Professional Documents

Culture Documents

Practical 3 Design of Spur Gear and Gear Box

Uploaded by

Fa CaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Practical 3 Design of Spur Gear and Gear Box

Uploaded by

Fa CaCopyright:

Available Formats

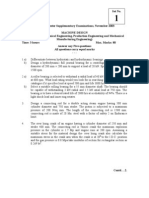

GUJARAT TECHNOLOGICAL UNIVERSITY

Bachelor of Engineering

Subject Code: 3171917

DESIGN OF MACHINE ELEMENTS

B.E. 7thSEMESTER

w.e.f. AY 2018-19

Practical 3: Design Spur gear and Gear Box

1. A 15 kW and 1200 rpm. motor drives a compressor at 300 rpm. through a pair of spur

gears having 20° stub teeth. The centre-to-centre distance between the shafts is 400

mm. The motor pinion is made of forged steel having an allowable static stress as 210

MPa, while the gear is made of cast steel having allowable static stress as 140 MPa.

Assuming that the drive operates 8 to 10 hours per day under light shock conditions,

find from the standpoint of strength,

1. Module; 2. Face width and 3. Number of teeth and pitch circle diameter of each

gear.

Check the gears thus designed from the consideration of wear. The surface endurance

limit may be taken as 700 MPa.

Assignment:

1. Design a three stage, 18 step, speed gear box with n min=16 and ф=1.26 is

powered by a 7.5 kW motor running at 1440 rpm. Draw the structural diagram

and speed chart of the speed gear box.

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Car Engine Parts GuideDocument20 pagesCar Engine Parts GuideHealth Club100% (2)

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Unit 2Document1 pageUnit 2Dhileepan KumarasamyNo ratings yet

- NR 320301 Machine DesignDocument8 pagesNR 320301 Machine DesignSrinivasa Rao GNo ratings yet

- DMM-III Assignment TestDocument2 pagesDMM-III Assignment TestSaibabu SoloNo ratings yet

- Sheet (2) Belt Drive: Standard)Document2 pagesSheet (2) Belt Drive: Standard)AmrAliNo ratings yet

- Soal Ujian Elemen Mesin I 2021 - 2022Document1 pageSoal Ujian Elemen Mesin I 2021 - 2022Asri imanuel BareduNo ratings yet

- Tutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentDocument12 pagesTutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentSURYA S96No ratings yet

- Me 8651Document10 pagesMe 8651selvam cNo ratings yet

- MM N S MM N SDocument4 pagesMM N S MM N SAnchita Singh RajawatNo ratings yet

- Dts Important Ques 2 16 MarksDocument5 pagesDts Important Ques 2 16 MarksBas RamuNo ratings yet

- ED7204-Integrated Mechanical Design QBDocument7 pagesED7204-Integrated Mechanical Design QBBakkiya RajNo ratings yet

- Final Design Work SheetDocument7 pagesFinal Design Work SheetKINDUNo ratings yet

- SRM Valliammai Engineering College Question Bank on Design of Transmission SystemsDocument23 pagesSRM Valliammai Engineering College Question Bank on Design of Transmission SystemsVenkadesh Arumugam (Esaikaathalan)No ratings yet

- ME6601.16 MarksDocument6 pagesME6601.16 Markssathiskumar411No ratings yet

- Sheet 1 Spur GearsDocument2 pagesSheet 1 Spur Gearsمحمود بسيوني نصارNo ratings yet

- Assignment MD IIDocument6 pagesAssignment MD IIRupali PatilNo ratings yet

- ME 331 - DESIGN OF MACHINE ELEMENTS EXAMDocument5 pagesME 331 - DESIGN OF MACHINE ELEMENTS EXAMarumugam_rNo ratings yet

- Tutorial MD II 2015 1Document1 pageTutorial MD II 2015 1rip111176No ratings yet

- 01 Helical Gear ONLY ProblemsDocument2 pages01 Helical Gear ONLY Problemskamal0% (1)

- ME6601 QbsdfwsdfsDocument8 pagesME6601 QbsdfwsdfsvivekzzNo ratings yet

- Me 1352Document6 pagesMe 1352arunramakrishnanNo ratings yet

- Imp Qoestions MDDocument3 pagesImp Qoestions MDvenuedNo ratings yet

- Tutorial MD II 2015 1Document2 pagesTutorial MD II 2015 1rip111176No ratings yet

- Dme 2Document6 pagesDme 2NITHISH KUMAR M SNo ratings yet

- Me 2352 - DTS Q BankDocument5 pagesMe 2352 - DTS Q Bankpaul_jaikumarm27530% (1)

- Case Study and Stress Analysis of A 3Document12 pagesCase Study and Stress Analysis of A 3Talha MemonNo ratings yet

- 04 Different Assignments Based - Spur Gear BasicsDocument5 pages04 Different Assignments Based - Spur Gear BasicssusheelgadaleyNo ratings yet

- Tutorial Sheet No 1 On Spur GearDocument3 pagesTutorial Sheet No 1 On Spur GearChirayuNo ratings yet

- 12 Me 5dcdm2Document3 pages12 Me 5dcdm2Abhyudaya SinghNo ratings yet

- DtsDocument11 pagesDtsSridiwakaran ParameswaranNo ratings yet

- Design of Mechanical Drives: B.E. (Mechanical Engineering / Power Engineering) Seventh Semester (CBS)Document3 pagesDesign of Mechanical Drives: B.E. (Mechanical Engineering / Power Engineering) Seventh Semester (CBS)Komal HingeNo ratings yet

- Machine Design Answer KeyDocument16 pagesMachine Design Answer KeyK.KESAVARAJ HICET STAFF MCTSNo ratings yet

- Me0405 7 SemDocument2 pagesMe0405 7 SemSurya BalamuruganNo ratings yet

- Designn of Tranmission SystemDocument4 pagesDesignn of Tranmission Systemsathiskumar411No ratings yet

- ME6601 Transmission Design QuestionsDocument11 pagesME6601 Transmission Design QuestionsMURUGANNo ratings yet

- Projects For Lab BDocument91 pagesProjects For Lab BPeter AshrafNo ratings yet

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDocument2 pages2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusNo ratings yet

- Design problem solutionsDocument10 pagesDesign problem solutionsCHAKRINo ratings yet

- Unit VDocument32 pagesUnit Vrahulmeenameenarahul26No ratings yet

- Fabrication of Special Purpose Machine: R Kumar, Hemanth Kumar J, Chethan KumarDocument4 pagesFabrication of Special Purpose Machine: R Kumar, Hemanth Kumar J, Chethan KumarMikyas BelayNo ratings yet

- MD II Machine Design AssignmentsDocument5 pagesMD II Machine Design Assignmentsrishabhk28995No ratings yet

- ME2352 Design of Transmission Question BankDocument4 pagesME2352 Design of Transmission Question BankKarthik SubramaniNo ratings yet

- 2012 An Axial-Flux Permanent Magnet (AFPM) Generator For Defence Applications - Paradigm Shift in Electrical Machine (Cored Rotor and Stator) PDFDocument5 pages2012 An Axial-Flux Permanent Magnet (AFPM) Generator For Defence Applications - Paradigm Shift in Electrical Machine (Cored Rotor and Stator) PDFFazal Karim MahsudNo ratings yet

- 0326 Me 2303 Design of Machine ElementsDocument3 pages0326 Me 2303 Design of Machine ElementsSaravanan MathiNo ratings yet

- Design spur gears transmit powerDocument3 pagesDesign spur gears transmit powerMohammed YunusNo ratings yet

- 3 Mech Me8594 Dom QBDocument29 pages3 Mech Me8594 Dom QBSurya SNo ratings yet

- A Low-Speed, High-Torque, Direct-Drive Permanent Magnet Generator For Wind TurbineDocument8 pagesA Low-Speed, High-Torque, Direct-Drive Permanent Magnet Generator For Wind TurbineHelicon1No ratings yet

- TutorialDocument1 pageTutorialAtul GaurNo ratings yet

- MODEL QUESTION PAPER Mechanical VibrationsDocument3 pagesMODEL QUESTION PAPER Mechanical VibrationsDarani PriyaNo ratings yet

- Design of Transmission ElementDocument42 pagesDesign of Transmission ElementVenkatesh MohanNo ratings yet

- DMD PDFDocument14 pagesDMD PDFAstik ThombareNo ratings yet

- Assignment 1 (Unit 1 and 2)Document5 pagesAssignment 1 (Unit 1 and 2)Atharva ChoudhariNo ratings yet

- Tutorial 4 – Spur Gears 5MEC312 Design of Machine Elements III (1)Document1 pageTutorial 4 – Spur Gears 5MEC312 Design of Machine Elements III (1)Gcwalisile DlaminiNo ratings yet

- ME3201 Tutorial4Document1 pageME3201 Tutorial4Nachiket Dev me18b017No ratings yet

- Final Exam MCT3214 Nov09Document6 pagesFinal Exam MCT3214 Nov09Deerah Aziz100% (1)

- Dts Model Que Type B 2018-19Document2 pagesDts Model Que Type B 2018-19rammit2007No ratings yet

- Dom 3151911Document3 pagesDom 3151911Bhagirathsinh ZalaNo ratings yet

- Assignment 1 Steady State Heat Conduction 2Document2 pagesAssignment 1 Steady State Heat Conduction 2Fa CaNo ratings yet

- Operation Research Subject GuideDocument3 pagesOperation Research Subject GuideFa CaNo ratings yet

- HSDE - Requirements of C.C-1Document39 pagesHSDE - Requirements of C.C-1Fa CaNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19Fa CaNo ratings yet

- Practical 2 Design of Helical and Leaf SpringsDocument2 pagesPractical 2 Design of Helical and Leaf SpringsFa CaNo ratings yet

- Engine Performance Parameters GuideDocument16 pagesEngine Performance Parameters GuideFa CaNo ratings yet

- MFA AssignmentsDocument1 pageMFA AssignmentsFa CaNo ratings yet

- Design of Pressure Vessels and Hydraulic CylindersDocument1 pageDesign of Pressure Vessels and Hydraulic CylindersFa CaNo ratings yet

- Guideline For Evaluation - Internship (3181901)Document3 pagesGuideline For Evaluation - Internship (3181901)Fa CaNo ratings yet

- Gujarat Technological University: Page 1 of 3Document3 pagesGujarat Technological University: Page 1 of 3Fa CaNo ratings yet

- Sr. No. Practical 1: Static and Dynamic Balancing of Rotating MassesDocument21 pagesSr. No. Practical 1: Static and Dynamic Balancing of Rotating MassesFa CaNo ratings yet

- Ppe Assignment 3171910Document1 pagePpe Assignment 3171910Fa CaNo ratings yet

- OR TutorialsDocument8 pagesOR TutorialsFa CaNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document2 pagesGujarat Technological University: W.E.F. AY 2018-19Fa CaNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityKSghNo ratings yet

- Gujarat Technological University: Page 1 of 3Document3 pagesGujarat Technological University: Page 1 of 3Fa CaNo ratings yet