Professional Documents

Culture Documents

Design Sheet: WELDING CHECK (Nozzle To Repad)

Design Sheet: WELDING CHECK (Nozzle To Repad)

Uploaded by

Muhamad Amar Hakimmie SuhaimiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Sheet: WELDING CHECK (Nozzle To Repad)

Design Sheet: WELDING CHECK (Nozzle To Repad)

Uploaded by

Muhamad Amar Hakimmie SuhaimiCopyright:

Available Formats

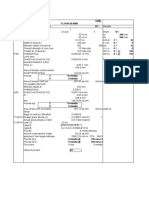

DOC NO.

-

DESIGN SHEET DATE 13/08/2021

SHEET NO. 1 of 5

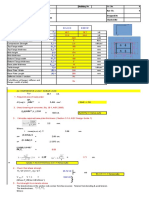

WELDING CHECK (Nozzle to Repad)

Nozzle : M1 (24")

Material : A36

Nozzle Diameter D = 0.60 m

Nozzle Height H = 0.30 m

Wind Speed V = 32.00 m/s2 115.2 km/h

Wind Pressure Pws = 0.89 x (V/190)^2

0.33 kPa

Wind Load Fs = (2 x H^2 x Pws)/(pi x D)

31.24 N

Nozzle weight W = 114.30 kg

Nozzle load Fn = 1121.28 N

Live Load Fl = 1000 N

External Pressure Pe = 2.00 kPa

Weld Line

Repad

Weld thickness t = 8.00 mm

Weld throat 0.707 x t = 5.66 mm

Weld Length (pi * D) L = 1884.96 mm

Effective area of weld (L * 0.707 * t) A = 10661.31 mm2

Weld strength (Base material yield stress) Pweld = 250.00 MPa

Allowable weld strength (0.3 x Pweld) Pwa = 75.00 MPa

Wind + Nozzle + Live Load (Fs + Fn + Fl) F = 2152.53 N

(Wind + Nozzle + Live) + External Pressure P = (F/A) + Pe

0.20 MPa

Pwa > P, WELD SIZE IS ACCEPTABLE

WELDING CHECK (Repad to Top cover)

Nozzle

Weld line

Diameter of repad Dr = 830 mm

Weld thickness t = 8 mm

Weld throat 0.707 x t = 5.66 mm

Weld Length (pi * D) L = 2607.52 mm

Effective area of weld (L * 0.707 * t) A = 14748.14 mm2

Weld strength (Base material yield stress) Pweld = 250.00 MPa

Allowable weld strength (0.3 x Pweld) Pwa = 75.00 MPa

Wind + Nozzle + Live Load (Fs + Fn + Fl) F = 2152.53 N

(Wind + Nozzle + Live) + External Pressure P = (F/A) + Pe

0.1479524 MPa

Pwa > P, WELD SIZE IS ACCEPTABLE

DOC NO. -

DESIGN SHEET DATE 13/08/2021

SHEET NO. 2 of 5

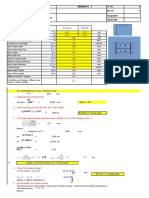

WELDING CHECK (Nozzle to Repad)

Nozzle : N2 (DN 50 SCH. XS)

Material : A106-B

Nozzle Diameter D = 0.0603 m

Nozzle Height H = 0.30 m (from top of cover plate)

Wind Speed V = 32.00 m/s2 115.2 km/h

Wind Pressure Pws = 0.89 x (V/190)^2

0.33 kPa

Wind Load Fs = (2 x H^2 x Pws)/(pi x D)

310.88 N

Nozzle weight W = 17.90 kg

Nozzle load Fn = 175.60 N

Live load Fl = 1000 N

External Pressure Pe = 2.00 kPa

Weld Line

Repad

Weld thickness t = 6.00 mm

Weld throat 0.707 x t = 4.24 mm

Weld Length (pi * D) L = 189.44 mm

Effective area of weld (L * 0.707 * t) A = 803.60 mm2

Weld strength (Base material yield stress) Pweld = 250.00 MPa

Allowable weld strength (0.3 x Pweld) Pwa = 75.00 MPa

Wind + Nozzle + Live Load (Fs + Fn + Fl) F = 1486.48 N

(Wind + Nozzle + Live) + External Pressure P = (F/A) + Pe

1.85 MPa

Pwa > P, WELD SIZE IS ACCEPTABLE

WELDING CHECK (Repad to Top cover)

Nozzle

Weld line

Diameter of repad Dr = 175 mm

Weld thickness t = 10 mm

Weld throat 0.707 x t = 7.07 mm

Weld Length (pi * D) L = 549.78 mm

Effective area of weld (L * 0.707 * t) A = 3886.94 mm2

Weld strength (Base material yield stress) Pweld = 250.00 MPa

Allowable weld strength (0.3 x Pweld) Pwa = 75.00 MPa

Wind + Nozzle + Live Load (Fs + Fn) F = 1486.48 N

(Wind + Nozzle + Live) + External Pressure P = (F/A) + Pe

0.3844296 MPa

Pwa > P, WELD SIZE IS ACCEPTABLE

DOC NO. -

DESIGN SHEET DATE 13/08/2021

SHEET NO. 3 of 5

WELDING CHECK (Nozzle to Repad)

Nozzle : K1 (DN 50 SCH. XS)

Material : A106-B

Nozzle Diameter D = 0.0603 m

Nozzle Height H = 0.30 m (from top of cover plate)

Wind Speed V = 32.00 m/s2 115.2 km/h

Wind Pressure Pws = 0.89 x (V/190)^2

0.33 kPa

Wind Load Fs = (2 x H^2 x Pws)/(pi x D)

310.88 N

Nozzle weight W = 18.30 kg

Nozzle load Fn = 179.52 N

Live load Fl = 1000.00 N

External Pressure Pe = 2.00 kPa

Weld Line

Repad

Weld thickness t = 6.00 mm

Weld throat 0.707 x t = 4.24 mm

Weld Length (pi * D) L = 189.44 mm

Effective area of weld (L * 0.707 * t) A = 803.60 mm2

Weld strength (Base material yield stress) Pweld = 250.00 MPa

Allowable weld strength (0.3 x Pweld) Pwa = 75.00 MPa

Wind + Nozzle + Live Load (Fs + Fn + Fl) F = 1490.40 N

(Wind + Nozzle + Live) + External Pressure P = (F/A) + Pe

1.86 MPa

Pwa > P, WELD SIZE IS ACCEPTABLE

WELDING CHECK (Repad to Top cover)

Nozzle

Weld line

Diameter of repad Dr = 175 mm

Weld thickness t = 10 mm

Weld throat 0.707 x t = 7.07 mm

Weld Length (pi * D) L = 549.78 mm

Effective area of weld (L * 0.707 * t) A = 3886.94 mm2

Weld strength (Base material yield stress) Pweld = 250.00 MPa

Allowable weld strength (0.3 x Pweld) Pwa = 75.00 MPa

Wind + Nozzle + Live Load (Fs + Fn + Fl) F = 1490.40 N

(Wind + Nozzle + Live) + External Pressure P = (F/A) + Pe

0.3854391 MPa

Pwa > P, WELD SIZE IS ACCEPTABLE

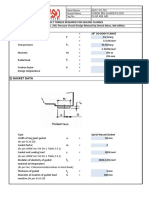

DOC NO. -

DESIGN SHEET DATE 13/08/2021

SHEET NO. 4 of 5

WELDING CHECK (Nozzle to Repad)

Nozzle : N1 (DN 100 SCH. STD)

Material : A106-B

Nozzle Diameter D = 0.1143 m

Nozzle Height H = 0.30 m (from top of cover plate)

Wind Speed V = 32.00 m/s2 115.2 km/h

Wind Pressure Pws = 0.89 x (V/190)^2

0.33 kPa

Wind Load Fs = (2 x H^2 x Pws)/(pi x D)

164.01 N

Nozzle weight W = 52.40 kg

Nozzle load Fn = 514.04 N

Live load Fl = 1000 N

External Pressure Pe = 2.00 kPa

Weld Line

Repad

Weld thickness t = 6.00 mm

Weld throat 0.707 x t = 4.24 mm

Weld Length (pi * D) L = 359.08 mm

Effective area of weld (L * 0.707 * t) A = 1523.23 mm2

Weld strength (Base material yield stress) Pweld = 250.00 MPa

Allowable weld strength (0.3 x Pweld) Pwa = 75.00 MPa

Wind + Nozzle + Live Load (Fs + Fn + Fl) F = 1678.05 N

(Wind + Nozzle) + External Pressure P = (F/A) + Pe

1.10 MPa

Pwa > P, WELD SIZE IS ACCEPTABLE

WELDING CHECK (Repad to Top cover)

Nozzle

Weld line

Diameter of repad Dr = 275 mm

Weld thickness t = 10 mm

Weld throat 0.707 x t = 7.07 mm

Weld Length (pi * D) L = 863.94 mm

Effective area of weld (L * 0.707 * t) A = 6108.04 mm2

Weld strength (Base material yield stress) Pweld = 250.00 MPa

Allowable weld strength (0.3 x Pweld) Pwa = 75.00 MPa

Wind + Nozzle + Live Load (Fs + Fn + Fl) F = 1678.05 N

(Wind + Nozzle + Live) + External Pressure P = (F/A) + Pe

0.2767283 MPa

Pwa > P, WELD SIZE IS ACCEPTABLE

DOC NO. -

DESIGN SHEET DATE 13/08/2021

SHEET NO. 5 of 5

WELDING CHECK (Nozzle to Repad)

Nozzle : N3 (DN 100 SCH. STD)

Material : A106-B

Nozzle Diameter D = 0.1143 m

Nozzle Height H = 0.60 m (from top of cover plate)

Wind Speed V = 32.00 m/s2 115.2 km/h

Wind Pressure Pws = 0.89 x (V/190)^2

0.33 kPa

Wind Load Fs = (2 x H^2 x Pws)/(pi x D)

656.03 N

Nozzle weight W = 25.80 kg

Nozzle load Fn = 253.10 N

Live load Fl = 1000 N

External Pressure Pe = 2.00 kPa

Weld Line

Repad

Weld thickness t = 6.00 mm

Weld throat 0.707 x t = 4.24 mm

Weld Length (pi * D) L = 359.08 mm

Effective area of weld (L * 0.707 * t) A = 1523.23 mm2

Weld strength (Base material yield stress) Pweld = 250.00 MPa

Allowable weld strength (0.3 x Pweld) Pwa = 75.00 MPa

Wind + Nozzle + Live Load (Fs + Fn + Fl) F = 1909.13 N

(Wind + Nozzle + Live) + External Pressure P = (F/A) + Pe

1.26 MPa

Pwa > P, WELD SIZE IS ACCEPTABLE

WELDING CHECK (Repad to Top cover)

Nozzle

Weld line

Diameter of repad Dr = 275 mm

Weld thickness t = 10 mm

Weld throat 0.707 x t = 7.07 mm

Weld Length (pi * D) L = 863.94 mm

Effective area of weld (L * 0.707 * t) A = 6108.04 mm2

Weld strength (Base material yield stress) Pweld = 250.00 MPa

Allowable weld strength (0.3 x Pweld) Pwa = 75.00 MPa

Wind + Nozzle + Live Load (Fs + Fn + Fl) F = 1909.13 N

(Wind + Nozzle + Live) + External Pressure P = (F/A) + Pe

0.3145599 MPa

Pwa > P, WELD SIZE IS ACCEPTABLE

You might also like

- Lifting Lug Excel SheetDocument8 pagesLifting Lug Excel Sheetshazan67% (3)

- Ladder Calculation 9april2018Document2 pagesLadder Calculation 9april2018Diosdado Mingi Jr.No ratings yet

- DEST Pipeline Calculation Rev.1 (By Hasan Asif)Document11 pagesDEST Pipeline Calculation Rev.1 (By Hasan Asif)Saqib LaeeqNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Conservation of FurnitureDocument2 pagesConservation of FurnitureSalander21No ratings yet

- Physics AssignmentDocument13 pagesPhysics Assignmentkhushi dharajiyaNo ratings yet

- Lifting Lug Calculation 4april2018Document2 pagesLifting Lug Calculation 4april2018Diosdado Mingi Jr.No ratings yet

- Project Name DOC. No.: Tank Name Rev No.: Item No.Document4 pagesProject Name DOC. No.: Tank Name Rev No.: Item No.AnggaNo ratings yet

- A2 Physics NotesDocument3 pagesA2 Physics NotesZain ImranNo ratings yet

- Fillet Weld Strength CheckDocument5 pagesFillet Weld Strength CheckMuhamad Amar Hakimmie SuhaimiNo ratings yet

- Master Bolt CalculationDocument2 pagesMaster Bolt CalculationSudar MyshaNo ratings yet

- Bolt TorqueDocument3 pagesBolt TorqueHeri KurniawanNo ratings yet

- Lifting Lug CalculationsDocument1 pageLifting Lug CalculationsshazanNo ratings yet

- Slab Design 2 Way IsDocument3 pagesSlab Design 2 Way IsRam LangheNo ratings yet

- PadEye Genset 300kvaDocument3 pagesPadEye Genset 300kvadandy imam fauziNo ratings yet

- Davit Design Calculation: L 1 D V H V H V DDocument2 pagesDavit Design Calculation: L 1 D V H V H V DSiva baalanNo ratings yet

- Eng - M - Lifting Lug Cal - 2Document6 pagesEng - M - Lifting Lug Cal - 2Ricardo NapitupuluNo ratings yet

- Slab Design 2 Way IsDocument5 pagesSlab Design 2 Way IsPirpasha UjedeNo ratings yet

- Slab-Design-2 Way - ISDocument5 pagesSlab-Design-2 Way - ISKamran AliNo ratings yet

- DesignOfFooting JOSDocument26 pagesDesignOfFooting JOSJhoe SamNo ratings yet

- AISC Connection-2nd Edition - (2+2) Anchor Rod-FixedDocument16 pagesAISC Connection-2nd Edition - (2+2) Anchor Rod-FixedTuấnThanhNo ratings yet

- Isolated Footing - MomentsDocument1 pageIsolated Footing - MomentsKaushlendra KumarNo ratings yet

- AISC Connection-2nd Edition - (3+3) Anchor Rod-FixedDocument14 pagesAISC Connection-2nd Edition - (3+3) Anchor Rod-FixedTuấnThanhNo ratings yet

- Design of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)Document30 pagesDesign of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)raman212No ratings yet

- Design Codes & ReferencesDocument9 pagesDesign Codes & Referencesnavneet3bawaNo ratings yet

- Plinth Beams DesignDocument24 pagesPlinth Beams DesignRathinavel VenkateshwaranNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal VesselshaishavNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal VesselshaishavNo ratings yet

- Design CalculationsDocument8 pagesDesign CalculationsJIBEESH01No ratings yet

- Design of Base Plate 2Document2 pagesDesign of Base Plate 2Andro RebuyasNo ratings yet

- AISC Connection-2nd Edition - (4+4) Anchor Rod-FixedDocument14 pagesAISC Connection-2nd Edition - (4+4) Anchor Rod-FixedTuấnThanhNo ratings yet

- Engineering and Development Corporation of The Philippines: H P H PDocument2 pagesEngineering and Development Corporation of The Philippines: H P H Pmark ignacioNo ratings yet

- Design Data: Design For Base Plate (Fixed)Document4 pagesDesign Data: Design For Base Plate (Fixed)Wibawa WorksNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- Anchor Bolt Calculation 21-2231Document2 pagesAnchor Bolt Calculation 21-2231Huu Nguyen100% (1)

- MJ4 11Document1 pageMJ4 11EakJhuanNo ratings yet

- 1) Design Data: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4rd EditionDocument6 pages1) Design Data: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4rd Editionsouren1975No ratings yet

- Head Nozzle and Flange Calculation, DN100 (CF) Size NozzleDocument7 pagesHead Nozzle and Flange Calculation, DN100 (CF) Size Nozzleakın ersözNo ratings yet

- Design of End Plate ConnectionDocument2 pagesDesign of End Plate ConnectionAndro RebuyasNo ratings yet

- Master of Lifting CalculationDocument7 pagesMaster of Lifting CalculationSudar MyshaNo ratings yet

- Ferrofab Fze: Collar Bolt Sizing CalculationDocument2 pagesFerrofab Fze: Collar Bolt Sizing CalculationMohammad Zahid50% (2)

- HDD Installation CalculationsDocument4 pagesHDD Installation Calculationslive4sankar100% (1)

- Node - 639 - Anc Bolt Strength CheckDocument1 pageNode - 639 - Anc Bolt Strength CheckAS DesignanddraftNo ratings yet

- Input Rev. NO: L + (c1 + c2) TWDocument6 pagesInput Rev. NO: L + (c1 + c2) TWMudasir MughalNo ratings yet

- NODE - 30 - 4 Nos ANC BOLT STRENGTH CHECKDocument2 pagesNODE - 30 - 4 Nos ANC BOLT STRENGTH CHECKAS DesignanddraftNo ratings yet

- Given: 3. Purlins DesignDocument3 pagesGiven: 3. Purlins DesignJake CortezNo ratings yet

- Pad Footing 1Document4 pagesPad Footing 1John SmithNo ratings yet

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Document42 pages8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- Operating Case Trunnion Calculation Sheet: Input DataDocument1 pageOperating Case Trunnion Calculation Sheet: Input DataJagadish JasNo ratings yet

- Design of Baseplate With Large EccentricityDocument4 pagesDesign of Baseplate With Large EccentricityLeah Ann ManuelNo ratings yet

- Rolled - MomentDocument5 pagesRolled - MomentAdekimi EmmanuelNo ratings yet

- Cal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Document5 pagesCal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Anisa Rifqi0% (1)

- Footing GayakDocument26 pagesFooting GayakJhoe SamNo ratings yet

- Node - 3454 - Anc Bolt Strength CheckDocument1 pageNode - 3454 - Anc Bolt Strength CheckAS DesignanddraftNo ratings yet

- Steel Bunker DesignDocument13 pagesSteel Bunker Designsreenivasulu chenchugariNo ratings yet

- BEAMS DesignDocument22 pagesBEAMS DesignRathinavel VenkateshwaranNo ratings yet

- Node - 971 - Anc Bolt Strength CheckDocument1 pageNode - 971 - Anc Bolt Strength CheckAS DesignanddraftNo ratings yet

- Square Blind Flange With Stiffener ULDocument5 pagesSquare Blind Flange With Stiffener ULjoeriji100% (1)

- RB8 1200x1200 PDFDocument6 pagesRB8 1200x1200 PDFsallysel90No ratings yet

- Node - 342 - Anc Bolt Strength CheckDocument1 pageNode - 342 - Anc Bolt Strength CheckAS DesignanddraftNo ratings yet

- Corbel DesignDocument4 pagesCorbel DesignTan Choon LengNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Perforated Thk. 2mmDocument99 pagesPerforated Thk. 2mmMuhamad Amar Hakimmie SuhaimiNo ratings yet

- Fillet Weld Strength CheckDocument5 pagesFillet Weld Strength CheckMuhamad Amar Hakimmie SuhaimiNo ratings yet

- Perforated Plate THK Calc.: SB SD AcceptableDocument1 pagePerforated Plate THK Calc.: SB SD AcceptableMuhamad Amar Hakimmie SuhaimiNo ratings yet

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Document42 pages8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- Nozzle SCHDocument1 pageNozzle SCHMuhamad Amar Hakimmie SuhaimiNo ratings yet

- Shell Plate ArrangementDocument1 pageShell Plate ArrangementMuhamad Amar Hakimmie SuhaimiNo ratings yet

- Temporary Roof Supports Capacity Check: Design CalculationDocument4 pagesTemporary Roof Supports Capacity Check: Design CalculationMuhamad Amar Hakimmie SuhaimiNo ratings yet

- Anchor Chair Height CalculationDocument1 pageAnchor Chair Height CalculationMuhamad Amar Hakimmie SuhaimiNo ratings yet

- Unit 6 AEROSOLSDocument29 pagesUnit 6 AEROSOLSorindiaNo ratings yet

- Machine DesignDocument84 pagesMachine DesignJehan FernandoNo ratings yet

- Departure FunctionDocument6 pagesDeparture FunctionzidinhoNo ratings yet

- 1.2 Involutes - Question Bank and SolutionsDocument4 pages1.2 Involutes - Question Bank and SolutionsMartin De Boras PragashNo ratings yet

- N1 - PN Junction DiodeDocument4 pagesN1 - PN Junction DiodeavduttaNo ratings yet

- 2-Planck's Constant-FORMAT 1Document5 pages2-Planck's Constant-FORMAT 1VAIBHAV KUMARNo ratings yet

- Forget What You Know About Good Study HabitsDocument3 pagesForget What You Know About Good Study Habitsmohdzamrimurah_gmailNo ratings yet

- 2012 Imas Lower Division First Round Paper PDFDocument6 pages2012 Imas Lower Division First Round Paper PDFdenitsappNo ratings yet

- AMR Hutter S02 KinBasicDocument8 pagesAMR Hutter S02 KinBasicMuthuKumaranNo ratings yet

- Thesis ListingDocument8 pagesThesis ListingLawrence LingNo ratings yet

- ITT American Electric Horizontal Luminaire Series 327 & 328 Spec Sheet 2-79Document8 pagesITT American Electric Horizontal Luminaire Series 327 & 328 Spec Sheet 2-79Alan Masters100% (1)

- F0812 P1A Introduction To Course and Accounting TheoryDocument30 pagesF0812 P1A Introduction To Course and Accounting TheoryHerry SetiawanNo ratings yet

- AcousticsDocument46 pagesAcousticsbzkizo_sbbNo ratings yet

- Souvik Sen, Mohamed Abioui, Shib Sankar Ganguli, Ahmed Elsheikh, Akash Debnath, Mohammed Benssaou, Ahmed Awad AbdelhadyDocument16 pagesSouvik Sen, Mohamed Abioui, Shib Sankar Ganguli, Ahmed Elsheikh, Akash Debnath, Mohammed Benssaou, Ahmed Awad Abdelhadyshib ganguliNo ratings yet

- Ei Elective PDFDocument18 pagesEi Elective PDFtushardkdNo ratings yet

- Detailed Lesson PlanDocument17 pagesDetailed Lesson PlanShery Mae CariagaNo ratings yet

- SIEMENS - G120 CU250S-2 Operating InstructionsDocument522 pagesSIEMENS - G120 CU250S-2 Operating InstructionsIng Capriel CaprielNo ratings yet

- Fybsc Practicals PDocument23 pagesFybsc Practicals PAshviniJadhavNo ratings yet

- Digital Control System Paper PDFDocument2 pagesDigital Control System Paper PDFdeepaksaini14No ratings yet

- PHY108L ManualDocument58 pagesPHY108L ManualSalman Hossain SahilNo ratings yet

- Beltcon ConveyorDocument13 pagesBeltcon ConveyorPedro Elías Coronado HidalgoNo ratings yet

- Jovan Marjanovic Veljko Milkovic Kinetic Energy and OverunityDocument11 pagesJovan Marjanovic Veljko Milkovic Kinetic Energy and Overunitylzk2d2No ratings yet

- 07a4bs02 Mathematics - IIIDocument8 pages07a4bs02 Mathematics - IIIaditya56No ratings yet

- Spline DIN 5480Document27 pagesSpline DIN 5480ewillia13100% (3)

- FACTS Technologies SVCDocument9 pagesFACTS Technologies SVCSalah SouidNo ratings yet

- Learning Activity Sheet On Properties of LightDocument3 pagesLearning Activity Sheet On Properties of LightResttie ĐaguioNo ratings yet

- Ricci: A Mathematica Package For Doing Tensor Calculations in Differential GeometryDocument90 pagesRicci: A Mathematica Package For Doing Tensor Calculations in Differential GeometryAbdul Baist Muhammad AliNo ratings yet