Professional Documents

Culture Documents

Analysis On Torque, Flowrate, and Volumetric Displacement of Gerotor Pump - Motor

Analysis On Torque, Flowrate, and Volumetric Displacement of Gerotor Pump - Motor

Uploaded by

Luka JelovčanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis On Torque, Flowrate, and Volumetric Displacement of Gerotor Pump - Motor

Analysis On Torque, Flowrate, and Volumetric Displacement of Gerotor Pump - Motor

Uploaded by

Luka JelovčanCopyright:

Available Formats

연구논문 Journal of Drive and Control, Vol.17 No.2 pp.28-37 Jun.

2020

ISSN 2671-7972(print) ISSN 2671-7980(online)

http://dx.doi.org/10.7839/ksfc.2020.17.2.028

Analysis on Torque, Flowrate, and Volumetric Displacement of

Gerotor Pump/Motor

Hongsik Yun1, Young-Bog Ham2 and Sungdong Kim1*

Received: 02 Apr. 2020, Revised: 14 May 2020, Accepted: 18 May 2020

Key Words:Torque Equilibrium, Energy Conservation, Volumetric Displacement, Flowrate, Rotation Speed,

Gerotor Pump/Motor

Abstract: It is difficult to analytically derive the relationship among volumetric displacement, flowrate, torque, and

rotation speed regarding an instantaneous position of gerotor hydraulic pumps/motors. This can be explained by the

geometric shape of the rotors, which is highly complicated. Herein, an analytical method for the instantaneous

torque, rotation speed, flowrate, and volumetric displacement of a pump/motor is proposed. The method is based on

two physical concepts: energy conservation and torque equilibrium. The instantaneous torque of a pump/motor shaft

is determined for the posture of rotors from the torque equilibrium. If the torque equilibrium is combined with the

energy conservation between the hydraulic energy of the pump/motor and the mechanical input/output energy, the

formula for determining the instantaneous volumetric displacement and flowrate is derived. The numerical values of

the instantaneous volumetric displacement, torque, rotation speed, and flowrate are calculated via the MATLAB

software programs, and they are illustrated for the case in which inner and outer rotors rotate with respect to fixed

axes. The degrees of torque fluctuation, speed fluctuation, and flowrate fluctuation can be observed from their

instantaneous values. The proposed formula may provide a better understanding of the design or analysis process of

gerotor pumps/motors.

Nomenclature : distance from the center of outer rotor to the

center of circular part

: eccentricity between centers of inner and outer : contact force

rotors : load torque on a pump/motor shaft

: force induced by pressure distribution : volumetric displacement per revolution

: number of outer rotor's lobes

: coordinates of pitch point Subscripts

: instantaneous flow rate

: radius of outer rotor's circular part 1 : inner rotor

2 : outer rotor

* Corresponding author: sdkim@kumoh.ac.kr

1 Department of Mechanical System Engineering, Kumoh

1. Introduction

National Institute of Technology, Gumi 39177, Korea

2 Energy Systems Research Division, KIMM, Deajeon 34103,

Gerotor gears have been used for small-sized pumps

Korea

Copyright Ⓒ 2020, KSFC and high-torque hydraulic motors. They produce an

This is an Open-Access article distributed under the terms of the

Creative Commons Attribution Non-Commercial License(http://

internal contact movement and rotate at a speed that is

creativecommons.org/licenses/by-nc/3.0) which permits unrestricted inversely proportional to the number of lobes (or gears)

non-commercial use, distribution, and reproduction in any medium,

provided the original work is properly cited. of the outer rotors, thereby maintaining the centers and

28 Journal of Drive and Control 2020. 6

Hongsik Yun, Young-Bog Ham and Sungdong Kim

pitch point of the inner and outer rotors fixed in space. calculation to obtain the contact points is also

Circular arc curves are generally used as lobe profiles introduced. This study was conducted for the case of

of outer rotors for design and processing convenience. rotating inner and outer rotors, as shown in Fig. 1. The

The shapes of the inner rotors are generated by the centers of the rotors, O1 and O2, and the pitch point, p,

gear profiles of the outer rotors and exhibit a trochoid were assigned as spatially constant points. The

curve1-4). numerical values of the instantaneous volumetric

Generally, gerotor hydraulic pumps/motors exhibit displacement, torque, rotation speed, and flowrate were

highly complicated geometric shapes, which complicate calculated via MATLAB software programs, and they

the calculation of their volumetric displacements using are illustrated herein for the case in which the inner

geometric methods. Previous studies5-7) have proposed and outer rotors rotate with respect to the fixed axes.

methods for calculating the volumetric displacement by The degrees of torque, speed, and flowrate fluctuations

directly calculating the chamber volume between the were observed from the instantaneous values of torque,

contact points of the inner and outer rotors. The speed, and flowrate, respectively.

procedures and formulas of this method are highly

complicated; therefore, the method is difficult to reflect

in design. For example, the flowrate of pumps/motors

and the torque and rotation speed of pump/motor shafts

are difficult to calculate.

Many studies8-13) have introduced formulas for

calculating volumetric displacement using the contact

point lengths of inner and outer rotors (hereinafter, vane

length). The vane length method is based on kinematic

analysis of the inner and outer rotors’ motion, and thus,

it is hard to understand how the pressure and contact

forces between the rotors affect the instantaneous torque

Fig. 1 Rotation of inner and outer rotors

of the pump/motor shaft. The vane length method is

also hard to give relations among torque, flowrate and

2. Torque, volumetric displacement, and

volumetric displacement of the gerotor pump/motors.

flowrate

This study considered a method for calculating the

instantaneous volume change rate, rotation speed, and

2.1 Energy conservation

torque of pumps/motors based on two concepts: the

The energy conservation principle was applied

torque equilibrium of the rotors and energy conservation

between the hydraulic energy and the mechanical torque

between the hydraulic energy of pumps/motors and

energy in the hydraulic pump/motor, as shown in Fig.

mechanical energy of driving shafts. The torque of the

2. For the convenience of interpretation, we assumed

pump/motor is derived from the torque equilibrium,

that the efficiency was ideally 100%, the pressure of

which may provide direct insight into the torque and

the high-pressure section was , and that of the

show how the pressure and contact forces affect the

low-pressure section was 0.

instantaneous torque fluctuation. The formula equations

Based on these assumptions, we derived the energy

about the instantaneous flowrate, rotor speed and

conservation equation with respect to the rotation of the

volumetric displacement of the pump/motor are also

pump/motor shaft by , as follows:

derived from combining the torque equilibrium with the

energy conservation equation. The contact points

∙ ∙ (1)

between the inner and outer rotors should be used in

the calculation process of volumetric displacement. The

where is the load torque on the pump/motor

드라이브 · 컨트롤 2020. 6 29

Analysis on Torque, Flowrate, and Volumetric Displacement of Gerotor Pump/Motor

shaft, the volumetric displacement or supply inner and outer rotors, is number of the outer

volume of fluid with respect to the rotation by , rotor’s lobes, and subscript means the th chamber.

and the supply pressure.

a) pump b) motor

Fig. 2 Hydraulic energy and shaft torque energy

Fig. 3 Free-body diagram of the inner rotor

of pump/motors

2.2 Torque equilibrium

The load torque, , can be obtained as a function

of the pressure, , from the torque equilibrium

equation with respect to the free-body diagram of the

inner and outer rotors, as shown in Figs. 3 and 4.

Although a slight difference existed according to

whether the driving axis of the pump/motor is

connected to the inner rotor or to the outer rotor, we

assumed that the driving axis was connected to the

Fig. 4 Free-body diagram of the outer rotor

inner rotor because of its similarity to the development

process of interpretation.

As shown in Fig. 5, the effect of torque by the

In Fig. 3 and 4, is the force on the contact

hydraulic force between and can be expressed

point, , of the inner and outer rotors, and is the

with respect to the centers, O1 and O2, respectively, as

hydraulic force by the pressure, . The contact and

follows:

hydraulic forces, which act on the inner and outer

rotors, respectively, establish the relationship between

the force and reaction force, creating a pair; hence,

although their action points and sizes are identical, they

act in opposite directions from the inner and outer

(4)

rotors. The effect of hydraulic force on the cross

section is dependent on the projected area of the cross

(5)

section and is independent of the shape of the cross

section; it can be expressed as follows:

for ⋯ (2)

In equation (5), the first “–” represents the opposite

direction from that of the torque acting on the inner

(3) rotor. and represent the

hydraulic force components in the x- and y- directions,

where is the distance between the adjacent

contact points and , b is the thickness of the respectively; and are the

30 Journal of Drive and Control 2020. 6

Hongsik Yun, Young-Bog Ham and Sungdong Kim

coordinates of the centers of the hydraulic force;

(7)

and are the

lengths of the moment arm with respect to the rotation The torque generated from the outer rotor, ∑ ,

centers of the inner and outer rotors, respectively. is transferred to the inner rotor in the proportion of the

pitch radius of the inner rotor, , to the pitch radius

of the outer rotor, . Additionally, the proportion of

to is proportional to the number of lobes of the

inner and outer rotors.

(8)

Rearranging equations (7) and (8) and substituting

Fig. 5 Volume of a chamber between two

into equation (6) yields

contact points and and

In the free-body diagram shown in Fig. 3, the

(9)

horizontal and vertical components of the contact force,

, and the hydraulic force, , achieve equilibrium

Substituting equations (4) and (5) into equation (9)

with the support force of the bearing. However, in this

yields

case, the bearing force can be disregarded because it is

not a parameter of interest. The moment equilibrium

equation with respect to the center of the inner rotor,

(10)

O1, is expressed in the form of equilibrium between the

load torque and the sum of the torque effect of the

hydraulic force , ∑ , and that of the contact

force of the lobes of the outer rotor, ∑ , is

expressed as follows:

Many contact points equal to the number of lobes of

(6)

the outer rotor emerge between the inner and outer

rotors, as shown in Fig. 3 and 4. Assuming that the

where is the number of chambers of the chambers emerging from the contact points from to

high-pressure section on which the pressure, , of the

are high-pressure chambers, the torque effect of all

high-pressure section acts.

high-pressure chambers, ∑ , can be expressed using

Because the load torque, , does not act on the

only the initial and final contact points of the

torque equilibrium of the outer rotor, as shown in the

high-pressure section, and , respectively. This is

free-body diagram in Fig. 4, the torque effect of the

hydraulic force enters equilibrium with that of the because the coordinate of a high-pressure chamber

contact force; that is, the reaction torque transferred corresponds to of the next high-pressure chamber,

through the contact points from the inner rotor, and they offset each other. Equation (10) simplifies this

∑ , has the same magnitude as that of the as follows:

hydraulic force, ∑ .

드라이브 · 컨트롤 2020. 6 31

Analysis on Torque, Flowrate, and Volumetric Displacement of Gerotor Pump/Motor

corresponding angles.

max min

max min

max min

max min

max min

max min

max min

∙ max min

max

min

max min

max

min

max min

(11)

max min

where m ax m ax is the farthest contact point

max min

max

min

max min

from the pitch point, ; m in m in is the

(14)

nearest contact point, ; is the number of

high-pressure chambers; is equal to if the In addition, the volumetric displacement per rotation,

number of lobes of the outer rotor, , is an even , is obtained by multiplying Formula (14) by one

number. By contrast, if is an odd number, it can be rotation, 2π rad.

expressed as a function of the rotation of the inner

rotor, , as follows:

∙

max min

for ≤ ≤

∙

max min

for ≤ ≤

max

max min

min

max min

for ⋯ (12) max min

2.3 Volumetric displacement and flowrate of

max min

max min

pump/motors (15)

By substituting equation (11) into equation (1), the

volume change rate of fluid with respect to the rotation The instantaneous flowrate, , can be expressed as

by , , can be obtained as follows: follows:

max min

max min lim

→

max min

max min

max

min

max min

max min max min

max min

max

min

max min max min

max

min max min

(13)

max

max min

min

The volume change rate, , represents the (16)

instantaneous volume change rate with respect to the

where is the angular velocity of the inner rotor

instantaneous rotation angle of the rotor.

The average value of the volume change rates of all and is the time.

high-pressure chambers, , is obtained by The average flowrate, , can be expressed as

integrating equation (13) for the range of angles in follows:

equation (12) and dividing the integrated values by the

32 Journal of Drive and Control 2020. 6

Hongsik Yun, Young-Bog Ham and Sungdong Kim

connecting the pitch point to the center coordinate of

(17)

the circular part of the outer rotor,

is as follows:

3. Contact points of the inner and outer

rotors

(22)

The motion of the rotors comprises the rotation of

sin

the inner rotor, , and that of the outer rotor, , as

cos

shown in Fig. 1. The instantaneous displacement of the

pitch point, , at the center of the inner rotor, ,

The circular equation of the outer rotor with as

coincides with the displacement at the center of the the center is as follows:

outer rotor, .

(23)

(18)

where is the radius of the outer rotor’s circular

Because the proportion of to is proportional to part.

the number of lobes of the inner and outer rotors, The intersection points of equations (22) and (23)

become the contact points, .

(19)

4. Numeric examples

The contact points at these respective lobes are the Based on equations (11)–(23), the instantaneous

points at which the line connecting the center of the volume change rate, flowrate, torque, and rotation speed

circular arc gear profile of the outer rotor to the pitch were calculated via a MATLAB program code. The

point meets the circular arc gear profile curve, as gerotor considered in the numeric example was the case

shown in Fig. 1. The center coordinate of the circular in which the inner and outer rotors rotated with respect

part of the outer rotor,

, varies with the rotation

to the fixed axes.

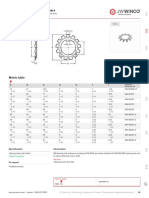

angle, , and can be expressed as follows: Table 1 lists the basic specifications of the gerotor

pump/motor used for the numerical analysis, and Fig. 6

(20) shows the profiles of the inner and outer rotors of the

cos sin

basic specifications. Additionally, Fig. 6 shows the

states of the inner and outer rotors at the rotation angle

of in the inner rotor. Fig. 7 shows the flowchart of

where and are the unit vectors in the horizontal the MATLAB program.

axial and vertical axial directions, respectively. is the

distance from the axis, of the outer rotor to the Table 1 Specifications of gerotor pump/motor

center of the circular part. used in numerical analysis

The coordinates of the pitch points, which are fixed Item Data (mm)

points, are Number of outer rotor lobes 4

Number of inner rotor lobes 3

(21) Eccentricity (e) 2.5

Radius of circular part of outer rotor ( ) 6.5

where is the eccentricity between the centers of the Distance of O2 – Sk ( ) 16.5

inner and outer rotors. The linear equation Rotor thickness (b) 1.5

드라이브 · 컨트롤 2020. 6 33

Analysis on Torque, Flowrate, and Volumetric Displacement of Gerotor Pump/Motor

Fig. 6 Profiles of the inner and outer rotors used

Fig. 8 Plot of volume change rate

in the analysis

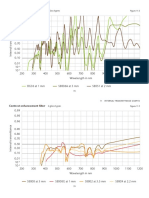

The maximum value of the volume change rate is

75.0 mm3/rad when the rotation angle of the inner

rotor, , is zero. The minimum volume change rate is

56.25 mm3/rad at of 1.047 rad. The maximum

fluctuation from the average value is 7.54 %, whereas

the minimum fluctuation is 19.34 %.

The instantaneous flowrate discharged from a pump

can be calculated from equation (16). Figs. 9 and 10

illustrate the flowrates for two cases: when the pump

driving shaft speeds are 183.26 rad/s (or 1750 rpm) and

122.52 rad/s (or 1170 rpm). Figs. 9 and 10 show plots

of the instantaneous pump flowrate with respect to the

rotation angle of the inner rotor and time,

respectively. These figures are similar to Fig. 8. All the

fluctuation ratios of the instantaneous pump flowrate are

the same as that of the volume change ratio, which is

shown in Fig. 8.

Fig. 7 Flowchart to calculate numeric values

Fig. 8 illustrates a graph of the volume change rate

based on equation (13) in Section 2.3. The data values

on the horizontal axis are the rotation angles of the

inner rotor, , and at the point where is ± 0.5818

rad, the volume change rate is identical to the average

volume change rate of 69.74 mm3/rad. The value

multiplied by is the volumetric displacement per

revolution, which is calculated to be 438.19

Fig. 9 Plots of pump flowrates with respect to

mm3/revolution.

rotation angle of inner rotor

34 Journal of Drive and Control 2020. 6

Hongsik Yun, Young-Bog Ham and Sungdong Kim

Fig. 11 Plots of motor rotation speed with

Fig. 10 Plots of pump flowrates with respect to

respect to rotation angle of inner rotor

time

Equation (16) may be used to calculate the

instantaneous rotation speed of a gerotor-type motor.

Hydraulic fluid was assumed to be incompressible and

the pressure in a relief valve was set much higher than

the normal range of working pressure of the gerotor

motor, that is, the inertia load pressure was negligibly

small. The flowrate supplied into the motor was

assumed to be constant. Under these assumptions, the

instantaneous speed of the motor can be expressed as

follows:

Fig. 12 Plots of motor rotation speed with

respect to time

(24)

Figs. 13 and 14 show plots of instantaneous motor

Figs. 11 and 12 show plots of the instantaneous torques with respect to the rotation angle of the inner

motor rotation speed with respect to the rotation angle rotor, and time, respectively. The main features of

of the inner rotor, and time, respectively. Figs. 11 these figures are similar to those of Fig. 8–10.

and 12 illustrate the flowrates for two cases: when the If equation (11) is transformed to the following

3

motor flowrates are 3.33× m /s (or 20 lpm) and equation (25), the equation may be applicable to

3

1.67×

m /s (or 10 lpm). The shape of the motor calculate the instantaneous outlet pressure of a

speed fluctuation resembles a upside down shape of gerotor-type pump when the input torque is assumed to

Fig. (8)–(10). This is because the motor speed is be constant.

inversely proportional to the volume change rate,

. (25)

The output torque of a motor can be calculated from

equation (11). Figs. 13 and 14 illustrate the load where the volume change rate is given as

torques acting on a motor shaft for two cases: when the equation (13). Equation (25) is a static relation and the

5 2

supply pressures to the motor are 100× 10 N/m (or pump should rotate at a low speed such that equation

100 bar) and 70× 105 N/m2 (or 70 bar). (25) can be used reasonably.

드라이브 · 컨트롤 2020. 6 35

Analysis on Torque, Flowrate, and Volumetric Displacement of Gerotor Pump/Motor

should be calculated in the calculation process of the

volume change rate, rotation speed, and torque of the

pump/motor. A series of responses of the instantaneous

volume change rate, rotation speed, and torque of

pumps/motors was illustrated for specific geometric

parameters of a gerotor shape. However, those

calculated responses may show some errors from real

responses because the inertia of the pump/motors and

compliance effect of oil are not considered in those

torque equilibrium and energy conservation equations.

Fig. 13 Plots of motor output torque with respect Acknowledgement

to rotation angle of inner rotor

This research was supported by Kumoh National

Institute of Technology (grant number 2019-104-048).

Conflicts of Interest

The authors declare that there is no conflict of

interest.

References

1) J. R. Colbourne, "The Geometry of Trochoid

Envelopes and their Application in Rotary Pumps",

Fig. 14 Plots of motor output torque with respect Mechanism and Machine Theory, Vol.9,

to time pp.421-435, 1974.

2) C. B. Tsay and C. Y. Yu, "Mathematical Model

However, typical pumps are operated at high speeds for the Profile of Gerotor Pumps", Journal of the

and the outlet pressure should be set dynamically based

Chinese Society of Mechanical Engineers, Vol.10,

on the flow continuity of the outlet volume, pumping

No.1, pp.41-47, 1989.

flowrate fluctuation, fluid compressibility, etc. Therefore,

3) D. W. Dudley, Handbook of Practical Gear Design,

equation (25) may be meaningless when real pumps are

McGraw-Hill, New York, pp.1-33, 1984.

used.

4) H.-S. Jung, Y. M. Lim and Y.-B. Ham, "New

Tooth Type Design and Characteristic Analysis for

5. Conclusion

High Density Gerotor Pump", Journal of Drive and

Control, Vol.16 No.4, pp.80-86, 2019.

This study proposed a method for calculating the

5) J. R. Colbourne, "Gear Shape and Theoretical Flow

instantaneous volume change rate, flowrate, rotation

Rate in Internal Gear Pumps", Transactions of the

speed, and torque of pumps/motors based on two basic

Canadian Society for Mechanical Engineering,

concepts: the torque equilibrium of rotors and the

Vol.3, No.4, pp.215-223, 1975.

energy conservation between the hydraulic energy of

6) S.-C. Lee, "Profile Design of the Inner Rotor of a

pumps/motors and mechanical energy of driving shafts.

Gerotor by the Composite Curve of Circular Arcs",

The contact points between the inner and outer rotors

36 Journal of Drive and Control 2020. 6

Hongsik Yun, Young-Bog Ham and Sungdong Kim

Journal of the Korean Society of Tribologists and Pumps", Journal of Mechanical Design, Vol.132,

Lubrication Engineers, Vol.22, No.2, pp.79-86, 2006. 064503, 2010.

7) J. C. Kim, J. H. Shin, and S. M. Kwon, "A Study 11) D. C. H. Yang, Jia Yan and S.-H. Tong, "Flowrate

on Gear Tooth Profile of a Positive Displacement Formulation and Displacement Analyses for

Rotor Pump", Proceedings of the Korean Society of Deviation Function-based Gerotor Pumps",

Machine Tool Engineers, Fall Conference, Proceedings of the Institution of Mechanical

pp.106-111, 2006. Engineers, Part C: Journal of Mechanical

8) S. D. Kim et al., "An Analysis on Volumetric Engineering Science, Vol.225, pp.480-487, 2010.

Displacement of Gerotor Pump/Motor Using Vane 12) K. J. Huang and W. C. Lian, "Kinematic Flowrate

Length", Transactions of the Korea Fluid Power Characteristics of External Spur Gear Pumps using

Systems Society, Vol.8, No.2, pp.8-16, 2011. an Exact closed Solution", Mechanism and Machine

9) N. D. Manring and S. B. Kasaragadda, "The Theory, Vol.44, pp.1121-1131, 2009.

Theoretical Flow Ripple of an External Gear 13) S. W. Choi, C. D. Lee and S. Y. Yang, "A Study

on Simulation of Piston Number for Development

Pump", Journal of Dynamic Systems, Measurement,

of Axial Piston Pump for Wheeled Armored

and Control, Vol.125, No.3, pp.396-404, 2003.

Vehicle", Journal of Drive and Control, Vol.16,

10) D. C. H. Yang, J. Yan, S.-H. Tong, "Flowrate

No.1, pp.14-21, 2019.

Formulation of Deviation Function Based Gerotor

드라이브 · 컨트롤 2020. 6 37

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rotor Balancing Simulator: Fourth Year Graduation ProjectDocument21 pagesRotor Balancing Simulator: Fourth Year Graduation ProjectMahmoud SamirNo ratings yet

- Tos - General Physics 1 Quarter 1Document3 pagesTos - General Physics 1 Quarter 1Javer Degorio100% (1)

- Class 9th NBF 2022 (CH 1 2 3 4 5 6 7) Conceptual QuestionsDocument67 pagesClass 9th NBF 2022 (CH 1 2 3 4 5 6 7) Conceptual QuestionsGhalib khattakNo ratings yet

- CEP233 - M5 - Taping CorrectionsDocument29 pagesCEP233 - M5 - Taping CorrectionsRobert Macalanao100% (2)

- Parker TB Series CatalogDocument26 pagesParker TB Series CatalogLuka JelovčanNo ratings yet

- Pel Job EB25.4 DataDocument6 pagesPel Job EB25.4 DataLuka JelovčanNo ratings yet

- AD.5.I... Cetop 5: Automatic Reciprocating ValvesDocument1 pageAD.5.I... Cetop 5: Automatic Reciprocating ValvesLuka JelovčanNo ratings yet

- Gear Pumps Motor gr.1 2 3 Catalogue ENGDocument184 pagesGear Pumps Motor gr.1 2 3 Catalogue ENGLuka JelovčanNo ratings yet

- Proxima: Proxima CL Proxima HsDocument16 pagesProxima: Proxima CL Proxima HsLuka JelovčanNo ratings yet

- Proxima Patio Ceiling Fan Installation InstructionsDocument10 pagesProxima Patio Ceiling Fan Installation InstructionsLuka JelovčanNo ratings yet

- Thrust Ball Bearings, Single Direction - 20210507Document3 pagesThrust Ball Bearings, Single Direction - 20210507Luka JelovčanNo ratings yet

- Bearing Lock Washers: Metric TableDocument1 pageBearing Lock Washers: Metric TableLuka JelovčanNo ratings yet

- Thermochemistry 2 - Entropy and EnthalpyDocument18 pagesThermochemistry 2 - Entropy and Enthalpyx seyiNo ratings yet

- KOKM 072 Xa 10 - 1VLC000600 Rev. 2, en 2016 - 12 - 08Document7 pagesKOKM 072 Xa 10 - 1VLC000600 Rev. 2, en 2016 - 12 - 08TetianaNo ratings yet

- Endress-Hauser RTD-Assembly U S Style T14 ENDocument4 pagesEndress-Hauser RTD-Assembly U S Style T14 ENangel uscangaNo ratings yet

- GMP 13 Good Measurement Practice For Ensuring Metrological TraceabilityDocument16 pagesGMP 13 Good Measurement Practice For Ensuring Metrological TraceabilityLaukuervogiraldogmail.com CuervoNo ratings yet

- GCSE - AQA - Forces and Their Interactions - MSDocument9 pagesGCSE - AQA - Forces and Their Interactions - MSOlayinkaNo ratings yet

- Experiment 110-Kirchhoffs-LawsDocument5 pagesExperiment 110-Kirchhoffs-LawsKarl CastroNo ratings yet

- Short NotesDocument23 pagesShort NotesPAVANKUMAR SHIRASANGINo ratings yet

- Module 1 Fundamentals of Deformable Bodies StressDocument16 pagesModule 1 Fundamentals of Deformable Bodies StressJune del MundoNo ratings yet

- Assessment Test in Tle Ict TD 10 (For Uploading)Document2 pagesAssessment Test in Tle Ict TD 10 (For Uploading)Marlon Joseph D. ManzanoNo ratings yet

- RL RLC Load 222Document3 pagesRL RLC Load 222hamza mandlwiNo ratings yet

- Schott Optical 8Document6 pagesSchott Optical 8mardonio andradeNo ratings yet

- ICSE Class 10 Physics Paper-1 Question Paper Solutions 2018Document14 pagesICSE Class 10 Physics Paper-1 Question Paper Solutions 2018Venu MaheshNo ratings yet

- Sub-Electrical Machine and Switchgear Subjectcode-Ee21118 Branch-MeDocument11 pagesSub-Electrical Machine and Switchgear Subjectcode-Ee21118 Branch-MeDeepan DattaNo ratings yet

- Cen-Tech 63759Document8 pagesCen-Tech 63759GregNo ratings yet

- ATV930 - Unidade de Frenagem e Resistencias de Frenagem - Nov2018Document8 pagesATV930 - Unidade de Frenagem e Resistencias de Frenagem - Nov2018Dyana GontijoNo ratings yet

- Physics 28th June Shift-2Document20 pagesPhysics 28th June Shift-2Suman KumariNo ratings yet

- Zelio Control RM4TA32 PDFDocument7 pagesZelio Control RM4TA32 PDFariessukmawanNo ratings yet

- MATH 1240 Sorge s23.T00727646.Homework Set 2Document6 pagesMATH 1240 Sorge s23.T00727646.Homework Set 2priyanshuNo ratings yet

- Measurement Second Quarter - Module 15: MathematicsDocument30 pagesMeasurement Second Quarter - Module 15: MathematicsHe HeNo ratings yet

- S4e350 Ao02 98Document5 pagesS4e350 Ao02 98Arnold Olivares GomezNo ratings yet

- Carver AV-405 Service ManualDocument38 pagesCarver AV-405 Service ManualTom KakanowskiNo ratings yet

- Physics Lab LQ2 Misterm - Group 2Document5 pagesPhysics Lab LQ2 Misterm - Group 2Stefhanie Brin BotalonNo ratings yet

- Bsc. Csit Entrance Mock Test - V: Saral Notes Presents in Association With Iit NepalDocument4 pagesBsc. Csit Entrance Mock Test - V: Saral Notes Presents in Association With Iit NepalassfdfsdfafNo ratings yet

- TESTO 104 Digital Thermometer OKDocument3 pagesTESTO 104 Digital Thermometer OKAaron Matthew BasteNo ratings yet

- CGCAT Exam For TECHNICAL Officers (Mechanical) - Model QPDocument9 pagesCGCAT Exam For TECHNICAL Officers (Mechanical) - Model QPBiswanath SamantarayNo ratings yet

- Chapter 7Document2 pagesChapter 7Monisha RNo ratings yet