Professional Documents

Culture Documents

Power Supply Ground Circuit Elements

Uploaded by

Erickson GarciaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Supply Ground Circuit Elements

Uploaded by

Erickson GarciaCopyright:

Available Formats

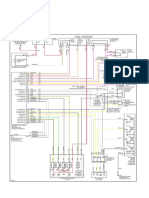

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

K ELECTRICAL

B

SECTION

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS C

E

CONTENTS

POWER SUPPLY ROUTING CIRCUIT ...................... 3 GROUND ................................................................... 29 F

Schematic ................................................................ 3 Ground Distribution ................................................. 29

Wiring Diagram — POWER — ................................. 4 MAIN HARNESS ................................................. 29

BATTERY POWER SUPPLY — IGNITION SW. ENGINE ROOM HARNESS ................................ 32 G

IN ANY POSITION ................................................ 4 ENGINE CONTROL HARNESS .......................... 34

ProCarManuals.com

ACCESSORY POWER SUPPLY — IGNITION BODY HARNESS ................................................ 35

SW. IN “ACC” OR “ON” ......................................... 9 BODY NO. 2 HARNESS ..................................... 37

H

IGNITION POWER SUPPLY — IGNITION SW. HARNESS ................................................................. 38

IN “ON” AND/OR “START” .................................. 10 Harness Layout ...................................................... 38

Fuse ....................................................................... 16 HOW TO READ HARNESS LAYOUT ................. 38

Fusible Link ............................................................ 16 OUTLINE ............................................................. 39 I

Circuit Breaker ....................................................... 16 MAIN HARNESS ................................................. 40

IPDM E/R (INTELLIGENT POWER DISTRIBUTION ENGINE ROOM HARNESS ................................ 43

MODULE ENGINE ROOM) ...................................... 17 ENGINE CONTROL HARNESS .......................... 46 J

System Description ................................................ 17 BODY HARNESS ................................................ 48

SYSTEMS CONTROLLED BY IPDM E/R ........... 17 BODY NO. 2 HARNESS ..................................... 50

CAN COMMUNICATION LINE CONTROL ......... 17 ROOM LAMP HARNESS .................................... 51

PG

IPDM E/R STATUS CONTROL ........................... 18 FRONT DOOR HARNESS .................................. 52

CAN Communication System Description .............. 18 REAR DOOR HARNESS .................................... 53

CAN Communication Unit ...................................... 18 BACK DOOR HARNESS .................................... 54

Function of Detecting Ignition Relay Malfunction ... 18 Wiring Diagram Codes (Cell Codes) ...................... 55 L

CONSULT-II Function (IPDM E/R) ......................... 19 ELECTRICAL UNITS LOCATION ............................ 58

CONSULT-II INSPECTION PROCEDURE ......... 19 Electrical Units Location ......................................... 58

SELF-DIAG RESULTS ........................................ 19 ENGINE COMPARTMENT .................................. 58 M

DATA MONITOR ................................................. 19 PASSENGER COMPARTMENT ......................... 59

ACTIVE TEST ..................................................... 21 LUGGAGE COMPARTMENT .............................. 61

Auto Active Test ..................................................... 21 HARNESS CONNECTOR ......................................... 62

DESCRIPTION .................................................... 21 Description .............................................................. 62

OPERATION PROCEDURE ............................... 21 HARNESS CONNECTOR (TAB-LOCKING

INSPECTION IN AUTO ACTIVE TEST MODE ... 22 TYPE) .................................................................. 62

Schematic .............................................................. 24 HARNESS CONNECTOR (SLIDE-LOCKING

IPDM E/R Terminal Arrangement ........................... 25 TYPE) .................................................................. 63

IPDM E/R Power/Ground Circuit Inspection .......... 26 HARNESS CONNECTOR (LEVER LOCKING

Inspection with CONSULT-II (Self-Diagnosis) ........ 27 TYPE) .................................................................. 64

Removal and Installation of IPDM E/R ................... 28 ELECTRICAL UNITS ................................................ 65

REMOVAL ........................................................... 28 Terminal Arrangement ............................................ 65

INSTALLATION ................................................... 28 SMJ (SUPER MULTIPLE JUNCTION) ..................... 67

Terminal Arrangement ............................................ 67

Revision: 2006 July PG-1 2007 Murano

STANDARDIZED RELAY .......................................... 68 FUSE BLOCK - JUNCTION BOX (J/B) ....................70

Description .............................................................. 68 Terminal Arrangement .............................................70

NORMAL OPEN, NORMAL CLOSED AND FUSE, FUSIBLE LINK AND RELAY BOX ................71

MIXED TYPE RELAYS ........................................ 68 Terminal Arrangement .............................................71

TYPE OF STANDARDIZED RELAYS .................. 68

ProCarManuals.com

Revision: 2006 July PG-2 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

POWER SUPPLY ROUTING CIRCUIT PFP:24110

A

Schematic NKS0025A

G

ProCarManuals.com

PG

TKWB2680E

Revision: 2006 July PG-3 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

Wiring Diagram — POWER — NKS0025B

BATTERY POWER SUPPLY — IGNITION SW. IN ANY POSITION

ProCarManuals.com

TKWB2681E

Revision: 2006 July PG-4 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

G

ProCarManuals.com

PG

TKWB2682E

Revision: 2006 July PG-5 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

ProCarManuals.com

TKWB2683E

Revision: 2006 July PG-6 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

G

ProCarManuals.com

PG

TKWB2684E

Revision: 2006 July PG-7 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

ProCarManuals.com

TKWB2685E

Revision: 2006 July PG-8 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

ACCESSORY POWER SUPPLY — IGNITION SW. IN “ACC” OR “ON”

A

G

ProCarManuals.com

PG

TKWB2686E

Revision: 2006 July PG-9 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

IGNITION POWER SUPPLY — IGNITION SW. IN “ON” AND/OR “START”

ProCarManuals.com

TKWB2687E

Revision: 2006 July PG-10 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

G

ProCarManuals.com

PG

TKWB2688E

Revision: 2006 July PG-11 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

ProCarManuals.com

TKWB0538E

Revision: 2006 July PG-12 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

G

ProCarManuals.com

PG

TKWB0539E

Revision: 2006 July PG-13 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

ProCarManuals.com

TKWB2689E

Revision: 2006 July PG-14 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

G

ProCarManuals.com

PG

TKWA1753E

Revision: 2006 July PG-15 2007 Murano

POWER SUPPLY ROUTING CIRCUIT

Fuse NKS0025C

● If fuse is blown, be sure to eliminate cause of malfunction before

installing new fuse.

● Use fuse of specified rating. Never use fuse of more than speci-

fied rating.

● Do not partially install fuse; always insert it into fuse holder prop-

erly.

● Remove fuse for “ELECTRICAL PARTS (BAT)” if vehicle is not

used for a long period of time.

CEL083

Fusible Link NKS0025D

A melted fusible link can be detected either by visual inspection or by

feeling with finger tip. If its condition is questionable, use circuit

tester or test lamp.

CAUTION:

● If fusible link should melt, it is possible that critical circuit

(power supply or large current carrying circuit) is shorted.

In such a case, carefully check and eliminate cause of mal-

function.

ProCarManuals.com

● Never wrap outside of fusible link with vinyl tape. Important:

Never let fusible link touch any other wiring harness, vinyl

or rubber parts. CKIB0293E

Circuit Breaker NKS0025E

The PTC thermistor generates heat in response to current flow. The

temperature (and resistance) of the thermistor element varies with

current flow. Excessive current flow will cause the element's temper-

ature to rise. When the temperature reaches a specified level, the

electrical resistance will rise sharply to control the circuit current.

Reduced current flow will cause the element to cool. Resistance falls

accordingly and normal circuit current flow is allowed to resume.

SEL109W

Revision: 2006 July PG-16 2007 Murano

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PFP:284B7 A

System Description NKS0025F

● IPDM E/R (Intelligent Power Distribution Module Engine Room) integrates the relay box and fuse block B

which were originally placed in engine compartment. It controls integrated relay via IPDM E/R control cir-

cuit.

● IPDM E/R-integrated control circuit performs ON-OFF operation of relay, CAN communication control, oil

pressure switch signal, and hood switch signal reception, etc. C

● It controls operation of each electrical part via ECM, BCM and CAN communication lines.

CAUTION:

None of the IPDM E/R-integrated relays can be removed. D

SYSTEMS CONTROLLED BY IPDM E/R

IPDM E/R receives a request signal from each control unit with CAN communication. It controls each system. E

Control system Transmit control unit Control part

● Headlamps (HI, LO)

Lamp control BCM ● Front fog lamps F

● Parking, license plate, side marker and tail lamps

Wiper control BCM Front wipers

G

Rear window defogger control BCM Rear window defogger

ProCarManuals.com

A/C compressor control ECM A/C compressor (magnet clutch)

Cooling fan control ECM Cooling fan H

Horn control BCM Horn

CAN COMMUNICATION LINE CONTROL I

With CAN communication, by connecting each control unit using two communication lines (CAN L line, CAN H

line), it is possible to transmit maximum amount of information with minimum wiring. Each control unit can

transmit and receive data, and reads necessary information only.

J

Fail-Safe Control

● When CAN communication with other control units is impossible, IPDM E/R performs fail-safe control.

After CAN communication recovers normally, it also returns to normal control. PG

● Operation of control parts by IPDM E/R during fail-safe mode is as follows:

Controlled system Fail-safe mode

L

● With the ignition switch ON, the headlamp (LO) is ON.

Headlamp

● With the ignition switch OFF, the headlamp (LO) is OFF.

● With the ignition switch ON, the parking, license plate, side marker and tail lamps are ON. M

Parking, license plate, side marker and

tail lamps ● With the ignition switch OFF, the parking, license plate, side marker and tail lamps are

OFF.

● With the ignition switch ON, the cooling fan HI operates.

Cooling fan

● With the ignition switch OFF, the cooling fan stops.

Until the ignition switch is turned OFF, the front wiper LO and HI remains in the same status

Front wiper

it was in just before fail−safe control was initiated.

Rear window defogger Rear window defogger relay OFF

A/C compressor A/C compressor OFF

Front fog lamps Front fog lamp relay OFF

Revision: 2006 July PG-17 2007 Murano

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R STATUS CONTROL

In order to save power, IPDM E/R switches status by itself based on each operating condition.

1. CAN communication status

● CAN communication is normally performed with other control units.

● Individual unit control by IPDM E/R is normally performed.

● When sleep request signal is received from BCM, mode is switched to sleep waiting status.

2. Sleep waiting status

● Process to stop CAN communication is activated.

● All systems controlled by IPDM E/R are stopped. When 3 seconds have elapsed after CAN communi-

cation with other control units is stopped, mode switches to sleep status.

3. Sleep status

● IPDM E/R operates in low power mode.

● CAN communication is stopped.

● When a change in CAN communication line is detected, mode switches to CAN communication status.

● When a change hood switch or ignition switch signal is detected, mode switches to CAN communica-

tion status.

CAN Communication System Description NKS0025G

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Modern

vehicles are equipped with many electronic control units and each control unit shares information and links

ProCarManuals.com

with other control units during operation (not independent). In CAN communication, control units are con-

nected with 2 communication lines (CAN H line, CAN L line) allowing a high rate of information transmission

with less wiring. Each control unit transmits/receives data but selectively reads required data only.

CAN Communication Unit NKS0025H

Refer to LAN-49, "CAN System Specification Chart" .

Function of Detecting Ignition Relay Malfunction NKS0025I

● When contact point of integrated ignition relay is stuck and cannot be turned OFF, IPDM E/R turns ON tail

and parking lamps for 10 minutes to indicate ignition relay malfunction.

● When a state of ignition relay having built-in does not agree with a state of Ignition switch signal input by a

CAN communication from BCM, IPDM E/R lets tail lamp relay operate.

Ignition switch signal Ignition relay status Tail lamp relay

ON ON —

OFF OFF —

ON OFF —

OFF ON ON (10 minutes)

NOTE:

When the ignition switch is turned ON, the tail lamps are OFF.

Revision: 2006 July PG-18 2007 Murano

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

CONSULT-II Function (IPDM E/R) NKS0025J

A

CONSULT-II can display each diagnostic item using the diagnostic test mode shown following.

Inspection Item, Diagnosis Mode Description

SELF-DIAG RESULTS The IPDM E/R performs diagnosis of the CAN communication and self-diagnosis. B

DATA MONITOR The input/output data of the IPDM E/R is displayed in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

C

ACTIVE TEST The IPDM E/R sends a drive signal to electronic components to check their operation.

CONSULT-II INSPECTION PROCEDURE

D

Refer to GI-37, "CONSULT-II Start Procedure" .

SELF-DIAG RESULTS

Operation Procedure E

1. Touch “SELF-DIAG RESULTS” on “SELECT DIAG MODE” screen.

2. Check display content in self-diagnostic results.

Display Item List F

CONSULT-II TIME

Display Items Malfunction detecting condition Possible causes

display code CRNT PAST G

NO DTC IS

ProCarManuals.com

DETECTED.FURTHER

- - - - -

TESTING MAY BE

H

REQUIRED.

● If CAN communication reception/transmis- Any of or several items

sion data has a malfunction, or if any of the below have errors.

control units malfunction, data reception/ I

CAN COMM CIRCUIT U1000 transmission cannot be confirmed. × × ● TRANSMIT DIAG

● ECM

● When the data in CAN communication is not

received before the specified time ● BCM/SEC J

NOTE:

The details for display of the period are as follows:

PG

● CRNT: Error currently detected with IPDM E/R.

● PAST: Error detected in the past and memorized with IPDM E/R.

DATA MONITOR L

Operation Procedure

1. Touch “DATA MONITOR” on “SELECT MONITOR ITEM ” screen.

2. Touch “ALL SIGNALS”, “MAIN SIGNALS” or “SELECTION FROM MENU” on the “DATA MONITOR” M

screen.

ALL SIGNALS All items will be monitored.

MAIN SIGNALS Monitor the predetermined item.

SELECTION FROM MENU Select any item for monitoring.

3. Touch the required monitoring item on “SELECTION FROM MENU”. In “ALL SIGNALS”, all items are

monitored. In “MAIN SIGNALS”, predetermined items are monitored.

4. Touch “START”.

5. Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”.

Revision: 2006 July PG-19 2007 Murano

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

All Signals, Main Signals, Selection From Menu

Monitor item selection

CONSULT-II SELEC-

Item name Display or unit ALL MAIN TION Description

screen display

SIGNALS SIGNALS FROM

MENU

Motor fan request MOTOR FAN REQ 1/2/3/4 × × × Signal status input from ECM

Compressor request AC COMP REQ ON/OFF × × × Signal status input from ECM

Tail & clear request TAIL&CLR REQ ON/OFF × × × Signal status input from BCM

H/L LO request HL LO REQ ON/OFF × × × Signal status input from BCM

H/L HI request HL HI REQ ON/OFF × × × Signal status input from BCM

Front fog request FR FOG REQ ON/OFF × × × Signal status input from BCM

Headlamp washer HL WASHER

ON/OFF × × Signal status input from BCM

request REQ*1

STOP/1LOW/

Front wiper request FR WIP REQ × × × Signal status input from BCM

LOW/HI

Wiper auto stop WIP AUTO STOP ACT P/STOP P × × × Output status of IPDM E/R

Wiper protection WIP PROT OFF/BLOCK × × × Control status of IPDM E/R

Starter request ST RLY REQ*2 ON/OFF × × Status of input signal

ProCarManuals.com

Ignition relay status monitored

Ignition relay status IGN RLY ON/OFF × × ×

with IPDM E/R

Rear window defog-

RR DEF REQ ON/OFF × × × Signal status input from BCM

ger request

Oil pressure switch OIL P SW OPEN/CLOSE × × Signal status input in IPDM E/R

Day time light request DTRL REQ*1 ON/OFF × × Signal status input from BCM

Hood switch HOOD SW ON/OFF × × Signal status input in IPDM E/R

Theft warning horn

THFT HRN REQ ON/OFF × × Signal status input from BCM

request

Horn chirp HORN CHIRP ON/OFF × × Output status of IPDM E/R

NOTE:

● Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is at ACC, the display may not be cor-

rect.

● *1: This item is displayed, but does not function.

● *2: The vehicle without the Intelligent Key system displays only ON without change.

Revision: 2006 July PG-20 2007 Murano

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

ACTIVE TEST

Operation Procedure A

1. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Touch item to be tested.

B

3. Touch “START”, and confirm its operation.

4. Touch “STOP” while testing to stop the operation.

Test item CONSULT-II screen display Description C

With a certain ON-OFF operation, the tail lamp relay can be oper-

Tail lamp operation TAIL LAMP

ated.

Rear window defogger opera- With a certain ON-OFF operation, the rear window defogger relay D

REAR DEFOGGER

tion can be operated.

With a certain operation (OFF, HI ON, LO ON), the front wiper relay

Front wiper (HI, LO) operation FRONT WIPER

(Lo, Hi) can be operated.

E

Cooling fan operation MOTOR FAN With a certain operation (1,2,3,4), the cooling fan can be operated.

Headlamp washer operation HEAD LAMP WASHER NOTE —

With a certain operation (OFF, HI ON, LO ON, FOG ON), the lamp F

Lamp (HI, LO, FOG) operation LAMPS

relay (Lo, Hi, Fog) can be operated.

Horn operation HORN Push “ON” button, horn relay operates 20ms.

G

NOTE:

Headlamp washer item is displayed, but cannot be tested.

ProCarManuals.com

Auto Active Test NKS0025K H

DESCRIPTION

In auto active test mode, operation inspection can be performed when IPDM E/R sends a drive signal to the

following systems: I

● Rear window defogger

● Front wipers

● Parking, license plate, side marker and tail lamps J

● Front fog lamps

● Headlamps (Hi, Lo)

● A/C compressor (magnetic clutch) PG

● Cooling fan

OPERATION PROCEDURE L

1. Close hood and front door (passenger side), and then lift wiper arms away from windshield (to prevent

glass damage by wiper operation).

NOTE: M

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn ignition switch OFF.

3. Turn ignition switch ON, and within 20 seconds, open and close 10 times of front door LH. Then turn igni-

tion switch OFF.

4. Turn ignition switch ON within 10 seconds after ignition switch OFF.

5. When auto active test mode is actuated, horn chirps once. Oil pressure warning lamp starts blinking.

6. After a series of operations is repeated three times, auto active test is completed.

NOTE:

When auto active test mode has to be cancelled halfway, turn ignition switch OFF.

CAUTION:

Be sure to inspect BL-43, "Check Door Switch" when the auto active test cannot be performed.

Revision: 2006 July PG-21 2007 Murano

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

INSPECTION IN AUTO ACTIVE TEST MODE

When auto active test mode is actuated, the following eight steps are repeated three times.

SKIB7835E

(A): Oil pressure warning lamp is blinking when the auto active test operating.

Operation steps

ProCarManuals.com

Test item Operation time/ frequency

1 Rear window defogger 10 seconds

2 Front wiper LO 5 seconds → HI 5 seconds

3 Parking, license plate, side marker and tail lamps 10 seconds

4 Front fog lamps 10 seconds

5 Headlamp (LO) 10 seconds

6 NOTE ON⇔OFF 5 times

Headlamp (HI)

7 A/C compressor (magnetic clutch) ON⇔OFF 5 times

8 Cooling fan LO 5 seconds → HI 5 seconds

NOTE:

Turns ON-OFF the solenoid to switch HI/LO. In this case, the bulb does not illuminate.

Revision: 2006 July PG-22 2007 Murano

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Concept of Auto Active Test

● IPDM E/R actuates auto active test mode when it receives door switch signal from BCM via CAN commu- A

nication line. Therefore, when auto active test mode is activated successfully, CAN communication

between IPDM E/R and BCM is normal.

● If any of systems controlled by IPDM E/R cannot be operated, possible cause can be easily diagnosed B

using auto active test.

Diagnosis chart in auto active test mode

Symptom Inspection contents Possible cause C

YES ● BCM signal input system malfunction

Any of front wipers, tail ● Lamp/wiper motor malfunction

and parking lamps, front Perform auto active D

● Lamp/wiper motor ground circuit malfunction

fog lamps, and head test. Does system in

lamps (Hi, Lo) do not question operate? NO ● Harness/connector malfunction between IPDM E/R and system in

operate. question

E

● IPDM E/R (integrated relay) malfunction

YES ● BCM signal input circuit malfunction

Perform auto active ● Rear window defogger relay malfunction F

Rear window defogger test. Does rear win- ● Harness/connector malfunction between IPDM E/R and rear window

does not operate. dow defogger oper- NO defogger relay

ate?

● Open circuit of rear window defogger G

● IPDM E/R malfunction

ProCarManuals.com

● BCM signal input circuit malfunction

YES ● CAN communication signal between BCM and ECM. H

Perform auto active ● CAN communication signal between ECM and IPDM E/R

A/C compressor does

test. Does magnetic ● Magnetic clutch malfunction

not operate.

clutch operate? I

● Harness/connector malfunction between IPDM E/R and magnetic

NO

clutch

● IPDM E/R (integrated relay) malfunction

J

● ECM signal input circuit

YES

● CAN communication signal between ECM and IPDM E/R

Perform auto active

Cooling fan does not ● Cooling fan motor malfunction PG

test. Does cooling fan

operate. ● Harness/connector malfunction between IPDM E/R and cooling fan

operate?

NO

motor

● IPDM E/R (integrated relay) malfunction L

● Harness/connector malfunction between IPDM E/R and oil pressure

switch

YES

Perform auto active ● Oil pressure switch malfunction M

Oil pressure warning test. Does oil pres-

● IPDM E/R malfunction

lamp does not operate. sure warning lamp

blink? ● CAN communication signal between BCM and unified meter and A/C

NO amp.

● Combination meter

Revision: 2006 July PG-23 2007 Murano

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Schematic NKS0025L

ProCarManuals.com

TKWB2690E

Revision: 2006 July PG-24 2007 Murano

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R Terminal Arrangement NKS0025M

G

ProCarManuals.com

PG

CKIB0042E

Revision: 2006 July PG-25 2007 Murano

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R Power/Ground Circuit Inspection NKS0025N

1. CHECK FUSES AND FUSIBLE LINKS

Make sure the following fusible links or IPDM E/R fuses are not blown.

Terminal No. Power source Fuse and fusible link No.

C

E

1, 2 Battery power

71

78

OK or NG

OK >> GO TO 2.

NG >> Replace fuse or fusible link.

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector E3.

3. Check voltage between IPDM E/R harness connector E3 termi-

nals 1, 2 and ground.

1, 2 - Ground : Battery voltage

ProCarManuals.com

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

PKIB6562E

3. CHECK GROUND CIRCUIT

1. Disconnect IPDM E/R harness connectors E8 and E9.

2. Check continuity between IPDM E/R harness connectors E8 ter-

minal 38, E9 terminal 50, 60 and ground.

38, 50, 60 - Ground : Continuity should exist.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

SKIA6184E

Revision: 2006 July PG-26 2007 Murano

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Inspection with CONSULT-II (Self-Diagnosis) NKS0025O

A

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

B

1. CHECK SELF DIAGNOSTIC RESULT

1. Connect CONSULT-II and select “IPDM E/R” on “SELECT SYSTEM” screen.

2. Select “SELF-DIAG RESULTS” on the “SELECT DIAG MODE” screen. C

3. Check display content in self diagnostic results.

CONSULT-II TIME D

CONSULT-II display Details of diagnosis result

display code CRNT PAST

NO DTC IS DETECTED.

- - - No malfunction

FURTHER TESTING MAY BE REQUIRED. E

Any of or several items below have errors.

● TRANSMIT DIAG

CAN COMM CIRCUIT U1000 × ×

● ECM F

● BCM/SEC

NOTE:

G

The details for display of the period are as follows:

ProCarManuals.com

● CRNT: Error currently detected with IPDM E/R.

● PAST: Error detected in the past and memorized with IPDM E/R. H

Contents displayed

NO DTC IS DETECTED. FURTHER TESTING MAY BE REQUIRED.>> INSPECTION END

CAN COMM CIRCUIT>> After print-out of the monitor items, refer to LAN-49, "CAN System Specification I

Chart" .

PG

Revision: 2006 July PG-27 2007 Murano

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Removal and Installation of IPDM E/R NKS0025P

REMOVAL

1. Remove IPDM E/R cover A and IPDM E/R cover.

2. While spreading pawls on both side of IPDM E/R cover B,

remove IPDM E/R from IPDM E/R cover B.

3. Remove harness connector from IPDM E/R.

ProCarManuals.com

SKIA4048E

INSTALLATION

Installation is the revers order of removal.

Revision: 2006 July PG-28 2007 Murano

GROUND

GROUND PFP:00011

A

Ground Distribution NKS0025Q

MAIN HARNESS

B

G

ProCarManuals.com

PG

CKIB0294E

Revision: 2006 July PG-29 2007 Murano

GROUND

ProCarManuals.com

CKIB0295E

Revision: 2006 July PG-30 2007 Murano

GROUND

G

ProCarManuals.com

PG

CKIB0296E

Revision: 2006 July PG-31 2007 Murano

GROUND

ENGINE ROOM HARNESS

ProCarManuals.com

CKIB0297E

Revision: 2006 July PG-32 2007 Murano

GROUND

G

ProCarManuals.com

PG

CKIB0309E

Revision: 2006 July PG-33 2007 Murano

GROUND

ENGINE CONTROL HARNESS

ProCarManuals.com

CKIB0298E

Revision: 2006 July PG-34 2007 Murano

GROUND

BODY HARNESS

A

G

ProCarManuals.com

PG

CKIB0300E

Revision: 2006 July PG-35 2007 Murano

GROUND

ProCarManuals.com

CKIB0301E

Revision: 2006 July PG-36 2007 Murano

GROUND

BODY NO. 2 HARNESS

A

G

ProCarManuals.com

PG

CKIB0302E

Revision: 2006 July PG-37 2007 Murano

HARNESS

HARNESS PFP:00011

Harness Layout NKS0025R

HOW TO READ HARNESS LAYOUT

The following Harness Layouts use a map style grid to help locate

connectors on the figures:

● Main Harness

● Engine Room Harness (Engine Compartment)

● Engine Control Harness

● Body Harness

SEL252V

To Use the Grid Reference

1. Find the desired connector number on the connector list.

2. Find the grid reference.

3. On the figure, find the crossing of the grid reference letter column and number row.

4. Find the connector number in the crossing zone.

5. Follow the line (if used) to the connector.

CONNECTOR SYMBOL

ProCarManuals.com

Main symbols of connector (in Harness Layout) are indicated in the below.

CKIT0108E

Revision: 2006 July PG-38 2007 Murano

HARNESS

OUTLINE

A

G

ProCarManuals.com

TKIA0022E I

PG

Revision: 2006 July PG-39 2007 Murano

HARNESS

MAIN HARNESS

ProCarManuals.com

TKIB0607E

Revision: 2006 July PG-40 2007 Murano

HARNESS

G

ProCarManuals.com

PG

TKIB0608E

Revision: 2006 July PG-41 2007 Murano

HARNESS

ProCarManuals.com

TKIB0609E

Revision: 2006 July PG-42 2007 Murano

HARNESS

ENGINE ROOM HARNESS

Engine Compartment A

G

ProCarManuals.com

PG

TKIB0610E

Revision: 2006 July PG-43 2007 Murano

HARNESS

ProCarManuals.com

TKIB0611E

Revision: 2006 July PG-44 2007 Murano

HARNESS

Passenger Compartment

A

G

ProCarManuals.com

PG

TKIM0821E

Revision: 2006 July PG-45 2007 Murano

HARNESS

ENGINE CONTROL HARNESS

ProCarManuals.com

TKIB0613E

Revision: 2006 July PG-46 2007 Murano

HARNESS

G

ProCarManuals.com

PG

TKIM0822E

Revision: 2006 July PG-47 2007 Murano

HARNESS

BODY HARNESS

ProCarManuals.com

TKIB0615E

Revision: 2006 July PG-48 2007 Murano

HARNESS

G

ProCarManuals.com

PG

TKIB0616E

Revision: 2006 July PG-49 2007 Murano

HARNESS

BODY NO. 2 HARNESS

ProCarManuals.com

TKIB0617E

Revision: 2006 July PG-50 2007 Murano

HARNESS

ROOM LAMP HARNESS

A

G

ProCarManuals.com

PG

TKIB0618E

Revision: 2006 July PG-51 2007 Murano

HARNESS

FRONT DOOR HARNESS

LH Side

ProCarManuals.com

TKIB0619E

RH Side

TKIB0620E

Revision: 2006 July PG-52 2007 Murano

HARNESS

REAR DOOR HARNESS

LH Side A

G

ProCarManuals.com

I

TKIB0100E

RH Side

J

PG

TKIM0906E

Revision: 2006 July PG-53 2007 Murano

HARNESS

BACK DOOR HARNESS

ProCarManuals.com

TKIM0908E

Revision: 2006 July PG-54 2007 Murano

HARNESS

Wiring Diagram Codes (Cell Codes) NKS0025S

A

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

B

Code Section Wiring Diagram Name

A/C ATC Air Conditioner

ABS BRC Anti-Lock Brake System C

AF1B1 EC Air Fuel Ratio Sensor 1 Bank 1

AF1B2 EC Air Fuel Ratio Sensor 1 Bank 2

AF1HB1 EC Air Fuel Ratio Sensor 1 Heater Bank 1

D

AF1HB2 EC Air Fuel Ratio Sensor 1 Heater Bank 2

APPS1 EC Accelerator Pedal Position Sensor E

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC Automatic Speed Control Device (ASCD) Brake Switch F

ASC/SW EC Automatic Speed Control Device (ASCD) Steering Switch

ASCBOF EC Automatic Speed Control Device (ASCD) Brake Switch

G

ASCIND EC Automatic Speed Control Device (ASCD) Indicator

ProCarManuals.com

AUDIO AV Audio

AUT/DP SE Automatic Drive Positioner H

AUTO/L LT Automatic Light System

AWD TF AWD System

I

B/DOOR BL Back Door Opener

BACK/L LT Back-Up Lamp

BRK/SW EC Brake Switch J

CAN CVT CAN Communication Line

CAN EC CAN Communication Line

PG

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime L

COMBSW LT Combination Switch

COMM AV Audio Visual Communication Line

COMPAS DI Compass M

COOL/F EC Cooling Fan Control

CVTIND DI CVT Indicator Lamp

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp – With Daytime Light System

ECM/PW EC ECM Power Supply for Back-Up

ECTS EC Engine Coolant Temperature Sensor

EMNT EC Engine Mount

ETC1 EC Electric Throttle Control Function

ETC2 EC Electric Throttle Control Motor Relay

ETC3 EC Electric Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

Revision: 2006 July PG-55 2007 Murano

HARNESS

Code Section Wiring Diagram Name

FTS CVT CVT Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUELB1 EC Fuel Injection System Function (Bank 1)

FUELB2 EC Fuel Injection System Function (Bank 2)

H/AIM LT Headlamp Aiming Control System

H/LAMP LT Headlamp

HORN WW Horn

HSEAT SE Heated Seat

I/KEY BL Intelligent Key System

I/MIRR GW Inside Mirror (Auto Anti-Dazzling Mirror)

IATS EC Intake Air Temperature Sensor

IGNSYS EC Ignition System

ILL LT Illumination

INF/D AV Vehicle Information and Integrated Switch System

INJECT EC Injector

IVCB1 EC Intake Valve Timing Control Solenoid Valve Bank 1

IVCB2 EC Intake Valve Timing Control Solenoid Valve Bank 2

ProCarManuals.com

KEYLES BL Remote Keyless Entry System

KS EC Knock Sensor

L/USSV CVT Lock-Up Select Solenoid Valve

LPSV CVT Line Pressure Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN EC Main Power Supply and Ground Circuit

METER DI Speedometer, Tachometer, Temp. and Fuel Gauges

MIL/DL EC MIL & Data Link Connector

MIRROR GW Power Door Mirror

MMSW CVT Manual Mode Switch

NATS BL Nissan Anti-Theft System

NAVI AV Navigation System

NONDTC CVT Non-Detective Items

O2H2B1 EC Heated Oxygen Sensor 2 Heater Bank 1

O2H2B2 EC Heated Oxygen Sensor 2 Heater Bank 2

O2S2B1 EC Heated Oxygen Sensor 2 Bank 1

O2S2B2 EC Heated Oxygen Sensor 2 Bank 2

P/SCKT WW Power Socket

PEDAL AP Adjustable Pedal System

PGC/V EC EVAP Canister Purge Volume Control Solenoid Valve

PHSB1 EC Camshaft Position Sensor (PHASE) (Bank1)

PHSB2 EC Camshaft Position Sensor (PHASE) (Bank2)

PNP/SW CVT Park/Neutral Position Switch

PNP/SW EC Park/Neutral Position Switch

POS EC Crankshaft Position Sensor (CKPS) (POS)

POWER CVT Transmission Control Module (Power Supply)

POWER PG Power Supply Routing Circuit

Revision: 2006 July PG-56 2007 Murano

HARNESS

Code Section Wiring Diagram Name

A

PRE/SE EC EVAP Control System Pressure Sensor

PRIPS CVT Primary Pressure Sensor

PRSCVT CVT Primary Speed Sensor CVT (Revolution Sensor) B

PS/SEN EC Power Steering Pressure Sensor

ROOM/L LT Interior Room Lamp

RP/SEN EC Refrigerant Pressure Sensor C

SEAT SE Power Seat

SECPS CVT Secondary Pressure Sensor

D

SECPSV CVT Secondary Pressure Solenoid Valve

SEN/PW EC Sensor Power Supply

SESCVT CVT Secondary Speed Sensor CVT (Revolution Sensor) E

SHIFT CVT CVT Shift Lock System

SPSW CVT Second Position Switch

F

SROOF RF Sunroof

SRS SRS Supplemental Restraint System

START SC Starting System G

STM CVT Step Motor

ProCarManuals.com

STOP/L LT Stop Lamp

H

STSIG CVT Start Signal Circuit

T/WARN WT Low Tire Pressure Warning System

TAIL/L LT Parking, License and Tail Lamps I

TCV CVT Torque Converter Clutch Solenoid Valve

TPS1 EC Throttle Position Sensor (Sensor 1)

TPS2 EC Throttle Position Sensor (Sensor 2)

J

TPS3 EC Throttle Position Sensor

TRNSCV BL Homelink Universal Transceiver PG

TURN LT Turn Signal and Hazard Warning Lamp

VDC BRC Vehicle Dynamics Control System

VEHSEC BL Vehicle Security System L

VENT/V EC EVAP Canister Vent Control Valve

VIAS EC Variable Induction Air Control System

M

VIAS/V EC VIAS Control Solenoid Valve

WARN DI Warning Lamps

WINDOW GW Power Window

WIP/R WW Rear Wiper and Washer

WIPER WW Front Wiper and Washer

Revision: 2006 July PG-57 2007 Murano

ELECTRICAL UNITS LOCATION

ELECTRICAL UNITS LOCATION PFP:25230

Electrical Units Location NKS0025T

ENGINE COMPARTMENT

ProCarManuals.com

CKIB0303E

Revision: 2006 July PG-58 2007 Murano

ELECTRICAL UNITS LOCATION

PASSENGER COMPARTMENT

A

G

ProCarManuals.com

PG

CKIB0304E

Revision: 2006 July PG-59 2007 Murano

ELECTRICAL UNITS LOCATION

ProCarManuals.com

CKIB0305E

Revision: 2006 July PG-60 2007 Murano

ELECTRICAL UNITS LOCATION

LUGGAGE COMPARTMENT

A

G

ProCarManuals.com

PG

CKIB0306E

Revision: 2006 July PG-61 2007 Murano

HARNESS CONNECTOR

HARNESS CONNECTOR PFP:00011

Description NKS0025U

HARNESS CONNECTOR (TAB-LOCKING TYPE)

● The tab-locking type connectors help prevent accidental looseness or disconnection.

● The tab-locking type connectors are disconnected by pushing or lifting the locking tab(s). Refer to the fig-

ure below.

Refer to the next page for description of the slide-locking type connector.

CAUTION:

Never pull the harness or wires when disconnecting the connector.

[Example]

ProCarManuals.com

SEL769DA

Revision: 2006 July PG-62 2007 Murano

HARNESS CONNECTOR

HARNESS CONNECTOR (SLIDE-LOCKING TYPE)

● A new style slide-locking type connector is used on certain systems and components, especially those A

related to OBD.

● The slide-locking type connectors help prevent incomplete locking and accidental looseness or discon-

nection. B

● The slide-locking type connectors are disconnected by pushing or pulling the slider. Refer to the figure

below.

CAUTION: C

● Never pull the harness or wires when disconnecting the connector.

● Be careful not to damage the connector support bracket when disconnecting the connector.

D

[Example]

G

ProCarManuals.com

PG

SEL769V

Revision: 2006 July PG-63 2007 Murano

HARNESS CONNECTOR

HARNESS CONNECTOR (LEVER LOCKING TYPE)

● Lever locking type harness connectors are used on certain control units and control modules such as

ECM, ABS actuator and electric unit (control unit), etc.

● Lever locking type harness connectors are also used on super multiple junction (SMJ) connectors.

● Always confirm the lever is fully locked in place by moving the lever as far as it will go to ensure full con-

nection.

CAUTION:

Always confirm the lever is fully released (loosened) before attempting to disconnect or connect these

connectors to avoid damage to the connector housing or terminals.

ProCarManuals.com

LKIA0670E

1. Control unit with single lever 2. Control unit with dual levers 3. SMJ connector

A. Fasten A. Levers A. Lever

B. Loosen B. Fasten B. Fasten

C. Lever C. Loosen C. Loosen

Revision: 2006 July PG-64 2007 Murano

ELECTRICAL UNITS

ELECTRICAL UNITS PFP:00011

A

Terminal Arrangement NKS0025V

G

ProCarManuals.com

PG

CKIA0322E

Revision: 2006 July PG-65 2007 Murano

ELECTRICAL UNITS

ProCarManuals.com

CKIB0051E

Revision: 2006 July PG-66 2007 Murano

SMJ (SUPER MULTIPLE JUNCTION)

SMJ (SUPER MULTIPLE JUNCTION) PFP:B4341

A

Terminal Arrangement NKS0025W

G

ProCarManuals.com

PG

CKIA0292E

Revision: 2006 July PG-67 2007 Murano

STANDARDIZED RELAY

STANDARDIZED RELAY PFP:00011

Description NKS0025X

NORMAL OPEN, NORMAL CLOSED AND MIXED TYPE RELAYS

Relays can mainly be divided into three types: normal open, normal closed and mixed type relays.

ProCarManuals.com

SEL881H

TYPE OF STANDARDIZED RELAYS

1M ···················· 1 Make 2M ···················· 2 Make

1T ···················· 1 Transfer 1M·1B ···················· 1 Make 1 Break

SEL882H

Revision: 2006 July PG-68 2007 Murano

STANDARDIZED RELAY

G

ProCarManuals.com

PG

SEL188W

Revision: 2006 July PG-69 2007 Murano

FUSE BLOCK - JUNCTION BOX (J/B)

FUSE BLOCK - JUNCTION BOX (J/B) PFP:24350

Terminal Arrangement NKS0025Y

ProCarManuals.com

CKIM0725E

Revision: 2006 July PG-70 2007 Murano

FUSE, FUSIBLE LINK AND RELAY BOX

FUSE, FUSIBLE LINK AND RELAY BOX PFP:24382

A

Terminal Arrangement NKS0025Z

G

ProCarManuals.com

PG

CKIB0308E

Revision: 2006 July PG-71 2007 Murano

FUSE, FUSIBLE LINK AND RELAY BOX

ProCarManuals.com

Revision: 2006 July PG-72 2007 Murano

You might also like

- Power Supply, Ground & Circuit Elements: SectionDocument88 pagesPower Supply, Ground & Circuit Elements: SectionЗахарПивоваровNo ratings yet

- Nissan-Versa 2015 EN US Manual de Taller Ecu Modulo Carroceria Relay-Of-Ventilador Radiador Etc A21c4b9aaa.Document72 pagesNissan-Versa 2015 EN US Manual de Taller Ecu Modulo Carroceria Relay-Of-Ventilador Radiador Etc A21c4b9aaa.victor borjaNo ratings yet

- Nissan-Versa 2015 EN US Manual de Taller Bateria Fusible Principal Manojo de Cable Etc 91df20fe6dDocument72 pagesNissan-Versa 2015 EN US Manual de Taller Bateria Fusible Principal Manojo de Cable Etc 91df20fe6dvictor borjaNo ratings yet

- Hyundai VelosterDocument21 pagesHyundai VelosterVitorMelloNo ratings yet

- EngineDocument184 pagesEngineBruce McarthurNo ratings yet

- Driveshaft Servicing GuideDocument19 pagesDriveshaft Servicing GuideNilson BarbosaNo ratings yet

- Vehicle Diagnostics and Repair Manual SectionsDocument388 pagesVehicle Diagnostics and Repair Manual SectionsPaúl TorresNo ratings yet

- Catalog Dill 2022Document64 pagesCatalog Dill 2022BillNo ratings yet

- Suzuki LianaDocument23 pagesSuzuki Lianawebscanz100% (2)

- Ford Fiesta Common Problems Solutions Hints and TipsDocument6 pagesFord Fiesta Common Problems Solutions Hints and TipsEndro PrayitnoNo ratings yet

- Ford Courier ('91) 1.3 engine specificationsDocument2 pagesFord Courier ('91) 1.3 engine specificationscosminNo ratings yet

- Subaru Symmetrical A WD 2Document4 pagesSubaru Symmetrical A WD 2Anonymous 3NmUUDtNo ratings yet

- Audi A8 2018 EwdDocument2,392 pagesAudi A8 2018 EwdNguyen Sy Duc100% (1)

- TRANSMISSION - Pontiac Grand Prix GTP 1997 - SYSTEM WIRING DIAGRAMS PDFDocument3 pagesTRANSMISSION - Pontiac Grand Prix GTP 1997 - SYSTEM WIRING DIAGRAMS PDFRicardo Alejandro Castro HernándezNo ratings yet

- Workshop Manual: EngineDocument228 pagesWorkshop Manual: EngineAlexander Rivera100% (1)

- Electronic Control ModulesDocument294 pagesElectronic Control ModulesMuhammed DoumaNo ratings yet

- DTC P0100 Mass or Volume Air Flow Circuit DTC P0102 Mass or Volume Air Flow Circuit Low Input DTC P0103 Mass or Volume Air Flow Circuit High InputDocument7 pagesDTC P0100 Mass or Volume Air Flow Circuit DTC P0102 Mass or Volume Air Flow Circuit Low Input DTC P0103 Mass or Volume Air Flow Circuit High InputImesh SachinthaNo ratings yet

- Immobilizer ECU User's Manual: 1. GeneralDocument2 pagesImmobilizer ECU User's Manual: 1. GeneralObd King TgiNo ratings yet

- Vincard16 Car 08-23-16 r1.12Document29 pagesVincard16 Car 08-23-16 r1.12rahulNo ratings yet

- Toyota CH-R Service Manual - Passenger Side Buckle Switch Circuit Malfunction (B1771) - Occupant Classification SystemDocument13 pagesToyota CH-R Service Manual - Passenger Side Buckle Switch Circuit Malfunction (B1771) - Occupant Classification SystemJulius ThomasNo ratings yet

- Group 11aDocument105 pagesGroup 11azeljkoNo ratings yet

- Section: Body InteriorDocument54 pagesSection: Body Interiortecnicofigueroa100% (1)

- Riverside County Short-Term Rental Ordinance ChangesDocument22 pagesRiverside County Short-Term Rental Ordinance ChangesThe Press-Enterprise / pressenterprise.comNo ratings yet

- Engine Component Removal GuideDocument126 pagesEngine Component Removal Guidevictor borjaNo ratings yet

- Regulation R115 Handbook LPG Sequent SystemDocument35 pagesRegulation R115 Handbook LPG Sequent SystemEliel Costa SilvaNo ratings yet

- Technical Service Information: Automatic Transmission Service GroupDocument4 pagesTechnical Service Information: Automatic Transmission Service GroupPlanta Damiana2No ratings yet

- Evb PDFDocument185 pagesEvb PDFinterlo0% (1)

- 2012 Audi S4 Engine AssemblyDocument186 pages2012 Audi S4 Engine AssemblymattNo ratings yet

- FordDocument43 pagesFordval boz100% (1)

- Jaguar XF Engine Junction BoxDocument3 pagesJaguar XF Engine Junction BoxAlex GovorovNo ratings yet

- Dayco Serpentine Belt GuideDocument89 pagesDayco Serpentine Belt GuidemastervikingNo ratings yet

- Lada 4X4 User PDFDocument85 pagesLada 4X4 User PDFVasile Alexandru MuresanNo ratings yet

- JHQ3750 Ins PDFDocument34 pagesJHQ3750 Ins PDFAlice ZakariaNo ratings yet

- Subaru Impreza 2007 Factory Service Repair ManualDocument5,199 pagesSubaru Impreza 2007 Factory Service Repair ManualBenRoqhqioeNo ratings yet

- CVT PDFDocument358 pagesCVT PDFMan Jeans SportNo ratings yet

- 2013 Ford Transit ConnectDocument321 pages2013 Ford Transit ConnectramzibtrNo ratings yet

- Versa RadioDocument90 pagesVersa Radiomysticdrag0n555100% (1)

- A00IGA40220 MaintenanceDocument135 pagesA00IGA40220 MaintenanceStanciu Ionuţ100% (1)

- Check Crankshaft and Camshaft Sensor LocationsDocument3 pagesCheck Crankshaft and Camshaft Sensor LocationsLeandro FerreiraNo ratings yet

- 2013 GMC Terrain OwnersDocument362 pages2013 GMC Terrain Ownerstechnowizard100% (2)

- Your car and the MOT: essential checks for roadworthinessDocument8 pagesYour car and the MOT: essential checks for roadworthinessvidhyaa1011No ratings yet

- Electrical Component LocationsDocument59 pagesElectrical Component Locationsdanieldario33No ratings yet

- General Information OverviewDocument48 pagesGeneral Information OverviewKhalid AwanNo ratings yet

- 2010 Ford Transit Connect Cole Story Ford Kalamazoo MIDocument15 pages2010 Ford Transit Connect Cole Story Ford Kalamazoo MICole Story FordNo ratings yet

- Electrical DistributionDocument94 pagesElectrical DistributionRepuesto GeneralNo ratings yet

- 2016 Cadillac CtsDocument399 pages2016 Cadillac CtsСергій БоженкоNo ratings yet

- Ford 2011 ObdDocument251 pagesFord 2011 ObdschraeubleNo ratings yet

- Volvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi 2-3 SEZ4Document47 pagesVolvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi 2-3 SEZ4Luciano Liuzzi0% (1)

- Autel MaxScan GS500 Scan Tool User ManualDocument50 pagesAutel MaxScan GS500 Scan Tool User ManualQuliar Lucy100% (1)

- Service BulletinDocument5 pagesService Bulletinohromeo100% (1)

- Electrical System: GI MADocument324 pagesElectrical System: GI MADarioNo ratings yet

- QR25DE Starting System GuideDocument56 pagesQR25DE Starting System GuideDiego496No ratings yet

- Juke 2012Document145 pagesJuke 2012Jhonn OliveraNo ratings yet

- Toro Super Recycler 3322-287Document24 pagesToro Super Recycler 3322-287skustarzNo ratings yet

- L314 Freelander 2004 LHDDocument165 pagesL314 Freelander 2004 LHDDubois BoxNo ratings yet

- Lan System: SectionDocument103 pagesLan System: SectiontecnicofigueroaNo ratings yet

- 303-14 Electronic Engine Controls - Diagnosis and TestingDocument38 pages303-14 Electronic Engine Controls - Diagnosis and TestingCARLOS LIMADANo ratings yet

- D3E800C3A16-Heating Ventilation and Air ConditioningDocument731 pagesD3E800C3A16-Heating Ventilation and Air ConditioningAlvaro pionNo ratings yet

- Cableado Tierra Electrica y Circuitos Nissan VersaDocument78 pagesCableado Tierra Electrica y Circuitos Nissan VersaHumberto Vega Sanchez100% (1)

- Manual x431Document102 pagesManual x431Erickson GarciaNo ratings yet

- Abs App Chart Euro Asian UpgradeDocument5 pagesAbs App Chart Euro Asian UpgradeErickson GarciaNo ratings yet

- Fuel System Guide for B Engine SectionDocument12 pagesFuel System Guide for B Engine SectionErickson GarciaNo ratings yet

- Minimum System Requirements: Important: Please Do Not Disconnect The Tool, Close The Windows®Document1 pageMinimum System Requirements: Important: Please Do Not Disconnect The Tool, Close The Windows®Erickson GarciaNo ratings yet

- dct250 Powershift Rebuild ManualDocument94 pagesdct250 Powershift Rebuild ManualErickson Garcia100% (4)

- Technical Bulletin # 1264: Valve Body BreakdownDocument5 pagesTechnical Bulletin # 1264: Valve Body BreakdownErickson GarciaNo ratings yet

- Engine MechanicalDocument154 pagesEngine MechanicalErickson GarciaNo ratings yet

- LAN SYSTEM OVERVIEWDocument94 pagesLAN SYSTEM OVERVIEWErickson GarciaNo ratings yet

- Starting Charging SystemDocument30 pagesStarting Charging SystemErickson GarciaNo ratings yet

- Adjustable Pedal System OverviewDocument18 pagesAdjustable Pedal System OverviewErickson GarciaNo ratings yet

- Body Control System OverviewDocument14 pagesBody Control System OverviewErickson GarciaNo ratings yet

- RoofDocument44 pagesRoofErickson GarciaNo ratings yet

- RoofDocument44 pagesRoofErickson GarciaNo ratings yet

- Vehicle Coverage Upgrade To Get The Codes.: US/Support/DownloadDocument1 pageVehicle Coverage Upgrade To Get The Codes.: US/Support/DownloadErickson GarciaNo ratings yet

- Manual de Reparacion para Transmision Automatica Modelo A130Document89 pagesManual de Reparacion para Transmision Automatica Modelo A130Jose David Huanca Taype100% (5)

- Body Control SystemDocument14 pagesBody Control SystemErickson GarciaNo ratings yet

- Auto Cruise Control SystemDocument2 pagesAuto Cruise Control SystemErickson GarciaNo ratings yet

- Vehicle Coverage Upgrade To Get The Codes.: US/Support/DownloadDocument1 pageVehicle Coverage Upgrade To Get The Codes.: US/Support/DownloadErickson GarciaNo ratings yet

- Daewoo 8140le RepairDocument90 pagesDaewoo 8140le RepairCarlos Aceldo Toromoreno67% (3)

- Previous MenuDocument88 pagesPrevious MenuFSR1407100% (1)

- Daewoo 8140le RepairDocument90 pagesDaewoo 8140le RepairCarlos Aceldo Toromoreno67% (3)

- Vehicle Coverage Upgrade To Get The Codes.: US/Support/DownloadDocument1 pageVehicle Coverage Upgrade To Get The Codes.: US/Support/DownloadErickson GarciaNo ratings yet

- Product Information: Monte Diesel Engine Oil Api Service Cf-4Document1 pageProduct Information: Monte Diesel Engine Oil Api Service Cf-4PT.TANESHA INDUSTRINo ratings yet

- Research Proposal: Customer Attitude Towards "TATA NANO" On Present ScenarioDocument18 pagesResearch Proposal: Customer Attitude Towards "TATA NANO" On Present ScenarioDhaval RamiNo ratings yet

- Toyota U151E U151F Transmission Repair Manual RM1021UDocument155 pagesToyota U151E U151F Transmission Repair Manual RM1021UJd Diaz100% (1)

- Locomotive - IntroductionDocument13 pagesLocomotive - IntroductionArpan MaheshwariNo ratings yet

- ESMF 2 Collective CLOA Environmental Social Performance CC-ESP Assessment - Latest Version - Labels - 2022-10!03!02!09!12Document212 pagesESMF 2 Collective CLOA Environmental Social Performance CC-ESP Assessment - Latest Version - Labels - 2022-10!03!02!09!12Liko DollNo ratings yet

- DD422iE Development Drill: Technical SpecificationDocument4 pagesDD422iE Development Drill: Technical SpecificationCindy MoralesNo ratings yet

- PU-Series Electric Pumps EN-USDocument2 pagesPU-Series Electric Pumps EN-USChinmay ChawareNo ratings yet

- Manual Tire Changer ACCU 5802 HPDocument68 pagesManual Tire Changer ACCU 5802 HPlilaupc0% (1)

- PSI Inspection SheetDocument9 pagesPSI Inspection SheetSalman BankariNo ratings yet

- PRD108Document2 pagesPRD108Rizki Heru HermawanNo ratings yet

- 40 Series SM 11026743Document40 pages40 Series SM 11026743gerallazo29No ratings yet

- 2100s-2110s Yedek Parça KatalogDocument251 pages2100s-2110s Yedek Parça KatalogЧанко ДеневNo ratings yet

- Owner'S Manual: Model SE-1-12S Automatic Battery Charger / MaintainerDocument8 pagesOwner'S Manual: Model SE-1-12S Automatic Battery Charger / MaintainerFXNScottNo ratings yet

- Marketing Strategy of Tata MotarsDocument63 pagesMarketing Strategy of Tata MotarsPriyanka SharmaNo ratings yet

- The Future of Electric Vehicles in IndiaDocument15 pagesThe Future of Electric Vehicles in Indiamayurkh73No ratings yet

- Deutz 1011 Spec SheetDocument6 pagesDeutz 1011 Spec SheetJulian Alberto AlvarezNo ratings yet

- Tupi BV: Cosco (Dalian)Document4 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Project Maruti SuzukiDocument77 pagesProject Maruti SuzukiKushal Nandwani33% (3)

- Machine IntroductionDocument53 pagesMachine IntroductionSyahrir KobarNo ratings yet

- Ae Ae Ad Ac Ab Aa Z y X W V U T S R Q P o N M L K J I H G F e D C B ADocument1 pageAe Ae Ad Ac Ab Aa Z y X W V U T S R Q P o N M L K J I H G F e D C B ACRACNo ratings yet

- Two Wheel Drive Forklift For Indusrial WarehousesDocument31 pagesTwo Wheel Drive Forklift For Indusrial WarehousesKalai SelvanNo ratings yet

- D8 Instruments and controlsDocument73 pagesD8 Instruments and controlsFernando KrothNo ratings yet

- GL XX Mobil Polyrex EM SeriesDocument3 pagesGL XX Mobil Polyrex EM SeriesRakka HardiyantaNo ratings yet

- EN CANbus Filter by Engine StateDocument5 pagesEN CANbus Filter by Engine StateCesar MartinezNo ratings yet

- SM VOLVO L90C WHEEL LOADER Service Repair ManualDocument16 pagesSM VOLVO L90C WHEEL LOADER Service Repair ManualMarco Yarasca Romero100% (2)

- Rivian CEO RJ Scaringe E-Mail To Customers July 16, 2021Document1 pageRivian CEO RJ Scaringe E-Mail To Customers July 16, 2021CNBC.comNo ratings yet

- Tamd 63Document2 pagesTamd 63Cristiano NunesNo ratings yet

- ZF 5055 NR2HDocument4 pagesZF 5055 NR2HJUNIOR OLIVONo ratings yet

- Joshua Custodio Bsme 5B 1Document4 pagesJoshua Custodio Bsme 5B 1Datu JonathanNo ratings yet

- C K4SD Manual Jan.2021Document8 pagesC K4SD Manual Jan.2021RadNo ratings yet