Professional Documents

Culture Documents

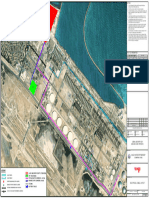

4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 (2) - 16-05-2021

Uploaded by

AlihassanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 (2) - 16-05-2021

Uploaded by

AlihassanCopyright:

Available Formats

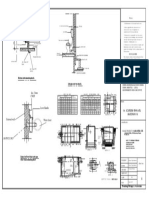

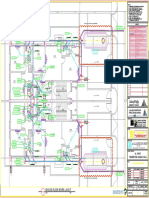

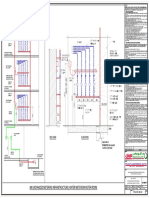

NOTES:

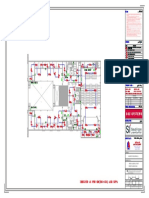

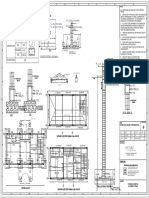

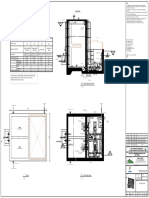

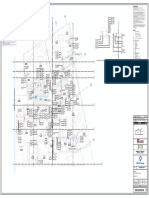

1. Water meters, 50mm dia. and greater sizes shall be installed horizontally inside the meter chambers as shown in standard

GENERAL ARRANGEMENT OF METER CHAMBERS WITHIN BLOCKPAVING AREAS installation drawing PEW-STD-AMI-004. These meters shall be installed in concrete waterproof chambers in the same level

of mainline or raised to ground level as per the site condition to avoid ground water flooding inside the meter chamber.

2. Bulk meter 50mm dia. and greater sizes should not be installed in the basement, pump room, meter room, upper floors or roof

of the buildings under any circumstances.

3. Water meter location and its access should be free from any obstruction such as signboards, barriers, plants& gardens etc. and

minimum 2 mtr. Clearance away from any electrical services.

4. Meter installation guidelines shall strictly be followed while installing the meter.

VARIES

5. Meter should not be allowed to fall or receive impact damage during installation.

100 100

100 200 VARIES 200 100 6. Meter shall be installed in accordance with the arrows shown on the body of the meter.

CONCRETE/BRICK CEMENT SCREED OVER EXTERIOR BLOCK WORK SURFACES 7. Meter register shall be arranged to read the meter easily from outside the chamber.

SUPPORT FOR BOTH

200 100 100

150X150X100MM

IP68 PVC JB VALVES 8. Pipes, valves and all other fittings used for meter connection shall be high quality, heavy duty, non-toxic, non-corrosive

material. All nuts & bolts shall be stainless steel 316L.

2 NO.S 25mmØ CPVC CONDUIT

FOR COMMUNICATION 9. Installation of T joints, bends etc. immediately before or after the meter should be avoided.

HDPE BOX 200X200X200 RECESSED 10. The meter should always be full of water to avoid air flow through the meter, a 90 deg. bend raised upwards shall be

IN INTERLOCK PAVED AREA installed after meter to connect it to customer pipeline, as required.

TO LV/ELECTRICAL ROOM 900

11. Proper Concrete Support shall be provided for the Valves, Strainer, Pipes and fittings inside the meter chamber in order to

THRUST BLOCK FOR ELBOW avoid any displacement of meter and associated fittings. Water Meter and Strainer body, flanges or any other part should not

90° ELBOW SMART

NON RETURN VALVE be covered by concrete.

WATER METER GRE ELBOW 90° TO

DOUBLE FLANGED

G F A RISE OUTLET PIPE

BOTH SIDES F G 300 12. Do not step on the meter while installation, reading or maintenance of the meter.

300 (DOUBLE FLANGED)

A *

VARIES

13. All connections shall be checked thoroughly for leak after installation of the meter.

M 14. Do not attempt to correct problems by hitting the body of the meter.

TO CONSUMER

STORAGE TANK 15. Never try to adjust the meter position after tightening the bolts.

B B 16. Pipeline shall be flushed thoroughly before the installation of the meter.

FLOW OF WATER

CONSUMER SIDE VALVE

SPIGOT FLANG (FOR MAINTENANCE PURPOSE) 17. A Strainer shall be fitted downstream the meter to avoid entry of debris into customer pipelines and reservoir.

ADAPTOR

18. Full-bore valves shall be fitted upstream & downstream to isolate the meter for maintenance.

THRUST BLOCK G F B C D E F G

200

FOR ELBOW CLASS 20/10/S SOLID CONCRETE BLOCKWORK WALLS 19. Consumer shall install a separate valve outside the meter chamber on their pipeline to isolate water supply for any

VARIES

maintenance works.

WALL 20. A Non-Return Valve (NRV) shall be installed outside the meter chamber on customer pipeline to restrict reverse flow of water from customer storage

GRE SPOOL

DOUBLE FLANGED Note: Size of the pipeline connected after the meter should be the same size of the meter until it tank to Dewa water network/meter.

100

DOUBLE FLANGED

BURIED

10MM NEOPRENE

MEMBRANS 2 GATE VALVE SUMP PIT reaches to the Consumer Tank.

GATE VALVE 300x300x150mm 21. Installation of water booster pump upstream or downstream the meter is prohibited, any violations will be penalized as

LAYERS SLIP AND per the applicable laws.

DOUBLE FLANGED STRAINER

MASTIC SEALANT CLASS 20/10/S SOLID CONCRETE

AS SPECIFIED BLOCKWORK SUPPORT WITH 22. Consumers can install water pumps after their storage tank, if required.

GRP LADDER CEMENT MORTAR 1:3

SOCKET 23. Ensure the construction/installation of meter chamber including the chamber cover is completed before installing the

GATE VALVE meter to avoid damage to the meter.

DOUBLE FLANGED STRAINER SPIGOT FLANGE ADAPTOR

24. Detailed shop drawing shall be submitted for DEWA approval before commencement of work.

GRE SPIGOT

SOCKET ELECTRO

FLANG ADAPTOR GATE VALVE GUIDELINES FOR BULK WATER METER CHAMBERS

MAGNETIC WATER

METER DOUBLE FLANGED

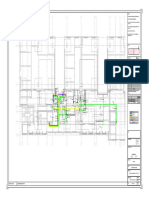

1. The meter shall be installed in a chamber (meter shall not be buried) suitable in size for fitting in, maintenance and removal of

GRE 'T' TWO SIDE MAIN LINE the meter.

SPIGOT ONE SIDE

FLANGED

VALVE AND FLOW METER ARRANGEMENT 2. The meter chamber, precast HDPE or Concrete, shall be waterproof, clear of obstacles, even, rigid and not slippery. There shall

be a sump pit inside chamber for draining water.

PLAN 3. A non-corrosive/GRE ladder shall be provided permanently in chambers deeper than 1mtr for easy access to the meter.

4. Ladder shall be installed away from the meter to provide sufficient space for water meters to permit installation, reading,

M.S.CHEQURED PLATE COVER servicing and removal of the meters.

CEMENT MORTAR(1:3) BEDDING 5. Meter chamber shall be protected from getting buried by sand, rainwater, flooding and barricaded to avoid parking vehicles on

TO BLOCKPAVING the chamber.

LIFTING HOOKS TO BE SEALED 10 THK.CEMENT MORTAR (1:3) SEATING

WITH CEMENT MORTAR (1:3) FOR MANHOLE COVER 6. The flange or body of the meter, strainer and valve should not be covered by concrete while constructing the chamber.

AFTER PLACING

7. Nut & Bolt shall be positioned in such a way that Nut on wall/concrete block side and Bolt on Meter/Valve side for easy

HDPE BOX 200x200x200 tightening and removal of the same.

CLASS 30/20/S PRECAST CONCRETE 8. A 25mm dia. heavy duty conduit shall be laid between Water Meter Chamber and LV room for Meter communication cable.

BLOCKPAVING LEVEL

COVER SLAB

9. The conduit shall be GI if routed along walls/ceilings leading to LV room or CPVC (with wall thickness of 2.8mm) if laid

underground in sand or concealed in concrete/block walls. In any case, while entering the LV room, the conduit shall be

changed to GI at a minimum of 2m distance before entering LV room.

10. A two way junction box of appropriate material shall be provided at every 25m length and each corner (direction change)

of the conduit with metallic pulling spring for cable pulling purpose. In case of underground conduit, a concrete pit of

dimension 200X200X150mm shall be provided to accommodate the two way Junction box. The connection of conduit to

Ø12 @ 200 BOTH WAY TOP&BOTTOM Junction box shall be done with proper couplings/adaptors.

PVC CONDUIT

50mm THK.CEMENT MORTAR (1:3) SEATING 11. A PVC Junction box of dimension 100X100X50mm and IP 68 rating shall be provided inside Meter Chamber and fitted

25MM CPVC CONDUIT FOR PRECAST CONCRETE COVER SLAB CONSUMER SIDE VALVE with a PVC PG-7 gland.

TO LV ROOM FOR METER NON RETURN VALVE (FOR MAINTENANCE PURPOSE)

WATER PROOFING MEMBRANE 150X150X100MM

COMMUNICATION 15mm THICK PLASTERING

AND PROTECTION BOARD IP68 PVC JB 12. A HDPE box of dimension 200X200X150mm shall be recessed on the floor near Meter Chamber and connected to the

AS SPECIFIED FINISHED SMOOTH Junction box inside Chamber through a separate 25mm CPVC conduit with proper couplings/adaptors as shown in the

VARIES

drawing.

CLASS 20/10/S SOLID

CONCRETE BLOCKWORK WALLS STRAINER

TO CONSUMER 13. A GI Junction box of dimension 150X150X50mm and IP 56 rating shall be installed inside the LV room on wall at a

SEE NOTE NO.11 WATER METER POINTING INSIDE STORAGE TANK suitable position at a height of 1600mm from finished floor level. The connection between conduit and Junction box shall be

BOTH SIDES * through suitable couplings/adaptors.

300 300

14. A HDPE box of dimension 200x200x150mm shall be recessed on the interlock paved floor near meter chamber and

connected to the JB inside chamber through 25mm CPVC conduit with proper couplings/adaptors. Interlock tiles shall be

THRUST BLOCK FOR ELBOW

VARIES

paved on the surface area (Min. 1000mm width) around the meter chamber.

FLOW OF

GRE ELBOW 90° TO RISE

WATER 15. Meter chamber cover shall be of GRP material so that wireless/radio signals can get through for meter communication.

300

OUTLET PIPE

DOUBLE FLANGED

16. Meter chamber cover shall be clearly and indelibly marked with DEWA logo and the wording 'Water Meter' on the cover in

PROTECTIVE SCREED

200

GRE SPIGOT Arabic and English language.

FLANG ADAPTOR

50

CLASS 20/20/S CONCRETE BLINDING 17. DEWA Account No. plate shall be affixed inside the meter chamber wall for identification.

75

CONCRETE SUPPORT BELOW WATER PROOFING MEMBRANE The inlet valve and pipe before the meter shall be directly buried with a 150mm dia. ductile iron cover to the inlet valve, and

GAP BETWEEN BLOCKWORK

AND PIPE TO BE STRAINER WITH meter, strainer, outlet valve and associated pipes & fittings shall be inside the chamber for 200mm dia. and greater size

RUBBER PACKING CLASS 30/20/S RC BOTTOM SLAB meters

SEALED AS SPECIFIED

2 LAYERS SLIP MEMBRANE BETWEEN CONCRETE/BRICK SUPPORT 18. DEWA is responsible for the supply and installation of water meters, strainers and valves for new connections. Meters are

Ø12 @ 200 SUPPORT AND CHAMBER FLOOR installed either by DEWA staff or Contractors acting on behalf of DEWA. Customers and property developers are responsible

FOR BOTH VALVES WITH

BOTH WAY

RUBBER PACKING for supply and installation of all ancillary fittings and pipe-work after the meter and connecting the supply from the meter to

TOP & BOTTOM

their pipe connections/storage tank in accordance with relevant DEWA specifications and standard drawings.

19. Meter sizes, minimum and maximum size of the pipe in accordance with size of the meter required for meter installation,

SECTION 'A-A' quantity of water each size of meter can deliver in 24 hours and capacity of storage tank required for each type of premises

are as shown.

CEMENT MORTAR(1:3) BEDDING M.S.CHEQURED PLATE COVER M.S.CHEQURED PLATE COVER

TO BLOCKPAVING

10 THK.CEMENT MORTAR (1:3) SEATING 10 THK.CEMENT MORTAR (1:3) SEATING

FOR MANHOLE COVER FOR MANHOLE COVER

LIFTING HOOKS TO BE SEALED

WITH CEMENT MORTAR (1:3) CHAMBER COVER FRAME TO BE BOLTED CHAMBER COVER FRAME TO BE BOLTED

AFTER PLACING TO THE PRECAST CONCRETE COVER SLAB TO THE PRECAST CONCRETE COVER SLAB

BLOCKPAVING LEVEL CLASS 30/20/S PRECAST CONCRETE BLOCKPAVING LEVEL CLASS 30/20/S PRECAST CONCRETE

COVER SLAB COVER SLAB

4`Y' 12`L' SHAPPED

TRIMMER BARS TOP & BOTTOM

WATER PROOFING MEMBRANE Ø12 @ 200 Ø12 @ 200

BOTH WAY BOTH WAY

DUBAI ELECTRICITY & WATER AUTHORITY

AND PROTECTION BOARD 50mm THK.CEMENT MORTAR (1:3)

TOP&BOTTOM TOP&BOTTOM Y16 @ 200

AS SPECIFIED SEATING FOR PRECAST CONCRETE COVER SLAB

VARIES

VARIES

WATER PROOFING MEMBRANE

CLASS 20/10/S SOLID G.R.P LADDER AND PROTECTION BOARD P.O.BOX: 564, DUBAI - U.A.E., FAX :324 4922, TEL : 324 4444

15mm THICK PLASTERING FINISHED SMOOTH AS SPECIFIED Y12 @ 200

CONCRETE BLOCKWORK WALLS

SEE NOTE NO.11

POINTING INSIDE 30/20/S REINFORCED CONCRETE WALL

DOOR HINGES PROJECTS & ENGINEERING (WATER)

WATER STOPER

SUMP PIT 300x300x150mm

CONSTRUCTION JOINT `Y '12@150 c/c

BOTHWAYS TOP & BOTTOM

300 Slope 300 Slope

AMI (ADVANCED METERING INFRASTRUCTURE)

75 50 200

75 50 200

WATER METER INSTALLATION

300

300

PROTECTIVE SCREED

CLASS 20/20/S CONCRETE BLINDING CLASS 20/20/S CONCRETE BLINDING

GRP FITTING AS SPECIFIED WATER PROOFING MEMBRANE WATER PROOFING MEMBRANE 200MM DIA CIRCULAR CI STEEL CHAMBER COVER

COVER FOR VALVE AMI - WATER

CLASS 30/20/S RC BOTTOM SLAB

SECTION 'B-B' CLASS 30/20/S RC BOTTOM SLAB

Ø12 @ 200

SECTION 'B-B' BULK WATER METERS IN CHAMBER (FOR BULK

BOTH WAY

TOP & BOTTOM

2 LAYERS SLIP MEMBRANE

BETWEEN SUPPORT AND CHAMBER FLOOR

Ø12 @ 200

BOTH WAY

STEEL DETAIL IN CASE OF RCC WALL 2 LAYERS SLIP MEMBRANE

BETWEEN SUPPORT AND CHAMBER FLOOR

REINFORCEMENT DETAILS METERS 50MM TO 300MM DIA. CONNECTION)

TOP & BOTTOM

16.05.2021

AMI 2" to 12" BULK WATER METER INSTALLATION IN CHAMBER PEW-STD-AMI-004 2

You might also like

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Eng Peter Elevations and Roof Layouts PDFDocument1 pageEng Peter Elevations and Roof Layouts PDFRooney mutetiNo ratings yet

- R07 HC3D02 MML 00 XX DWG El 10801Document1 pageR07 HC3D02 MML 00 XX DWG El 10801Muhammad FaheemNo ratings yet

- Gerald NM BLACKDocument1 pageGerald NM BLACKgeraldnguma8No ratings yet

- M100Document1 pageM100Ahmed YaseenNo ratings yet

- R.C Wall Block Wall Vent Pipe Low Level CisternDocument1 pageR.C Wall Block Wall Vent Pipe Low Level CisternAmadi HenryNo ratings yet

- Electrical Work KeshoDocument1 pageElectrical Work Keshosngunjiri60No ratings yet

- Fire alarm system specification requirementsDocument1 pageFire alarm system specification requirementsAhmed KhalilNo ratings yet

- Basement 4 1:150: Lettabe Area Usable Decks & Terrace Common InfrastructureDocument12 pagesBasement 4 1:150: Lettabe Area Usable Decks & Terrace Common InfrastructureKay EMNo ratings yet

- Exist/ New Asphalt Road & Rig Road Crossing Details Table-1Document1 pageExist/ New Asphalt Road & Rig Road Crossing Details Table-1Er Md AamirNo ratings yet

- (0030) Salman Town Solar Project Solar SMDBDocument6 pages(0030) Salman Town Solar Project Solar SMDBSavio SunnyNo ratings yet

- KJ-WTS-1C0-PL-3005 - A - Typical Drain Station Shaft - Guide DrawingDocument6 pagesKJ-WTS-1C0-PL-3005 - A - Typical Drain Station Shaft - Guide DrawingAshraf AliNo ratings yet

- Pdch14-Gaj-Dwg-000-Xxx-Arc-31701-Pdf (T00) - Aluminium Louver Door Screen Typical DetailsDocument1 pagePdch14-Gaj-Dwg-000-Xxx-Arc-31701-Pdf (T00) - Aluminium Louver Door Screen Typical DetailsZaido Al HalabiNo ratings yet

- Substation LayoutDocument1 pageSubstation LayoutMohamedNo ratings yet

- FJS 1923000149Document1 pageFJS 1923000149SHAHZAD LATIFNo ratings yet

- 5213-Cec-Pl-Ma-4201 B3Document1 page5213-Cec-Pl-Ma-4201 B3Arun UdayabhanuNo ratings yet

- Moihq Abf b01 Arc SHD 2710 00Document1 pageMoihq Abf b01 Arc SHD 2710 00ayman ammarNo ratings yet

- G-126 - Lighting Control System Schematic Diagram PDFDocument1 pageG-126 - Lighting Control System Schematic Diagram PDFsyed ghufran HASSANNo ratings yet

- S-2 RDocument1 pageS-2 Rविवेक कुमारNo ratings yet

- Column construction detailsDocument1 pageColumn construction detailsSelvakumar SNo ratings yet

- Sewage pumping station design and layoutDocument1 pageSewage pumping station design and layoutwael72No ratings yet

- Northern Railway: Ircon International LTDDocument4 pagesNorthern Railway: Ircon International LTDRayees AhmadNo ratings yet

- 200M3 IGNITION OIL TANK 2 (R-03) - ModelDocument1 page200M3 IGNITION OIL TANK 2 (R-03) - Modelery achjariNo ratings yet

- 200M3 IGNITION OIL TANK3 (R-03) - ModelDocument1 page200M3 IGNITION OIL TANK3 (R-03) - Modelery achjariNo ratings yet

- Al Jafer GROUND FLOOR DRAINAGE SYSTEM (AS&US)Document1 pageAl Jafer GROUND FLOOR DRAINAGE SYSTEM (AS&US)atefNo ratings yet

- Alghanim International: General Trading & Contracting Co. LTDDocument1 pageAlghanim International: General Trading & Contracting Co. LTDahmadtaiyabiNo ratings yet

- Foundation Plan: Foundation Layout & Column Schedule (SHEET-1 OF 2) SAMATVA-E-DD-01-R0Document11 pagesFoundation Plan: Foundation Layout & Column Schedule (SHEET-1 OF 2) SAMATVA-E-DD-01-R0Parth K PatelNo ratings yet

- Fa 3RDDocument1 pageFa 3RDAhmed KhalilNo ratings yet

- Concrete Storage Tanks Rev 1 Structurals 171102-1Document9 pagesConcrete Storage Tanks Rev 1 Structurals 171102-1Chancedaniels EmunaNo ratings yet

- Colombo Residential Tower: Inclined Tower Level Unit B - Wall SectionDocument1 pageColombo Residential Tower: Inclined Tower Level Unit B - Wall SectionHirushan MenukaNo ratings yet

- 5th Floor Plan-Layout1Document1 page5th Floor Plan-Layout1yadvikram7No ratings yet

- Drawing 3.Document1 pageDrawing 3.tiyaniNo ratings yet

- 07 RmmuDocument7 pages07 RmmuveerendrareddyNo ratings yet

- Road "01" Profile: ROAD 01 C STATION 1+000.000 TO 1+500.000 LDocument1 pageRoad "01" Profile: ROAD 01 C STATION 1+000.000 TO 1+500.000 LtogireeshNo ratings yet

- General notes for construction drawingsDocument1 pageGeneral notes for construction drawingsmhazarath murariNo ratings yet

- Hs CD 23 00187-Landscpe Layout 2 of 4 - 946589Document1 pageHs CD 23 00187-Landscpe Layout 2 of 4 - 946589api-193778159No ratings yet

- Db68-03340a-05 Im Joint Eu en 240110-D05Document2 pagesDb68-03340a-05 Im Joint Eu en 240110-D05Made Aditya Jaya MahardikaNo ratings yet

- Tab Riy Me SD DR SFL 104aDocument1 pageTab Riy Me SD DR SFL 104aamostafacandpegNo ratings yet

- QP10 Q 2426 - TypicalSteelTank10,000m TopInlet Rev0Document1 pageQP10 Q 2426 - TypicalSteelTank10,000m TopInlet Rev0Nassif Abi AbdallahNo ratings yet

- M BD3 1F8000 Cutl Edr 000303Document1 pageM BD3 1F8000 Cutl Edr 000303ahmed.abdelmegeed78No ratings yet

- LS Fence 2Document1 pageLS Fence 2jimNo ratings yet

- Road E: Line Sd-1Document1 pageRoad E: Line Sd-1karem YousefNo ratings yet

- 01 Villa 03Document1 page01 Villa 03Rahman ArchitectNo ratings yet

- FS0654-DOD-XX-00-DR-P-4002 - Ground Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0Document1 pageFS0654-DOD-XX-00-DR-P-4002 - Ground Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0mvrisleyNo ratings yet

- FS0654-DOD-XX-00-DR-P-4001 - Ground Floor Domestic Water Services Sheet 1 of 2 - Construction - C01 - 0Document1 pageFS0654-DOD-XX-00-DR-P-4001 - Ground Floor Domestic Water Services Sheet 1 of 2 - Construction - C01 - 0mvrisleyNo ratings yet

- Adp-Ksa-Sol-Dwg-El-Td-Det-412 - Stair 1 DetailDocument1 pageAdp-Ksa-Sol-Dwg-El-Td-Det-412 - Stair 1 Detailekhaa.awal1No ratings yet

- 106 - E1.0-Electrical Site PlanDocument1 page106 - E1.0-Electrical Site PlanJosé Luis Falcon100% (1)

- Adp-Ksa-Sol-Dwg-El-Td-Det-411 - Railing DetailDocument1 pageAdp-Ksa-Sol-Dwg-El-Td-Det-411 - Railing Detailekhaa.awal1No ratings yet

- DrawingDocument1 pageDrawingahmedNo ratings yet

- Amc Ksa Gam DWG Me CD 5101Document1 pageAmc Ksa Gam DWG Me CD 5101Dan SarmientoNo ratings yet

- Jubail-4&6 ElecticalDocument1 pageJubail-4&6 Electicalnazih sedrakNo ratings yet

- Concrete Weir Structure Design and SpecificationsDocument1 pageConcrete Weir Structure Design and SpecificationssclbscplNo ratings yet

- Timboon Housing Estate PlansDocument17 pagesTimboon Housing Estate PlansKyra GillespieNo ratings yet

- 2021 09 20 Garden Mall-A10.04-Typical Details - ScreenDocument1 page2021 09 20 Garden Mall-A10.04-Typical Details - ScreenDan SarmientoNo ratings yet

- Notes:: Packaged Rooftop Units Schedule Split System Schedule (Heat Pump) Sand Trap Louver ScheduleDocument1 pageNotes:: Packaged Rooftop Units Schedule Split System Schedule (Heat Pump) Sand Trap Louver SchedulemohammedNo ratings yet

- Appendix 6 - Tile Location - REFERENCEDocument10 pagesAppendix 6 - Tile Location - REFERENCEJpbNo ratings yet

- LS Fence 1Document1 pageLS Fence 1jimNo ratings yet

- Manpower 15 Steel Fixers 15 Carpenters: Steel Work Fixing Steel at Retaining WallDocument2 pagesManpower 15 Steel Fixers 15 Carpenters: Steel Work Fixing Steel at Retaining WallHamza QudahNo ratings yet

- Restaurant Floor Plan (1st Floor)Document1 pageRestaurant Floor Plan (1st Floor)Ma. Isabel RodriguezNo ratings yet

- Linear Slot Diffusers 1Document13 pagesLinear Slot Diffusers 1AlihassanNo ratings yet

- Guidelines for installing and constructing water metersDocument1 pageGuidelines for installing and constructing water metersAlihassanNo ratings yet

- E20s HAP50 - Manual HAP PDFDocument144 pagesE20s HAP50 - Manual HAP PDFAnonymous XhkjXCxxsT100% (1)

- Calorequipos PDFDocument6 pagesCalorequipos PDFMaulana MaftuhiNo ratings yet

- Hvac Interview Faq & Answers: Impres S Wi TH Con Fi Den CeDocument13 pagesHvac Interview Faq & Answers: Impres S Wi TH Con Fi Den CeAlihassanNo ratings yet

- Upc 1 2021Document495 pagesUpc 1 2021Alihassan100% (2)

- MEP Drawings Legends and SymbolsDocument14 pagesMEP Drawings Legends and SymbolsMenchebelle Grace Talha Tabarno0% (1)

- Pump Room Future EngineersDocument26 pagesPump Room Future EngineersZain ShariffNo ratings yet

- Basic Fire Alarm TrainingDocument46 pagesBasic Fire Alarm Trainingsmahesh_1980No ratings yet

- 3a Domestic Water Meter Installation in Meter Room DrawingPEWSTDAMI003 PDFDocument1 page3a Domestic Water Meter Installation in Meter Room DrawingPEWSTDAMI003 PDFAlihassanNo ratings yet

- What Is HeadDocument8 pagesWhat Is HeadAsan IbrahimNo ratings yet

- Pressure Variation in Tunnels Sealed Trains PDFDocument258 pagesPressure Variation in Tunnels Sealed Trains PDFsivasankarNo ratings yet

- Drone Hexacopter IjisrtDocument4 pagesDrone Hexacopter IjisrtDEPARTEMEN RUDALNo ratings yet

- Is BN 9789526041957Document72 pagesIs BN 9789526041957supriya rakshitNo ratings yet

- Alfa Laval DecanterDocument16 pagesAlfa Laval DecanterAKSHAY BHATKARNo ratings yet

- Structural Crack Identification in Railway Prestressed Concrete Sleepers Using Dynamic Mode ShapesDocument3 pagesStructural Crack Identification in Railway Prestressed Concrete Sleepers Using Dynamic Mode ShapesNii DmNo ratings yet

- Dream Drills for High Hardened SteelDocument8 pagesDream Drills for High Hardened SteelPuneeth KumarNo ratings yet

- Short Time Fourier TransformDocument37 pagesShort Time Fourier TransformGopikaPrasadNo ratings yet

- Datasheet 1MBH 50D - 60Document5 pagesDatasheet 1MBH 50D - 60jtec08No ratings yet

- Informatica Mapping ScenariosDocument81 pagesInformatica Mapping ScenariosSri Kanth SriNo ratings yet

- Infineon IKCM30F60GD DataSheet v02 - 05 ENDocument17 pagesInfineon IKCM30F60GD DataSheet v02 - 05 ENBOOPATHIMANIKANDAN SNo ratings yet

- Practice Exercise For Final Assessment 2221Document3 pagesPractice Exercise For Final Assessment 2221Guneet Singh ChawlaNo ratings yet

- The School and The Community: Prepared By: Sen Xiao Jun Mohana Sundra Segaran Kaviyanayagi PonuduraiDocument26 pagesThe School and The Community: Prepared By: Sen Xiao Jun Mohana Sundra Segaran Kaviyanayagi PonuduraiKaviya SKTDSNo ratings yet

- REHAU 20UFH InstallationDocument84 pagesREHAU 20UFH InstallationngrigoreNo ratings yet

- Valve Control System On A Venturi To Control FiO2 A Portable Ventilator With Fuzzy Logic Method Based On MicrocontrollerDocument10 pagesValve Control System On A Venturi To Control FiO2 A Portable Ventilator With Fuzzy Logic Method Based On MicrocontrollerIAES IJAINo ratings yet

- ZFDC 20 1HDocument1 pageZFDC 20 1Hkentier21No ratings yet

- Free Fall ExperimentDocument31 pagesFree Fall ExperimentLeerzejPuntoNo ratings yet

- Hazardous Area ClassificationDocument100 pagesHazardous Area Classificationcherif yahyaouiNo ratings yet

- OPM - Assignment 2Document12 pagesOPM - Assignment 2Nima IraniNo ratings yet

- Socrates 8dDocument8 pagesSocrates 8dcarolinaNo ratings yet

- Physics 8 - EnergyDocument54 pagesPhysics 8 - EnergyHakim AbbasNo ratings yet

- Review of Train Wheel Fatigue LifeDocument15 pagesReview of Train Wheel Fatigue Lifeabdurhman suleimanNo ratings yet

- Analyzing Reality vs Fantasy in English LessonsDocument7 pagesAnalyzing Reality vs Fantasy in English Lessonsjerico gaspanNo ratings yet

- Babylonian Mathematics (Also Known As Assyro-BabylonianDocument10 pagesBabylonian Mathematics (Also Known As Assyro-BabylonianNirmal BhowmickNo ratings yet

- Liquefaction of Soil in KathmanduDocument9 pagesLiquefaction of Soil in Kathmanduajay shresthaNo ratings yet

- Kathryn Stanley ResumeDocument2 pagesKathryn Stanley Resumeapi-503476564No ratings yet

- Equipment & Piping Layout T.N. GopinathDocument88 pagesEquipment & Piping Layout T.N. Gopinathhirenkumar patelNo ratings yet

- Catalan NumbersDocument17 pagesCatalan NumbersVishal GuptaNo ratings yet

- Econometrics IIDocument4 pagesEconometrics IINia Hania SolihatNo ratings yet

- Abstract PracticeDocument4 pagesAbstract PracticerifqiNo ratings yet

- Oracle Property Manager System OptionsDocument6 pagesOracle Property Manager System OptionsAhmadShuaibiNo ratings yet