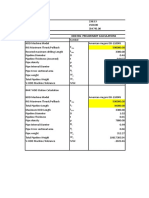

Pipe, Operational, Installation & Site Characteristics Values Units Values Units

Steel Grade 9

Specified Minimum Yield Strength SMYS 450.00 N/mm2 70049.49 lb/in2

Young's Modulus Es 200.0E+3 N/mm2 29,006,000 lb/in2

Poisson's Ratio vs 0.30

Coefficient of Thermal Expansion T 1.17E-05 per oC

Design Stress Factor F 0.72

Outside Diameter D 28.00 inches 711.20 mm

Wall Thickness tw 22.20 mm 0.874 in

Depth H 15,000 mm

Bored Diameter and Type Bd 1,066.80 mm Type: HDD

Maximum Allowable Operating Pressure P 86.00 barg 8.60 N/mm2

Temperature at time of Installation Tmax 30.00 C o

86.00

Design Temperature Max Tmax 50.00 oC 122.00 oF

Design Temperature Min Tmin 15.00 oC 59.00 oF

Temperature Derating Factor T 1.000 (B31.8 Table 841.116A)

Spec & Pipe Class 19.00

Longitudinal Joint Factor E 1.00 (B31.8 Table 841.115A)

HDD Rig size Fr 200.00 tons

Rig Pulling factor Sr 75.00 %

Allowable tensile stress factor Ft 0.40

Time under tension design factor St 0.91

Length of Drill L 800.00 m 2,624.64 ft

Total change of angle over L 16.00 degrees

Radius of curvature 1,300.00 m

pendix 4 Page 1 of 4

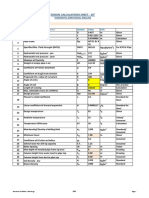

� 1.0 Check Allowable Barlow Stresses (API 1102 Equation 8b) Values Units

Actual Barlow Stress 137.75 N/mm2

Allowable Barlow Stress 324.00 N/mm2

Actual Barlow Stress < Allowable Stress

1.1 Installation Stresses- Bending Stress

The pipe stress due to bending stress of pipe is determined as follows

R A ( L / A ) 688

RA = Maximum Radius of Curvature (inch)-(For 8 Degrees)

L = Length drilled (ft)

Maximum Radius of Curvature in Drilled hole (in) RA 112,859.52 in 2866.63 m

Min.Radius of Curvature in Drilled hole used RD 51,181.10 in 1300.00 m

f b ( ED ) /( 2 R D )

fb = Longitudinal Bending Stress (lb/in2)

Longitudinal Bending Stress (lb/in2) fb 7,934.26 lb/in2 54.71 N/mm2

F b =0.75F y for D/t 1,500,000/F y

F b = [0.84-(1.74F y D)/(Et)]F y for 1,500,000/F y D/t 3,000,000/F y

F b = [0.72-(0.58F y D)/(Et)]F y for 3,000,000/F y D/t 300,000

Maximum allowable Bending Stress (lb/in2) Fb -9,429.96 lb/in2 65.02 N/mm2

Longitudinal bending stress < Allowable bending stress

1.2 Installation Stresses- External Hoop Stress

The pipe thickness due to external hoop stress of pipe is determined as follows

t D / 12 ( 864 P ext / E ) 1 / 3

D/t 50 D/t = 48.20

t = Pipe wall thickness (inch)

P ext = Uniform external Pressure in lb/in 2 (Assumed as 7.5-Percent E )

E = Modulus of Steel in lb/in 2

Optimum thickness (D/t 50) t 14.224

Pipe wall thickness due to External Hoop Stress

Actual thickness > Allowable Thickness

t 14.755 mm

pendix 4 Page 2 of 4

� 1.3 Installation Stresses- Tensile Stress

The pipe stress due to pulling tensile stress of pipe is determined as follows

ft S y S tT y

Sy = Tensile Yield Factor

St = Time under tension design factor

Ty = Tensile yield strength

Ft = Allowable Tensile Stress

Allowable Tensile Stress ft 163.800 N/mm2 23,755.91 lb/in2

1.4 Installation Stresses- Required Pipe thickness to meet allowable tensile stress

The pipe thickness due to pulling tensile stress of pipe is determined as follows

tr ( pi( Do / 2) 2 (((Fr / Sr ) / f t ) / pi) * 2

Fr = HDD Rig size

Sr = Rig pulling factor

Ft = Allowable Tensile Stress

Do = Outside pipe diameter

tr = Required pipe wall thickness to meet allowable tensile stress

Pipe wall thickness due to Tensile Stress t r 14.44 mm

Pipe wall thickness to be used t 22.20 mm

Actual thickness > Allowable Thickness

1.5 Installation Stresses- Pipe combined installation stress

The pipe stress due to combined stresses is determined as follows

f t / 0 . 9 F y f b / Fb 1

Ft = Allowable Tensile Stress (lb/in2)

fy = Pipe minimum yield strength (lb/in2)

fb = Longitudinal Bending Stress (lb/in2)

Fb = Maximum allowable Bending Stress (lb/in2)

f t / 0.9 F y + f b / F b = -0.436943

Actual thickness > Allowable Thickness

pendix 4 Page 3 of 4

� 2.0 Operating Stresses- Internal Hoop Stress

The pipe stress during operation due to hoop stress is determined as follows

f h ( Pint D ) /( 2 t )

fh = Pipe hoop stress due to internal pressure (lb/in2)

P int = Uniform internal pressure (lb/in2)

t = Pipe wall thickness (in)

f h 70% SMYS

Pipe hoop stress due to internal pressure fh 19,974 lb/in2

137.73 N/mm2

Actual internal hoop stress < Allowable internal hoop stress

2.1 Operating Stresses- Combined Operating Stress

The pipe stress during operation due to hoop stress is determined as follows

For worst case, fc fh , fv ( fc fl ) / 2

fv ( fh fc ) / 2

f l ( f cV f b )

fb

f v f h [(1 v ) / 2)

2

f v 45% SMYS

fv = Longitudinal component oF circumferential stress (lb/in2)

fc = Total circumferential stress (lb/in2)

fl = Total Longitudinal stress, fb (lb/in2)

Longitudinal component of circumferential stress fv 3,023.94 lb/in2

20.85 N/mm2

Actual combined operating stress < Allowable combined stress

pendix 4 Page 4 of 4