Professional Documents

Culture Documents

APIC Template For Report On Nitrosamine Risk Assessment-Final

Uploaded by

Darshan PatelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APIC Template For Report On Nitrosamine Risk Assessment-Final

Uploaded by

Darshan PatelCopyright:

Available Formats

REPORT ON THE RISK OF POTENTIAL PRESENCE

OF NITROSAMINE IMPURITIES

Document ID:

MATERIAL

Name : …………………………………………………………………………………………………………………………

Material code(s) :………………………………………………………………………………………………………………………………………………………

MANUFACTURER (refers to the manufacturing site)

Name :……………………………………………………………………………………………………………………………………………………………………

Address :……………………………………………………………………………………………………………………………………………………………………..

This report was completed by [person / central service]:

▪ Name and position: …………………………………………………………………………………………………………………………………………………………….

▪ E-mail address: ………………………………………………………………………………………………………………………………………………………………………….

▪ Postal address: …………………………………………………………………………………………………………………………………………

Declaration:

The current manufacturing process of (the name of the substance) was assessed with respect to the risk of the presence of

Nitrosamine impurities.

The signatory expressly recognizes that all information contained in this report is based on current knowledge and is true and

sincere to his / her actual knowledge considering available supplier information and likely chemical production processes where

information from the supplier is not available. The signatory further confirms that he / she has the authority to act on behalf of

the company they represent.

The information in this document may be updated as more information becomes available.

Date, Signature and Company stamp

Document ID: Page 1 of 9

Delete this page when issuing the letter.

Instructions when using this template.

1. Replace APIC logo by your company logo.

2. In the footer, replace CEFIC logo by “This document was prepared based on APIC

template”.

3. In various places in the template, text appears in italics in square brackets, e.g. [Option 1,

Option 2, Option3]. Keep the text that applies and remove the text that don’t apply to the

situation which is being described.

4. In section 3, the detail would depend on the customer with whom the report will be

shared. The process description can be replaced by a workflow with the relevant

information for the assessment or just to reference the filing applicable section.

5. In section 3, a description of the process step where the risk assessment was initiated,

e.g. from starting material or from intermediate, should be provided with a rationale for

the selection.

6. For table in section 6, fill one line per nitrosamine which has been identified as being

possibly generated during the API manufacturing process.

Document ID: Page 2 of 9

1 INTRODUCTION

This document reports the outcome of the Risk Assessment on the above mentioned API based

on the requirements defined in the EMA notices Information on nitrosamines for marketing

authorisation holders EMA/189634/2019 and Questions and answers on ”Information on

nitrosamines for marketing authorisation holders” EMA/428592/2019 and following revisions

and other similar published by other Health Agencies.

Such evaluation on the potential risk of presence of nitrosamine impurities in the APIs was

performed using quality risk management principles, as per ICH Q9 guideline and ICH M7.

Manufacturing processes are being reviewed to identify and, if found, to mitigate risk of presence

of N-nitrosamine impurities during manufacture and storage of the drug substance.

2 SCOPE

The Risk Assessment has evaluated the following items as potential sources of nitrosamines or

their precursors in line with root causes described in Questions and answers on Information on

nitrosamines for marketing authorisation holders EMA/428592/2019:

1. Use of sodium nitrite or other nitrosating agents in presence of secondary, or tertiary

amines, or quaternary ammonium salts within the API manufacturing process either within

the same or at different process steps.

2. Use of sodium nitrite or other nitrosating agents in combination with reagents, solvents,

and catalysts, which are susceptible to degradation to secondary or tertiary amines, within

the same or different process steps.

3. Use of contaminated raw materials (e.g. solvents, reagents, catalysts)

4. Use of recovered materials (e.g. solvents, reagents, catalysts)

5. Use of contaminated starting materials and intermediates supplied by vendors.

6. Potential contamination due to risk for cross-contamination or carry over in multipurpose

plants

7. Degradation processes of starting materials, intermediates, or drug substances.

8. Primary packaging materials.

Document ID: Page 3 of 9

3 MANUFACTURING / PROCESS STEPS COVERED BY RISK ASSESSEMENT

The Manufacturing Process described below may not contain some process details due to

Intellectual Property Protection as per Company Policy.

Document ID: Page 4 of 9

4 RISK ASSESSMENT METHODOLOGY

The Risk Assessment methodology used has been [FMEA / Questionnaire / other]. The risk

assessment for potential presence of nitrosamines has been conducted taking into account the

following dimensions [severity, probability, detectability].

5 SUMMARY OF ITEMS REVIEWED FOR THE RISK ASSESSMENT

For each of the following items, indicate whether a risk for potential presence of nitrosamines has been

identified or not. As applicable, comment on the response provided whether the response is yes or no.

5.1 Use of sodium nitrite or other nitrosating agents in presence of secondary, or tertiary amines,

or quaternary ammonium salts within the API manufacturing process either within the same

or at different process steps.

Risk for presence of nitrosamines identified: YES ☐ NO ☐

Comment:

5.2 Use of sodium nitrite or other nitrosating agents in combination with reagents, solvents, and

catalysts, which are susceptible to degradation to secondary or tertiary amines, within the same

or different process steps.

Risk for presence of nitrosamines identified: YES ☐ NO ☐

Comment:

5.3 Use of contaminated raw materials (e.g. solvents, reagents, catalysts)

Risk for presence of nitrosamines identified: YES ☐ NO ☐

Comment:

5.4 Use of recovered materials (e.g. solvents, reagents, catalysts)

Risk for presence of nitrosamines identified: YES ☐ NO ☐ N/A ☐

Comment:

Document ID: Page 5 of 9

5.5 Use of contaminated starting materials and intermediates supplied by vendors.

Risk for presence of nitrosamines identified: YES ☐ NO ☐

Comment:

5.6 Potential contamination due to risk for cross-contamination or carry over in multipurpose

plants

Risk for presence of nitrosamines identified: YES ☐ NO ☐

Comment:

5.7 Degradation processes of starting materials, intermediates, or drug substances.

Risk for presence of nitrosamines identified: YES ☐ NO ☐

Comment:

5.8 Packaging materials

Risk for presence of nitrosamines identified: YES ☐ NO ☐

Comment:

Document ID: Page 6 of 9

6 RISK ASSESSMENT RESULT

Based on the risk assessment conducted, the risk for presence of nitrosamines is evaluated as:

☐ negligible

☐ potentially present

If the risk for contamination by nitrosamines is potentially present, indicate the possible

nitrosamine impurity, the origin of contamination and proposed mitigation measures:

Possible Nitrosamine Origin of contamination Mitigation measures

(Name and Structure) (specify nitrosating and

nitrosable agents)

Document ID: Page 7 of 9

7 ADDITIONAL INFORMATION TO SUPPORT THE RISK ASSESSMENT BY

THE DRUG PRODUCT MANUFACTURER / MARKETING AUTHORIZATION

HOLDER (MAH)

As the drug product manufacturer is responsible to evaluate whether any residual nitrosating or

nitrosable substances from the API may lead to potential formation of nitrosamines in the Drug

Product, the following information is provided.

Based on the manufacturing process reviewed and on its related risk assessment for potential

presence of nitrosamines, the API manufacturer declares that there is

7.1 For nitrosating agents:

- ☐ Nitrosating agents are not likely to be present in the final API.

- ☐ A risk for potential presence of nitrosating agents in the final API (see table below

for details).

Table 1. Nitrosating agents

Nitrosating agent (NO)* Structure Potentially

present in

final API

Nitrite salts MNO2

Nitrate salts MNO3

Nitrous acid HNO2

Nitrous acidium ion H2O+-NO

Nitric acid (contains N2O4) HNO3

Alkyl nitrites R-ONO

Peroxynitrite ONOO(-)

Nitrosonium ion NO+

Nitro compounds R-NO2

Nitrous anhydride N2O3

Dinitrogen tetroxide N2O4

Nitrosyl halides Halide-NO

Nitrosyl thiocyanate ONSCN

Nitrosophenol Phenol-NO

Nitrosothiol SH-NO

Aqua regia HCl + HNO3

Nitryl chloride NO2Cl

Other (specify)

Document ID: Page 8 of 9

7.2 For Nitrosable substances:

- ☐ Nitrosable substances are not likely to be present in the final API.

- ☐ A risk for potential presence of nitrosable substances in the final API or as integral

part of the API (see table below for details).

Table 2. Nitrosable substances

Nitrosatable substance Structure byproducts (Potentially)

present in final

API

Secondary amines R1-NH-R2 -

(cyclic and acyclic)

Tertiary amines (cyclic NHR1R2,

and acyclic) NHR1R3, or/and

NHR2R3

Hydrazine derivatives NH2-NR1R2 NHR1R2

N-methyl-2- N-methyl-4-

pyrrolidinone aminobutyric acid

Tertiary amides R1CONR2R3 NHR2R3

N-Chloroalkylamines R1R2N-Cl NHR1R2

N-alkylcarbamates R1O-CO-NR2R3 NHR2R3

Other (specify)

8 CHANGES IN MANUFACTURING PROCESS WITH POTENTIAL IMPACT ON

NITROSAMINE IMPURITY FORMATION

In case of changes in the manufacturing process, starting materials, suppliers etc. that may affect

this risk assessment, we will evaluate the impact, revise this assessment when necessary and

inform our customers of the outcome.

Document ID: Page 9 of 9

You might also like

- Mónica Cevallos ESA Combo Housing & TravelDocument3 pagesMónica Cevallos ESA Combo Housing & TravelMonica Cevallos100% (1)

- USP-NF 1079.4 Temperature Mapping For The Qualification of Storage AreasDocument7 pagesUSP-NF 1079.4 Temperature Mapping For The Qualification of Storage Areasdirector67% (3)

- Purified Water - British PharmacopoeiaDocument5 pagesPurified Water - British PharmacopoeiaAinul Huda100% (4)

- Qualification of Purified Water Systems PDFDocument12 pagesQualification of Purified Water Systems PDFDontYou KnowMeNo ratings yet

- Guidance Template Qualified Persons Declaration Concerning Good Manufacturing Practice GMP - enDocument8 pagesGuidance Template Qualified Persons Declaration Concerning Good Manufacturing Practice GMP - enLook AheadNo ratings yet

- SOP-QA-002-00-Document Preparation, Control and RetentionDocument7 pagesSOP-QA-002-00-Document Preparation, Control and RetentionNgoc Sang HuynhNo ratings yet

- SOP For Handling of Spillage of Solid - Liquid Media Containing Growth - Pharmaceutical GuidelinesDocument1 pageSOP For Handling of Spillage of Solid - Liquid Media Containing Growth - Pharmaceutical GuidelinesJose Ramon Dalo BautistaNo ratings yet

- Out of Specification (OOS) and Out of Trend (OOT) Analysis in Pharmaceutical Manufacturing Investigations (MIR) : A OverviewDocument9 pagesOut of Specification (OOS) and Out of Trend (OOT) Analysis in Pharmaceutical Manufacturing Investigations (MIR) : A OverviewDHiana100% (2)

- Analytical Method EquivalencyDocument9 pagesAnalytical Method EquivalencySrinivas Reddy MaramNo ratings yet

- Environmental Monitoring Incubation Conditions - JustificationDocument4 pagesEnvironmental Monitoring Incubation Conditions - Justificationveerreddy_157808No ratings yet

- USP - Statistical Tools For Procedure ValidationDocument35 pagesUSP - Statistical Tools For Procedure Validationramban11100% (1)

- Validation Master PlanDocument3 pagesValidation Master PlanPrince MoniNo ratings yet

- Reactor Cleaning Standard Operating ProcedureDocument2 pagesReactor Cleaning Standard Operating ProcedureGreg VoloshenkoNo ratings yet

- An Examination of The Idea of The Worthy and Unworthy Poor and Corresponding Social Work Practice d6Document9 pagesAn Examination of The Idea of The Worthy and Unworthy Poor and Corresponding Social Work Practice d6api-509668427No ratings yet

- Purvi Enterprises: Detailed Project ReportDocument19 pagesPurvi Enterprises: Detailed Project Report8897477809No ratings yet

- APIC Template For Report On Nitrosamine Risk Evaluation Update-QA-Rev12 Final 211022Document9 pagesAPIC Template For Report On Nitrosamine Risk Evaluation Update-QA-Rev12 Final 211022AlejandroNo ratings yet

- Nitrosamines-Emea-H-A53-1490-Questions-Answers-Information-Nitrosamines-Marketing-Authorisation - en (Update Dec 2019)Document10 pagesNitrosamines-Emea-H-A53-1490-Questions-Answers-Information-Nitrosamines-Marketing-Authorisation - en (Update Dec 2019)Fransisca FortunataNo ratings yet

- Active Pharmaceutical Ingredients Committee (APIC)Document12 pagesActive Pharmaceutical Ingredients Committee (APIC)Ngoc Sang Huynh100% (1)

- SOP For HPLC Column Receipt, Checking and Regeneration - PharmaguidelineDocument3 pagesSOP For HPLC Column Receipt, Checking and Regeneration - PharmaguidelineMahmoud MahmoudNo ratings yet

- Cleaning Validation Guidelines - A Complete ListDocument11 pagesCleaning Validation Guidelines - A Complete ListSanjay SharmaNo ratings yet

- USP 645 - Water ConductivityDocument4 pagesUSP 645 - Water ConductivityEvelyse Lima100% (1)

- Good Chromatography PracticesDocument23 pagesGood Chromatography PracticesknbiolabsNo ratings yet

- SOP For Preparation and Handling of Working StandardsDocument5 pagesSOP For Preparation and Handling of Working StandardsSolomon100% (2)

- 1238 - Medicinal AirDocument3 pages1238 - Medicinal Airpires35100% (1)

- A Review On Cleaning Validation Sampling TechniquesDocument5 pagesA Review On Cleaning Validation Sampling Techniquesedgar palominoNo ratings yet

- Vostem REPORT RegistDocument22 pagesVostem REPORT RegistFajarRachmadiNo ratings yet

- Methods For Identifying Out of Trends in Ongoing StabilityDocument10 pagesMethods For Identifying Out of Trends in Ongoing StabilityPiruzi MaghlakelidzeNo ratings yet

- SOP For Analyst ValidationDocument5 pagesSOP For Analyst ValidationGencay Ergin100% (1)

- Evaluation Reporting of Results Core Document PDFDocument6 pagesEvaluation Reporting of Results Core Document PDFParkhomyukNo ratings yet

- PICS Quality System RequirementDocument12 pagesPICS Quality System RequirementMd Nasir Uddin KhanNo ratings yet

- SOP For Handling of Out of Specification Results-1Document54 pagesSOP For Handling of Out of Specification Results-1osamatqm9No ratings yet

- Impurity ProfileDocument17 pagesImpurity ProfileNishit SuvaNo ratings yet

- Usp 788Document3 pagesUsp 788Wesley OliveiraNo ratings yet

- Qualification of GC and GC/MS SystemsDocument1 pageQualification of GC and GC/MS SystemsKiran ChokshiNo ratings yet

- Retention Reserve and Reference SamplesDocument20 pagesRetention Reserve and Reference SamplesDeepakNo ratings yet

- Empagliflozin TabletDocument3 pagesEmpagliflozin TabletAmik TuladharNo ratings yet

- Forced DegradationDocument8 pagesForced DegradationBiyaya San PedroNo ratings yet

- Rosuvastatin IP MonographDocument4 pagesRosuvastatin IP Monographvijay PugalNo ratings yet

- MICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological LaboratoryDocument11 pagesMICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological Laboratoryspp100% (1)

- Risk Assessment in DispensingDocument6 pagesRisk Assessment in Dispensinghina babar aliNo ratings yet

- Cleaning Validation Master Plan PDFDocument9 pagesCleaning Validation Master Plan PDFBREWSKINo ratings yet

- Hold Time Study ProtocolDocument9 pagesHold Time Study ProtocolMubarak Patel100% (1)

- Usp Package Integrity Leak Test TechnologiesDocument15 pagesUsp Package Integrity Leak Test TechnologiesuNo ratings yet

- Design Qualification Document SampleDocument25 pagesDesign Qualification Document SampleMr. YellNo ratings yet

- Determination of Acceptance Criteria For Cleaning Validation StudiesDocument5 pagesDetermination of Acceptance Criteria For Cleaning Validation Studiesapi-19716958100% (1)

- 2014 05 21 - GMP Question and Answer Guide PDFDocument152 pages2014 05 21 - GMP Question and Answer Guide PDFs.sabapathyNo ratings yet

- Validacio Microbio.Document15 pagesValidacio Microbio.cgannauNo ratings yet

- Development MethodDocument5 pagesDevelopment MethodBayu RefindraNo ratings yet

- Calculation of System Suitability ParametersDocument10 pagesCalculation of System Suitability ParametersMubarak Patel100% (2)

- Guide To Inspections of Pharmaceutical Quality Control LaboratoriesDocument16 pagesGuide To Inspections of Pharmaceutical Quality Control Laboratoriessubrata1100% (1)

- Analytical Report For Ketofast 10 TabletDocument20 pagesAnalytical Report For Ketofast 10 TabletShagorShagorNo ratings yet

- QBD Application in Pharm Industry PDFDocument83 pagesQBD Application in Pharm Industry PDFSetyo Budiarto100% (1)

- Revised USPSystem Suitability ParametersDocument21 pagesRevised USPSystem Suitability ParametersImas Sumiyati100% (1)

- CIQA PQ Template Protocol Lyophilization Process Sample VersionDocument3 pagesCIQA PQ Template Protocol Lyophilization Process Sample VersionAbdul KalimNo ratings yet

- Amv SopDocument14 pagesAmv SopNishit SuvaNo ratings yet

- Management of Out of Specification (OOS) For Finished ProductDocument12 pagesManagement of Out of Specification (OOS) For Finished Productpires35100% (1)

- GMP Requirements For Annual Product ReviewsDocument8 pagesGMP Requirements For Annual Product ReviewsGjorgji ZhezhovNo ratings yet

- SOP For Reduce Testing For Raw MaterialDocument3 pagesSOP For Reduce Testing For Raw MaterialMubarak Patel100% (1)

- Report Approval Sheet: Modi Sugar Mills, ModinagarDocument7 pagesReport Approval Sheet: Modi Sugar Mills, Modinagar9889187549100% (2)

- Workflows For Quality Risk Management-2Document24 pagesWorkflows For Quality Risk Management-2sarada jenaNo ratings yet

- Environmental Monitoring Risk AssessmentDocument22 pagesEnvironmental Monitoring Risk AssessmentMarcelo CarvalhoNo ratings yet

- SOP For Reprocessing and Reworking - PharmaguidelineDocument2 pagesSOP For Reprocessing and Reworking - PharmaguidelineTuriyo AnthonyNo ratings yet

- Corrective And Preventative Action A Complete Guide - 2020 EditionFrom EverandCorrective And Preventative Action A Complete Guide - 2020 EditionNo ratings yet

- SOP-QA-024-00 - Authorized SignaturesDocument4 pagesSOP-QA-024-00 - Authorized SignaturesNgoc Sang HuynhNo ratings yet

- SimethiconeDocument2 pagesSimethiconeNgoc Sang HuynhNo ratings yet

- Blend Content Uniformity Process Flow Diagram Design Validation (Withdrawn Draft) 1Document18 pagesBlend Content Uniformity Process Flow Diagram Design Validation (Withdrawn Draft) 1Ngoc Sang HuynhNo ratings yet

- MasterControl - Cloud FAQDocument18 pagesMasterControl - Cloud FAQNgoc Sang HuynhNo ratings yet

- Change Control - Continuous Quality Improvement in Fda and Iso EnvironmentsDocument6 pagesChange Control - Continuous Quality Improvement in Fda and Iso EnvironmentsNgoc Sang HuynhNo ratings yet

- Mastercontrol ImplementationDocument7 pagesMastercontrol ImplementationNgoc Sang HuynhNo ratings yet

- The Ultimate Guide To Digitizing The Shop FloorDocument35 pagesThe Ultimate Guide To Digitizing The Shop FloorNgoc Sang HuynhNo ratings yet

- Mastercontrol Cloud Platform Frequently Asked Questions (Faq)Document18 pagesMastercontrol Cloud Platform Frequently Asked Questions (Faq)Ngoc Sang HuynhNo ratings yet

- Mastercontrol Integrations FaqDocument8 pagesMastercontrol Integrations FaqNgoc Sang HuynhNo ratings yet

- Mastercontrol Integration ServicesDocument3 pagesMastercontrol Integration ServicesNgoc Sang HuynhNo ratings yet

- PQRI - Biosimilar USADocument27 pagesPQRI - Biosimilar USANgoc Sang HuynhNo ratings yet

- 04 Solutions For Tablet Film CoatingDocument30 pages04 Solutions For Tablet Film CoatingNgoc Sang HuynhNo ratings yet

- PQRI - Excipient Considerations For Parenteral Drug Development (2020)Document30 pagesPQRI - Excipient Considerations For Parenteral Drug Development (2020)Ngoc Sang HuynhNo ratings yet

- PQRI - Biosimilar OverviewDocument20 pagesPQRI - Biosimilar OverviewNgoc Sang HuynhNo ratings yet

- A Methodology For Knowledge Management in Biopharmacuetical ProductionDocument5 pagesA Methodology For Knowledge Management in Biopharmacuetical ProductionNgoc Sang HuynhNo ratings yet

- SOP-QA-013-00-corrective and Preventive ActionDocument10 pagesSOP-QA-013-00-corrective and Preventive ActionNgoc Sang HuynhNo ratings yet

- PQRI Biopharmaceutics Technical Committee 2018 Webinar SeriesDocument13 pagesPQRI Biopharmaceutics Technical Committee 2018 Webinar SeriesNgoc Sang HuynhNo ratings yet

- Solitaire Pharmacia Pvt. LTD.: Restricted Circulation Authorised Persons OnlyDocument8 pagesSolitaire Pharmacia Pvt. LTD.: Restricted Circulation Authorised Persons OnlyNgoc Sang HuynhNo ratings yet

- Solitaire Pharmacia Pvt. LTD.: Restricted Circulation Authorised Persons OnlyDocument7 pagesSolitaire Pharmacia Pvt. LTD.: Restricted Circulation Authorised Persons OnlyNgoc Sang HuynhNo ratings yet

- MES Cost & BenifitDocument5 pagesMES Cost & BenifitNgoc Sang HuynhNo ratings yet

- The Power of Design ReviewDocument15 pagesThe Power of Design ReviewNgoc Sang HuynhNo ratings yet

- EFCG APIC IPEC-SupplyChain INFOGRAPHIC V14Document4 pagesEFCG APIC IPEC-SupplyChain INFOGRAPHIC V14Ngoc Sang HuynhNo ratings yet

- Auditing Guide: Active Pharmaceutical Ingredients Committee (APIC)Document26 pagesAuditing Guide: Active Pharmaceutical Ingredients Committee (APIC)Ngoc Sang HuynhNo ratings yet

- The APIC Audit Programme Version 6Document18 pagesThe APIC Audit Programme Version 6Ngoc Sang HuynhNo ratings yet

- Manual 034 Determination of Storage Periods For API Excipients Intermediates and Raw MaterialsDocument3 pagesManual 034 Determination of Storage Periods For API Excipients Intermediates and Raw MaterialsNgoc Sang HuynhNo ratings yet

- APIC CEFIC Auditing Guide August 2016 - Annex 2Document50 pagesAPIC CEFIC Auditing Guide August 2016 - Annex 2Ngoc Sang HuynhNo ratings yet

- Periodicity of Metals - TeacherDocument6 pagesPeriodicity of Metals - TeacherTruong AnhNo ratings yet

- Seattle Coffee LRDocument4 pagesSeattle Coffee LRIan JaredNo ratings yet

- Thermal Balance Test Report For Blast Furnace Hot StovesDocument16 pagesThermal Balance Test Report For Blast Furnace Hot StovesSamanway DasNo ratings yet

- Radioactivity 6 QPDocument6 pagesRadioactivity 6 QPshookookie 101No ratings yet

- Lenormand Meanings - ProphetDocument2 pagesLenormand Meanings - Prophetlottimagi100% (1)

- Karin Hallock ResumeDocument3 pagesKarin Hallock ResumekghillNo ratings yet

- Inspection and Test Plan For Pressure VesselDocument2 pagesInspection and Test Plan For Pressure Vesselalokbdas50% (2)

- Pdfanddoc 915793Document64 pagesPdfanddoc 915793prajaNo ratings yet

- All Day Food MenuDocument2 pagesAll Day Food Menudryklief27No ratings yet

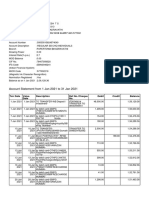

- Account Statement From 1 Jan 2021 To 31 Jan 2021: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument2 pagesAccount Statement From 1 Jan 2021 To 31 Jan 2021: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalancevenkNo ratings yet

- Engineering Mechanics (ME 105) Tutorial Sheet-4Document4 pagesEngineering Mechanics (ME 105) Tutorial Sheet-4nsbaruaoleNo ratings yet

- SLEEPING BEAUTY - Narrative TextDocument6 pagesSLEEPING BEAUTY - Narrative TextPande AdnyanaNo ratings yet

- Fatty Alcohol Production ProcessDocument9 pagesFatty Alcohol Production ProcessZevaniNo ratings yet

- Gastropod Saudi ArabiaDocument9 pagesGastropod Saudi Arabiajadoonreal1979No ratings yet

- Sri Ramakrishna Engineering College: CircularDocument4 pagesSri Ramakrishna Engineering College: CircularDhaha RoohullaNo ratings yet

- Pulse Quality Possible Indication Notes & Formulas:: Right CunDocument5 pagesPulse Quality Possible Indication Notes & Formulas:: Right CunPedro Maia100% (2)

- Song Old MacDonald Had A Farm With ActivitiesDocument2 pagesSong Old MacDonald Had A Farm With ActivitiesDayse LopesNo ratings yet

- Women's Right As Human RightDocument14 pagesWomen's Right As Human RightHuong BuiNo ratings yet

- Mason Jar FermentingDocument24 pagesMason Jar FermentingVJ0% (1)

- 10 Decisions You Will RegretDocument6 pages10 Decisions You Will RegretFelician UrsacheNo ratings yet

- Method Statement: SUB - Dismantling Activities For Upto 15 MTRDocument4 pagesMethod Statement: SUB - Dismantling Activities For Upto 15 MTRMichael AgnaelNo ratings yet

- Physics 22 - The Nuclear AtomDocument13 pagesPhysics 22 - The Nuclear AtomMuhammad Amin SuhaimiNo ratings yet

- Summative Test 3 Q 3 Gen - Chem 2 SY 2022 2023 Copy - Edited Copy - Edited.edited Copy - EditedDocument12 pagesSummative Test 3 Q 3 Gen - Chem 2 SY 2022 2023 Copy - Edited Copy - Edited.edited Copy - EditedJV Subang PatindolNo ratings yet

- Analisis Penerapan Total Productive Maintenance (TPM) Dengan Metode Overall Equipment Effectiveness (OEE) Pada MesinDocument14 pagesAnalisis Penerapan Total Productive Maintenance (TPM) Dengan Metode Overall Equipment Effectiveness (OEE) Pada MesinHASEA BEDIIVAN ANUGERAHNo ratings yet

- Port Numbers - Deep SecurityDocument6 pagesPort Numbers - Deep SecurityrepotecNo ratings yet

- Safety Data Sheet: Valvoline Valplex EP GreaseDocument7 pagesSafety Data Sheet: Valvoline Valplex EP Greasediah ayuNo ratings yet

- Worksheet 1 Microscopic Visualization of Bacteria Differential and Structural StainingDocument6 pagesWorksheet 1 Microscopic Visualization of Bacteria Differential and Structural StainingKyra ErniNo ratings yet