerNo ratings yet

- Safety Relief ValveDocument52 pagesSafety Relief ValvekicsnerNo ratings yet

- TS - 19series SafetyDocument4 pagesTS - 19series SafetykicsnerNo ratings yet

- Top Entry Ball ValvesDocument32 pagesTop Entry Ball ValveskicsnerNo ratings yet

- Commercial ProductsDocument198 pagesCommercial ProductskicsnerNo ratings yet

- ActuatorDocument48 pagesActuatorkicsnerNo ratings yet

- Instruments Valve ManifoldDocument7 pagesInstruments Valve ManifoldkicsnerNo ratings yet

- Pairsof Angles LinesDocument16 pagesPairsof Angles LinesSero ArtsNo ratings yet

- ASME Section V Art 2 SpanishDocument8 pagesASME Section V Art 2 SpanishScribdTranslationsNo ratings yet

- The Engineering Mathematics For ENGINEERS PDFDocument2 pagesThe Engineering Mathematics For ENGINEERS PDFSidhu0017No ratings yet

- VS2 Series Opposed-Mode SensorsDocument4 pagesVS2 Series Opposed-Mode SensorsWilmer Yesid Granados JaimesNo ratings yet

- EarthingDocument6 pagesEarthingRelay ProtectionNo ratings yet

- ABB Thermal Overload RelaysDocument6 pagesABB Thermal Overload RelaysNicolaos MavrogenisNo ratings yet

- 4.1.2 Moments: Name: - Class: - DateDocument4 pages4.1.2 Moments: Name: - Class: - DateTikTok ProductionsNo ratings yet

- Arduino-Based Alcohol SprayerDocument4 pagesArduino-Based Alcohol SprayerJP AmarantoNo ratings yet

- AD 23NLB SpecSheet - ZoFQ4BlTV4Document2 pagesAD 23NLB SpecSheet - ZoFQ4BlTV4Norman MendozaNo ratings yet

- RELATION BETWEEN FIRING ANGLE OF THREE-PHASE RectifierDocument7 pagesRELATION BETWEEN FIRING ANGLE OF THREE-PHASE Rectifier01666754614No ratings yet

- 3 Digit SeriesDocument5 pages3 Digit Seriesharshileng3992No ratings yet

- MCQ Unit 2 PhysicsDocument18 pagesMCQ Unit 2 PhysicsJAGANATHNo ratings yet

- NCERT Rationalised Content Vs Updated Syllabus of NEET-2024 - PhysicsDocument1 pageNCERT Rationalised Content Vs Updated Syllabus of NEET-2024 - PhysicsAnanya Praveen0% (1)

- Review Report of Blast Resistant Properties of Composite Structures in Naval Vessels.Document125 pagesReview Report of Blast Resistant Properties of Composite Structures in Naval Vessels.Ali HassanNo ratings yet

- Vulcraft Joist Girders Product Catalog B13281Document161 pagesVulcraft Joist Girders Product Catalog B13281joseNo ratings yet

- Advanced Particle Physics - Volume I - Boyarkin PDFDocument628 pagesAdvanced Particle Physics - Volume I - Boyarkin PDFFRANCISCO2003360602No ratings yet

- Saudi Arabian Oil Company: DA-727741 003 P 0D3 K06 RestrictedDocument1 pageSaudi Arabian Oil Company: DA-727741 003 P 0D3 K06 RestrictedWaqarNo ratings yet

- Science 8 Phase Change SLG 1Document32 pagesScience 8 Phase Change SLG 1JillianNo ratings yet

- Water Splitting by Nanocrystalline TiO2 in A Complete Photoelectrochemical Cell Exhibits Efficiencies Limited by Charge RecombinationDocument7 pagesWater Splitting by Nanocrystalline TiO2 in A Complete Photoelectrochemical Cell Exhibits Efficiencies Limited by Charge RecombinationJoe ValerioNo ratings yet

- High Temperature Epoxy Tooling Board: Trelleborg Applied TechnologiesDocument3 pagesHigh Temperature Epoxy Tooling Board: Trelleborg Applied TechnologiesMert KıraçNo ratings yet

- Archiman Lahiry IEEE Internet of Things Journal Paper PublicationDocument16 pagesArchiman Lahiry IEEE Internet of Things Journal Paper PublicationArchiman LahiryNo ratings yet

- LED Light RepairingDocument11 pagesLED Light RepairingDeepanwita SarNo ratings yet

- Return-Wo 471 20nov2021Document12 pagesReturn-Wo 471 20nov2021gigopulikkottilNo ratings yet

- MYP5 Deductive Geometry (Sheet 3)Document20 pagesMYP5 Deductive Geometry (Sheet 3)Mohammad AliNo ratings yet

- Vector Analysis: 7e Applied EM by Ulaby and RavaioliDocument40 pagesVector Analysis: 7e Applied EM by Ulaby and RavaioliMunie RosnanNo ratings yet

- MilitaryArchitectureinEnglandDuringtheMiddleAges 10061529Document417 pagesMilitaryArchitectureinEnglandDuringtheMiddleAges 10061529jurebieNo ratings yet

- Interpretation of Gas-In-Oil Analysis Using New IEC Publication 60599 and IEC TC 10 DatabasesDocument11 pagesInterpretation of Gas-In-Oil Analysis Using New IEC Publication 60599 and IEC TC 10 DatabasesSergio OrtegaNo ratings yet

- 630 enDocument20 pages630 enAvishay TufikianNo ratings yet

- 3 Module 1 PDFDocument2 pages3 Module 1 PDFAnna KallivayalilNo ratings yet