Professional Documents

Culture Documents

Selection of Motor Types & Sizes

Uploaded by

NathanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Selection of Motor Types & Sizes

Uploaded by

NathanCopyright:

Available Formats

General technical specification

Mechanical and electrical design

Mounting arrangements

Code I/Code II Product code pos. 12

Foot-mounted motor. IM B3 IM V5 IM V6 IM B6 IM B7 IM B8 A = foot-mounted,

IM 1001 IM 1011 IM 1031 IM 1051 IM 1061 IM 1071 term.box top

R = foot-mounted,

term.box RHS

L = foot-mounted,

1 term.box LHS

Flange-mounted motor, IM B5 IM V1 IM V3 *) *) *) B = flange mounted,

large flange IM 3001 IM 3011 IM 3031 IM 3051 IM 3061 IM 3071 large flange

Flange-mounted motor, IM B14 IM V18 IM V19 *) *) *) C = flange mounted,

small flange IM 3601 IM 3611 IM 3631 IM 3651 IM 3661 IM 3671 small flange

Foot- and flange-mounted IM B35 IM V15 IM V36 *) *) *) H = foot/flange-mounted,

motor with feet, IM 2001 IM 2011 IM 2031 IM 2051 IM 2061 IM 2071 term.box top

large flange S = foot/flange-mounted,

term.box RHS

T = foot/flange-mounted,

term.box LHS

Foot- and flange-mounted IM B34 IM V17

motor with feet, IM 2101 IM 2111 IM 2131 IM 2151 IM 2161 IM 2171 J = foot/flange-mounted,

small flange small flange

Foot-mounted motor,

shaft with free extensions IM 1002 IM 1012 IM 1032 IM 1052 IM 1062 IM 1072

*) Not stated in IEC 60034-7.

6 ABB/ LV Motors / Cat. BU / Process performance motors GB 03-2005

Cooling

Designation system concerning Example

methods of cooling refers to IC 4 (A) 1 (A) 6

standard IEC 60034-6.

International Cooling

Circuit arrangement

0: Free circulation (open circuit)

4: Frame surface cooled

Primary coolant

A for air (omitted for simplified designation)

Method of movement of primary coolant

0: Free convection

1: Self-circulation

6: Machine-mounted independent component

Secondary coolant

1

A for air (omitted for simplified designation)

W for water

Method of movement of secondary coolant

0: Free convection

1: Self-circulation

6: Machine-mounted independent component

8: Relative displacement

Degrees of protection: IP code/IK code

Classification of degrees of protection provided by IP protection:

enclosures of rotating machines are refers to: Protection of persons against getting in contact with

- Standard IEC 60034-5 or EN 60529 for IP code (or approaching) live parts and against contact with

- Standard EN 50102 for IK code moving parts inside the enclosure. Also protection of

the machine against ingress of solid foreign objects.

Protection of machines against the harmful effects due

to the ingress of water

IP 5 5

Characteristic letter

Degree of protection to persons and to parts of the motors inside the enclosure

2: Motors protected against solid objects greater than 12 mm

4: Motors protected against solid objects greater than 1 mm

5: Dust-protected motors

Degree of protection provided by the enclosure with respect

to harmful effects due to ingress of water

3: Motors protected against spraying water

4: Motors protected against splashing water

5: Motors protected against water jets

6: Motors protected against heavy seas

IK code:

Classification of degrees of protection provided by

enclosure for motors against external mechanical

impacts.

IK 08

International mechanical protection

Characteristic group

Relation between IK code and impact energy:

IK code IK 0 IK 01 IK 02 IK 03 IK 04 IK 05 IK 06 IK 07 IK 08 IK 09 IK 10

Impact * 0.15 0.2 0.35 0.5 0.7 1 2 5 10 20

energy ABB

Joule Standard

* not protected according to EN 50102

ABB/ LV Motors/ Cat. BU/ Process performance motors GB 03-2005 7

Insulation

ABB uses class F insulation systems, which, with Class F insulation system

temperature rise B, is the most common requirement - Max ambient temperature 40° C

among industry today. - Max permissible temperature rise 105 K

- Hotspot temperature margin + 10 K

The use of Class F insulation with Class B temperature

rise gives ABB products a 25° C safety margin. This can Class B rise

be used to increase the loading for limited periods, to - Max ambient temperature 40° C

operate at higher ambient temperatures or altitudes, or - Max permissible temperature rise 80 K

with greater voltage and frequency tolerances. It can also - Hotspot temperature margin + 10 K

be used to extend insulation life. For instance, a 10 K

Insulation system temperature class

temperature reduction will extend the insulation life.

- Class F 155° C

- Class B 130° C

1 - Class H 180° C

Safety margins per insulation class

All ABB high voltage motors are made with form wound

windings with Micadur® Compact Industry Insulation

System (class F). For more information, please see

the brochure Micadur® -Compact Industry, Insulation

System for Rotating Electrical Machines (code 3BFP

001 980 R0101 REV B 06/2003).

8 ABB/ LV Motors / Cat. BU / Process performance motors GB 03-2005

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Principles of Data VisualizationDocument2 pagesPrinciples of Data VisualizationAAKASHNo ratings yet

- MLT526Rev 11-02Document662 pagesMLT526Rev 11-02Razvan Mitru100% (2)

- Embedded C Interview Questions and Answers On Embedded Systems - Page 2Document9 pagesEmbedded C Interview Questions and Answers On Embedded Systems - Page 2aamyaNo ratings yet

- LINCS 1.2 Presentation r3 HiQ - Operator HandoutsDocument110 pagesLINCS 1.2 Presentation r3 HiQ - Operator HandoutsLuis Torres100% (1)

- Workbook LDSTDocument56 pagesWorkbook LDSTMuhammad HarisNo ratings yet

- Dust Control HandbookDocument314 pagesDust Control HandbookJoseph RileyNo ratings yet

- Tieu Chuan Kiem Tra Do Ben Vat Lieu FRPDocument3 pagesTieu Chuan Kiem Tra Do Ben Vat Lieu FRPNathanNo ratings yet

- ANSI B16.5 - Flanges & Bolts Dimension (Manufacturer 1)Document3 pagesANSI B16.5 - Flanges & Bolts Dimension (Manufacturer 1)NathanNo ratings yet

- ASME B18.2.2-2010 - Nuts For General Applications As Machine Screw - Hex.Square - Hex Flange - Coupling Nuts (Inch)Document40 pagesASME B18.2.2-2010 - Nuts For General Applications As Machine Screw - Hex.Square - Hex Flange - Coupling Nuts (Inch)NathanNo ratings yet

- B18 31 3 - 2009 PDFDocument14 pagesB18 31 3 - 2009 PDFCarlitos100% (1)

- Flange Dimensions 250# & 300#Document1 pageFlange Dimensions 250# & 300#NathanNo ratings yet

- ASME B16.9-2012 - Factory-Made Wrought Buttwelding FittingsDocument52 pagesASME B16.9-2012 - Factory-Made Wrought Buttwelding FittingsNathanNo ratings yet

- Resistant Emission Reducer: Kelvion Exhaust Gas Recirculation CoolerDocument2 pagesResistant Emission Reducer: Kelvion Exhaust Gas Recirculation CoolerNathanNo ratings yet

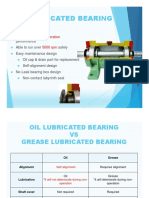

- Oil Lubricated Bearing: Better Vibration AccelerationDocument4 pagesOil Lubricated Bearing: Better Vibration AccelerationNathanNo ratings yet

- Optimisation of Sensor Locations For Measurement oDocument7 pagesOptimisation of Sensor Locations For Measurement oNathanNo ratings yet

- Efficiency Boost For Engines: Kelvion Charge Air CoolerDocument2 pagesEfficiency Boost For Engines: Kelvion Charge Air CoolerNathanNo ratings yet

- Boost Efficiency &: Lower EmissionsDocument15 pagesBoost Efficiency &: Lower EmissionsNathanNo ratings yet

- Guy Wires PDFDocument5 pagesGuy Wires PDFtylerlhsmithNo ratings yet

- C P T R F C P I: Athodic Rotection EST Eport ORM Over Age and NstructionsDocument5 pagesC P T R F C P I: Athodic Rotection EST Eport ORM Over Age and NstructionsNathanNo ratings yet

- Top-Level Engineering Solutions: Charge Air CoolersDocument24 pagesTop-Level Engineering Solutions: Charge Air CoolersNathanNo ratings yet

- "Designed and Engineered To Perform": Second EditionDocument96 pages"Designed and Engineered To Perform": Second EditionNathanNo ratings yet

- WikasealDocument57 pagesWikasealNathanNo ratings yet

- WK Cooling ElementDocument4 pagesWK Cooling ElementNathanNo ratings yet

- Xerox 3210Document140 pagesXerox 3210sdaidoxNo ratings yet

- Smart Programmable Panel Meter: Fully Field Configurable, 16-Bit Color Touch Screen DisplayDocument1 pageSmart Programmable Panel Meter: Fully Field Configurable, 16-Bit Color Touch Screen DisplayNathanNo ratings yet

- Dwyer SPPM CX Manual PDFDocument4 pagesDwyer SPPM CX Manual PDFNathanNo ratings yet

- Wa/fer W/Mayfie/a: Dec. 28, 1937. W. W. Mayfield 2,103,332Document6 pagesWa/fer W/Mayfie/a: Dec. 28, 1937. W. W. Mayfield 2,103,332NathanNo ratings yet

- Guysand AnchorsDocument34 pagesGuysand AnchorslatshareNo ratings yet

- A Procedure For Analysis of Guyline Tension PDFDocument49 pagesA Procedure For Analysis of Guyline Tension PDFJimmy Deswidawansyah NasutionNo ratings yet

- Dwyer SPPM CX Manual PDFDocument4 pagesDwyer SPPM CX Manual PDFNathanNo ratings yet

- UEP Bulletin 1724E-153Document29 pagesUEP Bulletin 1724E-153NathanNo ratings yet

- Construction Requirements For Pole Line Guys: Electric Design ManualDocument26 pagesConstruction Requirements For Pole Line Guys: Electric Design ManualNathanNo ratings yet

- TEN Group - NGK DynamometersDocument1 pageTEN Group - NGK DynamometersNathanNo ratings yet

- Vane-Type Mist EliminatorDocument1 pageVane-Type Mist EliminatorNathanNo ratings yet

- Magnetoelastic Sensors - Status, Commercial Readiness, and OutlookDocument2 pagesMagnetoelastic Sensors - Status, Commercial Readiness, and OutlookAakash ChopraNo ratings yet

- JTM-30C Configuration & User Manual Rev-I PDFDocument12 pagesJTM-30C Configuration & User Manual Rev-I PDFVladimirs ArzeninovsNo ratings yet

- APX5000 6000 Basic Service Manual 68012002028Document318 pagesAPX5000 6000 Basic Service Manual 68012002028Harry HallerNo ratings yet

- 5.1 Software Test AutomationDocument20 pages5.1 Software Test Automationudhayan udhaiNo ratings yet

- BONFYRE InterviewBook InternalComms FINALDocument56 pagesBONFYRE InterviewBook InternalComms FINALsdas123100% (1)

- Karta Enkoderowa Oraz RS232RS485Document15 pagesKarta Enkoderowa Oraz RS232RS485Saber LeffiNo ratings yet

- GDS-1000B Quick Start Guide ADocument2 pagesGDS-1000B Quick Start Guide Aketab_doostNo ratings yet

- PIC16f877 Based Simple Calculator ProjectDocument13 pagesPIC16f877 Based Simple Calculator ProjectBizuneh getuNo ratings yet

- NXC100 ControllerDocument2 pagesNXC100 ControllermartinimartiiniNo ratings yet

- Library Management SystemDocument10 pagesLibrary Management SystemMickey VillaflorNo ratings yet

- Advo IncDocument12 pagesAdvo IncKarthik ChanakyaNo ratings yet

- Crocus SHDSL g703Document302 pagesCrocus SHDSL g703Ahmed Sakr100% (1)

- Clown - BD v0.81 ChangelogDocument13 pagesClown - BD v0.81 ChangelogFaizurr HartmannNo ratings yet

- CLO 1 Scope and Role of SCM in An OrganizationDocument28 pagesCLO 1 Scope and Role of SCM in An OrganizationMelvinNo ratings yet

- Internet of ThingsDocument243 pagesInternet of ThingsWallie BillingsleyNo ratings yet

- Safety and Security: by Walusimbi KennethDocument55 pagesSafety and Security: by Walusimbi KennethSolángé MirembeNo ratings yet

- PalcoControl CP en PDFDocument7 pagesPalcoControl CP en PDFsulthan ariffNo ratings yet

- ANT-A08260PD00v06-4130 DatasheetDocument6 pagesANT-A08260PD00v06-4130 DatasheetInter MilanNo ratings yet

- Aruba AP-300 Series and AP-207: Ellie Huang, Sr. Product Marketing ManagerDocument11 pagesAruba AP-300 Series and AP-207: Ellie Huang, Sr. Product Marketing Managerarelyta8123No ratings yet

- BHMN SVI3 IOM 34587C 0421 EnglishDocument123 pagesBHMN SVI3 IOM 34587C 0421 Englishgasser ahmedNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- MS 2701 2018 - PrepdfDocument7 pagesMS 2701 2018 - PrepdfSiti Aishah Sahul HamidNo ratings yet

- Key Factors For The Pwa Solution: Agam SetiawanDocument18 pagesKey Factors For The Pwa Solution: Agam SetiawanYsn ArrfNo ratings yet

- Proposed Research Titles: ObjectivesDocument4 pagesProposed Research Titles: ObjectivesApril Danica BiernezaNo ratings yet

- LPG 2015 e CompleteDocument489 pagesLPG 2015 e CompleteJose MolinaNo ratings yet