Professional Documents

Culture Documents

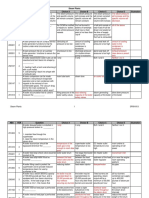

Longitudinal Section B-B Transverse Section A-A: Welding Details Not To Scale

Uploaded by

bunkeringOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Longitudinal Section B-B Transverse Section A-A: Welding Details Not To Scale

Uploaded by

bunkeringCopyright:

Available Formats

A

16 3187 16

B 640 449 505 628 358 608

12

377

LOW WATER LEVEL

16

2514

16

1575

50

1116

100° 50

50

120°

687

60

434

650 650

60

508

16

50

16

12

1594 933

300 2526 529 100 352

16 16 16

1504

B A LONGITUDINAL SECTION B-B ITEMS

DESCRIPTION QUANTITY MATERIAL REMARK

NO

TRANSVERSE SECTION A-A 1 WATER SHELL 1 SA-516 G70 12 thick

WELDING DETAILS 2 FRONT TUBE PLATE 1 SA-516 G70 16 thick

not to scale 3 REAR TUBE PLATE 1 SA-516 G70 16 thick

°

MAX. 6 3 35° 1-3 5 °-45

19° 19° 3 4 FURNACE 1 SA-516 G70 16 thick

348 348 HOLE

5 WET BACK WRAPPER PLATE 1 SA-516 G70 16 thick

6 WET BACK REAR PLATE 1 SA-516 G70 16 thick

35°

1.5 - 3

7 BAR STAY ROD 6 Ø40

- 45

SA-36

3

Ø283 Ø283

°

8 CLEANING HOLE 6 SA-105 6 thick

Ø261

3

Ø26

1 5°

9 FLANGE FOR CLEANING HOLE 6 SA-516 G70 12 thick

1 35°-4

STAND PIPE WELDING TO SHELL 10 MAIN STEAM STAND PIPE 1 SA-105 4 thick

TUBE PLATE TO SHELL WELDING MANHOLE TO SHELL WITH PAD WELDING FIGURE : 3.6.2 (1) BS 2790 11 FLANGE FOR MAIN STEAM STAND PIPE 1 SA-516 G70 12 thick

FIGURE : 3.5 (C) BS 2790

Ø200 Ø200 FIGURE : B(3) (B) BS 2790 12 SAFETY VALVE STAND PIPE 2 SA-105 3 thick

Ø125 CLEANING HOLE TO SHELL WITH PAD WELDING 13 FLANGE FOR SAFETY VALVE STAND PIPE 2 SA-516 G70 10 thick

Ø181

Ø181

FIGURE : 3.5 (C) BS 2790

14 FEED WATER STAND PIPE 1 SA-105 3 thick

MIN.3

45°

13 15 STAND FOR FEED WATER STAND PIPE 1 SA-516 G70 10 thick

Ø174

Ø174

50

1

35° 16 DRAIN VALVE STAND PIPE 1 SA-105 3 thick

3

32 - 45 1

Ø1 Ø132 °

17 FLANGE FOR DRAIN VALVE STAND PIPE 1 SA-516 G70 3 thick

304

50 18 WATER AUTO CONTROL STAND PIPE 2 SA-105 3 thick

Ø1

Ø5 hole

41

41 50

Ø1

19 FLANGE FOR WATER AUTO CONTROL STAND PIPE 2 SA-516 G70 10 thick

225

62 1.5

1-3 35° 3 20 TEMPERATURE GAUGE 1 - -

- 45

°

3

21 LIFTING LUG 2 MILD STEEL 25 thick

22 2nd PASS TUBE 48 SA 106 Ø51

SEAM PIPE TO SHELL WELDING REVERSAL CHAMBER STAYS

23 3rd PASS TUBE 44 SA 106 Ø51

60

FIGURE : 3.8.2(5)(b) BS 2790

FIGURE : 3.5 (C) BS 2790

DRAIN PIPE TO SHELL WELDING

TUBE PLATE TO TUBE WELDING (FIRETUBE & STAY TUBE) FIGURE : 3.5 (C) BS 2790 INSPECTING AUTHORITY

60°

50

FIGURE : 3.9.2 (2) BS 2790

BOILER DATA

HORIZONTAL FIRETUBE

BOILER TYPE

BOILER

1-3

RE-INFORCEMENT OF TUBE PLATE CODE AND STANDARD BBR, BS, ASME

1.5-3

STEAM CAPACITY 2000 KG/HR

SHELL SEAM WELDING (LONG & CROSS)

FIGURE : (B) (C) BS 2790 WORKING PRESSURE 150 psi or 10.54 kg/cm2

0

275 psi or 19.3kg/cm2

10

HYDRAULIC TEST PRESSURE

R-

FLANGE AS PER BBR

d DESIGN TEMPERATURE 184 °C

SL.

150

77

DESCRIPTION HOLE NO. hc

NO. QTY. id od d d-1 t t-1 h h-1 hc

DIA HOLE d-1 HEATING SURFACE 53.99 m2 / 581.14 ft2

od Ø76

id WATER HOLDING CAPACITY 4054.02 L DESIGN/MANUFACTURER TITLE

1 STEAM VALVE 1 50 58 154 76 12 4 150 1 120 12 6

10

GOLDEN BOILER COMPANY LIMITED THREE PASS WETBACK HORIZONTAL FIRETUBE BOILER

t

2 AUX. STOP VALVE 38 45 127 58 10 3 130 1 102 10 6 FUEL GAS OR OIL

76 200 Kuturia Bazar Main Road Ashulia, Savar, Dhaka CONSTRUCTIONAL DRAWING

h-1

3 SAFETY VALVE 2 32 38 120 54 10 3 200 1 94 10 6 OVERALL DIA 1751mm

TUBE HOLE CENTRE DISTANCE

h

4 PRESSURE GAUGE 1 20 25.40 106 40 9 2.70 125 1 84 9 4 OVERALL LENGTH 3855mm DESIGNED BY MODEL NO. GBC/HFT/2000/10.5 SCALE 1:20 PROJECTION

400

5 BLOWDOWN VALVE 1 38 45.00 127 58 10 3.50 130 1 102 10 6 OVERALL HEIGHT 2514mm

4 DRAIN PIPE 1 38 45 127 58 10 3.50 130 1 102 10 6

APPROVED BY REJVI AHMED DRAWING NO. GBC/HFT/2000/002 UNIT MILIMETER

6 FEED WATER PIPE 1 32 38 120 54 10 3 200 1 94 10 6

WATER GAUGE PIPE t-1 DETAILS OF LIFTING HOOK 01

7 1 32 38 120 54 10 3 200 1 94 10 6 DRAWN BY MAKERS NO. GBC/HFT/2000/002 SHEET NO. FORMAT A-2

You might also like

- Instant Assessments for Data Tracking, Grade 4: MathFrom EverandInstant Assessments for Data Tracking, Grade 4: MathRating: 5 out of 5 stars5/5 (2)

- Economiser Coil - DrawingDocument1 pageEconomiser Coil - DrawingAnjaneya ReddyNo ratings yet

- Ygnis Ingl+ S Multiflam 170.1-200.1Document24 pagesYgnis Ingl+ S Multiflam 170.1-200.1DihorulNo ratings yet

- PRO 810354 02 Poster-SteamBoilerEquipment enDocument1 pagePRO 810354 02 Poster-SteamBoilerEquipment enbertan dağıstanlıNo ratings yet

- DZL 4-1.25-AiiDocument10 pagesDZL 4-1.25-AiiSamulaNo ratings yet

- Steam Network - Spirax Sarco - Submittal PDFDocument388 pagesSteam Network - Spirax Sarco - Submittal PDFRamy MahmoudNo ratings yet

- D/LND Series Burners Installation, Operation, Service, and Parts Manual Table of ContentsDocument120 pagesD/LND Series Burners Installation, Operation, Service, and Parts Manual Table of ContentsRosanny Borges ChirinosNo ratings yet

- Research Study Diesel To BiomassDocument9 pagesResearch Study Diesel To BiomassDarrel MagnoNo ratings yet

- EPRF Report Com Fulton Steam BoilersDocument13 pagesEPRF Report Com Fulton Steam BoilersBlackzero68No ratings yet

- Miura Boilers Steam GeneratorsDocument2 pagesMiura Boilers Steam GeneratorsDhonyAhmedPradjoegoNo ratings yet

- SSGC New ConnectionDocument19 pagesSSGC New ConnectionmimranislamNo ratings yet

- Project On Conservation of Steam in Electroplating in Hero CyclesDocument7 pagesProject On Conservation of Steam in Electroplating in Hero Cyclessharanjeet4uNo ratings yet

- Bangladesh Datasheets January 2017 Wee ChieftainDocument1 pageBangladesh Datasheets January 2017 Wee ChieftainFAVIONo ratings yet

- Fulton ModSync Wiring DiagramDocument3 pagesFulton ModSync Wiring DiagramjrodNo ratings yet

- Borderer Boiler Complete ManualDocument228 pagesBorderer Boiler Complete ManualNitrogeno MPDNo ratings yet

- Boiler Comp. For 250bhpDocument2 pagesBoiler Comp. For 250bhpNewaz KabirNo ratings yet

- The Power of An Atom.: High Performance, Low Emissions, Real Energy Optimization and Trouble-Free PerformanceDocument12 pagesThe Power of An Atom.: High Performance, Low Emissions, Real Energy Optimization and Trouble-Free PerformanceCarlos LehmanNo ratings yet

- General Boiler Information on Low-Emission Firetube ModelsDocument10 pagesGeneral Boiler Information on Low-Emission Firetube Modelsnecio77No ratings yet

- Stainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Document5 pagesStainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Utada HikaruNo ratings yet

- Power plant condenser and pressure reducersDocument1 pagePower plant condenser and pressure reducersPrudhvi RajNo ratings yet

- Groundfos CR 10-10Document8 pagesGroundfos CR 10-10defriyantoNo ratings yet

- Ohio Special Operating and Maintenance Guide-Wetback 100-225HP PDFDocument135 pagesOhio Special Operating and Maintenance Guide-Wetback 100-225HP PDFIrvinSerranoJNo ratings yet

- KSR Kuebler Transparent Level Gauge Attc 5Document56 pagesKSR Kuebler Transparent Level Gauge Attc 5Hassan Sleem100% (1)

- Result: Economizer Heating Surface and Outlet Flue Gas Temperature CalculationDocument2 pagesResult: Economizer Heating Surface and Outlet Flue Gas Temperature CalculationjagjitNo ratings yet

- 2ND CLASS Boilers in Lahore CircleDocument14 pages2ND CLASS Boilers in Lahore CircleGoldenshakehandNo ratings yet

- Bill of Quantities of M. S. Pipe Fittings (O-14027)Document4 pagesBill of Quantities of M. S. Pipe Fittings (O-14027)Tanmoy DuttaNo ratings yet

- Aalborg XW SuperheaterDocument2 pagesAalborg XW SuperheaterPanagiotisNo ratings yet

- Steam Boiler Systems From Bosch: Highly Efficient and Reliable Process HeatDocument19 pagesSteam Boiler Systems From Bosch: Highly Efficient and Reliable Process Heatnemi90No ratings yet

- PRICE E1203257Mrev4-20-EST-JON EPPM MARAFIQ STG 5&6 FPS OPTION 2Document13 pagesPRICE E1203257Mrev4-20-EST-JON EPPM MARAFIQ STG 5&6 FPS OPTION 2AliZenatiNo ratings yet

- Boiler Log HourlyDocument2 pagesBoiler Log Hourlymohamed abd el attyNo ratings yet

- Eskom auxiliary boiler spare parts supply contract pricing dataDocument33 pagesEskom auxiliary boiler spare parts supply contract pricing dataTrịnh Đức HạnhNo ratings yet

- Boiler Parts and DefinitionDocument3 pagesBoiler Parts and DefinitionKarlFrederickNoblezaNo ratings yet

- Fulton RBCDocument112 pagesFulton RBCYolan Lopez100% (1)

- Greenoxe SeriesDocument32 pagesGreenoxe SeriesLorenzo MasottiNo ratings yet

- Booster Korean Steam Generator ManualDocument26 pagesBooster Korean Steam Generator ManualUmar MajeedNo ratings yet

- Boiler Design SoftwareDocument9 pagesBoiler Design SoftwareRaja T0% (1)

- Byworth Boilers MX Range Packaged Steam BoilersDocument8 pagesByworth Boilers MX Range Packaged Steam BoilersLEONARDO MOLERO CLEMENTENo ratings yet

- Fulton Boiler ManualDocument102 pagesFulton Boiler ManualElvis RivadeneiraNo ratings yet

- Steam Plant FundamentalsDocument228 pagesSteam Plant FundamentalsMark Allen San Antonio100% (1)

- 78 - Triumph Stoker BrochureDocument2 pages78 - Triumph Stoker BrochureMatias MancillaNo ratings yet

- RLP-1000-PM-SP-001 - IFI - Scope of Work For Detailed Engineering & Design For Storage Tanks, In-Plant Piping, Supports & Structural SteelDocument45 pagesRLP-1000-PM-SP-001 - IFI - Scope of Work For Detailed Engineering & Design For Storage Tanks, In-Plant Piping, Supports & Structural SteelAdewaleNo ratings yet

- Steam Boiler ProjectDocument32 pagesSteam Boiler ProjectSwastik BhokareNo ratings yet

- BR BoilerHouseComponents enDocument28 pagesBR BoilerHouseComponents enJosé Pedro MagalhãesNo ratings yet

- Waste Water Treatment PlantDocument10 pagesWaste Water Treatment PlantBoiler ScrubberNo ratings yet

- Central Boiler Board updates Indian boiler regulationsDocument12 pagesCentral Boiler Board updates Indian boiler regulationsGajanan JagtapNo ratings yet

- Boiler OfferDocument10 pagesBoiler OfferManohar PandianNo ratings yet

- WTP Drawings PDFDocument3 pagesWTP Drawings PDFpastorgeeNo ratings yet

- Model 4WI 100-800 HP Boilers Provides Low NOx Emissions and High EfficiencyDocument56 pagesModel 4WI 100-800 HP Boilers Provides Low NOx Emissions and High EfficiencyShafqat AfridiNo ratings yet

- Thermal Fluid Heaters Technical GuideDocument50 pagesThermal Fluid Heaters Technical GuideMuhamad Saukie100% (1)

- 400kgs Steam Boiler Oil FiredDocument5 pages400kgs Steam Boiler Oil FiredManikandanNo ratings yet

- Instruction, Operation, and Maintenance Manual Fulton Oil Fired/Gas Fired Steam BoilersDocument63 pagesInstruction, Operation, and Maintenance Manual Fulton Oil Fired/Gas Fired Steam BoilersKarla Sofia Torres Wong100% (1)

- Thermax BoilerDocument2 pagesThermax Boilerhara-kiri0% (2)

- Nrs 1-50 GestraDocument28 pagesNrs 1-50 Gestramike tsakirisNo ratings yet

- E101-3155 Package BoilersDocument12 pagesE101-3155 Package BoilersLuis Bravo SotoNo ratings yet

- Boiler: Heat Sources Materials Energy Boiler EfficiencyDocument10 pagesBoiler: Heat Sources Materials Energy Boiler EfficiencyrpercorNo ratings yet

- Boiler FormulasDocument3 pagesBoiler FormulasCaliman SabinaNo ratings yet

- STERLING 30 MTR RTM-Layout1Document1 pageSTERLING 30 MTR RTM-Layout1ASHOK KUMAR EEDAYNo ratings yet

- Bridge rail alignment optimizationDocument1 pageBridge rail alignment optimizationDINESHNo ratings yet

- L&T-MHI Flow Diagram From Heavy Fuel OilDocument1 pageL&T-MHI Flow Diagram From Heavy Fuel OilsambhuNo ratings yet

- Application of CFD To Debottleneck Production SepaDocument14 pagesApplication of CFD To Debottleneck Production SepaFernando AmoresNo ratings yet

- Questions Answers: Legarda vs. Saleeby: The Real Purpose of The Torrens System Is To Quiet Title To Land To Put A StopDocument19 pagesQuestions Answers: Legarda vs. Saleeby: The Real Purpose of The Torrens System Is To Quiet Title To Land To Put A StopNico RoaNo ratings yet

- "Employee Payroll Management System": Miss - Priyanka Abhaynath YadavDocument31 pages"Employee Payroll Management System": Miss - Priyanka Abhaynath Yadavhabeb TubeNo ratings yet

- Defying Danger RPGDocument9 pagesDefying Danger RPGmondytriggers2944No ratings yet

- Solar Bloc DatasheetDocument2 pagesSolar Bloc DatasheetandresNo ratings yet

- Master of Arts (Education) /post Graduate Diploma in Educational Management and Administration (Maedu/Pgdema) Term-End Examination June, 2020Document7 pagesMaster of Arts (Education) /post Graduate Diploma in Educational Management and Administration (Maedu/Pgdema) Term-End Examination June, 2020Shreyashi Santra MitraNo ratings yet

- CPO Science Foundations of Physics: Unit 7, Chapter 24Document47 pagesCPO Science Foundations of Physics: Unit 7, Chapter 24dheerajbhagwatNo ratings yet

- Constructors in JavaDocument5 pagesConstructors in JavaAnonymous GqTzzkOfNo ratings yet

- ISC 2023 English Language Question PaperDocument5 pagesISC 2023 English Language Question PaperMohit JoshiNo ratings yet

- MCM SQL PDFDocument8 pagesMCM SQL PDFJeyakumar NarasingamNo ratings yet

- S7SDocument336 pagesS7S217469492100% (1)

- Body in Movement - WorkshopDocument8 pagesBody in Movement - WorkshopAndrew CareyNo ratings yet

- 404handler PDFDocument33 pages404handler PDFAnonymous JijwlW7No ratings yet

- Future Developments in Management AccountingDocument4 pagesFuture Developments in Management AccountingAmar narayanNo ratings yet

- A Study of Impact of FMCG Product Packaging On Consumer Behaviour With Reference To Food Items - IOPDocument37 pagesA Study of Impact of FMCG Product Packaging On Consumer Behaviour With Reference To Food Items - IOPvaibhav rajputNo ratings yet

- Title of Training Presentation: Presented by Your NameDocument14 pagesTitle of Training Presentation: Presented by Your NameJudy UnreinNo ratings yet

- Fundamentals WindDocument67 pagesFundamentals WindwlyskrdiNo ratings yet

- ADC0804 Datasheet - ADC 0804 Pin Diagram & Description - EngineersGarageDocument3 pagesADC0804 Datasheet - ADC 0804 Pin Diagram & Description - EngineersGarageMehanathan Maggie MikeyNo ratings yet

- FREE BioGeometry Emitter PhotoDocument5 pagesFREE BioGeometry Emitter PhotoNisha Joshi75% (8)

- BP Planning&Scheduling CaterpillarDocument35 pagesBP Planning&Scheduling CaterpillarOfelia Umpire Ruiz100% (4)

- The Metacentric Height EX3Document3 pagesThe Metacentric Height EX3Edrees JamalNo ratings yet

- Feaps PortfolioDocument17 pagesFeaps Portfolioapi-317208189No ratings yet

- 4 - Microsoft PowerPoint - JDC Company ProfileDocument12 pages4 - Microsoft PowerPoint - JDC Company ProfileBill LiNo ratings yet

- Korepox Topcoat ET6572Document2 pagesKorepox Topcoat ET6572Isabelo AbaoNo ratings yet

- C++ Classes and ObjectsDocument4 pagesC++ Classes and ObjectsAll TvwnzNo ratings yet

- Vsia Ip AssetsDocument56 pagesVsia Ip AssetsAbelGuilherminoNo ratings yet

- Ch1 SlidesDocument47 pagesCh1 SlidesPierreNo ratings yet

- BukuDocument39 pagesBukusimon sembiringNo ratings yet

- BEETLE /M-II Plus: POS System For The Highest Standards of PerformanceDocument2 pagesBEETLE /M-II Plus: POS System For The Highest Standards of PerformanceHeather JensenNo ratings yet

- Navier-Stokes Equations - Wikipedia, The Free EncyclopediaDocument13 pagesNavier-Stokes Equations - Wikipedia, The Free EncyclopediaAwadeshNo ratings yet