Professional Documents

Culture Documents

Career Objective: Senior Production Engineer

Uploaded by

amol thengOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Career Objective: Senior Production Engineer

Uploaded by

amol thengCopyright:

Available Formats

RESUME

Subhash Chavan

Mob: +919766837404

Email Id:subhashvchavan@gmail.com

LinkedIn profile : www.linkedin.com/in/subhash-chavan-661415b1

Senior Production Engineer

CAREER OBJECTIVE

Seeking for a challenging position as a professional, where I am given the chance of proving my mettle to

the best. To accomplish my responsibilities to the best of my efficiency and to work hard to achieve

individual, group and organizational objectives.

SUMMARY

Overall, 8 years 3 months of professional experience as a Senior Production/Quality Engineer.

Having Knowledge of ISO 9001:2008 & ISO 9001:2015.

Having good knowledge of Seven QC Tools, Kaizen, Poka-yoke, TPM, APQP, PPAP, MSA, FMEA, SPC.

Learning new methodology like Quality Management, Production Scheduling in automobile & auto-

ancillary.

Worked on Profile Projector, TRIMOS, CMM, CONTRACER.

Excellent communication and presentation skills.

Highly determined, adaptive and committed towards work.

Good Knowledge and Work Experience in Customer complaints handling.

Also Familiar with 5S of Kaizen.

Experience as CFT member.

Desired Skills and Experience:

• Deep knowledge of manufacturing and production processes and concepts.

• Strong leadership skills.

• The ability to perform a multi-task job and adjust priorities as appropriate.

• Possess excellent time management skills. Be able to take the initiative to meet deadlines and the

ability to prioritize workload with minimal supervision.

ACADEMIC QUALIFICATIONS

Examination Year Board/University Percentage

B.E. 2012 MIT, Aurangabad. 66.50%

H.S.C. 2008 Govt. College Aurangabad 71.00%

S.S.C 2006 New High School A’ bad. 74.13%

CAREER PROFILE

Dates Organization Role

February 2020 – Till Date Acme Precision, Pune Senior Production

Engineer

July 2017 – February 2020 Patson auto products Pvt Ltd., Pune. Senior Quality Engineer

May 2013-June 2017 J.S. Engineering Pvt ltd., Aurangabad. Quality Engineer

TRAINING DETAIL

Dates Organization Stream

January 2012- July 2012 Aurangabad Electricals Limited In plant Training in Tool store

and manufacturing department

PROFESSIONAL EXPERIENCE

Job Title Senior Production Engineer

Experience Acme Precision Bhosari, Pune. (February 2020 to Till Date)

Total Duration 1 year and 7 months

Key Documenting current production procedures and create Company standards

Responsibilities to improve the efficiency of the Production Department.

Identify and implement continuous improvements to the Company’s pro-

duction processes.

Collaborate with Quality Department to identify and implement ongoing

quality improvements

Develop and implement production processes for new products, product

enhancements and product changes. Install related fixtures and tooling, as

required.

Ensuring that workflows, processes, and products comply with safety

regulations.

Investigating and troubleshooting product or production issues.

Collect, analyze, summarize and present production and process data, infor-

mation and trends to management

Identify new technological needs of process and implement new technologies

for the production to reduce cost and save time

Responsible for customers’ complaint analysis and interacting with custom-

ers to explain the failure Analysis details

Source new equipment and material suppliers as required.

Preparation daily and weekly schedule considering orders in hand, resource

requirements and customer delivery dates

Coordinating with customers / third party agencies regarding technical clari-

fication during witness inspection and assisting for documents completion

Assist in the evaluation of returned materials/products..

Estimate staffing requirements, production times, and relative costs to

provide data for operational decisions.

Key Appreciation from management for Successfully handling plant in COVID-19 Pe-

Achievements riod.

New product Development Team member.

Appreciation for New Vendor Development.

Job Title Senior Quality Engineer

Experience Patson auto products Pvt ltd. Bhosari, Pune. (July-2017 to February 2020)

Total Duration 2 year and 7 months

Key Reviews design plans, process procedures, test procedures, and quality man-

Responsibilities uals to understand the scope, requirements, and function of the problem.

Inspect & handle parts like Brake pistons, Bearing plates, Planet shafts, Planet

pins, Oil slingers, Bushing, Confinement Rings, Servo pistons, spool Shuttle.

Ensures that products meet the organizations and customers quality and

product integrity requirements.

Supports the product development or operations team by providing analysis

and expertise throughout the inspection process.

Calibration of all equipment & instruments used for inspection of auto com-

ponents

Conducted simulation trials along with the design team to reproduce the fail-

ure for confirmation on the root cause

Identify new technological needs of process and implement new technologies

for the production to reduce cost and save time

Responsible for customers’ complaint analysis and interacting with custom-

ers to explain the failure Analysis details

Expertise in Root Cause Analysis of internal production line failures

Control of quality documents and traceability maintenance of quality record

Coordinate and interact with Development & Design team for new develop-

ment

Preparation daily and weekly schedule considering orders in hand, resource

requirements and customer delivery dates

Coordinating with customers / third party agencies regarding technical clari-

fication during witness inspection and assisting for documents completion

Communicating with vendors for outsourcing processes.

Handle internal and external Audit.

Key Appreciation from management for suggesting ways to improve Quality Man-

Achievements agement System.

New product Development Team member.

Trained new employees according to standard ISO 9001:2008.

Job Title Quality Engineer

Experience J.S. Engineering put ltd., Aurangabad. (May-2013 to June-2017.)

Total Duration 4 years and 1 month

Key Inspection of tool holder used for CNC, VMC.

Responsibilities Inspect & handle tool holders like Turning tool holder, ISO & Special Car-

tridges, Indexable drills, Boring bars for roughing & finishing, milling cutters,

Grooving tool holders, Threading tools, End mill cutters.

Inspection of raw materials & outsourcing processes

In Process Inspection of quality of cutting tools

Final Inspection of Cutting tools and preparation of Final documentation

Calibration of all equipment & instruments used for inspection of tool holders

Identify new technological needs of process and implement new technologies

for the production to reduce cost and save time

Responsible for customers’ complaint analysis and interacting with custom-

ers to explain the failure Analysis details

Expertise in Root Cause Analysis of internal production line failures

Control of quality documents and traceability maintenance of quality record

Coordinate and interact with Development & Design team for new develop-

ment.

Key Trained new employees according to standard ISO 9001:2008

Achievements

PERSONAL DETAILS

Date of Birth 3rd Feb, 1990

Nationality Indian

Sex Male

Languages Known English, Marathi, Hindi.

You might also like

- ABAQUS TutorialsDocument59 pagesABAQUS TutorialsMikael Bezerra Cotias Dos Santos80% (5)

- Handbook H-28 (1957) Part-IDocument217 pagesHandbook H-28 (1957) Part-IPaulo Vicentin NetoNo ratings yet

- Quality Engineer Key SkillsDocument4 pagesQuality Engineer Key SkillsPradip MaheshwariNo ratings yet

- 3PAR FundamentalsDocument52 pages3PAR FundamentalsJayakrishna Para100% (1)

- Qa - QC ManagerDocument14 pagesQa - QC Managermunawar hussainNo ratings yet

- Fox Talas RLC - ManualDocument27 pagesFox Talas RLC - ManualFilipe LoureiroNo ratings yet

- Resume RahulDocument3 pagesResume RahulIndian MHNo ratings yet

- Extensive Experience in Quality Assurance and Manufacturing ExcellenceDocument4 pagesExtensive Experience in Quality Assurance and Manufacturing ExcellenceVarinder Pal SinghNo ratings yet

- Grove GMK6350Document20 pagesGrove GMK6350cornel_lupuNo ratings yet

- Ravi Halleppanavar ResumeDocument5 pagesRavi Halleppanavar ResumeMNR SolutionsNo ratings yet

- QA Professional's 7+ Years ExperienceDocument3 pagesQA Professional's 7+ Years Experiencemark kdNo ratings yet

- Shrikant R S - Quality ManagerDocument2 pagesShrikant R S - Quality ManagerParag WadekarNo ratings yet

- Career Objective:: Name Date of Birth Position Wanted Job Category E-Mail ID Permanent AddressDocument5 pagesCareer Objective:: Name Date of Birth Position Wanted Job Category E-Mail ID Permanent AddressvivekNo ratings yet

- CV for Quality Engineer RoleDocument4 pagesCV for Quality Engineer RoleSaurabh KulkarniNo ratings yet

- Dharmendra CVDocument6 pagesDharmendra CVAmandeep SharmaNo ratings yet

- J4nmo n8kb6Document2 pagesJ4nmo n8kb6UMESHNo ratings yet

- Finalize Resume.Document2 pagesFinalize Resume.Ravindra SinghNo ratings yet

- Yash Resume 2 2Document2 pagesYash Resume 2 2BaljeetNo ratings yet

- Resume-Love Kumar-1Document4 pagesResume-Love Kumar-1Yâśhïkā BhãtìåNo ratings yet

- Udaykiran - Sontyana - 07 Analyst-1Document2 pagesUdaykiran - Sontyana - 07 Analyst-1ankurNo ratings yet

- G. Siva Durga Pawan: ContactDocument2 pagesG. Siva Durga Pawan: ContactPS AdityaNo ratings yet

- CV Procurement Analyst Bengaluru ExperienceDocument4 pagesCV Procurement Analyst Bengaluru ExperiencevivekNo ratings yet

- Vinoth Sri - Supplier QualiDocument5 pagesVinoth Sri - Supplier QualiElanchezhian E S KNo ratings yet

- Curriculum Vitae: Personal Information Mohamed Nazeer IbrahimDocument5 pagesCurriculum Vitae: Personal Information Mohamed Nazeer IbrahimjennyNo ratings yet

- Rajesh Kumar Sharma Quality Control & Assurance Profile SummaryDocument2 pagesRajesh Kumar Sharma Quality Control & Assurance Profile SummaryRajesh kumar SharmaNo ratings yet

- Tushar Padave Resume - 0912Document4 pagesTushar Padave Resume - 0912tusharpadaveNo ratings yet

- Rahul Ghotekar (CV) - 2023Document3 pagesRahul Ghotekar (CV) - 2023Ashok ShelkeNo ratings yet

- Muhammad Adeel Quality AuditorDocument2 pagesMuhammad Adeel Quality AuditorFaisal AkhterNo ratings yet

- ResumeJegatheeshwaranPalanisamyDocument2 pagesResumeJegatheeshwaranPalanisamyNithish KuttanNo ratings yet

- Ramya D: Profile SummaryDocument2 pagesRamya D: Profile SummaryLakshmi JethendraNo ratings yet

- Quality Assurance Engineer PDFDocument3 pagesQuality Assurance Engineer PDFIonutz AsafteiNo ratings yet

- Ivan Ernesto - Ochoa Romero - CV (English) - NewDocument5 pagesIvan Ernesto - Ochoa Romero - CV (English) - NewRaymundo CotaNo ratings yet

- Objective: Robin R.PatelDocument5 pagesObjective: Robin R.PatelEr Jitendra AgrahariNo ratings yet

- JD - Quality ManagerDocument3 pagesJD - Quality ManagerRavi KanheNo ratings yet

- MD Shahnewaz Sabit Faisal: Phone: Home: EmailDocument4 pagesMD Shahnewaz Sabit Faisal: Phone: Home: Emailkiran2710No ratings yet

- Targeting Customer SatisfactionDocument4 pagesTargeting Customer SatisfactionAyisha PatnaikNo ratings yet

- Balachander1501@gmail bb-1Document3 pagesBalachander1501@gmail bb-1balachander1501No ratings yet

- Contact Details: Profile SummaryDocument2 pagesContact Details: Profile Summaryalka singhalNo ratings yet

- Machining OperatorDocument4 pagesMachining OperatorSwapnil SawantNo ratings yet

- Sandipkumar Arjun ShindeDocument3 pagesSandipkumar Arjun ShindeAditya NaikNo ratings yet

- VenkataSaiSumanth Divili CV-6Document3 pagesVenkataSaiSumanth Divili CV-6saisumanthdv1902No ratings yet

- Song ListDocument3 pagesSong ListUjjal MishraNo ratings yet

- Experienced Production Engineer Seeking New OpportunitiesDocument2 pagesExperienced Production Engineer Seeking New Opportunitiesw john franklinNo ratings yet

- Sankalp CurriculumVitaeDocument2 pagesSankalp CurriculumVitaeashutoshpal21No ratings yet

- Kushal Pardeshi resume QA engineerDocument5 pagesKushal Pardeshi resume QA engineerKushal PardeshiNo ratings yet

- Dditional SkillDocument3 pagesDditional SkillPraveen Singh BhagelNo ratings yet

- Ramkumar S: Manufacturing Engineer - Process Engineer - Quality Assurance EngineerDocument2 pagesRamkumar S: Manufacturing Engineer - Process Engineer - Quality Assurance Engineerganeshn1983631No ratings yet

- Resume - Aditya WDocument3 pagesResume - Aditya WadityaNo ratings yet

- Resume VikasDocument4 pagesResume VikasBaljeetNo ratings yet

- WAHID HUSSAIN - CV - Doc-1Document2 pagesWAHID HUSSAIN - CV - Doc-1Mubi MalikNo ratings yet

- Rajesh Kumar Sethi - 5+years - Project Control Engineer - Foster Wheeler - SenabiDocument4 pagesRajesh Kumar Sethi - 5+years - Project Control Engineer - Foster Wheeler - SenabiSubrata DuttaNo ratings yet

- Sureshkumar+CV 020622Document5 pagesSureshkumar+CV 020622Razvan GheorghiesNo ratings yet

- AbhijitBarik 12 0Document3 pagesAbhijitBarik 12 0almamunmolla96No ratings yet

- QC Inspector - LKDocument3 pagesQC Inspector - LKEngineering Affairs Dept.No ratings yet

- MD Shahnewaz: Manufacturing EngineerDocument4 pagesMD Shahnewaz: Manufacturing Engineerkiran2710No ratings yet

- Wa0002.Document6 pagesWa0002.subash murugaiyaNo ratings yet

- Nabeel Ahmed Malik: ExperienceDocument3 pagesNabeel Ahmed Malik: ExperiencenabeelNo ratings yet

- Mark Daniel Atienza. Bañarez: Barangay Real Calamba City, LagunaDocument2 pagesMark Daniel Atienza. Bañarez: Barangay Real Calamba City, LagunamarkNo ratings yet

- Abhijeet ResumeDocument2 pagesAbhijeet ResumeRaghunathNo ratings yet

- Curriculum Vitae Sumant Kumar Yadav Senior Project Engineer Mobile No.: +91 9142270310, 9099933972Document4 pagesCurriculum Vitae Sumant Kumar Yadav Senior Project Engineer Mobile No.: +91 9142270310, 9099933972Aadarsh PillaiNo ratings yet

- Vishal Chandarana Resume.Document2 pagesVishal Chandarana Resume.Marikya GuptaNo ratings yet

- Mechanical Engineer's ResumeDocument4 pagesMechanical Engineer's ResumeShyam J VyasNo ratings yet

- Shivaraj Mobile No: +91-9503898586 E-Mail: Present AddressDocument3 pagesShivaraj Mobile No: +91-9503898586 E-Mail: Present AddressSunil KalkoteNo ratings yet

- Muzammil Khan ResumeDocument2 pagesMuzammil Khan ResumeMuzammil KhanNo ratings yet

- Certificate of Interest Collected On Loans / AdvancesDocument2 pagesCertificate of Interest Collected On Loans / Advancesamol thengNo ratings yet

- Provisional Certificate 271120211727927Document1 pageProvisional Certificate 271120211727927amol thengNo ratings yet

- John Burton Technology Quotient Session Summary-FinalDocument4 pagesJohn Burton Technology Quotient Session Summary-Finalamol thengNo ratings yet

- GSTIN: 29AACCF1132H2ZX CIN: U67190MH2012PTC337657 Pan: Aaccf1132H State Code: 29Document1 pageGSTIN: 29AACCF1132H2ZX CIN: U67190MH2012PTC337657 Pan: Aaccf1132H State Code: 29amol thengNo ratings yet

- Ed 290051Document219 pagesEd 290051amol thengNo ratings yet

- Q. 1 - Q. 5 Carry One Mark Each.: GATE 2019 General Aptitude (GA) Set-8Document3 pagesQ. 1 - Q. 5 Carry One Mark Each.: GATE 2019 General Aptitude (GA) Set-8Chirag JainNo ratings yet

- John Burton Technology Quotient Session Summary-FinalDocument4 pagesJohn Burton Technology Quotient Session Summary-Finalamol thengNo ratings yet

- Provisional Certificate 271120211727927Document1 pageProvisional Certificate 271120211727927amol thengNo ratings yet

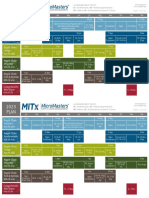

- MITx MicroMasters SCM ScheduleDocument2 pagesMITx MicroMasters SCM Scheduleamol thengNo ratings yet

- MITx MicroMasters SCM ScheduleDocument2 pagesMITx MicroMasters SCM Scheduleamol thengNo ratings yet

- Vil Receipt 9158251493 2022-01-12Document1 pageVil Receipt 9158251493 2022-01-12amol thengNo ratings yet

- Vil Receipt 9158251493 2022-01-12Document1 pageVil Receipt 9158251493 2022-01-12amol thengNo ratings yet

- Vil Receipt 9158251493 2022-01-12Document1 pageVil Receipt 9158251493 2022-01-12amol thengNo ratings yet

- Vil Receipt 9158251493 2022-01-12Document1 pageVil Receipt 9158251493 2022-01-12amol thengNo ratings yet

- Software Project Management (Includes Practicals)Document2 pagesSoftware Project Management (Includes Practicals)Dreamtech PressNo ratings yet

- Job ProductionDocument4 pagesJob ProductionTiana 'Chandie' ChandlerNo ratings yet

- Grundocrack ManualDocument66 pagesGrundocrack ManualKevin H A NoelNo ratings yet

- Frederick Winslow TaylorDocument6 pagesFrederick Winslow TaylorAngela AllenNo ratings yet

- Check Printing User Guide - OracleDocument452 pagesCheck Printing User Guide - Oracleayub_bmeNo ratings yet

- Summer Training PresentationDocument18 pagesSummer Training PresentationrhytamNo ratings yet

- Bill Gates Biography WikipediaDocument12 pagesBill Gates Biography WikipediaSaleem AzadNo ratings yet

- Ts2 Exercises Sample 2013 SampleDocument48 pagesTs2 Exercises Sample 2013 SamplemarcinparcinNo ratings yet

- What is a keepalive timeout in FCIPDocument2 pagesWhat is a keepalive timeout in FCIPsushant_beuraNo ratings yet

- Software LabDocument18 pagesSoftware LabRushabh PatelNo ratings yet

- Petroleum Exploration & Production POLICY 2012: Government of Pakistan Ministry of Petroleum & Natural ResourcesDocument54 pagesPetroleum Exploration & Production POLICY 2012: Government of Pakistan Ministry of Petroleum & Natural ResourcesabdullahiqbalNo ratings yet

- Processes 07 00377 PDFDocument12 pagesProcesses 07 00377 PDFKaul PatrickNo ratings yet

- Government of Maharashtra provisional allotment list for engineering admissionDocument7 pagesGovernment of Maharashtra provisional allotment list for engineering admissionSaniya PatilNo ratings yet

- DH 103 Hornet Building Guide: Scale Model Aircraft Assembly InstructionsDocument76 pagesDH 103 Hornet Building Guide: Scale Model Aircraft Assembly InstructionsBobNo ratings yet

- EscalatorDocument10 pagesEscalatorsagrikakhandkaNo ratings yet

- Caravan Claim Letter to Insurance CompanyDocument1 pageCaravan Claim Letter to Insurance CompanyJelena IdjoskiNo ratings yet

- Glaval Bus Owners ManualDocument30 pagesGlaval Bus Owners ManualLeo-Evelyn BrumNo ratings yet

- CNV Bidding Activities: Introduction - CNV Development SchemeDocument18 pagesCNV Bidding Activities: Introduction - CNV Development SchemeThem Bui XuanNo ratings yet

- Brochure o P Thrusters UmvDocument4 pagesBrochure o P Thrusters UmvAjay V RamadasNo ratings yet

- New York State and Municipal Facilities Program Project NominationDocument627 pagesNew York State and Municipal Facilities Program Project NominationNew York SenateNo ratings yet

- MTG STARMET STRADDLE ADAPTER Welding Wear Limit InstructionsDocument16 pagesMTG STARMET STRADDLE ADAPTER Welding Wear Limit InstructionsAhmed AtefNo ratings yet

- Alloy 7068 BrochureDocument6 pagesAlloy 7068 BrochuredaviescdNo ratings yet

- Cbrniac Newsletter Vol14 - Num3Document12 pagesCbrniac Newsletter Vol14 - Num3lzljbNo ratings yet

- Buyers Guide To CNC Machined PartsDocument16 pagesBuyers Guide To CNC Machined PartsnadoNo ratings yet

- Assessment Cycle in SapDocument9 pagesAssessment Cycle in SapSunando Narayan BiswasNo ratings yet