Professional Documents

Culture Documents

Engr. Romel N. Vingua Engr. Romel N. Vingua Construction Equipments Operations and Maintenance

Engr. Romel N. Vingua Engr. Romel N. Vingua Construction Equipments Operations and Maintenance

Uploaded by

Queenie PerezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engr. Romel N. Vingua Engr. Romel N. Vingua Construction Equipments Operations and Maintenance

Engr. Romel N. Vingua Engr. Romel N. Vingua Construction Equipments Operations and Maintenance

Uploaded by

Queenie PerezCopyright:

Available Formats

4.

DOCUMENTING SERVICE WORK AND PREVENTIVE FAILURE LEADS DIRECTLY TO SUDDEN FAILURE, BUT IT’S THE FIRST

MAINTENANCE:DOCUMENTING SERVICE WORK IS A CRITICAL PART OF A STEP TOWARD INTERMITTENT EQUIPMENT

PREVENTIVE MAINTENANCE PROGRAM. KEEPING RECORDS ON EACH FAILURE. FORTUNATELY, GRADUAL MACHINE FAILURE IS EASY TO

MACHINE GIVES A CLEAR PICTURE OF THE EQUIPMENT’S RECOGNIZE AND REPAIR. IT’S TIME-FORGIVING AND GIVES PLENTY OF

HISTORY. DOCUMENTATION ALSO RECORDS WHEN PREVENTIVE WARNING. SHARP INSPECTORS ALWAYS WATCH FOR GRADUAL FAILURE

MAINTENANCE INTERVENTION HAPPENED AND WHAT WAS DURING ROUTINE AND PREVENTIVE MAINTENANCE SCHEDULES.

ACCOMPLISHED. THESE MAINTENANCE RECORDS BUILD A PATTERN OF

MACHINERY BEHAVIOR, AND THEY CLEARLY PREDICT POTENTIAL TRAINING EMPLOYEES TO PROPERLY OPERATE CONSTRUCTION EQUIPMENT

PROBLEMS IN SIMILAR MACHINES. DOCUMENTS ALSO PROVE PROACTIVE

MAINTENANCE TASKS THAT SUPPORT A MACHINE’S VALUE AT RESALE. THERE’S PROBABLY NO BETTER RETURN ON CONSTRUCTION EQUIPMENT

INVESTMENT THAN TRAINING. EMPLOYEES WHO KNOW HOW TO PROPERLY

KNOW THE MAJOR TYPES AND CAUSES OF CONSTRUCTION EQUIPMENT OPERATE THEIR MACHINES AND TO WATCH FOR PROBLEMS ARE

FAILURE INVALUABLE. THEY ARE THE FRONT-LINE DEFENDERS OF A COMPANY’S

MECHANICAL ASSETS.

SUDDEN FAILURE:THIS IS THE MOST SERIOUS AND DAMAGING TYPE OF

EQUIPMENT FAILURE. IT HAPPENS WITH LITTLE WARNING AND NO IT TAKES TIME TO PROPERLY TRAIN AN EQUIPMENT

CONTINGENCY PLAN FOR RESPONSE. SUDDEN FAILURE LEAVES THE OPERATOR. THERE’S TIME INVOLVED IN VERBAL INSTRUCTION. THERE’S

MACHINE UNAVAILABLE UNTIL IT’S REPAIRED AND PUT BACK IN TIME INVOLVED IN DEMONSTRATION. AND THERE’S TIME INVOLVED IN

SERVICE. UNEXPECTED COSTS RANGE FROM MACHINE AND OPERATOR THE LEARNING CURVE WHILE A NEW OPERATOR GETS THE HANG OF

DOWNTIME TO MECHANIC FEES AND PARTS CHARGES. MOST SUDDEN THEIR MACHINE. ALL THIS TIME INVESTMENT IS WORTH IT,

EQUIPMENT FAILURES HAPPEN BECAUSE SOME COMPONENT WORE OUT AND ESPECIALLY IN THE BIG PICTURE OF SAFETY AND PREVENTION.

CAUSED A CHAIN REACTION. USUALLY, SUDDEN FAILURES ARE

PREVENTABLE BY RECOGNIZING FLAWS DURING ROUTINE INSPECTIONS. TRAINED OPERATORS ARE MORE CAREFUL WORKERS. THEY KNOW THEIR

MACHINE’S CAPACITY AND CAPABILITY. THEY ALSO KNOW HOW TO

INTERMITTENT FAILURE:THIS EQUIPMENT FAILURE TYPE IS SPORADIC. SAFELY USE THE MACHINE AND AVOID COSTLY DAMAGE TO PROPERTY

THERE ARE INTERMITTENT OPERATION INTERRUPTIONS THAT STALL A AND INJURIES TO PEOPLE. TRAINED OPERATORS ALSO RECOGNIZE WHEN

MACHINE OR CAUSE IT TO SPUTTER. OFTEN, EXPERIENCED OPERATORS A MACHINE REQUIRES ROUTINE AND PREVENTIVE

AND SERVICE PERSONNEL RECOGNIZE INTERMITTENT FAILURE SYMPTOMS MAINTENANCE. THEY’LL REPORT EVERY ISSUE AND START PREVENTION

AND TAKE IMMEDIATE STEPS TO CORRECT THE PROBLEM. LESS STEPS BEFORE THERE’S A BIG PROBLEM.

EXPERIENCED WORKERS SOMETIMES IGNORE WARNING SIGNS AND

NEGLECT TO REPORT THEM. THAT LEADS TO SUDDEN FAILURE,

IMMEDIATE DOWNTIME AND UNNECESSARY REPAIR EXPENSES.

GRADUAL FAILURE:THIS FAILURE TYPE HAPPENS SLOWLY AND OVER

TIME. OPERATORS AND THE SUPPORT TEAM RECOGNIZE GRADUAL

FAILURE AS PART OF THE WEAR-AND-TEAR PROCESS THAT AFFECTS

EVERY PIECE OF CONSTRUCTION EQUIPMENT. IT’S RARE THAT GRADUAL

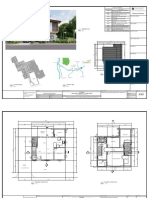

NAME: INSTRUCTOR: RESEARCH TITLE: SHEET CONTENT:

TAMAYO, KARLO D. BSCE VC CONSTRUCTION EQUIPMENTS

PEREZ, QUEENIE D. BSCE VC

LOPEZ, MICHELLE MAE G. BSCE VC

ENGR. ROMEL N. VINGUA OPERATIONS AND MAINTENANCE 6 19

You might also like

- Gem RemediesDocument49 pagesGem Remediesksrinivas9999100% (5)

- Operator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesFrom EverandOperator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesRating: 5 out of 5 stars5/5 (3)

- New Holland MH 5 6 EN City Plus PDF (001 312)Document312 pagesNew Holland MH 5 6 EN City Plus PDF (001 312)John Ronald Huacho100% (1)

- Chapter 9. Failure Root Cause PreventionDocument23 pagesChapter 9. Failure Root Cause PreventionAbdirahman Ali mohamudNo ratings yet

- The Color Purple NotesDocument9 pagesThe Color Purple NotesFreddy GaraboaNo ratings yet

- Vehicular AccidentDocument9 pagesVehicular AccidentCharm TanyaNo ratings yet

- Mobius Vibration Analysis Global Skill ShortageDocument8 pagesMobius Vibration Analysis Global Skill Shortageaal_shurafaNo ratings yet

- 7 15 Sentrina Alaminos Cost ControlDocument61 pages7 15 Sentrina Alaminos Cost ControlQueenie Perez100% (1)

- Workshop Manual MH6.6 PDFDocument638 pagesWorkshop Manual MH6.6 PDFАлександр Панкратов100% (1)

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- Machine Fault Signature Analysis With Particular Regard To Vibration AnalysisDocument15 pagesMachine Fault Signature Analysis With Particular Regard To Vibration AnalysisomkarmsheteNo ratings yet

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- R.A. 6675Document91 pagesR.A. 6675Donzzkie Don50% (2)

- Troubleshooting Skills Can Be LearnedDocument6 pagesTroubleshooting Skills Can Be LearnedpetarurosNo ratings yet

- Dispenser Manual 35835 - 1 2 PDFDocument58 pagesDispenser Manual 35835 - 1 2 PDFjuan carlos oliveros valetaNo ratings yet

- Cocoa-Value-Chain-Assessment-Pind FoundationDocument64 pagesCocoa-Value-Chain-Assessment-Pind FoundationAfaaqi Engineering LimitedNo ratings yet

- Industrial Accident and SafetyDocument64 pagesIndustrial Accident and Safetychandan914100% (1)

- User and Driving TFC 45 2002 PPM11Document363 pagesUser and Driving TFC 45 2002 PPM11Carlos Ernesto Flores Albino100% (1)

- Nuclear Maintenance Applications Center: Condenser Air Removal Equipment Maintenance GuideDocument218 pagesNuclear Maintenance Applications Center: Condenser Air Removal Equipment Maintenance GuideAmani AltarefeNo ratings yet

- ISO 17636-1 - Radiographic InspectionDocument42 pagesISO 17636-1 - Radiographic InspectionJohn100% (1)

- Machine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningFrom EverandMachine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningRating: 4.5 out of 5 stars4.5/5 (2)

- Group Cohesiveness Case StudyDocument9 pagesGroup Cohesiveness Case Studynsparth0% (1)

- Bombardier Aerospace Learjet Suppliers Listing by NameDocument1,307 pagesBombardier Aerospace Learjet Suppliers Listing by NameVanshi Sharma100% (1)

- Steam Bending WoodDocument10 pagesSteam Bending Wooddkpitterson0% (1)

- Accident Prevention TechniquesDocument8 pagesAccident Prevention TechniquesvsrslmNo ratings yet

- Vibration Analysis & Diagnostic StudiesDocument42 pagesVibration Analysis & Diagnostic Studiessoumya ranjan sahooNo ratings yet

- Introduction To Maintenance Management System CMMSDocument123 pagesIntroduction To Maintenance Management System CMMSVirtual almostNo ratings yet

- Batch 2 Arra Avina 30Document6 pagesBatch 2 Arra Avina 30Queenie PerezNo ratings yet

- 2633 Operators PDFDocument48 pages2633 Operators PDFManuelin RojasNo ratings yet

- Down Time Handbook PDFDocument13 pagesDown Time Handbook PDFZegera Mgendi100% (1)

- A Barangay Ordinance MalunggayDocument3 pagesA Barangay Ordinance Malunggaydon congNo ratings yet

- Autonomous MaintenanceDocument32 pagesAutonomous Maintenanceanoopkchand100% (3)

- 1-1 Corrective, Preventive, PredictiveDocument26 pages1-1 Corrective, Preventive, PredictiveAngie Barrera100% (1)

- Installing, Maintaining, and Verifying Your Charpy Impact MachineDocument26 pagesInstalling, Maintaining, and Verifying Your Charpy Impact MachineTurgay DeryaNo ratings yet

- Construction Equipments Operations and MaintenanceDocument1 pageConstruction Equipments Operations and MaintenanceQueenie PerezNo ratings yet

- Engr. Romel N. Vingua Construction Equipments Operations and MaintenanceDocument1 pageEngr. Romel N. Vingua Construction Equipments Operations and MaintenanceQueenie PerezNo ratings yet

- Maintenance ManagementDocument19 pagesMaintenance ManagementSagarNo ratings yet

- TPM & It's PillarsDocument21 pagesTPM & It's PillarsMANASNo ratings yet

- Instructions Manual: Rotatory SieveDocument53 pagesInstructions Manual: Rotatory SieveBogdan PistolNo ratings yet

- Recommandations GBDocument8 pagesRecommandations GBилья100% (1)

- Linked PDFDocument234 pagesLinked PDFSmolovic SrdjanNo ratings yet

- Presentation 1Document19 pagesPresentation 1JEAN KATHLEEN SORIANONo ratings yet

- COREN Olatunde TanimolaDocument43 pagesCOREN Olatunde TanimolaAdeola JosephNo ratings yet

- Industrail Safety An OverviewDocument43 pagesIndustrail Safety An OverviewPraveen PraveenNo ratings yet

- Breakdown MaintenanceDocument4 pagesBreakdown MaintenanceSankalp Sharma0% (1)

- Manuel ENDocument46 pagesManuel ENahmed hadjbenamaneNo ratings yet

- Safeguards For Machine Tools and Power Presses 1914 PDFDocument64 pagesSafeguards For Machine Tools and Power Presses 1914 PDFjohn silverNo ratings yet

- TRABALHO SEMESTRAL-1500 WordsDocument6 pagesTRABALHO SEMESTRAL-1500 WordsSeverino Manuel PedroNo ratings yet

- Osha ReportDocument12 pagesOsha ReportHusain MohdNo ratings yet

- Degraded ModesDocument12 pagesDegraded ModesSpeedbirdNo ratings yet

- Operation Manual Cold Water Direct Driven Pressure Washer: Ca-SeriesDocument44 pagesOperation Manual Cold Water Direct Driven Pressure Washer: Ca-SeriesJah hdo1No ratings yet

- Accident Preventer For Cutting MachineDocument5 pagesAccident Preventer For Cutting MachinevasanthavananNo ratings yet

- Automatic Accident Avoiding System in Pneumatic Bend and Bend Removing MachineDocument5 pagesAutomatic Accident Avoiding System in Pneumatic Bend and Bend Removing MachineShahnawaz AhmedNo ratings yet

- Production Through Safety Production Through Safety: We Practice Zero Tolerance When It Comes To SafetyDocument13 pagesProduction Through Safety Production Through Safety: We Practice Zero Tolerance When It Comes To SafetyPablo Puñal FieiraNo ratings yet

- Mark Lift Ch50 C-1 - OcrDocument60 pagesMark Lift Ch50 C-1 - Ocrel mendaNo ratings yet

- Review Article: Machine Fault Signature AnalysisDocument11 pagesReview Article: Machine Fault Signature AnalysisEclipse ShuNo ratings yet

- How To Make RCFA A Successful Business Improvement StrategyDocument6 pagesHow To Make RCFA A Successful Business Improvement StrategysureshchitraNo ratings yet

- Techniques of Hazard IdentificationDocument19 pagesTechniques of Hazard Identificationforzama100% (4)

- Group 3 Causes of Accidents in Process PlantsDocument12 pagesGroup 3 Causes of Accidents in Process PlantsFortuneNo ratings yet

- Use and Maintenance Manual: Hydraulic Folding Crane Art. 0063Document24 pagesUse and Maintenance Manual: Hydraulic Folding Crane Art. 0063jeffrey muscatNo ratings yet

- Engineer in Society and Engineering Code of EthicsDocument48 pagesEngineer in Society and Engineering Code of EthicsNelsonNo ratings yet

- Maint IntroDocument49 pagesMaint Intromind2008No ratings yet

- Ma It A Inability 2Document6 pagesMa It A Inability 2radzeeryNo ratings yet

- Procedure Based MaintDocument27 pagesProcedure Based Maintnish1802No ratings yet

- Mrs. Mbadugha Augustina O. (Instututionn Based Supervisor)Document31 pagesMrs. Mbadugha Augustina O. (Instututionn Based Supervisor)Michael Chris50% (2)

- Manager Plant Technical Services Dow Chemical, U.S.A. Freeport, TexasDocument8 pagesManager Plant Technical Services Dow Chemical, U.S.A. Freeport, TexasAugust Carl Bokingkito MalabagoNo ratings yet

- 0575 User ManualDocument28 pages0575 User Manualankit7588No ratings yet

- Meiko Operators Manual - K Series 101306Document24 pagesMeiko Operators Manual - K Series 101306Labadee Site EngineerNo ratings yet

- Maint IntroDocument49 pagesMaint IntroRanjit BanerjeeNo ratings yet

- Machine GuardingDocument10 pagesMachine GuardingYarenNo ratings yet

- Minor Age Employment in Construction Industry An Ethical AnalysisDocument18 pagesMinor Age Employment in Construction Industry An Ethical Analysisstructural mechanicsNo ratings yet

- Avina Arra RayaDocument1 pageAvina Arra RayaQueenie PerezNo ratings yet

- LavineDocument1 pageLavineQueenie PerezNo ratings yet

- AmiraDocument1 pageAmiraQueenie PerezNo ratings yet

- Lavine Model SMB Aug 2021Document37 pagesLavine Model SMB Aug 2021Queenie PerezNo ratings yet

- Avina Model SMB Aug. 2021Document27 pagesAvina Model SMB Aug. 2021Queenie PerezNo ratings yet

- Arra Model SMB Aug. 2021Document28 pagesArra Model SMB Aug. 2021Queenie PerezNo ratings yet

- Amira Model SMB Aug 2021Document38 pagesAmira Model SMB Aug 2021Queenie PerezNo ratings yet

- 7-8 Sentrina Alaminos Cost ControlDocument60 pages7-8 Sentrina Alaminos Cost ControlQueenie PerezNo ratings yet

- Soil Improvement: Pangasinan State University College of Engineering and Architecture Urdaneta City CampusDocument2 pagesSoil Improvement: Pangasinan State University College of Engineering and Architecture Urdaneta City CampusQueenie PerezNo ratings yet

- Engr. Romel N. Vingua Construction Manpower Health and SafetyDocument1 pageEngr. Romel N. Vingua Construction Manpower Health and SafetyQueenie PerezNo ratings yet

- Idesia Dasma Work ProgressDocument10 pagesIdesia Dasma Work ProgressQueenie PerezNo ratings yet

- 6-29 Sentrina Alaminos Cost ControlDocument60 pages6-29 Sentrina Alaminos Cost ControlQueenie PerezNo ratings yet

- Idesia Dasma Work ProgressDocument1 pageIdesia Dasma Work ProgressQueenie PerezNo ratings yet

- Engr. Romel N. Vingua Construction FieldworksDocument1 pageEngr. Romel N. Vingua Construction FieldworksQueenie PerezNo ratings yet

- Engr. Romel N. Vingua Construction ReportsDocument1 pageEngr. Romel N. Vingua Construction ReportsQueenie PerezNo ratings yet

- Engr. Romel N. Vingua: Interaction of ExpertiseDocument1 pageEngr. Romel N. Vingua: Interaction of ExpertiseQueenie PerezNo ratings yet

- Reaction:: Engr. Romel N. Vingua ReactionDocument1 pageReaction:: Engr. Romel N. Vingua ReactionQueenie PerezNo ratings yet

- Engr. Romel N. Vingua Computer Applications in Construction ManagementDocument1 pageEngr. Romel N. Vingua Computer Applications in Construction ManagementQueenie PerezNo ratings yet

- Engr. Romel N. Vingua Construction Manpower Health and SafetyDocument1 pageEngr. Romel N. Vingua Construction Manpower Health and SafetyQueenie PerezNo ratings yet

- Engr. Romel N. Vingua Reaction: Construction Construction Analysis BuildingDocument1 pageEngr. Romel N. Vingua Reaction: Construction Construction Analysis BuildingQueenie PerezNo ratings yet

- Construction Disputes and R.A. 9184 Provisions On Government InfrastructureDocument1 pageConstruction Disputes and R.A. 9184 Provisions On Government InfrastructureQueenie PerezNo ratings yet

- Engr. Romel N. Vingua: Name: Instructor: Sheet Content: Research TitleDocument1 pageEngr. Romel N. Vingua: Name: Instructor: Sheet Content: Research TitleQueenie PerezNo ratings yet

- Construction Methodologies & Operations of Different Item of WorkDocument1 pageConstruction Methodologies & Operations of Different Item of WorkQueenie PerezNo ratings yet

- Erectile Dysfunction FinalDocument68 pagesErectile Dysfunction Finalmuhibullah saifiNo ratings yet

- Mm-Etso-001 (2) - 16 05 13Document36 pagesMm-Etso-001 (2) - 16 05 13Anderson RamalhoNo ratings yet

- Carlos Palanca Memorial Awards 2010-2015: Best Short StoriesDocument43 pagesCarlos Palanca Memorial Awards 2010-2015: Best Short StoriesJohn Carl Ronato0% (1)

- Yarmouth Suspension BridgeDocument3 pagesYarmouth Suspension BridgeKea CuizonNo ratings yet

- 01 12 2015Document2 pages01 12 2015yashodharrajuNo ratings yet

- Specific Gravity of Soil SolidsDocument7 pagesSpecific Gravity of Soil SolidsChristian CabacunganNo ratings yet

- Probiotics and PrebioticsDocument19 pagesProbiotics and PrebioticsAbdul RehmanNo ratings yet

- Living With WolvesDocument11 pagesLiving With WolvesSuzanne AnthonyNo ratings yet

- Energy System Interplay WorksheetDocument2 pagesEnergy System Interplay Worksheettaylahuckel100% (1)

- 2018-08-01 PowerDocument148 pages2018-08-01 Powerbar catalinNo ratings yet

- ProFoss Datasheet PDFDocument4 pagesProFoss Datasheet PDFAdolfoNo ratings yet

- KOLO Information For HandbookDocument1 pageKOLO Information For HandbookYoga SamNo ratings yet

- Daddy Wasn't There, Abandonment PoemDocument2 pagesDaddy Wasn't There, Abandonment Poemonejako12No ratings yet

- Dosage Chapter 1 PDFDocument4 pagesDosage Chapter 1 PDFLena EmataNo ratings yet

- Fresh Water ModuleDocument24 pagesFresh Water Moduleanon_411130333No ratings yet

- NCP HeadDocument11 pagesNCP Headann-lisel-manahan-7670100% (2)

- Occidental Mindoro-sec-Agri Fishery ArtsDocument4 pagesOccidental Mindoro-sec-Agri Fishery ArtsPRC BoardNo ratings yet

- Repair Instructions TaurusDocument12 pagesRepair Instructions TaurusJo Arp100% (1)

- Mod 1 Intro, Solar Rad & MeasDocument121 pagesMod 1 Intro, Solar Rad & MeasChandrashekar ByalyalNo ratings yet

- When AN IEP Meeting Is ConvenedDocument9 pagesWhen AN IEP Meeting Is ConvenedTwinkle CambangNo ratings yet