Professional Documents

Culture Documents

Project Execution Statement 1 New

Project Execution Statement 1 New

Uploaded by

Nonsoufo ezeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Execution Statement 1 New

Project Execution Statement 1 New

Uploaded by

Nonsoufo ezeCopyright:

Available Formats

Shell Petroleum Development Company of Nigeria

Classification Status: Restricted

February 2022 GBU-SPDC-SGL-

PMS-STG-009

EPC FOR GBARAN PHASE 3B - UZU WITH CPF UPGRADE- PKG 2 FACILITIES

Project Execution Statement

Proprietary Information: This document contains proprietary information and may not

be partly or wholly reproduced without prior written permission from Shell Petroleum

Development Company

The Process Manager for this procedure is the Major Projects General Manager, the

Process Owner is the Major Projects Project Services Manager

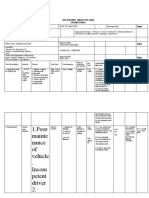

Revision Date Description Originator Checker Approver

R01 14/02/2022 Issued for review Nonso Eze Kehinde

Adeyemi

ADDITIONAL AGREEMENT/APPROVAL RECORD

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 1 of 76

This document is controlled electronically and is uncontrolled when printed

Party Ref Ind Name Sign Date

Revision Philosophy

All revisions for review will be issued at R01, with subsequent R02, R03, etc as

required.

All revisions approved for issue or design will be issued at A01, with

subsequent A02, A03, etc as required.

Documents approved for Construction will be issued at C01, C02, and C03

respectively. Documents or drawings revised as “As built” will be issued as Z01,

Z02 Z03 etc.

Narrative sections revised from previous approved issues are to be noted

in the table below and/or highlighted in the RH margin (using the

appropriate revision status) thus: | A02

Previous revision highlighting to be removed at subsequent issues.

Drawings/diagrams revised from previous approved issues are highlighted

by 'clouding' the affected areas and by the use of a triangle containing the

revision status.

Revision History

Revision No. Date of Reason for change

issue

R01 14/02/2022 Initial Issuance

1.0 INTRODUCTION

The Gbaran Integrated Oil and Gas node, situated in the seasonal fresh-water swamp

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 2 of 76

This document is controlled electronically and is uncontrolled when printed

covers an area approximately 3,000 km2 spread across Bayelsa, Rivers and Imo States

in the eastern part of the Niger Delta. It is a major oil and gas production hub in SPDC,

covering twelve producing fields – Gbaran, Etelebou, KoloCreekAdibawa, Adibawa NE,

Ahia, Assa, Enwhe, Mini-Nta, Obele, Rumuekpe, and Ubie – in Oil Mining Leases (OMLs)

16, 17, 21, 22, 27 and 28. The geographic centre of the Gbaran/Ubie node is located at

Gbaran, 100 km NW of Port Harcourt and 40 km NE of Yenagoa.

The Gbaran-Ubie Central Processing Facility (CPF) came on stream in year 2010. It

currently has a Gas production capacity of 1.2 Bscfd and oil production capacity of 120

Mbpd. There are remote field manifold locations at Zarama, Kolocreek, Gbaran and

Koroama for NAG well manifolds. The Gbaran CPF gas production capacity was

debottlenecked to to 1.2 Bscfd in 2013 and then 1.25 Bscfd in 2017. Current project

scope includes a CPF capacity upgrade to ca 1.4 Bscfd.

Uzu is a green field, but near Zarama, a producing field and 15km NE of Gbaran CPF.

Uzu field was discovered in 1971 and located in OML 28. Uzu appraisal well was drilled

from Zarama location (tagged ZARA015 well) thereby providing opportunity to utilize

existing facilities and RoWs in the Zarama area.

2.0 PROJECT OVERVIEW:

SPDC JV with Shell as operator of OMLs 16, 17, 21, 22, 27 and 28 on behalf of the joint

venture partners, embarked on the Gbaran Phase 3B - Uzu with CPF Upgrade project

which aims to develop 815Bscf (UR) of gas and 11.5MMbbls (UR) of oil & condensate to

meet SPDC’s commitment to sustain NLNG gas supply obligation and grow oil

production.

The project scope includes infill drilling involving 5 NAG wells and 1 oil well, flowlines, test

line and a NAG bulk line from the Uzu field to the Gbaran CPF. The facility upgrade scope

at the Gbaran Central Processing Facility include installation of a 200MMscfd TEG

dehydration train, ancillary units and brownfield tie-ins.

All six wells to be drilled as part of this development will be from two existing Zarama 15

and Zarama 08-11 NAG well locations. Three NAG wells will be drilled and one existing

well will be completed at Zarama 15 location. At the Zar 8-11 location, 1 NAG well and 1

Oil well will be drilled.

Extension of Zarama 15 location will be required to accommodate expansion of the

existing cellar for three more wells (with provision for relief well) and a new manifold

location, while free slots at Zarama 08-11 location will be used for the 1 NAG and 1 Oil

well drilling. Four NAG wells will be hooked up to the new Uzu-1 manifold (adjacent to

Zarama 15 well location) via 8” 1500# NAG DSS flow lines and bulk flowed via new 16”

x10km 1500# CS bulkline to a new Uzu-2 manifold at the Zarama NAG manifold location.

The new NAG well at Zarama 08-11 location will be hooked up to the new Uzu-2 manifold

via new 8” 1500# DSS flowline.

The Uzu NAG fluids will be evacuated via the existing 20-inch Zarama bulkline to the

Koroama Slug catcher at Gbaran CPF. A connection will be provided from the new Uzu-2

manifold (at Zarama NAG manifold location) to the existing Zarama bulkline. The existing

Zarama NAG wells will be evacuated to the CPF via a new 16” x 10km 1500# CS bulkline

connected to the Zarama slug catcher via the LP (compression) manifold.

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 3 of 76

This document is controlled electronically and is uncontrolled when printed

One oil well will also be drilled, completed and tied in to existing 16” x 17.5km Zarama Oil

bulkline and 6” x 17.5km Zarama test line via new 6” 1500# CS Oil and test flowlines. The

connection of the new oil and test line to the existing oil and test lines shall be via barred

tees.

3.0 EXISTING FACILITIES:

The Gbaran Central Processing Facility (CPF) collects Non-Associated Gas (NAG) from

the reservoirs at Gbaran, Zarama, Kolo Creek and Koroama as well as Oil and

Associated Gas (AG) from Etelebou, Kolo Creek, Gbaran Oil Manifold and Zarama. As

part of Phase 2A, NAG from Epu and additional NAG from Gbaran and Koroama will be

collected. Each field has its own remote well location(s) & bulkline(s) to the CPF. At the

CPF, each field has its own slugcatcher. NAG from the slugcatchers enter at ~100bar into

the 2 x 600 MMscf/d dehydration trains via the “dehydration inlet manifold”.

Non-Associated Gas (NAG) enters the plant at around 100 bar and is routed directly to

dehydration and then export via the new EGGS2 (Eastern Gas Gathering System-2)

pipeline to NLNG.

Oil and Associated Gas (AG) from XHP/HP wells enter the plant at the XHP header on

the Inlet manifold, the separated AG is compressed to the dehydration system pressure

using the main AG compressors. Oil and condensate are stabilized using the standard

flow station processes of staged pressure let down. Off-gas from the LP vessel and surge

vessel in the oil stabilization train is boosted to the main AG compressor suction pressure

using a reciprocating booster compressor.

The CPF facilities comprise the following main elements:

Separate Zarama NAG, Gbaran NAG, Koroama NAG and Kolo Creek NAG Slug

Catchers

1 XXHP Separator fed by manifold at CPF

1 XXHP Test Separator (Gbaran wells only)

2 XHP Separators fed by manifold

2 HP Separators fed by manifold

2 LP Separators at CPF

2 Surge Vessels

2 off 600 MMSCFD gas conditioning (TEG dehydration) trains

2 off 60,000 bpd oil export pump trains

2 off 11 MW AG Compression Trains

3x100% electric motor driven booster compressors (2x10MMSCFD /1x 20

MMSCFD)

3 off 10.92MW 11KV power generation (3 x50%)

1 off Oil Test Separators for XHP wells (300#)

1 off Oil Test Separators for LP and HP Wells (150#)

1 off 90,000 bbl storage tank.

2 off 32.5 MMSCFD (100%) CPF fuel gas supply systems

1 off 10 MMSCFD fuel gas conditioning train to supply the Bayelsa State Power

Station with dry hydrocarbon dew-pointed gas.

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 4 of 76

This document is controlled electronically and is uncontrolled when printed

Other facilities (for condensate spiking) within the CPF include:

4 off condensate spiking pumps

1 off 30Mbpd allocation meter

Associated piping & utilities tie-ins to the CPF facilities

4.0 OVERVIEW OF WORK SCOPE:

The Gbaran Ph 3B – Uzu with CPF Upgrade Project scope involves the following:

Zarama Well 15 and Uzu 1 NAG manifold location

Zarama Wells 08-11, Zarama NAG Manifold and Uzu 2 NAG Manifold location

The right of way between Zarama 15 Well Location and Zarama NAG Manifold

The right of way between the Zarama NAG Manifold and Gbaran CPF

The right of Way between Zarama Oil Manifold and Zarama 15 location

Gbaran CPF

In general, the scope of this contract includes the FEED Verification, update and taking

ownership thereafter; Detailed Engineering Design, Procurement, Fabrication, Testing,

Construction/Installation, Pre-commissioning, Commissioning and Start-up, Performance

and Reliability Testing, and Handover of the new facilities and spares at the Gbaran CPF,

Zarama 15, Zarama 8-11 well locations, Uzu 1 manifold location (adjacent to Zarama 15),

Uzu -2 manifold (at Zarama NAG manifold) and Zarama oil location.

The scope comprises the following:

Wellhead platforms around the 4 nos. wells at Zarama 15 and 2 nos. wells at the

Zarama 8-11 location.

4 nos 8” 1500# DSS flowlines from the NAG wells at the Zarama 15 location and

tie them in to the new Uzu-1 NAG manifold.

Uzu 1 remote NAG manifold complete with piping headers, wet-gas meters, vent

stack, closed drain vessel, transformers, transformer rectifiers, and utilities.

55 kPa blast resistant FAR and Substation packages at Uzu-1 NAG manifold

location.

Corrosion Inhibition Packages at Uzu-1 and Zarama NAG manifold locations.

Telecommunication systems

Wellhead control panels at Zarama 15 and Zarama 8-11 locations.

1 no 8” 1500# DSS flowline from the new NAG well at the Zarama 8-11 location

and tie-in to the new Uzu-2 NAG manifold.

Uzu-2 remote NAG manifold with piping headers, wet-gas meters and chemical

injection system.

Tie-in the new Uzu-2 NAG manifold to the existing vent stack, closed drain vessel

and other utilities at the existing Zarama NAG manifold location.

2nos 6” x circa 0.5km CS oil flowlines and accessories from the new oil well at the

Zarama 8-11 location.

Pig traps and associated piping systems, including connections to the new and / or

existing drains and vents at the Uzu 1, Uzu 2 and Zarama NAG manifolds, and

CPF.

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 5 of 76

This document is controlled electronically and is uncontrolled when printed

Above-ground sections of the bulk lines with valves, instrumentation systems,

flanges and flange fittings up to the last flange before the isolation joint for pig

launchers, and downstream of the last flange after the isolation joint for pig

receivers, with associated pipe supports at Uzu 1 and Uzu 2 manifolds and CPF.

Process control, safeguarding & instrumentation at the well locations, NAG

Manifolds and Gbaran CPF.

Integration of the well control systems to the existing Gbaran CPF control and

safeguarding system via the FARs at the Zarama NAG, Zarama Oil, Uzu 1 and

Uzu 2 NAG manifolds.

Boundary shutdown valves for the bulk lines, downstream of the pig launchers and

upstream of the pig receivers.

Tie-in the new Uzu-2 manifold to existing Zarama 20-inch DSS bulkline

Tie-in the existing Zarama NAG manifold to the new 16” CS Uzu bulkline.

Prepare and sand-fill the new Uzu 1 NAG manifold location with all necessary civil

provisions, including bund wall/embankment protection, drainage systems.

Equipment foundations, pipe supports, access platforms, cross-over bridge and

miscellaneous foundation (lighting poles, camera, instrument devices, call points,

F&G).

Construction of access roads, drainage and pavements.

Fencing works at Uzu-1 and Zarama NAG locations.

Pipe rack modification at CPF.

Pig restraining walls at Uzu-2 and CPF locations.

Illumination at the new Uzu-2, Uzu-1 and Zarama 15 locations.

Earthing, bonding and lightning protection system.

New manifold upstream of the Koroama I slug catcher at Gbaran CPF.

Tie-in the 16” CS Uzu bulkline to both new manifold upstream of Koroama 1 slug

catcher and the LP compression manifold (the latter to be installed by others).

Tie-in the existing 20” DSS Zarama bulkline to the Koroama I slug catcher via the

new manifold at the CPF.

Permanent cathodic protection systems

.

5.0 PURPOSE OF DOCUMENT

The purpose of the Project Execution Statement is to describe and define the

logic of inter-relationship for the implementation of SEFLAM’s Project Execution

Plan for GBARAN PHASE 3B - UZU WITH CPF UPGRADE- PKG 2 FACILITIES.

The PES shall specify an overview of how the project will be executed; how

project performance will be monitored, controlled, and updated. The Project

Execution State though a standalone document shall be supported by the project

execution plan and shall refer to other management plans; SPDC and Project

specification; procedures, codes, and standard were applicable.This document

shall be subject to project change control document procedure.

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 6 of 76

This document is controlled electronically and is uncontrolled when printed

6.0 REFERENCE DOCUMENT

8.0 DEFINITIONS AND ABBREVATIONS

ABCM Activity Based Cost Model

AG Associated Gas

AGIIP Associated Gas Initially In Place

ALARP As Low As Reasonably Practicable

BCOT Bonny Crude Oil Terminal

BERT Bit Error Rate Test

BSEB Bayelsa State Energy (Electricity) Board

CCTV Closed Circuit Television

CIIP Condensate Initially In Place

CIMT CONTRACTOR Interface Management Team

CITHP Closed In Tubing Head Pressure

CMD Corrosion Management Drawing

CMMS Computerised Maintenance Management System

CMS Completions Management System

COP Concurrent Operations Plan

CP Condensate Produced

CP Cathodic Protection

CPF Central Processing Facility

CRA Corrosion Resistant Alloy

CRO Community Relations Officer

CS Carbon Steel

CSU Commissioning and Start Up

CSV Comma Separated Value

DCAF Discipline Control and Assurance Framework

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 7 of 76

This document is controlled electronically and is uncontrolled when printed

DEM Design and Engineering Manual

DEP Design Engineering Practice

DG Decision Gate

DLU Data Loading Utility

DSS Duplex Stainless Steel

ECG Electro Cardiogram

EE Energy Efficiency

EIS Engineering Information Specification

EIA Environmental Impact Assessment

EGGS Eastern Gas Gathering System

EPC Engineering Procurement and Construction

ESD Emergency Shut Down

ESOP Electrical Safety Operational Procedure

ESR Electrical Safety Rules

FAR Field Auxiliary Room

FAT Factory Acceptance Test

F&G Fire and Gas

FBE Fusion Bonded Epoxy

FCV Flow Control valve

FDP Field Development Plan

FEED Front End Engineering Design

FEMS Field Engineering Management System

FF Foundation Field bus

F&G Fire & Gas

FGIIP Free Gas Initially In Place

FLB Field Logistics Base

FOC Fiber Optic Cable

FSI Flawless Start-up Initiative

FTHP Flowing Tubing Head Pressure

FTHT Flowing Tubing Head Temperature

FTO Freedom to Operate

GA General Arrangement

GP Produced Gas

GDT Gas Down To

GHG Green House Gas

HART Highway Addressable Remote Transducer

HAZID Hazard Identification

HMI Human Machine Interface

HAZOP Hazard and Operability

HP High Pressure

HPU Hydraulic Power Unit

HRA Health Risk Assessment

HSE Health Safety and Environment

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 8 of 76

This document is controlled electronically and is uncontrolled when printed

HVAC Heating Ventilation and Air Conditioning

I/O Input/Output

IPSC Integrated Production Safety Capacity

IQMF Information Quality Management Framework

JIMT Joint Interface Management Team

JV Joint Venture

JVP Joint Venture Partners

LIRA Logistic and Infrastructure Resource Assessment

LSOH Low Smoke Zero Halogen

LV Low Voltage

MAIP Maximum Allowable Incidental Pressure

MAOP Maximum Allowable Operating Pressure

MEG Mono Ethylene Glycol

MCC Motor Control Center

MCI Material, Corrosion and Inspection

MF Manifold

M&I Maintenance and Integrity

MJR Maintenance Job Routine

MOP Maximum Operating Pressure

MoU Memorandum of Understanding

MOV Motor Operated Valve

MTO Material Take Off

MW Molecular Weight

NACE Nation Association of Corrosion Engineers (International)

NAG Non-Associated Gas

NLNG Nigerian Liquefied Natural Gas

NP Produced Oil

OD Outer Diameter

ODBC Open Database Connectivity

OEM Original Equipment Manufacturer

OLE Object Linking and Embedding

OML Oil Mining Lease

OPC OLE for Process Control

OPEX Operating Expenditure

OR&A Operation Readiness & Assurance

PAGA Public Address and General Alarm

PAS Process Automation System

PAV Physical Asset Verification

PCAD Process Control Access Domain

PDMS Plant Design Management System

PEFS Process and Engineering Flow Scheme

PEL2 Land 2 East Asset

PEP Project Execution Plan

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 9 of 76

This document is controlled electronically and is uncontrolled when printed

PFS Process Flow Scheme

PIMS Pipeline Integrity Management System

PVT Pressure Volume Temperature

PWHT Post Weld Heat Treatment

QCP Quality Control Plan

QEP Quality Execution Plan

QMS Quality Management System

QRA Quantitative Risk Assessment

RBI Risk Based Inspection

RFSU Ready for Start Up

RMU Ring Main Unit

RMS Remote Monitoring System

ROCI Remote monitoring capability

ROW Right of Way

RTU Remote Terminal Unit

SAFOP Safety and Operability Studies

SAT Site Acceptance Test

SEFLAM SEFLAM SGL

SCD Sustainable Community Development

SCSSV Surface Controlled Surface Safety Valve

SDSS Supper Duplex Stainless Steel

SER Sequence of Events Recorder

SIL Safety Integrity Level

SGIIP Solution Gas Initially in Place

SHOC Safe Handling of Chemicals

SIS Safety Instrumented System

SPDC The Shell Petroleum Development Company of Nigeria

WBS Work Breakdown Structure

7.0 CONSORTIUM AND JOINT VENTURE (JV)

SEFLAM shall carry out the entire project 100% in country and in house and will

not go into any joint venture or partnership to carry out any part of the scope of

work and has not gone into any consortium or joint venture with any

company/firm/business/establishment and has no plans doing so going forward.

SEFLAM shall engage third party vendors directed by COMPANY as specified in

the contract and sub-contractors in line with SEFLAM Local Content Plan.

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 10 of 76

This document is controlled electronically and is uncontrolled when printed

8.0 WORKS TO BE SUB-CONTRACTED

Works Proposed Vendor

Borehole Drilling TBD

Ferrite Testing TBD

NDT TBD

Waste Disposal TBD

Trainings TBD

Detailed Engineering Design TBD

Geo Technical and Geo Physical/Survey TBD

Geo Technical and Geo Physical/Survey TBD

Civil Destructive testing TBD

Main Automation integration works Emerson as per contract

Freight forwarder TBD

Catering Services TBD

Asset Management (CMMS) TBD

Retainership Clinic TBD

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 11 of 76

This document is controlled electronically and is uncontrolled when printed

9.0 UZU 1 SCOPE OF WORK

9.1 MECHANICAL WORKS

SEFLAM shall carry out Detailed Engineering Design (DED), Procurement,

Fabrication, Testing,

Construction/Installation/Hook-up, Pre-commissioning, Commissioning, and

Handover.

Piping materials for the new facilities shall be in accordance with the piping class

designations indicated on the PEFS/UEFS. CONTRACTOR should note that

NACE-compliant materials as specified in the PEFS/data sheets shall be used.

All piping shall be protected from internal corrosion during installation. SEFLAM

shall ensure that line piping spools are protected with end caps to prevent ingress

of moisture and foreign matter from the time it leaves the mills to the time it is

installed at site. During installation, each open end of piping shall be securely

capped off at the end of each day to avoid ingress of moisture, debris and

animals. To meet this requirement, SEFLAM shall provide sufficient spare end

caps. Piping supports shall comply with DEP 31.38.01.29 - Gen. Pipe Supports.

All equipment and facilities including pipe-racks within the facilities shall be

painted in line with DEP 30.48.00.31-Gen

SEFLAM’s scope shall include all the mechanical equipment and piping at

Zarama 15 well location and UZU- 1 manifold location to the interface point with

P1 Contractor. This shall include all the flowlines from wellhead, process, piping

and utility piping related to the closed drains, vent, open drain, NAG well

equalisation system, Corrosion inhibition injection system, blowdown and relief

platform, utilities and the following specific items:

• All interconnecting process and utility piping, valves, headers and fittings

necessary to connect

the bulkline and pig launcher.

• Cathodic protection systems for buried equipment

• Installation of all interconnecting pipe works between equipment.

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 12 of 76

This document is controlled electronically and is uncontrolled when printed

• All piping support structures.

• Piping hook-up to the NAG wellheads and installation of all the valves and piping

to the battery

limit with P1 Contractor

9.2 CORROSION MANAGEMENT & MATERIAL SELECTION

SEFLAM shall ensure the following:

• Conduct the material selection study for the facilities

• Design, procure and install the cathodic protection system for all the on-plot

facilities.

• Provision of the hardware for the permanent Cathodic Protection systems to

enable hook up (by others)

• Design, procure and install corrosion inhibition packages at the Uzu-1 and Uzu-2

locations

• All dissimilar materials interfaces shall be duly insulated using insulation kits.

• That corrosion under insulation is prevented. SEFLAM shall ensure that any

personnel

protection/lagging material complies with specifications.

• Preparation and implementation of Corrosion Management Framework (CMF).

• Preparation and implementation of Corrosion Management Drawings.

• Monitoring device for the barred Tee (thickness measurement) on the Oil and

test line tie-in.

• All new installed above ground bulk line, structures, etc., shall be painted

according to SPDC

painting specification DEP.30.48.00.31-Gen. (Protective coatings for onshore and

offshore

facilities).

• Design procurement and installation of corrosion monitoring devices at the Uzu-

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 13 of 76

This document is controlled electronically and is uncontrolled when printed

1 and Uzu-2

locations.

• Installation of corrosion sampling connections at the Uzu-1 and Uzu-2 and CPF

locations

9.3 CONTROL AND INSTRUMENTATION

SEFLAM shall design, procure, test (FAT/SAT), install, pre-commission,

commission, start-up

all Instrumentation, Control and Automation (IC&A) equipment and infrastructure

necessary to meet the key operational requirements of all facilities installed under

the project.

SEFLAM scope shall include design, procurement, installation, pre-

commissioning,

commissioning and start-up of the following.

• All field instruments, sand detectors, F&G devices, valves, instrument cables,

cable trays, fiber optic cables, junction boxes, vendors’ equipment, and all

installation accessories related to the work

• Wellhead hook-up and all associated instrumentation

• Wellhead control panels including hydraulic tubings

• Surface hydraulic systems (SHS) and Smart wells servers for smart wells.

• All instrumentation for the NAG flowlines, pig launcher, well kill piping with

connection for

well kill facilities instrumentation in accordance with project specification.

• All instrumentation for the corrosion injection package

• All instrumentation for the header, pig launcher

• Manual choke, auto choke, check and motorised valves

• Wet gas meters complete with flow computer

• Vent gas flow meter

• Blast resilient Field Auxiliary Room (FAR) rated to 55kpa for 100ms.

• Controls, safeguarding, fire and gas and telecommunications systems. These

will be installed

in the FAR.

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 14 of 76

This document is controlled electronically and is uncontrolled when printed

Tie-in of third-party provided equipment such as wellhead control panel, Corrosion

injection

and SHS/smart wells server, wet gas meters to the new control and safeguarding

systems in

the FAR.

• Manual sampling system in line with specifications

• All communication cables between control/safeguarding systems in the Uzu-1

FAR

• All integration works as contained under the section titled ‘Facilities System

Integration’

9.4 TELECOMS SYSTEMS

SEFLAM scope shall include all new remote site telecom work related to the new

facilities including the following specific items;

1. All the remote site telecommunication system and equipment, including CCTV,

LAN/WAN, TETRA system and other Telecoms infrastructures as detailed in the

scope of work.

2. All Ex-telephones and other telephone systems in designated areas within the

Remote Location

UZU-1 MANIFOLD AND ZARAMA 15 WELL LOCATIONS

SEFLAM scope shall include all new remote site telecom SCOPE related to the

new facilities including the following specific items:

All the remote site telecommunication system and equipment, including CCTV,

LAN/WAN, TETRA system and other Telecoms infrastructures as detailed in the

SCOPE DESCRIPTION.

All Ex-telephones and other telephone systems in designated areas within the

Remote Location

9.5 ELECTRICAL

SEFLAM scope shall include design, procurement, installation, pre-commissioning

and

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 15 of 76

This document is controlled electronically and is uncontrolled when printed

commissioning of all new electrical and related facilities including the following:

• 55kpa @100ms Blast Resistant Packaged Substation with fenced Outdoor

Hermetically sealed

Transformer.

• Packaged equipment such as corrosion inhibition package, surface hydraulic

system for smart

wells.

• Perimeter, in-plot, platform, equipment shelter lighting

• Lightning protection, earthing system & bonding

• All HV, LV power, control, earth, communication cabling

• Dual Channel transformer rectifiers and hook-up to Well Head Control Panels

• All electrical equipment including cables, lighting fixtures and fittings, poles,

brackets,

earthing, bonding and lightning protection systems,

• Cable trays, ladders, and supports in accordance with specifications.

• Materials - cables (power, earth, control), junction boxes, glands, lugs, earth

bosses, welding

sockets, etc. required for all the installation & commissioning works.

• Earth rings/grids and earth chambers, and tie-in of new equipment/packages/all

metallic

structures to the earth grids.

• Temporary electrical power in line with Electrical Safety Rules and Electrical

Safety and

Operations Procedure.

• Cathodic protection systems for on-plot underground piping and facilities, as well

as the

permanent CP system for the 16” bulkline.

• HV discreet power cable termination by P1 contractor

9.6 CIVIL AND STRUCTURAL WORK

SEFLAM scope shall include all site civil and structural work related to the new

facilities, and the following specific items:

• Site preparation work including clearing the site of natural vegetation and organic

material,

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 16 of 76

This document is controlled electronically and is uncontrolled when printed

levelling, placement and compaction of engineered fill with appropriate coarse

graded sand

to the required site elevation that sufficiently eliminates flooding at the location.

• Topographical survey, probing for underground facilities in accordance with

Specifications.

• All structural steel works including pipe supports, valve access platforms,

overbridge, gantry

crane, water tank stand, shelters etc. including earthing and bonding.

• Fabrication and installation of Wellhead platforms; founded on existing cellar slab

using

expansion bolts with adequate grouting at the well area. All fabrications shall be

done offsite

to avoid hot works within the wellhead area.

• Extension of existing Zarama 15 well location Cellar slab and pit to include 3 new

well slots

• Foundations for the new equipment (Wellhead control panel, Pig launcher, Gantry

crane,

battery enclosure piping supports, shelters, platforms, chemical injection package

etc.)

• Miscellaneous concrete foundations for all free-standing equipment and fixtures

indicated

in the project specifications, such as in-plant phones, CCTV, Fire & gas detectors,

lighting

poles, transformers etc.

• Provision of Protective coating for all new sub and super structural members and

vessels

exposed to environmental impacts.

• Embankment protection (retaining walls) and fence reconstruction in line with

design

drawings for the well cluster area and the new remote manifold.

• Shelters for equipment that requires protection from rain and direct sunlight

Demolition of existing block wall fence at the well pad area and installation of new

high

security mesh fence with gates in line with project requirements.

• Drain pits for the new equipment foundations, pig traps, and extension of storm

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 17 of 76

This document is controlled electronically and is uncontrolled when printed

water drains

and culverts to cover the new facilities.

• Construction of storm water drains and concrete drain pits.

• Installation of drainage system for oil contaminated water.

• Guard accommodation.

• Pavements (rigid or flexible),

• Soft paving of 150mm-thick granite chipping of diameter- 20 - 25mm for all areas

other than

those earmarked for pavements (rigid or flexible), drains and hard stand.

• Reinstatement of location to original state including re-grading and repaving of

excavated

areas and damaged access roads

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 18 of 76

This document is controlled electronically and is uncontrolled when printed

10.0 UZU 2 SCOPE OF WORK

10.1 MECHANICAL WORKS

SEFLAM shall carry out Detailed Engineering Design (DED), Procurement,

Fabrication, Testing,

Construction/Installation/Hook-up, Pre-commissioning, Commissioning, and

Handover.

Piping materials for the new facilities shall be in accordance with the piping class

designations indicated on the PEFS/UEFS. SEFLAM should note that NACE-

compliant materials as specified in the PES/data sheets shall be used.All piping

shall be protected from internal corrosion during installation. SEFLAM shall

ensure that line piping spools are protected with end caps to prevent ingress of

moisture and foreign matter from the time it leaves the mills to the time it is

installed at site. During installation, each open end of piping shall be securely

capped off at the end

of each day to avoid ingress of moisture, debris and animals. To meet this

requirement, SEFLAM shall provide sufficient spare end caps. Piping supports

shall comply with DEP 31.38.01.29 - Gen. Pipe Supports. All equipment and

facilities including pipe-racks within the facilities shall be painted in line with DEP

30.48.00.31-Gen

SEFLAM scope shall include all the mechanical equipment, flowlines, piping, and

interconnecting pipework from the wellhead, all the way through to the interface

point with P1 Contractor. This includes all the process piping and utility piping

related to the drains, chemical injection, closed drains, vent, open drain, NAG well

equalization system, blowdown and relief platform and the following specific

items:

• All interconnecting process and utility piping, valves, headers and fittings

necessary to

connect the bulk line and pig launcher and receiver.

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 19 of 76

This document is controlled electronically and is uncontrolled when printed

• Cathodic protection systems for buried equipment

• Modification works to the existing piping within Zarama NAG Manifold.

• Installation of all interconnecting pipe works between equipment.

• All piping support structure

SEFLAM scope shall also include all the mechanical equipment, flowlines, piping,

and

interconnecting pipework from the oil wellhead, all the way through to the interface

point with P1

SEFLAM, including the following specific items;

• Piping Hook-up to the oil wellhead and installation of all the valves and piping to

the tie in

location for the oil line and test lines

10.2 CORROSION MANAGEMENT & MATERIAL SELECTION

SEFLAM shall ensure the following:

• Conduct the material selection study for the facilities

• Design, procure and install the cathodic protection system for all the on-plot

facilities.

• Provision of the hardware for the permanent Cathodic Protection systems to

enable hook up (by others)

• Design, procure and install corrosion inhibition packages at the Uzu-1 and Uzu-2

locations

• All dissimilar materials interfaces shall be duly insulated using insulation kits.

• That corrosion under insulation is prevented. SEFLAM shall ensure that any

personnel

protection/lagging material complies with specifications.

• Preparation and implementation of Corrosion Management Framework (CMF).

• Preparation and implementation of Corrosion Management Drawings.

• Monitoring device for the barred Tee (thickness measurement) on the Oil and test

line tie-in.

• All new installed above ground bulk line, structures, etc., shall be painted

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 20 of 76

This document is controlled electronically and is uncontrolled when printed

according to SPDC

painting specification DEP.30.48.00.31-Gen.

• Design procurement and installation of corrosion monitoring devices at the Uzu-1

and Uzu-2

locations.

• Installation of corrosion sampling connections at the Uzu-1 and Uzu-2 and CPF

locations

10.3 CONTROL AND INSTRUMENTATION

SEFLAM shall design, procure, test (FAT/SAT), install, pre-commission,

commission, start-up

all Instrumentation, Control and Automation (IC&A) equipment and infrastructure

necessary to meet the key operational requirements of all facilities installed under

the project.

SEFLAM scope shall include design, procurement, installation, pre-

commissioning,

commissioning and start-up of the following;

• All field instruments, sand detectors, F&G devices, valves, instrument cables,

cable trays, fiber optic cables, junction boxes, vendors’ equipment, and all

installation accessories related to the WORK

• Wellhead hook-up and all associated instrumentation

• Wellhead control panels including hydraulic tubing’s

• Installation of FOC, TFOCA cable and Optical splicing box (junction box) and

RMS panel for

down-hole gauges in the wells.

• All instrumentation for the NAG flowlines, pig launcher, well kill piping with

connection for

well kill facilities instrumentation in accordance with project specification.

• All instrumentation for the corrosion injection package

• All instrumentation for the header, pig launcher and pig receiver.

• Manual choke, auto choke, check and motorised valves

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 21 of 76

This document is controlled electronically and is uncontrolled when printed

• Wet gas meters complete with flow computer.

• Tie in of the new field instruments and devices to the existing controls,

safeguarding, fire and

gas and telecommunications systems in the existing Zarama NAG manifold FAR. If

spares are

insufficient, remote terminal units (RTUs) shall be provided by SEFLAM.

• Tie-in of third-party provided equipment such as wellhead control panel, downhole

gauges,

Corrosion injection and wet gas meters to the existing Zarama NAG manifold

control and

safeguarding systems .

• Manual sampling systems in line with specifications

• All integration works as contained under the section titled ‘Facilities System

Integration’

10.4 TELECOMS SYSTEMS

ZARAMA NAG MANIFOLD LOCATION

SEFLAM SCOPE shall include all new remote site telecom SCOPE related to

Zarama NAG facility including the following specific items:

All the remote site telecommunication system and equipment, including TETRA

MOBILE RADIO MTS2 SYSTEM and other Telecoms infrastructure as detailed in

the SCOPE DESCRIPTION.

2. Upgrade of existing Telecoms facilities at Zarama NAG for seamless

Integration of CCTV and LAN/WAN from UZU Locations.

3. Additional telecoms cabinet in the existing Zarama NAG FAR for Tetra MTS2

installation.

10.5 ELECTRICAL

SEFLAM scope shall include design, procurement, installation, pre-commissioning

and commissioning of all new electrical and related facilities including the

following:

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 22 of 76

This document is controlled electronically and is uncontrolled when printed

• Extension of existing Zarama NAG Switchboard SB160E1 with new, equipped

panels/Cubicles to accommodate all the new electrical Power requirements.

• Packaged equipment such as corrosion inhibition package. Dual Channel

Transformer Rectifier for powering of Well head Control Panel

• Cathodic protection systems for on-plot underground piping and facilities, as well

as the

permanent CP system for the bulkline

• Perimeter (Extended) collapsible lighting poles complete with HPS light fittings

• Low smoke zero halogen LV power and control cables in underground trenches

and cable trays and termination at the junction boxes and field electrical equipment

• All electrical equipment, cables, lighting fixtures and fittings, poles, brackets,

earthing, bonding

and lightning protection systems, etc.

• All junction boxes, hot dipped galvanised cable trays and ladders, supports, cable

ducts, earthing

and bonding, earth chambers, earth grids and tie-in to overall plant earth grid.

• Extension of earth rings/grids and earth chambers. Bonding and tie-in of new

equipment/packages, metallic structures, fences, permanent electrical

equipment/packages

and temporary generators to the earth grids.

• Provision of all termination materials - cables (power, earth, control), junction

boxes, glands,

lugs, earth bosses etc. required for all the installation & commissioning works.

• Temporary electrical power in line with Electrical Safety Rules and Electrical

Safety and

Operations Procedure.

10.6 CIVIL AND STRUCTURAL WORK

SEFLAM scope shall include all site civil and structural work related to the new

facilities, and the following specific items:

• Site preparation work including clearing the site of natural vegetation and organic

material,

levelling, placement and compaction of engineered fill with appropriate coarse

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 23 of 76

This document is controlled electronically and is uncontrolled when printed

graded sand

to the required site elevation that sufficiently eliminates flooding at the location.

• Topographical survey, probing for underground facilities in accordance with

Specifications.

• All structural steel works including pipe supports, access platforms and integrity

checks/modification of existing platforms, gantry crane, shelters, etc.

• Wellhead platforms modification; founded on existing cellar slab using expansion

bolts with

adequate grouting at the well area. All fabrications shall be done offsite to avoid hot

works

within the wellhead area.

• Modification of existing well location Cellar slab to support the drilling rig

• Foundations for the new equipment (Wellhead control panel, Pig launcher, pig

receiver

Gantry crane, lighting poles, battery enclosure piping supports, shelters, platforms,

chemical

injection package etc.)

• Miscellaneous concrete foundations for all free-standing equipment and fixtures

indicated

in the project specifications, such as in-plant phones, CCTV, Fire & gas detectors,

transformers etc.

• Provision of Protective coating for all new sub and super structural members and

vessels

exposed to environmental impacts.

• Pig restraining wall.

• Embankment protection and fence reconstruction in line with design drawings for

the well

cluster area and the new remote manifold.

• Shelters for equipment that requires protection from rain and direct sunlight.

• Demolition/Extension of existing fence at the manifold area in line with project

requirements.

• Drain pits for the new equipment foundations, pig traps, and extension of storm

water drains

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 24 of 76

This document is controlled electronically and is uncontrolled when printed

and culverts to cover the new facilities.

• Extension of drainage system for oil contaminated water

• Pavements (rigid or flexible),

• Soft paving of 150mm-thick granite chipping of diameter- 20 - 25mm for all areas

other than

those earmarked for pavements (rigid or flexible), drains and hard stand.

• Reinstatement of location to original state including re-grading and repaving of

excavated

areas and damaged access roads

11.0 CPF SCOPE OF WORK

11.1 MECHANICAL WORKS

SEFLAM shall carry out Detailed Engineering Design (DED), Procurement,

Fabrication, Testing,

Construction/Installation/Hook-up, Pre-commissioning, Commissioning, and

Handover.

Piping materials for the new facilities shall be in accordance with the piping class

designations indicated on the PEFS/UEFS. SEFLAM should note that NACE-

compliant materials as specified in the PEFS/data sheets shall be used.All piping

shall be protected from internal corrosion during installation. SEFLAM shall ensure

that line piping spools are protected with end caps to prevent ingress of moisture

and foreign matter from the time it leaves the mills to the time it is installed at site.

During installation, each open end of piping shall be securely capped off at the end

of each day to avoid ingress of moisture, debris and animals. To meet this

requirement, SEFLAM shall provide sufficient spare end caps.

Piping supports shall comply with DEP 31.38.01.29 - Gen. Pipe Supports.

All equipment and facilities including pipe-racks within the facilities shall be painted

in line with DEP 30.48.00.31-Gen

SEFLAM scope shall include mechanical equipment and piping at CPF to the

interface point with P1 Contractor. This shall include all process piping and utility

piping related to the tie-in of the pig receivers to the slug catchers, LP header,

closed drains, vent, open drain, blowdown and relief, utilities and the following

specific items:

• All interconnecting process and utility piping, valves, headers and fittings

necessary to connect

the bulkline, slug catcher and pig receiver

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 25 of 76

This document is controlled electronically and is uncontrolled when printed

11.2 CORROSION MANAGEMENT & MATERIAL SELECTION

SEFLAM shall ensure the following:

• Piping materials for the new facilities shall be in accordance with the piping class

designation

for the project and in alignment with the Materials Selection Report and the

PEFS/UEFS

• All dissimilar materials interfaces shall be duly insulated using insulation kits.

• That corrosion under insulation is prevented. SEFLAM shall ensure that any

personnel

protection/lagging material complies with specifications.

• All buried on-plot piping/vessel or equipment shall be protected adequately from

external

corrosion by sacrificial anode system in line with the specifications and drawings.

• Preparation and implementation of Risk-Based Inspection (RBI) including Threat

& Barrier

Matrix (TBM).

• Preparation and implementation of Corrosion Management Framework (CMF).

• Preparation and implementation of Corrosion Management Drawings.

• Assess the availability of spare capacity of the cathodic protection hardware for

protection of

sections of the 16” x10 km CS bulkline.

• Provision of connection cable for the hook up (by others) of the bulkline to the

cathodic

protection system.

• All new installed above ground bulk line, structures, etc., shall be painted

according to SPDC

painting specification DEP.30.48.00.31-Gen. (Protective coatings for onshore and

offshore

facilities).

11.3 CONTROL AND INSTRUMENTATION

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 26 of 76

This document is controlled electronically and is uncontrolled when printed

SEFLAM shall design, procure, test (FAT/SAT), install, pre-commission,

commission, start-up

all Instrumentation, Control and Automation (IC&A) equipment and infrastructure

necessary to meet the key operational requirements of all facilities installed under

the project.

SEFLAM scope shall include design, procurement, installation, pre-commissioning,

commissioning and start-up of the following;

• All field instruments, sand detector, F&G devices, valves, instrument cables,

cable trays,

junction boxes, and all installation accessories related to the WORK

• All instrumentation for Receiver

• Installation of a new fire and gas MIMIC panel at the Gbaran Central Control

Room (CCR) for

remote monitoring of the new locations

• Installation of new shutdown buttons on the existing HIS panel in Gbaran CCR to

enable

remote shutdown of the new facilities

• Tie-in of valves to the existing instrument air system.

• All integration works as contained under the section titled ‘Facilities System

Integration’

11.4 ELECTRICAL

The permanent CP system for the 16” bulkline.

• Low smoke zero halogen LV power and control cables in underground trenches

and cable trays and termination at the junction boxes and field electrical

equipment

• All electrical equipment, cables, lighting fixtures and fittings, poles, brackets,

earthing, bonding and lightning protection systems, etc.

• All junction boxes, hot dipped galvanised cable trays and ladders, supports,

cable ducts, earthing and bonding, earth chambers, earth grids and tie-in to

overall plant earth grid.

• Extension of earth rings/grids and earth chambers. Bonding and tie-in of new

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 27 of 76

This document is controlled electronically and is uncontrolled when printed

equipment/packages, metallic structures, fences, permanent electrical

equipment/packages

and temporary generators to the earth grids.

• Provision of all termination materials - cables (power, earth, control), junction

boxes, glands,

lugs, earth bosses etc. required for all the installation & commissioning works.

11.5 CIVIL AND STRUCTURAL WORK

SEFLAM scope shall include all site civil and structural work related to the new

facilities, and the following specific items:

• Site preparation work including clearing the site of natural vegetation and

organic material,

levelling,

• Topographical survey, probing for underground facilities in accordance with

Specifications.

• Interpret existing geotechnical survey reports

• All structural steel works (complete with all accessories) including piping

supports, access

platforms and integrity checks/modification of existing pipe racks, gantry crane,

shelters, etc.

• Foundations for the new equipment Pig Receiver, Gantry crane, battery

enclosure piping

supports, shelters, platforms, etc.)

• Pig restraining wall.

• Miscellaneous concrete foundations for all free-standing equipment and fixtures

indicated

in the project specifications, such as in-plant phones, CCTV, Fire & gas detectors,

lighting

poles etc.

• Provision of Protective coating for all new sub and super structural members and

vessels

exposed to environmental impacts.

• Shelters for equipment that requires protection from rain and direct sunlight.

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 28 of 76

This document is controlled electronically and is uncontrolled when printed

• Drain pits for the new equipment foundations, pig traps, and extension of storm

water drains

and culverts to cover the new facilities.

• Extension of drainage system for oil contaminated water

• Pavements (rigid or flexible),

• Soft paving of granite chipping in line with existing paving for all areas other than

those

earmarked for pavements (rigid or flexible), drains and hard stand.

• Reinstatement of location to original state including re-grading and repaving of

excavated

areas and damaged access roads

12.0 ZARAMA OIL MANIFOLD

12.1 CONTROL AND INSTRUMENTATION

SEFLAM shall carryout the following works ;

• Terminations of FOC cables in existing telecommunication cabinets

• Integration of the Uzu-1 manifold controls and safeguarding systems

12.2 TELECOMS SYSTEM

SEFLAM scope shall include all new telecom SCOPE related to the new facilities

at the Zarama Oil and Uzu locations including the following:

A new Telecoms infrastructure and integration with existing Telecommunications

systems

Upgrade of existing Telecoms facilities at Zarama Oil for seamless Integration of

LAN/WAN, Telephones and other systems from UZU Locations.

12.3 ELECTRICAL

HV discreet power cable termination by P1 contractor.

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 29 of 76

This document is controlled electronically and is uncontrolled when printed

13.0 GENERAL MECHANICAL WORKS

• Perform layout review using structured and auditable assessment methodology,

which

ensures that the requirements of other disciplines have been incorporated in the

design.

• Identify/confirm all piping tie-in locations and prepare detailed tie-in schedule.

• Preparation of piping general arrangement drawings and piping isometrics

drawings for the

systems, showing plans, elevations and cross sections to fully define routing and

location

piping.

• Preparation of a piping stress analysis specification in line with DEP and

performance of

stress analysis for the piping systems including

• Preparation of purchase specifications for piping materials, valves and special

items in line

with COMPANY standards.

• Prepare 3D PDMS model to incorporate the new systems.

• Provide appropriate equipment for lifting, fabrication and construction works

• Carry out installation of piping, valves, fittings, pipe supports and accessories;

modification

and tie in works in accordance with the relevant tie-in schedules, General

Arrangements,

isometric drawings and other installation drawings.

• Equipment alignment checks, mechanical completion works and site acceptance

test of

equipment

• Carry out demolition of piping as per the piping demolition drawings and piping

tie-in

documentation.

• Pipe fabrication, prefabrication, welding and testing shall be performed in

accordance with

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 30 of 76

This document is controlled electronically and is uncontrolled when printed

DEP-31.38.01.31-Gen. and DEP-61.10.08.11-Gen.

• Submit to COMPANY Welding procedure (WPS) for the Duplex Stainless Steel

welding and

other materials in accordance to ASME

• All weld repairs shall be carried out in accordance with approved procedures.

• There shall be visual and NDT (Radiography) inspections of all welded joints.

• Post weld heat treatment (PWHT) shall be carried where required.

• Internal cleaning /blowing of lines shall be carried out immediately after pressure

testing.

SEFLAM shall ensure that all pipe spools, valves, etc. are capped off using

temporary

plastic caps or wooden plates to avoid the ingress of water and foreign material

after line

blowing.

• Final piping and mechanical completion inspection shall be conducted using

SPDC check

sheets, findings shall be rectified and closed out before mechanical completion of

the work.

• Calibration and certification of all test equipment, lifting equipment, hooks, slings

and

shackles, hoses, power cables, etc.

• Proper Protection, preservation of piping and all installed equipment from the

time of

installation up to commissioning.

13.1 GENERAL CORROSION MANAGEMENT & MATERIAL SELECTION

Materials Selection has been done in accordance with DEP 39.01.10.11 –Gen

“Selection of materials for life cycle performance – Materials Selection Process”

and DEP 39.01.10.12 –Gen “Selection of materials for life cycle performance –

Upstream Equipment”. Documentation can be found in Section X - Technical

Information.

On-plot piping and flowlines are mostly corrosion resistant alloys (CRAs) while the

bulk lines are carbon steel material. SEFLAM shall generate Materials Selection

Reports and Diagrams for material specifications. To ascertain the integrity of

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 31 of 76

This document is controlled electronically and is uncontrolled when printed

Duplex Stainless-Steel fittings and to assure that inter-metallic phases are not

present; SEFLAM shall carry out ferrite meter reading on all fittings. Any duplex

component (base metal) with ferrite meter readings of less than 40% without any

metallographic test indicating the absence of inter-metallic phases shall be rejected.

The minimum acceptable range for ferrite readings shall be 40-60% for base

material and Heat Affected Zone (HAZ) and 35-65% for weld area. SEFLAM shall

nominate an independent inspection company who shall be qualified and approved

by SPDC to carry out the ferrite testing.

SEFLAM shall ensure that the line pipes for the bulk line are fit for purpose and that

any construction process/activities do not render the material unfit for intended

service.

SEFLAM shall ensure that the line pipes for the bulk line are fit for purpose and that

any construction process/activities do not render the material unfit for intended

service.

Coatings & Painting

For the buried equipment including buried vessels and piping, the primary barrier

against external

corrosion is appropriate coating while cathodic protection provides additional

protection according to the specifications. Both coating and cathodic protection

shall be provided for such equipment. Where the equipment is situated within the

on plot, the cathodic protection type shall be by sacrificial anode and shall be

designed for the life of the facility. Bulk lines shall be protected by both coating and

cathodic protection according to the specification. During construction, the buried

line shall be protected by sacrificial anode system while impressed current shall

protect the line upon completion.

For above ground piping, painting shall be applied according to the specification.

The purpose of the coating/painting is to prevent corrosive elements from reaching

the steel pipe surface and it is regarded as the primary corrosion protection system

of the lines. SEFLAM shall paint and coat

the piping and pipelines in line with the relevant specifications

14.0 GENERAL CONTROL AND INSTRUMENTATION

SEFLAM scope shall include following at all work locations (i.e Zarama oil, Uzu-1, Uzu-2

and

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 32 of 76

This document is controlled electronically and is uncontrolled when printed

CPF):

• The specification, procurement, layout design & installation of F&G devices

based on the

results of a detailed Fire and Gas Detection Mapping study. The mapping study

shall be

carried out during detailed design by COMPANY.

• Procurement and installation of all instrument cable trays, junction box stands,

instrument

supports, cable glands, cable slabs, cable shrouds, cable core markers, cable

route markers,

earthing cables, surge protectors and all other bulk materials and accessories.

• Excavation of cable route, laying and termination all instrument and inter-panel

cables.

Placement of cable slabs and backfilling.

• Engaging the services of the Main Automation Contractor (Emerson) for

integration works

• Testing of cabinets termination, I/O modules, instrument calibrations, internal

test, FAT/SAT

test and related documentation and certificates (commissioning)

• All communication cables between third party systems and control/safeguarding

system

15.0 GENERAL TELECOMS SYSTEMS

SEFLAM shall procure, install and commission the telecommunications

infrastructure to meet the facility operational requirements of high availability and

minimal manning. The telecommunications infrastructure to be deployed shall be

based on the Project Specifications as contained in Section X - Technical

Information. The following shall be provided and are detailed in the Articles below:

Telecommunications equipment cabinet.

All cabling and interconnecting accessories.

Closed Circuit Television. (CCTV)

IP DATA Network

Telephone.

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 33 of 76

This document is controlled electronically and is uncontrolled when printed

Digital Mobile Radio communication (TETRA)

Construction sites communication facilities.

Power supply to telecommunication equipment.

Integration with existing facilities.

Equipment support/Training

Telecommunications Equipment Cabinet (19inch – 42U 800mm x 800mm x 2000

type)

SEFLAM shall install and commission the Telecommunication Equipment Cabinet

at Zarama NAG FAR and UZU FAR to house the following systems/subsystems;

Backbone- LAN/WAN

UPS-MDF and CCTV Systems.

Equipment racks to be installed in the FAR at each remote location listed above.

Miscellaneous telecommunication items,

At Zarama NAG manifold, telecommunications equipment Cabinets shall be

provided to house the new Digital Mobile Radio communication (TETRA) system,

these cabinets shall be located at the existing ZARAMA NAG FAR.

At UZU manifold, telecommunications equipment Cabinets shall be provided to

house the new CCTV system, IP DATA Network and new fibre optic patch panels, -

these cabinets shall be located at the FAR. One cabinet shall be dedicated for

CCTV while the other equipment shall be housed in a separate cabinet.

The telecommunication equipment cabinet shall be indoor type metal enclosures

with front glass and rear access, fitted with lockable lift-off type doors. Doors and

framework shall be stiffened as required to form a sturdy and rigid assembly.

Cabinets shall be rugged and strong enough to sustain equipment loads. The

external finish and sealing shall be suitable to protect the internal equipment from

liquid splashes.

All cabinets shall be bottom-entry for power and signal cables with a means of

sealing the cable entry. The cabinets shall be equipped with 100mm high steel

plinths.

15.1 Structured Office Cabling

1. SEFLAM shall procure, install, pre-commission and commission structured

office cabling based on Category 6 (Cat6A) standards in the new FAR for the

extension of voice and data services to the desks inside the FAR and substation.

The miscellaneous 42U equipment rack shall house the central wiring closet from

where services will be distributed to end user desks. All cabling shall meet the

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 34 of 76

This document is controlled electronically and is uncontrolled when printed

SPDC Corporate Telecoms Installation Standards and project reference document

GBU4510196993-GEN-TA7770-00004-000- Structured Cabling system

specification.

15.2 Closed Circuit Television (CCTV)

1. SEFLAM shall procure, install, pre-commission and commission a closed-

circuit television (CCTV) system consisting of colour CCTV cameras, controller

matrix, consoles and other accessories for monitoring of all existing and new

process areas and for security surveillance of the UZU locations. The CCTV signals

from each camera at these sites shall be interfaced to the existing CCTV controller

matrix in Gbaran FLB/CPF via ZARAMA NAG over the existing inter-site fibre Optic

cables.

CCTV equipment shall be based on the existing PELCO SYSTEMS products

currently in use on the Gbaran Phase 1 for seamless integration. Refer to CCTV

equipment specification;

15.3 IP DATA NETWORK (Local and Wide Area Networks)

SEFLAM shall procure, install and (pre-) commission an SPDC local area network

(LAN) at the new remote locations FARs and a modification of the existing Zarama

Oil manifolds LAN/WAN to accommodate the new installed systems. The IP DATA

NETWORK implementation shall be deployed to conform to the COMPANY

Information Security Standard and will be a sub-network to the SPDC corporate

LAN. The network equipment to be deployed will be capable of handling VOIP

requirements. Reference should be made to the LAN/WAN Interface specification;

15.4 PAS LAN CONTRACTOR

Shall procure, install and (pre-) commission a separate transmission part for the

Process Automation Data originating from a dedicated PAS LAN. The new PAS

LAN shall be tied in to the existing PAS LAN at Zarama Oil Manifold. Connections

to the PAS LAN will be subjected to applicable DACA recommendation and

standards. This is to enable connection with SPDC central OSI-PI server in Port

Harcourt. The PAS Network shall be totally independent but accessible from the

office domain network via PCAD servers from workstations with appropriate access

permissions.

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 35 of 76

This document is controlled electronically and is uncontrolled when printed

15.5 Telephone System

1. SEFLAM shall procure; install telephone extensions/ sets at the new

remote locations.

The telephone extensions shall originate from the existing PABX in Gbaran

CPF/FLB and shall be relayed over LAN/WAN network to the new FARs using

VOIP technology. The gate houses shall also be provided with telephone

extensions/sets. All telephone sets to be provided shall be suitable for the

environment and hazardous area classification in the location in which they are to

be installed. Explosion proof telephones sets shall be deployed in the hazardous

areas

15.6 TETRA Mobile Radio System

SEFLAM shall supply, install, pre-commission and commission a TETRA digital

mobile Radio system at Zarama NAG manifold locations. The TETRA mobile

repeater system shall be based on Motorola DIMETRA IP MTS2 system. The

repeater system shall be interfaced to the master TETRA switch in SPDC IA Port

Harcourt over IP and E1 interfaces on the Microwave and LAN/ WAN network. The

Mobile radio system shall be supplied with all accessories. SEFLAM shall develop

as part of his engineering SCOPE detailed specification and interface drawings for

this system for COMPANY approval prior to implementation

15.7 Construction Sites Communication Facilities

1. SEFLAM shall install the telecommunications infrastructure to support

construction and commissioning activities at SEFLAM Engineering Office,

Fabrication Yard, Site Construction Bases, Storage Locations, Construction Sites

and SEFLAM’s base office covered under Project SCOPE DESCRIPTION.

15.8 Power Supply to Telecommunications Equipment

1. Power supply to all the new telecommunications equipment at the FARs in

the new remote locations shall be via a central AC UPS power system. SEFLAM

shall provide all necessary devices to convert the AC to 48VDC power as may be

required for the telecommunication equipment. SEFLAM shall also ensure that

adequate power and autonomy is provided for continuous operation of the

Telecommunication system in new FARs for at least 8 hours after mains power

failure

15.9 Integration with Existing Facilities

1. For seamless interface/integration with the existing facilities, system

products should be of same type with those deployed in Gbaran Phase 1 Project as

specified in the various telecom design specifications referenced in Section X -

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 36 of 76

This document is controlled electronically and is uncontrolled when printed

Technical Information. SEFLAM shall review all interface points of the new

installation with:

• Existing CCTV network at Gbaran CPF and Zarama NAG manifold

• Existing LAN at Gbaran CPF

• Existing LAN at Zarama Oil manifold

SEFLAM shall provide all necessary interface equipment to ensure seamless

integration of new systems to the existing systems.

15.10 Surge Protection Devices

1. All telecommunication equipment shall be supplied complete with

adequate surge protection devices.

15.11 Telecommunication Systems Support and Spares

SEFLAM will provide one-year post-implementation maintenance support that will

also include provision of spares. The Spares level to be provided shall be in

accordance with respective equipment manufacturers’ recommendations for each

telecoms infrastructure and shall be adequate for two years operation of the

systems.

16.0 GENERAL NEW ELECTRICAL FACILITIES

All new electrical, installation and commissioning activities shall be in compliance

with the

relevant project specifications, codes and standards.

Test certificates for materials as applicable shall be presented for inspection prior to

the equipment being used. SEFLAM shall be responsible for the preservation of all

electrically operated equipment and these may require the use of temporary power.

SEFLAM shall also carry out the following as part of the execution of the WORK;

• In liaison with Equipment manufacturers, develop all vendor drawings, inter wiring

connections and associated electrical systems. Update the existing electrical main

and control cable interconnection schedule and the cable schedules to include new

cables.

• Install (lay, gland, shroud, lug, test and terminate) all required Power, control,

communication and earth cables. All cables shall be low smoke zero halogen.

• Tie-in, integrate and Commission all installed electrical system

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 37 of 76

This document is controlled electronically and is uncontrolled when printed

16.1 TEMPORARY DIESEL GENERATOR –(Optional)

SEFLAM shall make provision for the optional use of a temporary diesel generator

to

provide electrical power for testing and pre-commissioning all facilities installed as

part of the

WORK, This generator will provide temporary power via temporary power supply

junction box .

16.2 UPS SYSTEMS

SEFLAM shall provide and install static AC UPS systems of 30mins and 8hr

autonomies

for Process and safeguarding /Telecoms / F & G systems respectively. These UPS

systems

shall be installed inside the Packaged Substation that will be installed at UZU-1

(Zarama 15

location)

16.3 ELECTRICAL POWER DISTRIBUTION SYSTEMS

The SEFLAM shall install new transformer and Substation at UZU-1 and extend

existing

Zarama NAG Switchboard SB160E1 by procuring, installing and Commissioning of

new

equipped panel/cubicles. The new feeders shall be used to supply the new

equipment at

UZU 2 (Zarama 08-11 location)

SEFLAM is responsible for all required cabling works (Power, Control,

Communication &

earth), tie-in, integration works and final commissioning of all equipment requiring

electrical

power in UZU-1 and UZU-2 manifolds. All electrical equipment and devices for use

in

Hazardous area (Ex certified) shall be come with accompanying ATEX certificates.

Power distribution cables and control cables installation shall be either above

ground on

cable trays/ladders, or underground or a combination of the two as may be

specified on the

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 38 of 76

This document is controlled electronically and is uncontrolled when printed

electrical layout drawings. Proper installation procedures in line with the relevant

drawings

shall be complied with.

16.4 EARTHING AND LIGHTNING PROTECTION

SEFLAM shall supply and install adequate earthing and lightning protection system

for

all new electrical equipment, shelters, metallic equipment and structures, supports,

tanks,

vessels, motors, temporary power equipment, lighting poles, fences, and facilities in

line with

the Electrical Engineering Guidelines, Philosophies and Specifications in Sections

X - Technical

Information of the Contract documents. All the power systems and installations,

including

metallic structures, shall be adequately earthed and their earth continuity

conductors tied in

to the main earth grid. All installations shall be tested and commissioned by

SEFLAM to

the satisfaction of COMPANY.

SEFLAM shall update the earthing grid drawings and bond the piles/foundation in

the

relevant facilities.

16.5 EXTERNAL LIGHTING AND SMALL POWER DISTRIBUTION

In line with layout drawings as well as Appendix D of Electrical Engineering

guidelines DEP

33.64.10.10 GEN for illumination requirements, SEFLAM shall procure, install, test

and

commission the external lighting for roads, manifolds and the Wellhead areas,

fence/security

areas, perimeter lighting,earth bonding of the Fence lines and lighting poles.

SEFLAM shall provide junction boxes, Welding socket outlets, and convenience

socket

outlets (230V 16A SPN + E) around the plant as necessary. Such outlets shall be

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 39 of 76

This document is controlled electronically and is uncontrolled when printed

automatically

isolated (ESD) when gas is detected anywhere in the plant. Such Junction boxes

and socket

outlets shall be Ex rated and weatherproof (IP66 and above). Road, fence and

perimeter

lighting shall provide illumination as per specification. This shall be photocell

controlled with

provision for manual switching. The lighting fixtures in non-hazardous areas shall

be suitable

for zone 1 hazardous area installation. Lighting poles shall be collapsible ABACUS

type.

16.6 CABLE DUCTS

Cables shall be installed in concrete cable ducts across drainages, road crossings,

paved areas

etc.

16.7 LOW VOLTAGE POWER AND CONTROL CABLES

The SEFLAM shall procure, install, pre-commission and commission all low voltage

power, control, earth and bonding cables including inter-wiring connections

between

equipment. All the low voltage cables shall be low smoke zero halogen.

The installation works shall include cable jointing, glanding, termination, earthing,

bonding

etc.

17.0 GENERAL CIVIL AND STRUCTURAL WORK

SEFLAM shall be responsible for all the architectural, geotechnical and

infrastructural activities,

civil and structural WORK described herein. All works shall be carried out in line

GBU-SPDC-SGL-PMS-STG-009 Project Execution Statement

Page 40 of 76

This document is controlled electronically and is uncontrolled when printed

with approved

standards contained in the appropriate project specifications, drawings, documents

as contained in Section X - Technical Information, which shall include as a

minimum the following:

• Underground facilities probing, topographic survey and setting out

• Site preparation, earthworks, all excavation (for foundation works, cables and

pipes), shoring

and dewatering (well-point dewatering pumps, etc) to ensure expeditious progress

of site

works;

• Installation of holding down bolts, base plate and others

• Extension of open drains and culverts, concrete paving, concrete hard stand and

access

walkways to the new facilities.

• Protective coating on all new Structural steel members exposed to environmental

impacts.

• Reinstatement of location to original state including re-grading and repaving of

excavated

areas; and reinstatement of damaged access roads.

17.1 SITE SURVEYS AND PROBING