Professional Documents

Culture Documents

Engineering Utilities 2 - Learning Material 5

Engineering Utilities 2 - Learning Material 5

Uploaded by

IvyJoama Batin-Barnachea PrioloCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Utilities 2 - Learning Material 5

Engineering Utilities 2 - Learning Material 5

Uploaded by

IvyJoama Batin-Barnachea PrioloCopyright:

Available Formats

FIXTURE TRAP

A fixture trap used in plumbing fixture is a device scientifically designed to prevent

the back flow of gases into the outlet of the fixture. The only separation between the

unhealthy gases in a sanitary drainage system and the air inside the room is the water

caught in the fixture trap after each discharge of the fixture. The column of water that is

retained between the overflow and the dip of the trap is called Trap Seal. It is sometimes

referred to as Water Seal.

The most practical form of trap ever developed is the P-Trap. Originally, this P-

Trap was called "Gooseneck” attributed to its form that is in the same manner as the neck

of a goose. The principle behind the use of P-Trap is to provide a mechanical barrier

against passage of noxious air from the septic tank or main sewer line into the outlet of

the fixtures.

Common Gases that are produced in a Sewage System:

1. Methane 2. Hydrogen Sulfide 3. Nitrogen 4. Carbon Monoxide

The Water Sealed P-Traps are Classified into Two Forms

1. The common seal 2. The deep seal

The Common Seal P-Trap has 5 centimeters (2”)

deep water seal between the overflow and the

dip. This type of trap is used on plumbing fixtures

that are subjected to normal conditions.

The Deep Seal P-Trap has from 7.5 to 10

centimeters column of liquid content between the

overflow and the dip. The deep seal trap may be

used under normal condition but it is purposely

designed for abnormal situations such as:

ME 131 – Engineering Utilities 2 | Instructor: Engr. Karl Hendrix G. Lontoc 1

a. Extreme heat condition in the area.

b. Increase and decrease of atmospheric condition

c. Circumstances where total ventilation cannot be obtained.

One advantage of the Deep Seal over the Common Seal is its greater re-sealing

quality. Re-seal is a term used to the scientific principle that water at rest tend to seek a

level and maintain it.

When the liquid content of a deep seal is disturbed, the water tends to level itself

sufficiently enough to seal the trap even partially. Meaning, because of the considerable

height of the water seal measured at 10 centimeters deep, even if disturbed by flushing

from the fixture discharge, by partial resealing up to 50%, the trap seal is still maintained.

The P-Trap is the most common and practical shape available in various sizes

from 32 mm to 150 mm diameter. These are suitable for fixtures that are suspended from

walls or supported on a pedestal such as:

1. Lavatories

2. Sinks

3. Urinals

4. Drinking fountain

5. Shower bath with less amount of water discharge

There is various form of water sealed traps which could be used to serve plumbing

fixtures. But among these various types. some are classified as Permissible Traps while

others are identified as Objectionable Traps.

The Permissible Type of Traps are:

1. P, Q and S-Trap

ME 131 – Engineering Utilities 2 | Instructor: Engr. Karl Hendrix G. Lontoc 2

P, Q, and S traps are classified according to their shape. They essentially consist

of U – Tube which retains water acting as seal between the foul gas and atmosphere.

The only difference between the P trap and the S trap is that the P trap is used for an

outlet through the wall, whereas S-trap is used for an outlet through the floor. This trap is

used in a toilet under-water closet. It is almost similar to the S trap and is used in the

upper story other than the ground floor.

2. Drum Trap

Drum traps, which resemble metal drums, are an important part of a home

plumbing system because their large openings allow you to more easily locate and

remove objects you need either to

retrieve or to remove from the

plumbing system. A drum trap

consists of an enlarged 'vessle' that

holds a large volume of water. Most

drum traps have a removable

cover, but drum traps are usually

located right below the floor,

making the lid extremely difficult to

access without cutting out the floor.

ME 131 – Engineering Utilities 2 | Instructor: Engr. Karl Hendrix G. Lontoc 3

3. Floor Trap

Floor trap is provided in to the floor to collect waste water from

bathroom, wash area, washbasin, and kitchen sink area.

These are available in UPVC or cast-iron material and have

removable grating on the top of the trap.

4. Gully Trap

Gully Trap, also known as G.T. is provided outside the building

before connecting it to the external sewerage line. It also collects

wastewater from the kitchen sink, washbasins, bath, and wash area.

5. Intercepting Trap

Intercepting trap is provided in to the Interceptor Manhole

(Interceptor Chamber). An Interceptor manhole is provided at the

interception of building sewer and Public sewer. Intercepting trap is

provided to prevent the foul gases from public sewers entering in to

the building sewer by providing water seal.

6. Bottle Trap

A bottle trap is provided to receive waste from washbasin,

kitchen sinks and other appliances where the appliances do not have

a built-in trap. In this type of trap, the waste pipe is fitted horizontally,

and you need to unscrew the bottom to clean it. Ideal to be installed

in limited spaces.

7. Grease Type

Grease trap is installed in the waste pipe from one or more fixtures for the purpose

of separating grease from the liquid and retaining the grease. Since these traps are used

ME 131 – Engineering Utilities 2 | Instructor: Engr. Karl Hendrix G. Lontoc 4

to reduce the amount of fats and oils entering the main sewer, these traps can be

found at commercial cooking facilities.

Aforementioned types of traps are widely used in plumbing work but an ideal plumbing

traps have following features or benefits:

• Resistance to the impact damage and house hold chemical

• Prevent entry of foul air, insects and parasites from the sewers

• Anti-rodent and self-cleaning

• Long service life

• Easier and quick installation

• Economical

Objectionable Traps that are Found Defective are:

1. The full-size S and the ¾ S Traps

2. The bag traps

3. Mechanically sealed traps

4. Light metal partition traps

Loss of Trap Seals

1. Siphonage- The withdrawal of a liquid from a trap due to a suction caused by liquid

flow in a pipe.

ME 131 – Engineering Utilities 2 | Instructor: Engr. Karl Hendrix G. Lontoc 5

2. Back Pressure- pressure developed in opposition to the flow of liquid in a pipe due to

friction, gravity or some other restriction to flow of the conveyed fluid. Excessive pressure

at the lowest branch causing trap seal to look for opening.

3. Evaporation- Occurs when a fixture is not used for a long time. A Deep seal is the best

solution but clogs the pipe due to accumulated solid wastes.

4. Capillary Attraction- foreign objects in the traps absorbing trap seal.

5. Wind Effects- strong winds through the vent system forcing water out of the trap.

The National Plumbing Code on Traps provided that: "Every trap shall be self-

cleaning. Traps for bathtubs, lavatories, sinks and other similar fixtures shall be made of

either lead, brass, cast iron, or of malleable iron galvanized, porcelain enameled inside

or plastic pipes”.

All traps are subject to stoppage. Hence, must be provided with a cleanout, or so

designed that they can be disassembled with little effort.

Fixtures to be Installed are Classified into Three:

1. Class 1 – For Private Use like fixtures in residential houses, apartment and private

bathroom of hotels and similar installations.

2. Class 2 – For Semi-Public Use applied to fixtures in office buildings, factories,

dormitories and the like, for occupant’s use only.

3. Class 3 – For Public Use such as schools, gymnasium, hotels, railroad and bus

terminals, public comfort rooms and other installation where several fixtures are installed

for unrestricted use.

ME 131 – Engineering Utilities 2 | Instructor: Engr. Karl Hendrix G. Lontoc 6

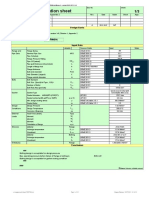

The nominal size (inside diameter) of trap and waste branch for a given fixture

shall not be less than that given in Table of Minimum Size of Fixture Trap given below.

KIND OF FIXTURE TRAP AND BRANCHES SIZE

Bath tub 38 mm 1 ½”

Bath shower stall 50 2

Bath sitz 38 1½

Bath foot 38 1½

Bidets 38 1½

Combination fixture 38 1½

Drinking fountain 32 1¼

Foundation cupsidors 32 1¼

Floor drains 50 2

Laundry trays 38 1½

Sinks, (kitchen of residence) 38 1½

Sinks, (hotel or public) 50 2

Sinks, (large hotel or public) 50 2

Sinks, (small pantry or bar) 32 1¼

Sinks, (dishwasher) 38 1¼

Sinks, Slop, with combined trap 75 3

Sinks, Slop, ordinary 50 2

Urinals Lip 38 1½

Urinals, through 50 2

Urinals, pedestal 75 3

Urinals, stall 50 2

Wash basin 32 1¼

Water closets 75 3

ME 131 – Engineering Utilities 2 | Instructor: Engr. Karl Hendrix G. Lontoc 7

You might also like

- Aqe ReviewerDocument21 pagesAqe ReviewerFredmon Choy Fernandez Narvasa50% (8)

- Chapter 3 Plumbing FixturesDocument21 pagesChapter 3 Plumbing FixturesJasleneDimarananNo ratings yet

- Plumbing Fixtures and FittingsDocument22 pagesPlumbing Fixtures and FittingsAnonymous 4iYnEhFO80% (5)

- National Plumbing Code of The PhilippinesDocument13 pagesNational Plumbing Code of The PhilippinesCarl Maneclang Abarabar60% (5)

- Surge CalculationsDocument21 pagesSurge CalculationsJai Krishna SahithNo ratings yet

- Plumbing 10Document4 pagesPlumbing 10Stanley Scott ArroyoNo ratings yet

- Building Design 1 - Trap For Plumbing FixturesDocument16 pagesBuilding Design 1 - Trap For Plumbing Fixturesjethrocunanan04No ratings yet

- Traps and SoventDocument32 pagesTraps and SoventEdwin LoquinaNo ratings yet

- Building DesignDocument31 pagesBuilding DesignSave YuNo ratings yet

- 9.0 Traps and Interceptors: RNPC Reviewer (Part 2) by Engr. Roger de DiosDocument6 pages9.0 Traps and Interceptors: RNPC Reviewer (Part 2) by Engr. Roger de Diosfreanne_0527No ratings yet

- Trap Seals.Document18 pagesTrap Seals.Emanuel SajutNo ratings yet

- Lesson 4 Plumbing Fixtures Part 2Document26 pagesLesson 4 Plumbing Fixtures Part 2Junnaz BalacuitNo ratings yet

- Sanitary Drainage SystemsDocument25 pagesSanitary Drainage Systemspepito manalotoNo ratings yet

- Arghyadip Sarkar - Section-A - Building Services - Ca-3 AssingmentDocument22 pagesArghyadip Sarkar - Section-A - Building Services - Ca-3 AssingmentArghyadip SarkarNo ratings yet

- PlumbingDocument8 pagesPlumbingBaby John lystier NadayaoNo ratings yet

- PlumbingDocument8 pagesPlumbingBaby John lystier NadayaoNo ratings yet

- Plumbing 5Document5 pagesPlumbing 5Stanley Scott Arroyo100% (1)

- Module 3 Plumbing Fixtures Accessories Fittings Copy 1Document105 pagesModule 3 Plumbing Fixtures Accessories Fittings Copy 1Daniel John CachoNo ratings yet

- TrapsDocument16 pagesTrapsABHISHEK NAVGIRENo ratings yet

- Above Ground Drainage Systems or Soil and Waste SystemsDocument26 pagesAbove Ground Drainage Systems or Soil and Waste SystemsnominalwatersolutionsNo ratings yet

- Chapter 10Document42 pagesChapter 10NIPAS, JON BENEDICT F.No ratings yet

- Bu1 Lesson 4Document66 pagesBu1 Lesson 4Ysa CambaNo ratings yet

- JTL Book Above Groung Discharge SystemsDocument54 pagesJTL Book Above Groung Discharge SystemsbendeniNo ratings yet

- Engineering UtilitiesDocument5 pagesEngineering UtilitiesAce Angelo CarreonNo ratings yet

- 3.1 Plumbing Fixtures and ComponentsDocument19 pages3.1 Plumbing Fixtures and ComponentsDESIREE VICENTENo ratings yet

- Week 13 ReportingDocument48 pagesWeek 13 ReportingCharles CresinoNo ratings yet

- Plumbing System: Prepared By: Group 7Document56 pagesPlumbing System: Prepared By: Group 7Glenn Midel Delos SantosNo ratings yet

- Chapter7-Plumbing system-WS&SEDocument30 pagesChapter7-Plumbing system-WS&SERwagatare civilcontractorsNo ratings yet

- Chapter 7 and 8-WS&SEDocument72 pagesChapter 7 and 8-WS&SEKunduwera MethodeNo ratings yet

- Lesson 3 Plumbing Fixtures Part 1Document19 pagesLesson 3 Plumbing Fixtures Part 1Junnaz BalacuitNo ratings yet

- Written R. PlumbingDocument5 pagesWritten R. PlumbingRia LopezNo ratings yet

- ARCH 348 CHP 5. Sanitary Fitments & Piping in Buildings: Assoc. Prof. Dr. Uğur AtikolDocument21 pagesARCH 348 CHP 5. Sanitary Fitments & Piping in Buildings: Assoc. Prof. Dr. Uğur AtikolMahmoud I. MahmoudNo ratings yet

- Sanitary Drainage SystemDocument5 pagesSanitary Drainage SystemLeann Kaizen SerencioNo ratings yet

- Research Work 7 1 ConDocument14 pagesResearch Work 7 1 ConMak AdanNo ratings yet

- CH 4. Sanitary Fixtures PDFDocument24 pagesCH 4. Sanitary Fixtures PDFashe zinabNo ratings yet

- PART1Document98 pagesPART1Raphael CajucomNo ratings yet

- SanitationDocument11 pagesSanitationRishabhNo ratings yet

- Reviewer Eu2Document8 pagesReviewer Eu2Jullie Anne SantoyoNo ratings yet

- Plumbing Systems For BuildingsDocument62 pagesPlumbing Systems For BuildingsDileep Kumar100% (1)

- Lecture 6 Plumbing Trap BasicsDocument30 pagesLecture 6 Plumbing Trap BasicsMiguel TaleonNo ratings yet

- Plumbing Ventilation and TrapsDocument5 pagesPlumbing Ventilation and TrapscessNo ratings yet

- 6035 L2u205 PPT Outcome3Document43 pages6035 L2u205 PPT Outcome3shahin.noktehdan4102No ratings yet

- Taps and Valves NotesDocument7 pagesTaps and Valves NotesEdwin Nyaga67% (3)

- 3 Refuse - Pipes TrapsDocument27 pages3 Refuse - Pipes TrapsThe White Beast YTNo ratings yet

- Building LawsDocument32 pagesBuilding LawsJayvee Latosa DividinaNo ratings yet

- Technical Terms: 1. PlumbingDocument7 pagesTechnical Terms: 1. PlumbingParth AnajwalaNo ratings yet

- Lecture 5 Sewage Disposal SystemDocument30 pagesLecture 5 Sewage Disposal Systempepito manaloto0% (1)

- Typical Plumbing System of A Toilet and BathDocument5 pagesTypical Plumbing System of A Toilet and BathSilverlandNo ratings yet

- Untitled DocumentDocument3 pagesUntitled Documentarnob hridoyNo ratings yet

- Eu2 Part 5Document20 pagesEu2 Part 5Gaspar, Matt LorenzNo ratings yet

- Bu1 Lesson 5Document44 pagesBu1 Lesson 5Ysa CambaNo ratings yet

- Zamora Bsce3b Cea132 Assignment-2Document9 pagesZamora Bsce3b Cea132 Assignment-2Mrdy CaiNo ratings yet

- Presentation 006 - The-Waste-and-Soil-Pipe-Report-Group-4Document17 pagesPresentation 006 - The-Waste-and-Soil-Pipe-Report-Group-4Mark Angelo Teodoro (Teodee)No ratings yet

- TLE - PlumbingDocument20 pagesTLE - PlumbingsaglebalNo ratings yet

- CH4. Drainage Above Ground - 2Document14 pagesCH4. Drainage Above Ground - 2Pubudu KalpageNo ratings yet

- Fixture TrapsDocument2 pagesFixture TrapsBrenzell BarugNo ratings yet

- Building Utilities Sanitary Sewage System 2Document47 pagesBuilding Utilities Sanitary Sewage System 2Bea Mae Bolay-ogNo ratings yet

- Distress (San Juan Group)Document21 pagesDistress (San Juan Group)IvyJoama Batin-Barnachea PrioloNo ratings yet

- Municipal (Town Mayor), Transferred The Government, and The New Poblacion Was Laid OutDocument2 pagesMunicipal (Town Mayor), Transferred The Government, and The New Poblacion Was Laid OutIvyJoama Batin-Barnachea PrioloNo ratings yet

- Ce LawsDocument37 pagesCe LawsIvyJoama Batin-Barnachea PrioloNo ratings yet

- The Tacoma Narrows Bridge Twisted Back and Forth in Strong Winds Before Collapsing in 1940. The Failure Is Now A Case Study For Physics StudentsDocument22 pagesThe Tacoma Narrows Bridge Twisted Back and Forth in Strong Winds Before Collapsing in 1940. The Failure Is Now A Case Study For Physics StudentsIvyJoama Batin-Barnachea PrioloNo ratings yet

- Guidelines To Practice Under The Fundamental Canons of EthicsDocument26 pagesGuidelines To Practice Under The Fundamental Canons of EthicsIvyJoama Batin-Barnachea PrioloNo ratings yet

- Questions For Midterm Exams in ETHICSDocument6 pagesQuestions For Midterm Exams in ETHICSIvyJoama Batin-Barnachea PrioloNo ratings yet

- Classification of Engineering ServicesDocument20 pagesClassification of Engineering ServicesIvyJoama Batin-Barnachea PrioloNo ratings yet

- Engineering Utilities 2 - Learning Material 2Document13 pagesEngineering Utilities 2 - Learning Material 2IvyJoama Batin-Barnachea PrioloNo ratings yet

- Influence Line For TrussDocument15 pagesInfluence Line For TrussIvyJoama Batin-Barnachea PrioloNo ratings yet

- Module 3. Construction Project RequirementsDocument4 pagesModule 3. Construction Project RequirementsIvyJoama Batin-Barnachea Priolo0% (1)

- Engineering Utilities 2 - Learning Material 1Document5 pagesEngineering Utilities 2 - Learning Material 1IvyJoama Batin-Barnachea PrioloNo ratings yet

- Novakey Fittings 2014Document4 pagesNovakey Fittings 2014Ben FriskneyNo ratings yet

- Chilled Water Pump CalculationsDocument4 pagesChilled Water Pump CalculationsNitesh SinghNo ratings yet

- AFM-IMP-OKL-G10-00078-R01 Overpressure Protection of AP Condensate Flash Drum From Fuel Gas SystemDocument18 pagesAFM-IMP-OKL-G10-00078-R01 Overpressure Protection of AP Condensate Flash Drum From Fuel Gas SystemYousuf Nasser ALAbriNo ratings yet

- MSS SP-45Document12 pagesMSS SP-45Allan SousaNo ratings yet

- Bolt and Stud DimentionDocument1 pageBolt and Stud DimentionwhngomjNo ratings yet

- TWAS-Tender Addendum - StructuralDocument116 pagesTWAS-Tender Addendum - StructuralnvnagarajuNo ratings yet

- M Fuel Oil Pipe System IC M FOP 00Document2 pagesM Fuel Oil Pipe System IC M FOP 00achusanachuNo ratings yet

- A GFSI-Fire ProtectionDocument7 pagesA GFSI-Fire ProtectionJonathan FerueloNo ratings yet

- Plans PDFDocument7 pagesPlans PDFAngelo MoralNo ratings yet

- Spec Piping Material PDFDocument18 pagesSpec Piping Material PDFMuchamad FaizNo ratings yet

- Spare Parts List Series M200LS: Effective Date: January 15, 2014 Supersedes: June 11, 2013Document16 pagesSpare Parts List Series M200LS: Effective Date: January 15, 2014 Supersedes: June 11, 2013Trần Quốc Đông100% (1)

- Mss sp-73 1991 PDFDocument5 pagesMss sp-73 1991 PDFChotiwan RattanasatienNo ratings yet

- RD Sharma Class 8 Chapter 11 Time and WorkDocument11 pagesRD Sharma Class 8 Chapter 11 Time and WorkAarav AroraNo ratings yet

- Valve StandardsDocument2 pagesValve Standardsengrmalik100% (1)

- PIP PN03SD0B02 Piping Material Specification 3SD0B02 Class 300, 316/316L Stainless Steel, Butt Weld, 0.000 C.A., Process (PTFE Packing/Gaskets)Document5 pagesPIP PN03SD0B02 Piping Material Specification 3SD0B02 Class 300, 316/316L Stainless Steel, Butt Weld, 0.000 C.A., Process (PTFE Packing/Gaskets)César SantanaNo ratings yet

- Case Study - Grab KitchenDocument5 pagesCase Study - Grab KitchenLester Bug-osNo ratings yet

- Mss sp952006 Swaged Nipples and Bull PlugsDocument16 pagesMss sp952006 Swaged Nipples and Bull PlugsDaryna KupriianovaNo ratings yet

- Pilot Valves and AccessoriesDocument12 pagesPilot Valves and Accessoriesvhfdz1175No ratings yet

- FM SFL BV 300 G V.mariposaDocument1 pageFM SFL BV 300 G V.mariposaEduardo Alex Eugenio MendezNo ratings yet

- Flange Asme Viii PDFDocument23 pagesFlange Asme Viii PDFChiheb KaanicheNo ratings yet

- Pluvia BrochureDocument11 pagesPluvia BrochureAsoka Kumarasiri JayawardanaNo ratings yet

- Manual Cuenta Litros TCS-700 30:35Document56 pagesManual Cuenta Litros TCS-700 30:35Alejandro AdriasolaNo ratings yet

- SHOPPING-MALL-SEWER-DESIGN-WORKSHOP - PDF Version 1Document12 pagesSHOPPING-MALL-SEWER-DESIGN-WORKSHOP - PDF Version 1Justine PechayNo ratings yet

- FAS Produk LPGDocument10 pagesFAS Produk LPGYogi MaulanaNo ratings yet

- Seaperch - PVC and CPVC Pipe DimensionsDocument10 pagesSeaperch - PVC and CPVC Pipe DimensionsArsenic DiacajoNo ratings yet

- Plumbing Code Final Coaching Answer KeyDocument9 pagesPlumbing Code Final Coaching Answer KeyDavid RaynneNo ratings yet

- TolDocument5 pagesTolLuka PersicNo ratings yet

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDocument12 pagesMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00No ratings yet